The global hand rotary pump market is experiencing steady growth, driven by increasing demand across agricultural, industrial, and emergency water supply applications. According to Mordor Intelligence, the global hand pumps market—of which hand rotary pumps are a key segment—is projected to grow at a CAGR of approximately 5.8% from 2023 to 2028. This expansion is fueled by rising off-grid water access initiatives, especially in rural and remote regions, and the need for reliable, low-maintenance pumping solutions in developing economies. Additionally, Grand View Research highlights that the broader manual pumps market is being propelled by advancements in corrosion-resistant materials and ergonomic designs, improving efficiency and lifespan. As sustainability and energy independence gain traction, hand rotary pumps are re-emerging as cost-effective, eco-friendly alternatives. In this evolving landscape, several manufacturers have distinguished themselves through innovation, durability, and global reach—setting the benchmark in performance and reliability.

Top 7 Hand Rotary Pump Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 131130100 KP 01 Hand Rotary Pump

Domain Est. 2007

Website: pclairtechnology.com

Key Highlights: 14-day returnsTECALEMIT’S hand-operated rotary KP 01 Hand Pump is for the distribution of oil out of drums and small containers. Suitable for diesel, gas oil, low viscosity ……

#2 Action Pump Co.

Domain Est. 1998

Website: actionpump.com

Key Highlights: Air Pumps, Accessories, Battery Pumps, Bung Adapters, DEF-UREA, Drum Pumps, Diaphragm Pumps, Drum Mixers, Electric Pumps, Filters, Regulators, Lubricators….

#3 GPI Rotary Hand Pump

Domain Est. 1998

#4 8 Gallon per 100 Revolutions Rotary Action Fluid Transfer Hand Pump

Domain Est. 1999

Website: greatplainsindustries.com

Key Highlights: In stock Rating 4.7 (9) The GPI RP-5 fluid transfer pump is a light-duty rotary action pump designed to deliver up to 8 gallons (30 Litres) per 100 revolutions for use with diese…

#5 Hand Pumps

Domain Est. 1999

#6 Aluminium Rotary Hand Fuel Transfer Pump

Domain Est. 1999

Website: centretank.com

Key Highlights: In stockThe Aluminium Rotary Hand Fuel Pump is a cost effective, lightweight and corrosion resistant option for dispensing diesel and oil from a drum or storage tank….

#7 Macnaught M3 High Flow Rotary Hand Pump – PN# FPM

Domain Est. 2000

Expert Sourcing Insights for Hand Rotary Pump

H2: 2026 Market Trends for Hand Rotary Pumps

The global hand rotary pump market is expected to witness steady growth and transformation by 2026, driven by increasing demand across various end-use industries, technological advancements, and a growing emphasis on sustainable and off-grid fluid handling solutions. Below are the key trends shaping the hand rotary pump market in 2026:

-

Rising Adoption in Rural and Off-Grid Applications

Hand rotary pumps continue to gain traction in rural and remote areas where access to electricity and modern infrastructure is limited. In agriculture, small-scale irrigation, and domestic water supply, especially in developing regions of Asia-Pacific, Africa, and Latin America, these manually operated pumps offer a reliable and cost-effective solution. Governments and NGOs are increasingly supporting off-grid water access initiatives, boosting demand for durable and low-maintenance hand pumps. -

Emphasis on Durable and Corrosion-Resistant Materials

Manufacturers are focusing on using advanced materials such as stainless steel, reinforced polymers, and brass to enhance the durability and lifespan of hand rotary pumps. This shift is particularly important in harsh environments, including saline or chemically aggressive applications in agriculture and industrial maintenance, where corrosion resistance is critical. -

Integration with Sustainable Development Goals (SDGs)

The United Nations’ SDG 6 (Clean Water and Sanitation) is driving investments in hand pump deployment across underserved communities. By 2026, many international aid programs and water sanitation projects are expected to prioritize hand rotary pumps due to their low operational cost, ease of maintenance, and minimal environmental impact. -

