The global grow tent market has experienced significant growth over the past decade, driven by the rising adoption of indoor farming, advancements in controlled environment agriculture, and increasing demand for high-yield, space-efficient cultivation solutions. According to a 2023 report by Mordor Intelligence, the indoor farming market—of which grow tents are a critical component—is projected to grow at a CAGR of 9.2% from 2023 to 2028. This growth is further supported by Grand View Research, which valued the global vertical farming market at USD 4.3 billion in 2022 and forecasted a CAGR of 9.4% from 2023 to 2030, underpinned by urbanization and sustainable agriculture trends. As cultivation technologies evolve, the demand for durable, reflective, and climate-controlled grow tent materials has surged, prompting innovation among manufacturers. In this landscape, a select group of companies has emerged as leaders in producing high-performance grow tent materials, combining technical fabrics, advanced coatings, and scalable solutions to meet the needs of commercial cultivators and hobbyists alike.

Top 9 Grow Tent Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Grow Light, LED Growlights, HPS Grow Lights, Grow Tents …

Domain Est. 2010

Website: growace.com

Key Highlights: As a leader in hydroponics equipment, we offer a range of items such as LED grow lights, grow tents, and HPS grow lights. Visit us online today at GrowAce….

#2 Advance Grow Tent Kits

Domain Est. 2012

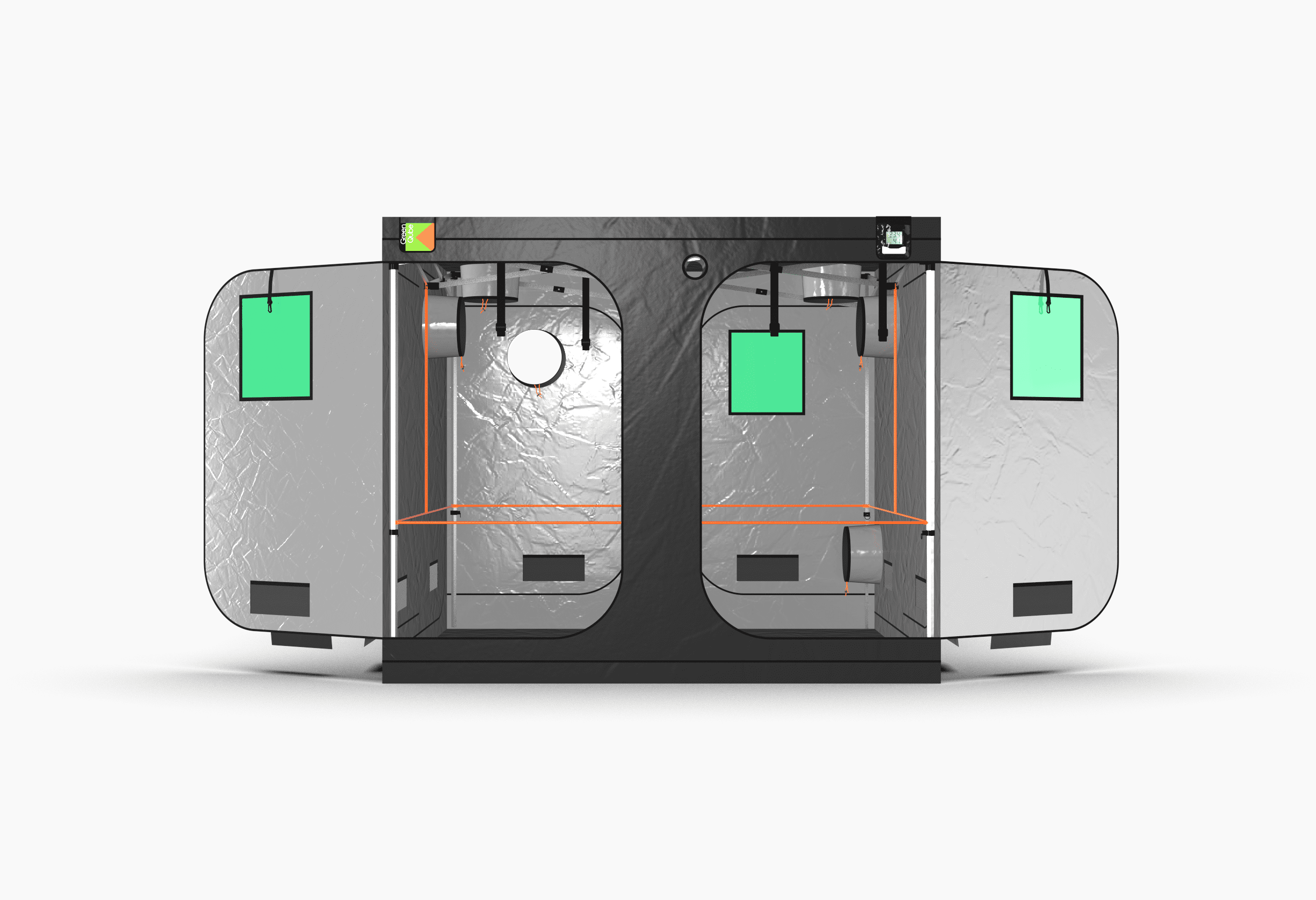

#3 Gorilla Grow Tent Pro

Domain Est. 2012

Website: gorillagrowtent.com

Key Highlights: Grow Tents: create the perfect environment for healthy plant growth. Durable, lightproof, and designed for maximum yields in indoor gardening setups!…

#4 Grow Generation

Domain Est. 2014

Website: growgeneration.com

Key Highlights: 7-day returnsExplore GrowGeneration, the largest hydroponics store in the U.S., offering grow lights, nutrients, tents & more. Shop online or find a store near you….

#5 Mars Hydro TS 600 + 2’x2′ Complete Grow Tent Kit

Domain Est. 2014

Website: ledgrowlightsdepot.com

Key Highlights: In stock Free deliveryHigh Quality Grow Tent: It’s made of thicker1680D canvas grow tent material(ALL OTHERS brands grow tent are 601D canvas), which is tear proof & perfect light …

#6 Vivosun Grow Tent 5×2 S538

Domain Est. 2015

Website: vivosun.com

