The global grindstone tool market is experiencing steady growth, driven by rising demand from metalworking, automotive, and construction industries. According to Grand View Research, the global abrasive market size was valued at USD 35.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. This growth is fueled by advancements in material science, increasing industrial automation, and the need for precision finishing in manufacturing processes. As the demand for high-performance grinding tools rises, a handful of manufacturers have emerged as leaders, combining innovation, durability, and global reach. Based on market presence, product range, and technological advancement, here are the top six grindstone tool manufacturers shaping the future of industrial abrasives.

Top 6 Grindstone Tool Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Grindstone

Domain Est. 1996

Website: colonysurvival.fandom.com

Key Highlights: The grindstone is the job block for the grinder. The grindstone can be crafted by the player through the crafting interface or by the crafter with a ……

#2 Grinding Stone

Domain Est. 1997

Website: hultafors.com

Key Highlights: Rating 4.0 (1) The grinding stone is of good size and designed to give a steady grip, protecting fingers and hands from cutting injuries….

#3

Domain Est. 1998

Website: nortonabrasives.com

Key Highlights: As a brand of Saint-Gobain, a world leader in sustainable habitat, Norton offers the widest portfolio of grinding, cutting, blending, finishing, ……

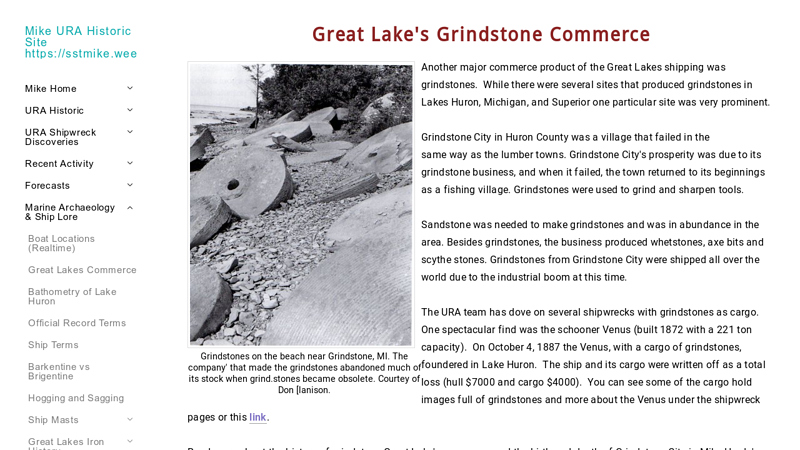

#4 Great Lake’s Grindstone Commerce

Domain Est. 2006

Website: sstmike.weebly.com

Key Highlights: Grindstone City became a fast growing industry that produced the largest and finest grindstones, scythestones, and honestones in the world….

#5 Grindstone Outdoors

Domain Est. 2009

Website: grindstoneoutdoors.com

Key Highlights: We offer a variety of the best landscaping products like veneer stone, tiles & pavers, fully-engineered outcropping stones, and more….

#6 Grindstone Tools

Website: grindstonetools.com

Key Highlights: Shop online at Grindstone Tools for a wide variety of hard surface tools and equipment for commercial and home use, including concrete saws, core drills, ……

Expert Sourcing Insights for Grindstone Tool

H2: 2026 Market Trends Analysis for Grindstone Tool

Looking ahead to 2026, Grindstone Tool is positioned at a pivotal intersection of technological advancement, shifting industry demands, and evolving customer expectations. Success will depend on strategic adaptation to the following key market trends:

1. Accelerated Adoption of Smart Manufacturing & Industry 4.0:

* Trend: The integration of IoT sensors, data analytics, and connected machinery (IIoT) into production floors will be mainstream by 2026. Predictive maintenance and real-time performance monitoring will be standard expectations.

