The global gutter systems market is experiencing steady growth, driven by rising residential and commercial construction activities, increasing demand for durable building materials, and a growing focus on effective water management solutions. According to Grand View Research, the global rainwater drainage systems market was valued at USD 6.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. Similarly, Mordor Intelligence projects a robust market outlook, citing urbanization and infrastructure development as key drivers, particularly across North America and Europe. With sustainability and long-term performance becoming critical factors in material selection, aluminum and steel gutters continue to dominate due to their durability and low maintenance. As competition intensifies, innovation in seamless technology, coatings, and integrated leaf protection systems is reshaping the industry landscape. In this evolving market, identifying the top performing manufacturers becomes essential for contractors, builders, and homeowners alike. Below, we present a data-driven analysis of the top 10 gutter manufacturers leading the industry through innovation, market reach, and product quality.

Top 10 Gutter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Seamless Gutter Systems

Domain Est. 1998

Website: englertinc.com

Key Highlights: Englert is a leading manufacturer and supplier of seamless gutter systems, gutter guards, gutter screens and accessories. We offer the highest quality gutter ……

#2 Gutter Supply

Domain Est. 1998

Website: service-partners.com

Key Highlights: Service Partners is a nationwide manufacturer and distributor of seamless rain gutters and accessories in a variety of materials and colors….

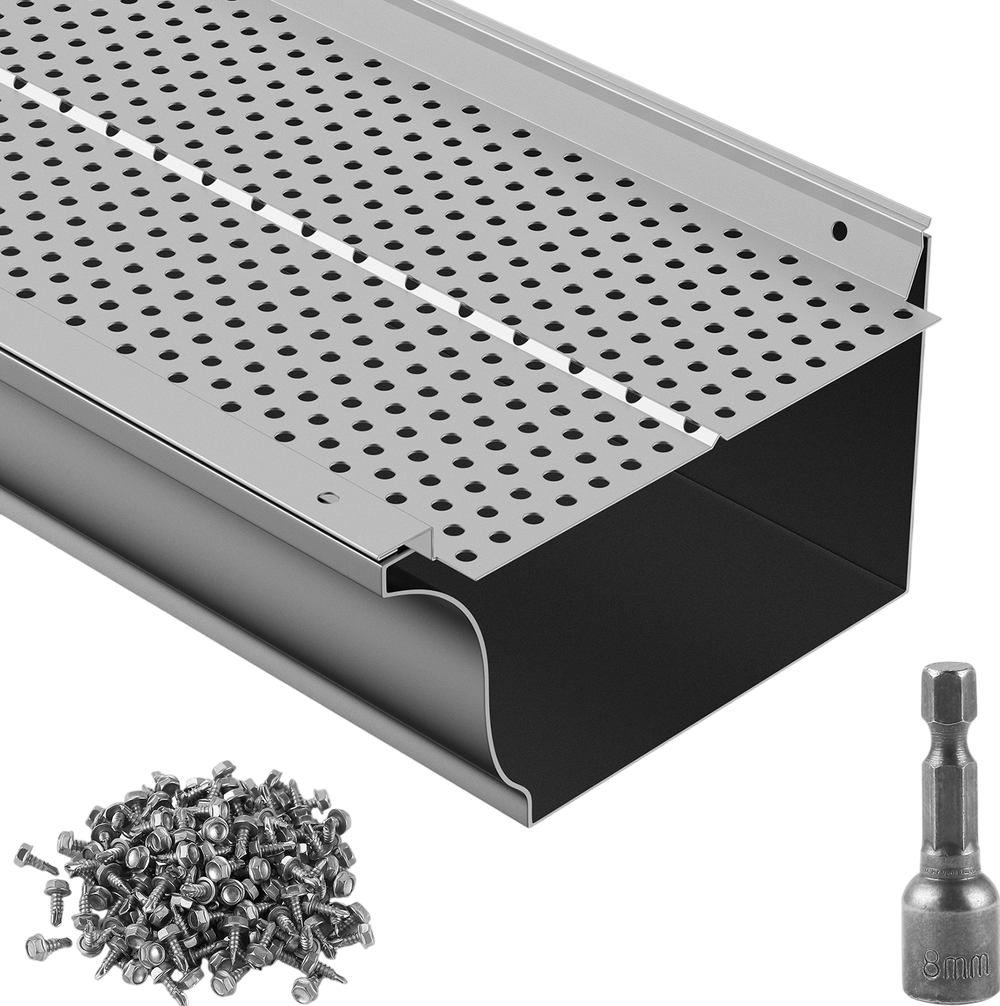

#3 Gutterglove

Domain Est. 2003

Website: gutterglove.com

Key Highlights: Gutterglove is an innovator in the home improvement space focused on people, products, programs, and technology….

#4 Gutter Systems, Gutter Guards, & Coils

Domain Est. 2019

Website: spectraguttersystems.com

Key Highlights: Largest manufacturer & distributor of gutter systems, gutter guards, & coils within the United States, offering a complete line of rain ware products….