Key Highlights: In stock Rating 4.9 (197) Vivosun Grow Tent is a clever solution to a grower’s needs. It’s made of high-quality materials, equipped with visual windows to monitor plant growth in…

#7 Indoor Planting Aesthetics White Grow Tent

Domain Est. 2019

Website: spider-farmer.com

Key Highlights: Free delivery Free 30-day returnsUpgraded 2000D Oxford Fabric Made from thick, durable 2000D Oxford cloth with superior light-blocking and reflective properties for enhanced growin…

#8 MELONFARM Grow tents [Hydroponics Online Store]

Domain Est. 2024

Website: melonfarm.shop

Key Highlights: melonfarm is your reliable supplier of high quality grow tents and everything you need to create the perfect growing environment….

#9 IPower ⚡️ ⚡️ Grow tents & Lights & Fans

Domain Est. 2024

Website: ipower-hydroponic.com

Key Highlights: ipower grow tent. Indoor Hydroponic Water-Resistant Complete System. Durable Material: iPower grow tent is made of high-quality Oxford fabric….

Expert Sourcing Insights for Grow Tent Material

2026 Market Trends for Grow Tent Materials

The global grow tent market is poised for significant transformation by 2026, driven by technological advancements, evolving consumer demands, and increasing legalization of cannabis cultivation in various regions. The materials used in grow tent construction are central to this evolution, with key trends shaping innovation and consumer preferences.

1. Enhanced Reflectivity and Light Efficiency

By 2026, manufacturers will prioritize materials with superior light reflectivity to maximize photosynthetic efficiency. Mylar (polyethylene terephthalate) with 95–98% reflectivity will remain dominant, but advanced metallized films and hybrid coatings will gain traction. Innovations such as diamond-textured Mylar or nano-coated surfaces will improve light diffusion, reducing hotspots and ensuring even canopy coverage. These materials will be especially critical for energy-conscious growers aiming to optimize LED light usage.

2. Sustainable and Eco-Friendly Materials

Environmental concerns will drive demand for sustainable alternatives. Biodegradable or recyclable fabrics and PVC-free tent linings will emerge as key differentiators. Companies will explore plant-based polymers and compostable inner layers to align with green consumer values. Certifications such as RoHS or Cradle-to-Cradle will become more common, appealing to eco-conscious urban and indoor farmers.