* Impact on Grindstone Tool: Customers will demand “smart” grinding solutions. Grindstone should prioritize embedding sensors into its tools and machinery to monitor wear, temperature, vibration, and performance. Offering companion software platforms for data visualization, predictive tool life estimation, and process optimization will become a critical differentiator, moving beyond selling just physical tools to providing value-added digital services.

2. Intensifying Focus on Sustainability and Circular Economy:

* Trend: Regulatory pressure (e.g., extended producer responsibility) and customer ESG (Environmental, Social, Governance) goals will drive demand for sustainable manufacturing practices. Reducing waste, energy consumption, and enabling tool reuse/recycling will be paramount.

* Impact on Grindstone Tool: Grindstone must innovate in material science (e.g., longer-lasting, more recyclable abrasives and bonds) and design for disassembly/repair. Developing robust tool reconditioning and refurbishment programs, promoting efficient grinding processes that minimize material removal and energy use, and transparently reporting on product lifecycle impact will be essential for market access and brand reputation.

3. Reshoring and Supply Chain Resilience:

* Trend: Geopolitical instability and pandemic lessons continue to push manufacturers towards nearshoring and reshoring, particularly in North America and Europe. This increases demand for locally supported, reliable, and agile suppliers.

* Impact on Grindstone Tool: Grindstone’s potential strength lies in its ability to offer shorter lead times, responsive technical support, and reduced logistics risk compared to distant competitors. Emphasizing local manufacturing capacity (if applicable), robust domestic supply chains for raw materials, and flexible production will be significant competitive advantages. Marketing should highlight reliability and partnership.

4. Rise of Advanced and Hard-to-Grind Materials:

* Trend: Industries like aerospace (ceramic matrix composites, advanced superalloys), EVs (silicon carbide in power electronics), and medical devices (titanium alloys, bioceramics) are increasingly using materials that are extremely hard, brittle, or heat-sensitive.

* Impact on Grindstone Tool: This creates a high-value niche. Grindstone needs to invest heavily in R&D to develop specialized grinding wheels, optimize diamond/CBN abrasive formulations, and create application-specific solutions (e.g., optimized dressing techniques, coolant delivery systems) for these challenging materials. Deep application engineering expertise will be a key selling point.

5. Labor Shortages and Skills Gap Driving Automation:

* Trend: The skilled machinist shortage will persist and worsen. Manufacturers will increasingly rely on automation (robotics, CNC grinders) to maintain output, requiring tools and processes optimized for unmanned operation.

* Impact on Grindstone Tool: Tools must offer exceptional consistency, longevity, and predictability to minimize intervention in automated cells. Grindstone should focus on ultra-consistent quality, develop tools specifically rated for high-duty cycles in automation, and provide clear data on expected performance for robotic programming. Collaboration with automation integrators will be crucial.

6. Customization and Application-Specific Solutions:

* Trend: While commoditized tools exist, high-value manufacturing increasingly demands bespoke solutions for unique parts, materials, or process bottlenecks. Customers seek partners, not just vendors.

* Impact on Grindstone Tool: Moving beyond standard catalog offerings, Grindstone should leverage its engineering expertise to offer co-development of custom grinding solutions. This includes specialized wheel geometries, hybrid tools, and integrated process consulting. Building strong technical sales and application engineering teams is vital.

Strategic Implications for Grindstone Tool (2026 Outlook):

* Shift to Solutions Provider: Transition from a product-centric to a solution-centric business model, bundling tools with data, software, and engineering services.

* Invest in Digitalization: Prioritize IoT integration, data analytics platforms, and cybersecurity for connected tools.

* Double Down on R&D: Focus on sustainable materials, advanced abrasives for new materials, and automation-optimized designs.

* Build Resilient Supply Chains: Secure reliable sources for critical raw materials and emphasize local/regional capabilities.

* Enhance Technical Expertise: Grow application engineering and technical sales capabilities to support complex customer needs and customization.

* Champion Sustainability: Develop and communicate clear sustainability initiatives for products and operations.