Technological Improvements in Ergonomics and Efficiency

Innovations in pump design—such as improved handle mechanics, optimized gear ratios, and reduced operational effort—are making hand rotary pumps more user-friendly. These improvements increase pumping efficiency and reduce operator fatigue, expanding their usability across different demographics, including women and elderly users. -

Growth in Industrial and Niche Applications

Beyond water transfer, hand rotary pumps are finding increased use in industrial maintenance, automotive workshops, and chemical transfer applications where precise, controlled manual pumping is required. Their portability and absence of electrical components make them ideal for hazardous or explosive environments. -

Regional Market Expansion in Emerging Economies

Countries such as India, Nigeria, Indonesia, and Bangladesh are expected to be key growth markets by 2026 due to large rural populations, government-led water security programs, and rising awareness about hygiene and sanitation. Local manufacturing and assembly are also reducing costs and improving supply chain efficiency. -

Competitive Landscape and Market Consolidation

The market is seeing increased competition among regional manufacturers and global players. Strategic partnerships, product differentiation, and after-sales service networks are becoming crucial for market penetration. Some companies are also bundling hand pumps with accessories or offering training programs to enhance customer adoption. -

Environmental and Regulatory Support

With rising concerns over energy consumption and carbon emissions, hand-operated pumps are being recognized as eco-friendly alternatives to motorized systems. Regulatory incentives and green infrastructure funding in several countries are expected to favor non-electric pumping solutions in specific applications.

In conclusion, the 2026 hand rotary pump market is poised for moderate but meaningful growth, underpinned by sustainability trends, technological refinements, and expanding access to clean water. While not a high-tech segment, its role in basic human needs and resilient infrastructure ensures ongoing relevance and steady demand globally.

Common Pitfalls Sourcing Hand Rotary Pumps (Quality & IP)

Sourcing hand rotary pumps, especially from cost-driven markets, presents several recurring challenges related to product quality and intellectual property (IP) protection. Being aware of these pitfalls is crucial for ensuring reliable performance, long-term cost efficiency, and legal compliance.