3. Durability and Fire Resistance

Safety and longevity will remain top priorities. Grow tent materials will increasingly incorporate fire-retardant (FR) treatments that meet strict regulatory standards without compromising reflectivity. Reinforced stitching and puncture-resistant outer shells made from high-density polyethylene (HDPE) or Oxford fabric will enhance durability, especially in commercial setups requiring long-term reliability.

4. Smart Integration and Material Innovation

Materials will evolve to support smart growing ecosystems. Conductive textiles may emerge to integrate sensors for humidity, temperature, and light directly into tent walls. Antimicrobial coatings will reduce mold and mildew, improving hygiene in controlled environments. Additionally, lightweight yet robust composite fabrics will enable modular, expandable tent designs suitable for vertical farming and compact urban spaces.

5. Regional Market Influences

Regional legalization of cannabis will spur localized material innovation. In North America and Europe, high-performance, compliant materials will dominate. In emerging markets, cost-effective yet durable options will be prioritized. Customizable materials catering to specific climate conditions—such as UV-stabilized fabrics for high-intensity environments—will see increased adoption.

Conclusion

By 2026, grow tent materials will be defined by performance, sustainability, and smart functionality. Manufacturers that innovate in reflectivity, safety, and environmental impact will lead the market, meeting the demands of both hobbyists and commercial cultivators in an increasingly competitive and regulated landscape.

Common Pitfalls Sourcing Grow Tent Material (Quality, IP)

Sourcing high-quality grow tent materials while protecting intellectual property (IP) involves several potential pitfalls. Being aware of these challenges can help prevent costly mistakes and ensure product integrity.

Poor Material Quality and Durability

One of the most frequent issues is receiving substandard materials that compromise the grow tent’s performance. Many suppliers, especially low-cost overseas manufacturers, may use inferior fabrics with low reflectivity (e.g., sub-500D mylar instead of 600D+), weak stitching, or flimsy zippers. These flaws reduce light efficiency, structural integrity, and lifespan. Buyers may not discover these defects until after production or customer complaints, leading to returns and reputational damage.

Misrepresentation of Specifications

Suppliers often exaggerate material specs—claiming “95% reflectivity” or “tear-resistant” fabrics without certification. Without independent testing or material data sheets, verifying these claims is difficult. Relying solely on supplier-provided documentation can result in receiving materials that underperform, especially in controlled grow environments where precision matters.

Lack of IP Protection in Manufacturing Agreements

When outsourcing production, especially overseas, failing to secure proper intellectual property agreements is a major risk. Design blueprints, proprietary ventilation systems, or unique tent configurations can be copied or sold to competitors if non-disclosure agreements (NDAs) and IP clauses are not strictly enforced. Some manufacturers may also produce counterfeit versions under different brand names.

Inconsistent Batch-to-Batch Quality

Even with a trusted supplier, inconsistency across production batches can occur. Variations in fabric thickness, color, or seam strength may go unnoticed until assembly, jeopardizing product uniformity. Without clear quality control (QC) protocols and third-party inspections, these inconsistencies can slip through.

Supply Chain Transparency Gaps

Limited visibility into the supply chain increases the risk of using materials sourced unethically or containing restricted substances. Without knowing the origin of textiles or metal poles, companies may inadvertently violate environmental or safety regulations, leading to compliance issues or consumer backlash.

Overlooking Tooling and Mold Ownership

If custom zippers, corners, or frame connectors are developed, failing to retain ownership of molds or tooling gives suppliers leverage. They may charge excessive fees for future production or threaten to halt supply. Clear contracts should specify that tooling remains the buyer’s property after payment.

Dependency on a Single Supplier

Relying on one supplier for critical materials creates vulnerability. Disruptions due to geopolitical issues, shipping delays, or supplier insolvency can halt production. Diversifying sources and maintaining safety stock helps mitigate this risk, but requires upfront investment and coordination.

Avoiding these pitfalls requires thorough due diligence, third-party material testing, strong legal contracts, and ongoing supplier audits to ensure both quality and IP protection are maintained.

Logistics & Compliance Guide for Grow Tent Material

When sourcing, shipping, and handling grow tent materials—such as reflective mylar, heavy-duty fabrics, zippers, PVC frames, and ventilation components—it’s essential to follow proper logistics procedures and adhere to regulatory compliance standards. This guide outlines key considerations to ensure smooth operations and legal adherence.