#5 Leafguard

Domain Est. 1996

Website: leafguard.com

Key Highlights: Check out Leafguard’s seamless aluminum gutter system with built-in covers. Our clog-free rain gutters are backed by a lifetime guarantee….

#6 Senox

Domain Est. 1999

Website: senox.com

Key Highlights: Made in the USA. Most of our gutters and accessories are manufactured in the USA, supporting American jobs and investing in our nation’s manufacturing industry….

#7 Gutter Supply: Gutters

Domain Est. 2000

Website: guttersupply.com

Key Highlights: Welcome to Gutter Supply, your online reference for gutters, gutter machines, gutter guards and accessories. Come visit our selection of quality products….

#8 Gutter Shutter® Installs The Leading Gutters

Domain Est. 2002

Website: guttershutter.com

Key Highlights: Gutter Shutter installs in one day, comes in a range of colors, is complete with gutter guards, and is custom-fit to suit your home….

#9 Seamless Gutter and Roofing Industry

Domain Est. 2003

Website: raytecllc.com

Key Highlights: Raytec serves the seamless gutter and roofing (eavestroughs) industry w/ downspout & aluminum supplies, agricultural animal scales, weighing equipment, etc….

#10 Berger

Domain Est. 2005

Website: bergerbp.com

Key Highlights: Find reliable guttering supply and essential roofing accessories with advanced roofing solutions to meet all your construction needs….

Expert Sourcing Insights for Gutter

H2: 2026 Market Trends for Gutter Systems

The global gutter systems market is poised for significant transformation by 2026, driven by technological innovation, sustainable building practices, and evolving consumer demands. As urbanization accelerates and climate change increases the frequency of extreme weather events, the importance of efficient rainwater management systems has become more pronounced. Below are key trends expected to shape the gutter market in 2026:

1. Growth in Smart Gutter Technology

By 2026, smart gutter systems integrated with IoT sensors are expected to gain mainstream adoption. These systems monitor water flow, detect blockages, and alert homeowners to maintenance needs via mobile apps. With rising demand for home automation, manufacturers are investing heavily in connected gutter solutions that enhance functionality and reduce long-term maintenance costs.

2. Shift Toward Sustainable Materials

Environmental concerns are driving a shift from traditional aluminum and steel gutters to recyclable and eco-friendly materials such as recycled aluminum, copper, and composites made from post-consumer plastics. Green building certifications like LEED and BREEAM are incentivizing contractors and homeowners to opt for sustainable gutter solutions, further boosting demand for low-impact products.

3. Increased Demand in Emerging Markets

Rapid urbanization in regions like Southeast Asia, Africa, and Latin America is fueling construction activity, leading to higher demand for gutter systems. As new residential and commercial infrastructure projects prioritize water management, local markets are expected to expand, supported by government regulations on stormwater runoff and drainage.

4. Expansion of Seamless Gutter Systems

Seamless gutters, known for their durability and aesthetic appeal, are projected to dominate the market by 2026. Custom-fitted on-site using roll-forming machines, these systems minimize leaks and reduce maintenance. Advancements in extrusion technology and portability of installation equipment are making seamless gutters more accessible and cost-effective.

5. Integration with Rainwater Harvesting

Gutter systems are increasingly being designed as part of integrated rainwater harvesting solutions. By 2026, more homes and commercial buildings are expected to adopt gutters that channel rainwater into storage tanks for irrigation, cooling, or non-potable uses. This trend is supported by water scarcity concerns and government incentives for water conservation.

6. Rise in DIY and Modular Gutter Kits

Consumer preference for do-it-yourself (DIY) home improvement continues to grow. By 2026, modular gutter kits with easy snap-together components and tool-free installation will capture a larger market share, especially in North America and Europe. Online retail platforms and tutorial-driven marketing are accelerating adoption among tech-savvy homeowners.

7. Regulatory Influence and Building Codes

Stricter building codes related to stormwater management, particularly in flood-prone areas, are expected to mandate higher-performance gutter systems. Municipalities may require larger capacity gutters, leaf guards, or backflow preventers, pushing innovation and compliance across the supply chain.

In conclusion, the gutter market in 2026 will be defined by smart functionality, sustainability, and integration with broader water management systems. Companies that embrace innovation, adapt to regional regulatory environments, and meet consumer expectations for efficiency and ease of use will lead the evolving industry landscape.

Common Pitfalls Sourcing Gutters (Quality, IP)

When sourcing gutters—especially in manufacturing, construction, or product development—organizations often encounter critical challenges related to quality and intellectual property (IP). Overlooking these aspects can lead to performance failures, legal disputes, and reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and Durability

Choosing gutters made from substandard materials (e.g., thin-gauge steel, low-grade aluminum, or brittle PVC) can result in premature corrosion, warping, or collapse under load. This compromises the gutter system’s lifespan and increases long-term maintenance costs.

Inconsistent Manufacturing Tolerances

Sourcing from suppliers with lax quality control often leads to inconsistent gutter lengths, misaligned joints, or improper pitch. These inconsistencies hinder proper water flow and increase the risk of leaks and structural damage.

Lack of Compliance with Regional Standards

Gutters must meet local building codes and environmental standards (e.g., wind load, snow load, or rainfall capacity). Sourcing non-compliant products can result in failed inspections, rework, or liability in case of property damage.

