The global gun drilling machine market has experienced steady growth, driven by rising demand for high-precision deep-hole drilling in industries such as automotive, aerospace, and energy. According to Grand View Research, the global deep hole drilling machine market size was valued at USD 682.3 million in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2024 to 2030. This growth is fueled by increasing production of complex engine components, fuel injection systems, and turbine shafts requiring tight tolerances and excellent surface finishes—key strengths of gun drilling technology. As manufacturers prioritize efficiency, accuracy, and automation, leading gun drilling machine suppliers are investing in advanced CNC systems, tooling innovations, and turnkey solutions. Based on market presence, technological capabilities, and customer reach, the following list highlights the top 10 gun drilling machine manufacturers shaping the future of precision deep-hole drilling.

Top 10 Gun Drilling Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Customized Gun Drilling Machines Manufacturers Suppliers …

Domain Est. 2018 | Founded: 2011

Website: guanludrilling.com

Key Highlights: Our factory Dezhou Guanlu Precision Machinery Co.,Ltd is founded in 2011,its main business is manufacturing: Gun drilling machine,deep hole drilling machine, ……

#2

Domain Est. 2000

Website: amgundrilling.com

Key Highlights: A 3rd Generation, Midwest-based machining company, American Machine & Gundrilling (AMG) specializes in complex drilling and boring holes in various materials….

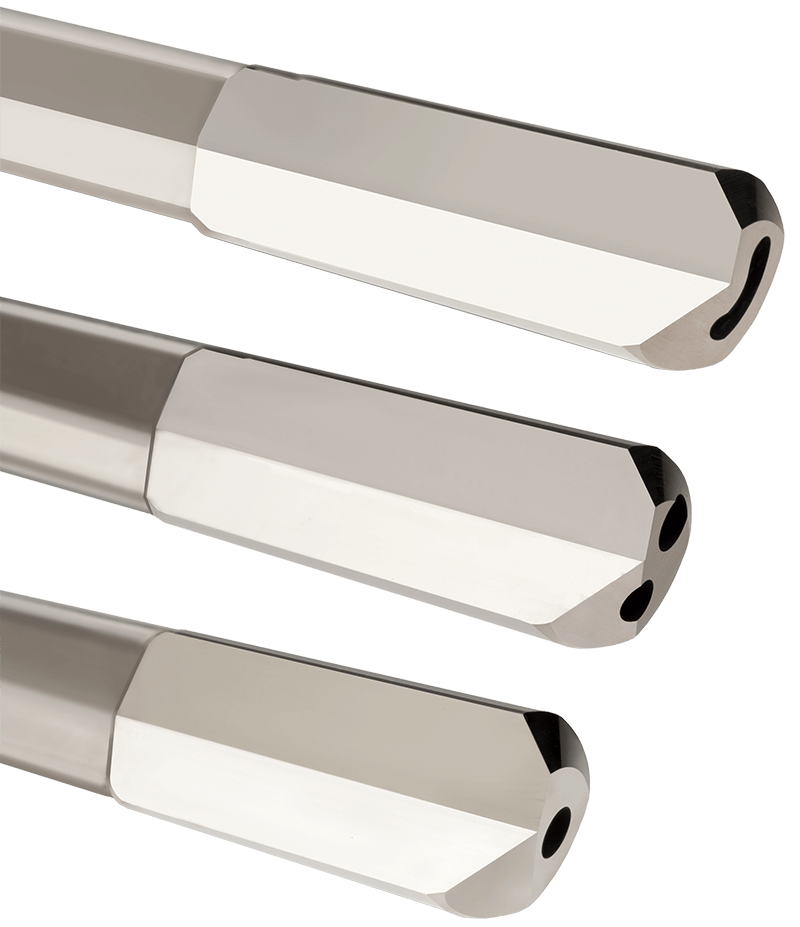

#3 Drill Masters Eldorado Tool

Domain Est. 2005

Website: dmetool.com

Key Highlights: Products: Gundrills. We are the largest supplier and manufacturer of deep hole drilling tools, fixtures, and accessories in the world. We have solutions for all ……

#4 Gun Drills, Drill Bit, Deep Hole Drilling Tools Wholesale

Domain Est. 2020

Website: drillstarcuttingtool.com

Key Highlights: Dezhou Drillstar Cutting Tool Co., Ltd. is a professional company engaged in the sales, manufacturing and technical services of deep hole processing tools….