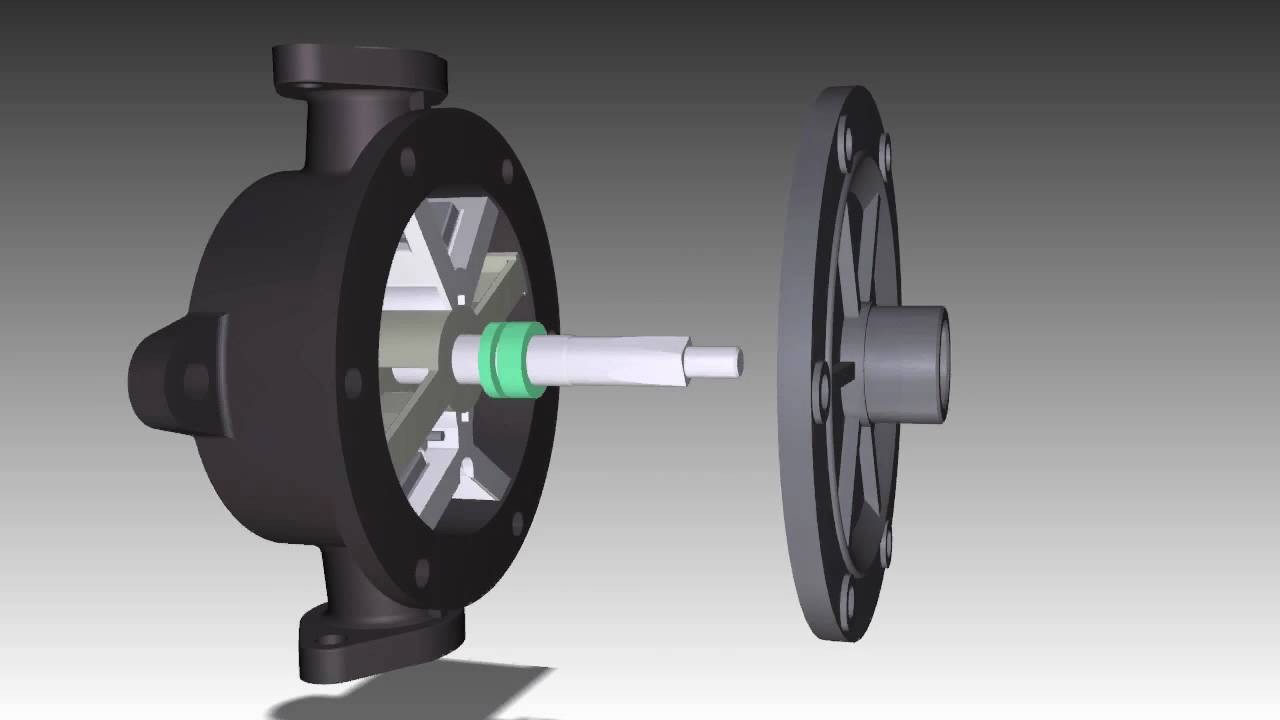

Quality Inconsistencies and Substandard Components

One of the most prevalent issues is inconsistent product quality. Suppliers may deliver samples meeting specifications, but production batches often suffer from deviations in materials, manufacturing tolerances, and assembly standards. Common problems include the use of inferior seals leading to leaks, weak or brittle plastic housings prone to cracking, and imprecise machining of rotor components causing reduced efficiency or binding. These inconsistencies stem from lax quality control processes, unqualified labor, or the use of substandard raw materials to cut costs. Buyers frequently discover these flaws only after deployment, resulting in downtime, maintenance costs, and reputational damage.

Lack of Genuine IP Compliance and Design Infringement

Many sourced hand rotary pumps are direct copies or close imitations of patented or trademarked designs from established manufacturers. Suppliers may falsely claim original design or compliance with international standards while replicating protected technologies. This exposes the buyer to significant IP risks, including legal action from rights holders, shipment seizures at customs, and damage to brand integrity. Conducting thorough due diligence—such as patent searches, verification of supplier certifications, and independent design reviews—is essential to avoid inadvertently sourcing counterfeit or infringing products.

Inadequate Documentation and Traceability

Reliable suppliers provide comprehensive technical documentation, including material specifications, performance test data, and traceable manufacturing records. However, many low-cost suppliers offer minimal or falsified documentation, making it difficult to verify compliance with industry standards (e.g., ISO, NSF) or ensure batch traceability in case of failure. This lack of transparency complicates quality audits, regulatory approvals, and after-sales support, increasing the total cost of ownership.

Hidden Costs from Poor Durability and Support

While initial pricing may appear attractive, poor build quality often leads to higher lifecycle costs. Frequent breakdowns, short service life, and the absence of readily available spare parts necessitate repeated replacements and unscheduled maintenance. Additionally, limited after-sales support or language barriers can delay troubleshooting and repairs. Buyers may also face logistical challenges in returning defective units or obtaining technical assistance, further compounding operational disruptions.

Conclusion

To mitigate these risks, buyers should prioritize supplier vetting, request independent third-party testing, insist on full documentation, and conduct on-site factory audits when possible. Engaging legal counsel to review IP rights and contracts can also safeguard against infringement claims. Investing time and resources upfront significantly reduces the likelihood of encountering these common pitfalls.

Logistics & Compliance Guide for Hand Rotary Pump

Product Classification and Documentation

Ensure accurate product classification for international shipping by identifying the correct Harmonized System (HS) Code for the hand rotary pump. Typical classifications may fall under HS Code 8413.70 (Other positive displacement pumps). Confirm with local customs authorities or a licensed customs broker, as variations may exist by country. Prepare essential documentation including commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Include detailed product descriptions, material composition, intended use, and applicable standards met.