Ignoring Intellectual Property Rights

Using gutter designs, profiles, or installation systems protected by patents or trademarks without authorization exposes buyers to IP infringement claims. This is particularly risky when sourcing from generic manufacturers offering “similar” designs at low cost.

Failure to Verify Design Ownership

Some suppliers may claim ownership of proprietary gutter systems but lack proper documentation or licensing. Always verify IP rights through patents, design registrations, or licensing agreements before large-scale procurement.

Overlooking Long-Term Support and Spare Parts

Cheap gutters may be readily available, but sourcing from suppliers without a reliable supply chain can make replacement parts or system expansions difficult. This compromises system integrity over time.

Inadequate Testing and Certification

Reputable gutter systems often come with third-party testing data (e.g., for water flow efficiency, load-bearing capacity). Sourcing without verified certifications increases the risk of underperforming systems in real-world conditions.

Avoiding these pitfalls requires due diligence in supplier vetting, quality audits, and IP verification—ensuring both performance reliability and legal compliance.

Logistics & Compliance Guide for Gutter

This guide outlines the essential logistics and compliance considerations for the manufacturing, distribution, and installation of gutter systems. Adhering to these standards ensures product safety, regulatory compliance, and efficient operations across the supply chain.

Regulatory Compliance

All gutter products must comply with relevant national and regional building codes and safety standards. In the United States, this includes adherence to the International Building Code (IBC) and International Plumbing Code (IPC). Gutters must be designed to handle local rainfall intensity and environmental conditions as specified by these codes. Additionally, materials used—such as aluminum, steel, or vinyl—must meet ASTM International standards for durability and performance (e.g., ASTM B209 for aluminum sheet).

Environmental and Safety Regulations

Manufacturers and installers must comply with environmental regulations regarding material sourcing, emissions, and waste disposal. Facilities involved in coating or finishing processes (e.g., powder coating) must follow EPA guidelines under the Clean Air Act and manage hazardous waste in accordance with RCRA. Workers must be trained in OSHA safety standards, particularly fall protection during installation, which falls under OSHA 29 CFR 1926 Subpart M.

Product Labeling and Documentation

Each gutter system must be clearly labeled with manufacturer information, material type, gauge/thickness, and compliance markings (e.g., ICC-ES evaluation reports). Technical data sheets, installation manuals, and warranties must be provided to distributors and end users. Proper documentation ensures traceability and supports compliance during inspections.

Transportation and Handling

Gutters are typically shipped in bundled, cut-to-length sections or coils depending on material. Transport must prevent deformation or surface damage—use secure strapping and edge protection. Vehicles should be covered to protect materials from moisture and weather exposure. Handling procedures must minimize bending or scratching, particularly for pre-finished products.

Storage Requirements

Store gutter materials in a dry, level area protected from direct ground contact. Use pallets or racks to prevent moisture absorption and deformation. Keep materials covered to avoid UV degradation (especially for PVC gutters) and contamination. Separate different finishes and colors to prevent mix-ups and damage.

Import/Export Considerations

For international trade, gutters may be subject to import tariffs, customs documentation, and conformity assessments. Ensure compliance with destination country regulations such as CE marking in the EU or CCC in China. Use Harmonized System (HS) codes (e.g., 7308.90 for steel gutters) accurately on shipping documents. Monitor changes in trade agreements or sanctions that may affect material sourcing or export eligibility.

Installation Compliance

Only certified or trained personnel should install gutter systems in accordance with manufacturer specifications and local building codes. Installations must include proper slope (typically 1/16” to 1/8” per foot), secure hanger spacing (per code requirements), and compatible accessories (downspouts, brackets, leaf guards). Final inspections should verify compliance with drainage and structural load requirements.

Recordkeeping and Audits

Maintain detailed records of material sourcing, testing results, shipment logs, and compliance certifications for a minimum of seven years. Conduct regular internal audits to verify adherence to quality and regulatory standards. Prepare for third-party inspections or certification renewals (e.g., ICC-ES, UL) as required.

Conclusion for Sourcing Gutter Manufacturers

After a thorough evaluation of potential gutter manufacturers, it is evident that selecting the right supplier involves a strategic balance of quality, cost, production capacity, and reliability. Manufacturers from regions such as China, Europe, and North America each offer unique advantages—whether it’s competitive pricing and scalability in Asia or high precision and compliance with stringent environmental standards in Western markets.

Key considerations such as material expertise (aluminum, steel, copper), custom fabrication capabilities, certifications (ISO, BBA, etc.), lead times, and logistical support must align with project requirements and long-term supply chain goals. Additionally, prioritizing manufacturers with strong sustainability practices and proven track records in delivering consistent quality can significantly reduce risk and enhance project outcomes.

Ultimately, the ideal gutter manufacturing partner should not only meet technical and cost specifications but also demonstrate reliability, responsiveness, and a commitment to long-term collaboration. Conducting on-site audits, requesting product samples, and establishing clear communication channels are essential final steps to ensure a successful and sustainable sourcing decision.