The global handheld laser cleaning machine market is experiencing robust growth, driven by increasing demand for eco-friendly, precision cleaning solutions across industries such as automotive, aerospace, and manufacturing. According to Grand View Research, the global laser cleaning market size was valued at USD 586.1 million in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 12.7% from 2023 to 2030. This surge is fueled by stringent environmental regulations favoring chemical-free cleaning methods and the rising adoption of advanced manufacturing technologies. As industrial players shift from traditional abrasive techniques to more sustainable alternatives, handheld laser cleaning systems have emerged as a preferred choice due to their portability, efficiency, and minimal maintenance. With market expansion comes intensified competition among manufacturers, leading to varied pricing structures based on power output, build quality, automation features, and application specificity. This report identifies the top 9 handheld laser cleaning machine manufacturers known for balancing performance, innovation, and competitive pricing in this rapidly evolving landscape.

Top 9 Handheld Laser Cleaning Machine Price Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 SHARK P CL Industrial Laser Cleaning Machines (100

Website: pulsar-laser.com

Key Highlights: SHARK P CL is an industrial pulsed laser cleaning machine series by PULSAR Laser with outputs from 100 W to 1000 W, air-cooled up to 500 W….

#2 Hand Held Laser Cleaning Machine Manufacturers, Suppliers

Website: hgtech-laser.com

Key Highlights: We’re professional hand held laser cleaning machine manufacturers and suppliers in China, specialized in providing high quality laser equipment….

#3 Laser Cleaning Machine Manufacturer

Website: hantencnc.com

Key Highlights: HANTENCNC is a professional laser cleaning machine manufacturer with over 20 years of experience. We offer a wide range of laser cleaners, from 100W to 3000W….

#4 Laser Cleaning Machine

Website: baikeopto.com

Key Highlights: BK-FL3000X 3000W Raycus Laser Source Energy Efficient Handheld Laser Cleaning Machine for Metal Stone Dust Rust Price. Model: CW Laser Cleaning Machine Power ……

#5 Handheld Laser Cleaning Machines

Website: ipgphotonics.com

Key Highlights: Handheld and portable laser cleaning machines designed for manual applications including rust removal, paint stripping, restoration, and more….

#6 Portable Laser Cleaning Machine

Website: laserphotonics.com

Key Highlights: Introducing the Marlin Professional Portable Finishing Laser 1010, explicitly designed for marine vessels and equipment maintenance….

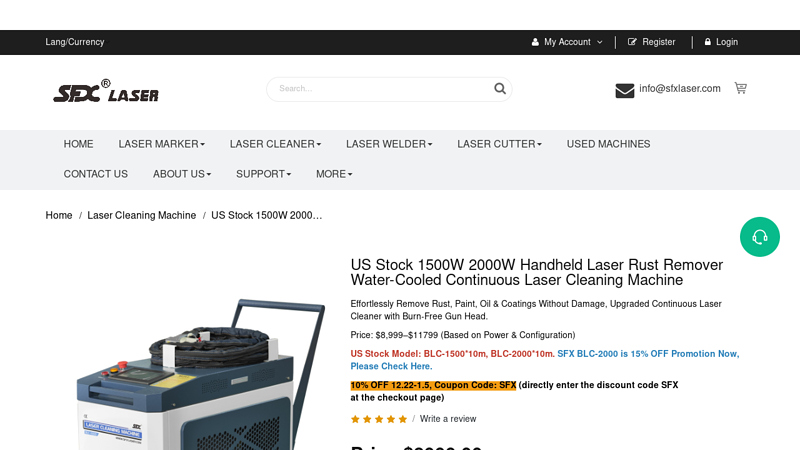

#7 US Stock 1500W 2000W Handheld Laser Rust Remover Water …

Website: sfxlaser.com

Key Highlights: In stock Rating 5.0 (1) Effortlessly Remove Rust, Paint, Oil & Coatings Without Damage, Upgraded Continuous Laser Cleaner with Burn-Free Gun Head. Price: $8,999–$11799 (Based on …

#8 HC series portable laser cleaning machine

Website: hg-star.com

Key Highlights: Laser cleaning machine can be used for metal rust removal, oil cleaning, local quenching, surface roughening, coating removal, weld cleaning….

#9 Best Fortune Laser Portable Mini 50W/100W/200W Pulse Fiber …

Website: fortunelaser.com

Key Highlights: This handheld portable laser cleaning machine is special designed in hand held usage. The total size is 32*13*28cm ,with the weight is 8kg/12.5kg, equipped ……

Expert Sourcing Insights for Handheld Laser Cleaning Machine Price

H2: Projected 2026 Market Trends for Handheld Laser Cleaning Machine Prices

Based on current industry dynamics, technological advancements, and market projections, the pricing landscape for handheld laser cleaning machines in 2026 is expected to be shaped by several converging trends:

1. Gradual Price Stabilization and Modest Decline: After significant price reductions observed between 2020-2024 due to manufacturing scale-up and increased competition, the rate of price decline is projected to slow down by 2026. While prices will likely continue a downward trend, the reductions will be more incremental (estimated 3-8% annually) rather than the double-digit drops seen earlier. This reflects market maturation, with costs approaching a new equilibrium driven by optimized production and stabilized component pricing (especially fiber lasers and diodes).