#5 Global Leader in Gundrilling Machines and BTA STS Deep Hole …

Domain Est. 1995

Website: tarus.com

Key Highlights: TARUS was the first company to build purpose-designed gun drilling for drilling large molds and we continue to be the leader with our DHDM line of machines….

#6 Contract Gundrilling Services

Domain Est. 1995

Website: carlsontool.com

Key Highlights: Gundrilling experts since the 70’s, we’ve drilled practically every metal alloy in all industries and can drill hole sizes as small as 0.055″…

#7 Gun Drilling Machines

Domain Est. 1997

Website: absolutemachine.com

Key Highlights: Gun drilling machines from Precihole perfectly fit the mold of extraordinary quality machines with superb precision, tolerance, and surface finish….

#8 Mollart

Domain Est. 1998

Website: mollart.com

Key Highlights: World Leading Tooling Solutions Mollart supplies a wide range of tooling for deep hole processing including: Gundrills and BTA drills, Hole Deburring and ……

#9 UNISIG Gundrilling Machines and Deep Hole Drilling Machines

Domain Est. 2004

Website: unisig.com

Key Highlights: UNISIG designs and manufactures precision gundrilling machines, tools, and automation systems. We deliver complete deep hole drilling solutions with expert ……

#10 M4 Sciences

Domain Est. 2006

Website: m4sciences.com

Key Highlights: Gun drilling and deep hole drilling greatly benefit from Modulation Assisted Machining (MAM) as fine chips are created from the highly controlled actuator ……

Expert Sourcing Insights for Gun Drilling Machine

H2: Analysis of 2026 Market Trends for Gun Drilling Machines

The global gun drilling machine market is poised for significant transformation by 2026, driven by technological advancements, rising industrial automation, and growing demand across key manufacturing sectors. Gun drilling machines—specialized deep-hole drilling equipment known for high precision and efficiency—are increasingly vital in industries such as aerospace, automotive, energy, and medical device manufacturing. This analysis explores the key market trends expected to shape the gun drilling machine industry in 2026.

1. Rising Demand in Aerospace and Automotive Sectors

The aerospace and automotive industries are major end-users of gun drilling machines due to their need for long, straight, and smooth deep holes in components like turbine shafts, fuel injection nozzles, and transmission parts. By 2026, increasing aircraft production and the global shift toward electric vehicles (EVs) will amplify demand for lightweight, high-strength components that require precise deep-hole drilling. This trend will drive investment in advanced gun drilling technologies capable of handling exotic materials such as titanium, Inconel, and high-strength steel.

2. Technological Advancements and Automation Integration

In 2026, gun drilling machines are expected to incorporate greater levels of automation, IoT connectivity, and AI-driven process optimization. Smart gun drills with real-time monitoring, predictive maintenance, and adaptive control systems will enhance precision, reduce tool wear, and minimize downtime. Integration with Industry 4.0 principles—such as digital twins and machine-to-machine communication—will enable manufacturers to achieve higher throughput and consistency, especially in high-mix, low-volume production environments.

3. Growth in the Energy Sector, Especially Oil & Gas and Renewables

The energy industry remains a critical market for gun drilling applications, particularly in drilling components for downhole tools, heat exchangers, and hydraulic systems. Despite fluctuations in oil prices, investments in deepwater and unconventional drilling are expected to sustain demand. Additionally, the expansion of renewable energy infrastructure—such as geothermal and concentrated solar power—will require specialized components that benefit from gun drilling capabilities, further supporting market growth.

4. Regional Market Dynamics

Asia-Pacific is projected to lead the gun drilling machine market by 2026, fueled by rapid industrialization, government initiatives to boost manufacturing (e.g., “Make in India,” “China Manufacturing 2025”), and strong growth in automotive and electronics production. North America and Europe will remain significant markets due to advanced aerospace and defense industries and a focus on high-precision engineering. Localized production and supply chain resilience will encourage regional manufacturers to upgrade their deep-hole drilling capabilities.