Regulatory Compliance

Grow tent materials are typically classified as general-purpose industrial or horticultural supplies, but certain components may be subject to specific regulations depending on their composition, origin, and end use.

- Material Safety Data Sheets (MSDS/SDS): Maintain up-to-date Safety Data Sheets for all chemical-based materials (e.g., flame-retardant coatings, adhesives). These documents are required under OSHA’s Hazard Communication Standard (HCS) in the U.S. and similar regulations globally.

- Flammability Standards: Many jurisdictions require grow tents to meet flammability standards (e.g., NFPA 701 in the U.S.). Ensure materials are tested and certified accordingly, especially for commercial or indoor agricultural applications.

- REACH & RoHS (EU Compliance): If exporting to the European Union, verify that materials comply with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, particularly for metal components and plastic additives.

- Import/Export Regulations: Check customs classifications (HS codes) for grow tent materials. Common codes include:

- 3921.90 (plastic sheets/coated fabrics)

- 5903.90 (textile impregnated with plastics)

Ensure proper declarations to avoid delays or penalties.

Packaging & Handling

Proper packaging ensures materials arrive undamaged and meet safety standards during transit.

- Roll Packaging: Reflective mylar and fabric materials should be rolled (not folded) with protective wrapping to prevent creasing, scratches, or moisture exposure.

- Moisture Protection: Use moisture-resistant packaging or desiccants, especially for shipments in humid climates or over long distances.

- Labeling: Clearly label packages with:

- Product description and SKU

- Handling instructions (e.g., “Do Not Fold,” “Keep Dry”)

- Compliance marks (e.g., CE, RoHS, flame-resistant certification)

Shipping & Transportation

Efficient logistics planning minimizes costs and delivery times while maintaining material integrity.

- Freight Mode Selection: Choose between air, sea, or ground freight based on urgency and volume. Bulk orders are typically shipped via sea freight (FCL/LCL), while small batches may use air or courier services.

- Storage Conditions: Store materials in a dry, temperature-controlled environment to prevent degradation. Avoid direct sunlight and extreme temperatures that can damage reflective coatings or weaken fabrics.

- Inventory Management: Use barcode or RFID tracking to manage stock levels and ensure FIFO (First In, First Out) rotation, especially for materials with shelf-life concerns.

Documentation & Traceability

Maintain accurate records to support compliance audits and streamline supply chain operations.

- Bill of Materials (BOM): Document all raw materials used in grow tent production, including supplier details and material specifications.

- Certificate of Conformity (CoC): Obtain CoCs from suppliers to verify compliance with safety and environmental standards.

- Customs Documentation: Prepare commercial invoices, packing lists, and certificates of origin for international shipments. Clearly state the intended use (e.g., “for horticultural equipment”) to avoid classification issues.

Sustainability & Disposal

Environmental responsibility is increasingly important in material sourcing and end-of-life handling.

- Recyclability: Prioritize materials that are recyclable or made from recycled content (e.g., PET-based mylar).

- Waste Management: Follow local regulations for disposing of off-cuts or non-conforming materials. Avoid landfill when possible; partner with recycling facilities that accept industrial plastics and textiles.

By adhering to this logistics and compliance guide, businesses can ensure the safe, legal, and efficient handling of grow tent materials across the supply chain.

In conclusion, sourcing high-quality grow tent material requires a careful balance of durability, light reflectivity, insulation, and ease of assembly. Key factors to consider include the strength of the fabric (typically 600D or higher), the effectiveness of the reflective interior (such as Mylar or diamond-pattern polyester), robust zippers and seams, and a sturdy frame structure. Additionally, sourcing from reputable suppliers who provide certifications and consistent product quality ensures long-term performance and reliability. Whether for personal cultivation or commercial operations, investing in premium grow tent materials significantly enhances environmental control, maximizes yields, and supports sustainable growth. Ultimately, thorough research and supplier vetting are essential steps in securing materials that meet both performance standards and budgetary needs.

![MELONFARM Grow tents [Hydroponics Online Store]](https://www.sohoinchina.com/wp-content/uploads/2026/01/melonfarm-grow-tents-hydroponics-online-store-574.jpg)