2. Intensified Competition Driving Value-Based Pricing: The market will remain highly competitive, with numerous established players (e.g., CleanLas, Laser Photonics, P-Laser) and aggressive entrants, particularly from China and Eastern Europe. This competition will shift the focus from pure price wars to value-based pricing. Manufacturers will differentiate through features like higher power efficiency, improved ergonomics, smart controls (IoT connectivity, real-time monitoring), enhanced safety features, and superior after-sales support. Premium models with these advanced features will command higher prices, while basic models will see tighter margins.

3. Power and Performance Tiering Driving Price Segmentation: The market will become more segmented based on laser power (typically 50W to 2000W+ for handheld units) and application focus. By 2026:

* Low-Power (<100W): Prices will likely stabilize in the $3,000 – $8,000 range, targeting light-duty maintenance and niche applications. Intense competition will keep prices low, but innovation in miniaturization and battery tech may add slight premiums.

* Mid-Power (100W – 500W): This high-growth segment (domestic industry, automotive, mold cleaning) is expected to see prices in the $8,000 – $25,000 range. Competition will be fierce, but differentiation in beam quality, software, and durability will allow for premium pricing within this tier.

* High-Power (>500W): Machines for heavy industrial use (shipbuilding, large-scale rust removal) will command prices from $25,000 to $60,000+. Prices here are less sensitive to mass-market competition and more driven by engineering complexity, component costs (high-power laser sources), and reliability. Incremental price decreases will be slower.

4. Impact of Technological Advancements and Input Costs:

* Efficiency Gains: Improvements in laser diode efficiency and electrical-to-optical conversion will reduce operational costs (electricity consumption), making the total cost of ownership (TCO) argument stronger, potentially justifying higher initial prices for efficient models.

* Component Costs: Fluctuations in key components (semiconductors for controls, specialty optics, high-power laser diodes) will influence prices. Geopolitical factors and supply chain resilience will be critical factors. Advancements in domestic (e.g., US, EU) or regional (e.g., ASEAN) manufacturing of core components could mitigate some supply risks but may initially carry a cost premium.

* Automation & AI: Integration of AI for process optimization and robotic arms for semi-automated cleaning (beyond pure handheld) may create hybrid product categories, potentially blurring lines and influencing pricing for advanced handheld systems.

5. Regional Price Variations and Trade Dynamics: Significant price differences will persist between regions:

* Asia-Pacific (especially China): Will remain the source of the most competitively priced machines, driving global price floors. Domestic demand growth will also support local price stability.

* North America & Europe: Prices will generally be 20-40% higher than comparable Asian models, reflecting higher distribution costs, service expectations, compliance standards (safety, EMC), and brand premiums. Demand for high-reliability, certified equipment in regulated industries (aerospace, pharma) will support these premiums.

6. Service and Consumables as Revenue Streams: As hardware margins potentially compress, manufacturers will increasingly generate revenue through service contracts, extended warranties, training, and proprietary consumables (e.g., specialized nozzles, protective filters). This “razor and blades” model could influence the perceived value and effective pricing of the core machine.

Conclusion for 2026: The handheld laser cleaning machine market in 2026 will feature stable but segmented pricing. While a general trend towards lower prices will continue due to competition and efficiency, the market will be characterized by clear differentiation based on power, features, and target application. Buyers can expect a wider range of options at various price points, but the focus will shift decisively towards total value, reliability, and specific performance capabilities rather than just the lowest upfront cost. Premium pricing will be justified by advanced technology, robust support, and proven TCO benefits, especially in demanding industrial sectors.

Common Pitfalls When Sourcing Handheld Laser Cleaning Machine Price (Quality, IP)

Sourcing a handheld laser cleaning machine involves more than just comparing prices—focusing solely on cost can lead to significant compromises in quality, performance, and intellectual property (IP) protection. Below are key pitfalls to avoid:

1. Prioritizing Low Price Over Build Quality

Opting for the cheapest option often results in machines built with inferior components—such as low-grade lasers, unstable cooling systems, or subpar ergonomics. These can lead to frequent breakdowns, reduced cleaning efficiency, and shorter machine lifespans. Always assess the materials, laser source brand (e.g., IPG, Raycus), and overall construction before finalizing a purchase.

2. Overlooking IP Protection and Genuine Technology

Many low-cost suppliers, especially from certain regions, may offer machines that mimic patented designs or use reverse-engineered technology. This raises IP infringement risks, particularly if you’re importing into markets with strict IP laws (e.g., EU, USA). Ensure the manufacturer holds proper certifications and can provide documentation proving original design and compliance.

3. Inadequate IP (Ingress Protection) Rating for Industrial Use

An insufficient IP rating (e.g., IP54 vs. IP65) can compromise durability in dusty or humid environments. Machines with poor sealing may suffer internal damage from debris or moisture, affecting laser alignment and electronic components. Always verify the IP rating matches your operational conditions.