5. Sustainability and Energy Efficiency Focus

Environmental regulations and sustainability goals will influence the design and operation of gun drilling machines. By 2026, manufacturers will prioritize energy-efficient motors, closed-loop coolant systems, and reduced fluid consumption to minimize environmental impact. Eco-friendly machine designs compliant with ISO 14001 and similar standards will become a competitive differentiator.

6. Competitive Landscape and Market Consolidation

The gun drilling machine market will see increased competition and consolidation, with key players investing in R&D and strategic partnerships. Companies such as Mitsubishi Heavy Industries, Guehring, and BTA/Deep Hole Drilling specialists will expand their product portfolios to include modular and customizable solutions. Smaller niche players may focus on hybrid systems that combine gun drilling with other machining processes (e.g., milling or turning) to offer integrated solutions.

Conclusion

By 2026, the gun drilling machine market will be characterized by innovation, automation, and sector-specific customization. Growth will be driven by demand from high-tech industries, the integration of smart manufacturing technologies, and a global push toward precision and sustainability. Manufacturers who adapt to these trends by offering advanced, efficient, and environmentally responsible solutions will be well-positioned to capture market share in an increasingly competitive landscape.

Common Pitfalls When Sourcing Gun Drilling Machines (Quality and Intellectual Property)

Sourcing gun drilling machines, especially from international or unfamiliar suppliers, presents several risks related to both machine quality and intellectual property protection. Being aware of these pitfalls helps avoid costly mistakes and ensures a reliable, legally sound investment.

Poor Build Quality and Substandard Components

Many suppliers, particularly low-cost manufacturers, may use inferior materials and components to reduce production costs. This can result in machines with poor rigidity, premature wear, and inconsistent drilling performance. Key areas to scrutinize include spindle accuracy, guideway quality (e.g., linear guides vs. box ways), and the durability of coolant systems. Machines with undocumented or uncertified parts may fail to meet required tolerances or safety standards.

Inadequate After-Sales Support and Technical Service

A common oversight is assuming that machine delivery marks the end of the transaction. In reality, gun drilling machines require regular maintenance, tooling support, and operator training. Sourcing from suppliers without a local service network or proven technical support can lead to extended downtime and production losses. Always verify the availability of trained technicians, spare parts inventory, and response times before purchase.

Misrepresentation of Machine Specifications and Capabilities

Some suppliers may exaggerate performance metrics such as drilling depth, straightness tolerance, or maximum spindle speed. This misrepresentation can result in the machine failing to meet production requirements. Always request third-party verification, on-site demonstrations, or references from existing customers using the machine for similar applications.

Lack of Compliance with International Standards

Gun drilling machines must adhere to safety and performance standards such as ISO, CE, or ANSI. Sourcing from manufacturers that do not comply with these standards not only poses safety risks but may also lead to legal or customs issues during import. Verify certification documentation and ensure electrical and mechanical designs meet regional regulatory requirements.

Intellectual Property (IP) Risks and Machine Cloning

One of the most serious and often overlooked risks is the potential for IP theft or infringement. Some suppliers may reverse-engineer proprietary designs or offer machines that closely mimic branded models without proper licensing. Purchasing such machines may expose your company to legal liability, especially if the machine incorporates patented technology. Additionally, using cloned equipment can compromise performance and reliability due to unlicensed modifications.

Insufficient Documentation and Software Licensing

Modern gun drilling machines often include CNC controls and proprietary software. Sourcing machines without proper documentation, control system licenses, or source code access limits your ability to troubleshoot, upgrade, or integrate the machine into existing systems. Ensure all software is legally licensed and that comprehensive manuals, electrical schematics, and maintenance guides are provided.

Hidden Costs and Unclear Warranty Terms

Upfront pricing may appear competitive, but hidden costs such as shipping, import duties, installation, and training can significantly increase total expenditure. Additionally, vague or limited warranty terms—especially those excluding critical components like spindles or electronics—can result in unexpected repair costs. Always request a detailed breakdown of all expenses and written warranty terms covering parts, labor, and response time.