Packaging and Handling Requirements

Package hand rotary pumps securely to prevent damage during transit. Use protective materials such as bubble wrap, foam inserts, or corrugated dividers within sturdy outer cartons. Label packages with handling instructions such as “Fragile,” “This Side Up,” and “Do Not Stack,” where applicable. Ensure packaging complies with international shipping standards (e.g., ISTA or ISO) and is suitable for multimodal transport (air, sea, road). Include internal product labeling with model number, serial number (if applicable), and manufacturer information.

Import/Export Regulations

Verify export control requirements based on the destination country. While hand rotary pumps are generally not subject to strict export controls, confirm they do not contain restricted materials or dual-use components (e.g., certain metals or precision engineering). Comply with U.S. Export Administration Regulations (EAR) or equivalent regulations in other jurisdictions. For imports, ensure adherence to local customs procedures, tariff classifications, and any import permits or declarations required by the destination country.

Safety and Compliance Standards

Ensure the hand rotary pump meets relevant safety and performance standards in target markets. Common certifications include CE marking (for EU markets) under applicable directives such as the Machinery Directive (2006/42/EC) or Pressure Equipment Directive (if applicable), and UKCA marking for the United Kingdom. In North America, compliance with ANSI or ASME standards may be required depending on application. Provide technical documentation, user manuals, and safety warnings in the local language(s) of the destination market.

Environmental and Chemical Compliance

Assess whether the hand rotary pump contains substances regulated under environmental legislation such as the EU’s REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) or RoHS (Restriction of Hazardous Substances). Confirm that materials used (e.g., seals, lubricants, housing) are compliant. Provide a Declaration of Conformity (DoC) and, if necessary, a Substance of Very High Concern (SVHC) statement. For pumps used with hazardous fluids, ensure design compatibility and provide appropriate warnings.

Transportation and Carrier Coordination

Coordinate with freight forwarders or carriers experienced in handling industrial equipment. Specify transport mode based on urgency, cost, and product sensitivity. For air freight, comply with IATA regulations; for sea freight, follow IMO and IMDG Code guidelines if transporting hazardous materials. Ensure proper weight distribution and secure loading to prevent shifting during transit. Track shipments using GPS or carrier tracking systems and maintain communication with logistics partners throughout the supply chain.

End-of-Life and Recycling Considerations

Provide guidance for end-of-life disposal or recycling in accordance with local environmental regulations. Inform customers of take-back programs or recycling options where available. Design pumps with recyclable materials (e.g., stainless steel, aluminum, thermoplastics) where possible. Comply with WEEE (Waste Electrical and Electronic Equipment) directives if applicable, even though hand rotary pumps are typically mechanical devices.

Conclusion for Sourcing Hand Rotary Pumps

In conclusion, sourcing hand rotary pumps requires a thorough evaluation of quality, cost, reliability, and supplier capabilities. These manually operated pumps are essential in various industries—such as agriculture, emergency response, and off-grid applications—where access to electricity is limited or reliability is paramount. After assessing multiple suppliers, it is evident that selecting a pump with durable construction, efficient performance, and compliance with relevant industry standards ensures long-term functionality and user satisfaction.

Key considerations such as material quality (e.g., stainless steel or corrosion-resistant alloys), ease of maintenance, portability, and compatibility with different fluids must be prioritized. Additionally, engaging with reputable suppliers offering strong after-sales support, warranties, and scalable supply options enhances supply chain resilience.

Ultimately, the successful sourcing of hand rotary pumps hinges on balancing performance requirements with cost-efficiency, ensuring that the chosen solution meets both operational needs and sustainability goals. By conducting due diligence and building strategic supplier relationships, organizations can secure reliable, high-quality hand pumps that deliver dependable service in critical applications.