4. Hidden Costs Not Reflected in Initial Price

The quoted price may exclude critical costs such as shipping, import duties, installation, training, or software updates. Additionally, lack of local service support can result in expensive downtime. Request a total cost of ownership breakdown before making a decision.

5. Misleading Laser Power Specifications

Some suppliers exaggerate peak laser power or use nominal values that don’t reflect real-world performance. For example, advertising “1000W” when average output is significantly lower. Always request third-party test reports or live demos to verify actual performance.

6. Lack of Safety Certifications and Compliance

Low-priced machines may not meet essential safety standards like CE, FDA, or IEC 60825. Using non-compliant equipment can lead to legal liability, workplace accidents, or import rejections. Confirm that the machine includes proper safety interlocks, shielding, and certification documentation.

7. Poor After-Sales Support and Warranty Terms

Cheap machines often come with limited or voidable warranties, especially if serviced by unauthorized technicians. Lack of firmware updates, spare parts availability, or technical support can render the machine unusable over time. Evaluate the supplier’s service network and support responsiveness.

By avoiding these common pitfalls, you can ensure that the handheld laser cleaning machine you source delivers reliable performance, complies with regulations, and protects your business from legal and operational risks.

Logistics & Compliance Guide for Handheld Laser Cleaning Machines

Understanding the logistics and compliance requirements is essential when importing or exporting handheld laser cleaning machines, especially when evaluating total landed costs beyond the initial price. Non-compliance can lead to shipment delays, fines, or confiscation.

Import/Export Regulations

Handheld laser cleaning machines are subject to international trade controls due to their laser classification and potential dual-use applications. Exporters and importers must comply with regulations in both the origin and destination countries. Key considerations include:

- Export Controls: In the U.S., lasers may be subject to the Export Administration Regulations (EAR) administered by the Bureau of Industry and Security (BIS). Check if the machine falls under ECCN 6A005 (lasers) and whether a license is required based on destination and end-use.

- Import Restrictions: Some countries restrict or require permits for high-powered lasers. For example, China, India, and members of the European Union may have specific import licensing or certification requirements.

- Customs Documentation: Accurate commercial invoices, packing lists, and a detailed product description (including laser class, wavelength, and power output) are required. Misclassification can result in delays and penalties.

Laser Safety & Certification Standards

Handheld laser cleaning machines must meet international safety standards to be legally sold and operated. Compliance reduces liability and ensures user safety.

- IEC 60825-1: International standard for laser product safety. Machines must be classified (typically Class 4 for cleaning devices) and bear appropriate warning labels.

- FDA/CDRH (U.S.): All laser products exported to or manufactured in the U.S. must comply with FDA regulations and include a product report, certification, and labeling per 21 CFR 1040.10.

- CE Marking (EU): Required for sale in the European Economic Area. Compliance with the Laser Products Directive (2006/25/EC) and the Machinery Directive (2006/42/EC) may be necessary.

- RoHS & REACH: Ensure the product complies with restrictions on hazardous substances and chemical safety in the EU.

Shipping & Handling Considerations

Due to their sensitive components and high-power nature, proper packaging and shipping protocols are critical.

- Fragile Equipment: Use anti-static, shock-resistant packaging to protect internal optics and electronics.

- Battery Regulations: If the device includes a lithium-ion battery, it must comply with IATA Dangerous Goods Regulations (e.g., UN38.3 testing, proper labeling) for air freight.

- Insurance: High-value laser equipment should be fully insured during transit to cover loss or damage.

- Incoterms: Clearly define responsibilities (e.g., FOB, CIF, DDP) in sales contracts to allocate costs and risks appropriately.

End-Use & End-User Verification

Many countries require end-use statements or end-user undertakings to prevent misuse in military or restricted applications.

- Conduct due diligence on customers, especially for exports to high-risk regions.

- Retain records of compliance checks and certifications for at least five years.

Conclusion

When assessing the price of a handheld laser cleaning machine, factor in potential logistics costs (shipping, insurance, duties) and compliance expenses (certifications, testing, legal fees). Proactive adherence to international regulations ensures smooth operations and protects your business from legal and financial risks.

Conclusion:

After evaluating various factors affecting the pricing of handheld laser cleaning machines, it is evident that costs can vary significantly based on power output, brand reputation, build quality, included accessories, and after-sales support. Entry-level models typically range from $3,000 to $6,000, suitable for light-duty or occasional use, while mid-range to high-end systems (ranging from $6,000 to $15,000+) offer greater power, durability, and advanced features ideal for industrial applications.

Key considerations when sourcing include verifying technical specifications, comparing warranty and service options, and assessing long-term operational costs such as maintenance and energy efficiency. Buying directly from reputable manufacturers or authorized distributors can ensure reliability and better pricing, especially when purchasing in bulk or negotiating bundled support packages.

Ultimately, the most cost-effective choice is not necessarily the cheapest option, but the one that balances upfront investment with performance, reliability, and total cost of ownership. Conducting thorough market research, requesting quotes from multiple suppliers, and evaluating real-world user feedback will enable informed decision-making and optimal return on investment.