Conclusion

To mitigate these risks, conduct thorough due diligence: audit suppliers, request machine trials, verify certifications, and consult legal counsel regarding IP and contractual terms. Investing time upfront ensures long-term operational success and protects your company from quality failures and legal exposure.

Logistics & Compliance Guide for Gun Drilling Machine

Transporting and operating a gun drilling machine involves navigating complex logistics and regulatory requirements due to its size, weight, precision components, and industrial nature. This guide outlines key considerations to ensure smooth delivery and compliance with relevant standards.

Classification and Export Controls

Gun drilling machines may be subject to export control regulations depending on their specifications and destination. Verify whether the machine falls under dual-use or strategic goods classifications such as those listed in the Wassenaar Arrangement or national export control lists (e.g., U.S. Commerce Control List – CCL). Obtain necessary export licenses or authorizations before shipment, particularly when exporting to restricted countries or regions.

International Shipping and Freight Logistics

Due to their substantial weight and dimensions, gun drilling machines typically require heavy-lift or project cargo solutions. Coordinate with freight forwarders experienced in industrial machinery transport. Use sea freight (FCL container or flat rack) for long-distance international shipments, or specialized heavy road transport for regional delivery. Ensure proper crating, securing, and moisture protection to prevent damage during transit.

Customs Documentation and Duties

Prepare comprehensive customs documentation including commercial invoice, packing list, bill of lading or air waybill, and certificate of origin. Accurately classify the machine using the correct HS (Harmonized System) code—typically under heading 8459 for “Machines for drilling… by means of rotating tools.” Be prepared to pay applicable import duties, VAT, and customs clearance fees in the destination country.

Machine Handling and Installation Requirements

Ensure the receiving site is accessible to large trucks and has adequate lifting equipment (e.g., forklifts, cranes) to offload the machine. Verify floor load capacity, power supply compatibility (voltage, phase, frequency), coolant system connections, and ventilation. Follow manufacturer guidelines for uncrating, positioning, and initial setup to avoid damage and ensure operational safety.

Safety and Operational Compliance

Gun drilling machines must comply with regional safety standards such as CE marking (EU), UL/CSA (North America), or other local certifications. Confirm the machine meets electrical safety, noise emission, and mechanical guarding requirements. Provide operators with training on safe operation, emergency shutdown procedures, and PPE (personal protective equipment) usage.

Environmental and Waste Management

Gun drilling processes generate metal chips and used coolant, which may be classified as hazardous waste depending on local regulations. Implement proper collection, recycling, and disposal protocols in accordance with environmental laws (e.g., EPA regulations in the U.S. or REACH/CLP in the EU). Use biodegradable or low-impact coolants where possible to minimize environmental impact.

After-Sales Support and Spare Parts Logistics

Establish a logistics plan for spare parts delivery and technical service access. Maintain an inventory of critical components (e.g., drill tubes, bearings, seals) to minimize downtime. Confirm service technician availability and ensure compliance with any import rules for warranty or repair parts shipped internationally.

Conclusion for Sourcing a Gun Drilling Machine

Sourcing a gun drilling machine is a strategic investment that significantly enhances precision, efficiency, and capability in deep hole drilling operations. After evaluating key factors such as machine specifications, automation level, manufacturer reputation, after-sales support, and total cost of ownership, it is evident that selecting the right gun drilling machine requires a comprehensive approach aligned with specific production needs.

The chosen machine should offer high rigidity, accurate spindle alignment, effective coolant delivery systems, and compatibility with required materials and part geometries. Additionally, integration capabilities with existing manufacturing systems and future scalability must be considered to ensure long-term value.

Prioritizing suppliers with proven industry experience, technical expertise, and reliable service networks ensures minimal downtime and sustained operational performance. Ultimately, sourcing the appropriate gun drilling machine not only improves product quality and throughput but also strengthens competitive advantage in industries such as aerospace, automotive, energy, and mold making.

In conclusion, a well-informed sourcing decision—based on thorough evaluation and alignment with production goals—will deliver lasting benefits in precision manufacturing and operational excellence.