By proactively aligning its strategy with these H2 2026 trends, Grindstone Tool can strengthen its competitive position, capture growth in high-value markets, and build deeper, more profitable customer relationships.

Common Pitfalls When Sourcing Grindstone Tools (Quality and Intellectual Property)

Sourcing grindstone tools—especially from international suppliers—can present significant challenges related to both quality consistency and intellectual property (IP) protection. Failing to address these pitfalls can result in production delays, safety issues, legal disputes, and reputational damage. Below are key risks to be aware of:

Quality Inconsistencies

One of the most common issues when sourcing grindstones is variability in product quality. Grindstones must meet strict performance and safety standards due to their use in high-speed, high-pressure industrial applications. Inconsistent quality can lead to tool failure, workplace hazards, and increased costs from rework or downtime.

- Material Composition Variability: Suppliers may use substandard abrasives or bonding agents to reduce costs, affecting cutting efficiency and durability.

- Tolerance and Dimensional Inaccuracy: Poor manufacturing controls can result in grindstones that don’t fit equipment properly or wear unevenly.

- Lack of Certification: Some suppliers may lack ISO, ANSI, or other relevant certifications, making it difficult to verify compliance with safety and performance standards.

- Inadequate Testing: Without rigorous in-house or third-party testing, defects such as internal cracks or imbalances may go undetected until the product is in use.

Mitigation Strategy: Conduct thorough supplier audits, require material certifications, and perform incoming quality inspections or third-party testing. Use detailed technical specifications and include quality clauses in contracts.

Intellectual Property Risks

Grindstone tool designs, formulations, and manufacturing processes can involve proprietary technology. When sourcing from third parties—particularly in regions with weaker IP enforcement—companies risk IP theft, reverse engineering, or unauthorized replication.

- Design and Formula Theft: Suppliers may copy proprietary abrasive blends or core structures and sell them to competitors.

- Unauthorized Production: A contract manufacturer might produce excess units and sell them on the gray market.

- Weak Contractual Protections: Agreements that lack clear IP ownership clauses, non-disclosure agreements (NDAs), or usage restrictions increase exposure.

- Jurisdictional Challenges: Enforcing IP rights across borders can be costly and time-consuming, especially in countries with limited IP legal frameworks.

Mitigation Strategy: Ensure robust legal agreements that clearly assign IP ownership, include confidentiality clauses, and restrict production rights. Consider working with trusted partners in jurisdictions with strong IP protection, and file patents or trademarks where applicable.

By proactively addressing both quality and IP concerns during the sourcing process, companies can safeguard performance, compliance, and innovation.

Logistics & Compliance Guide for Grindstone Tool

This guide outlines the essential logistics procedures and compliance requirements for Grindstone Tool to ensure efficient operations, regulatory adherence, and customer satisfaction.

Supply Chain Management

Grindstone Tool maintains a structured supply chain to source raw materials and components reliably. Approved suppliers are vetted for quality, ethical practices, and compliance with environmental and safety regulations. All procurement activities follow documented purchase order protocols, with supplier performance reviewed quarterly.

Inventory Management

Inventory is tracked using an integrated inventory management system that supports real-time monitoring of stock levels, lot numbering, and expiration dates (where applicable). Cycle counts are conducted bi-weekly, and annual physical audits are mandatory. Safety stock levels are established to prevent production delays.

Warehousing & Storage

Materials and finished goods are stored in climate-controlled, secure facilities compliant with OSHA and fire safety standards. Storage areas are organized to support FIFO (First In, First Out) practices. Hazardous materials (if applicable) are segregated and labeled according to EPA and OSHA guidelines.

Transportation & Distribution

Grindstone Tool partners with certified freight carriers experienced in industrial tool distribution. All shipments are insured and tracked end-to-end. Packaging complies with ISTA standards to prevent damage during transit. International shipments include proper export documentation and adhere to Incoterms agreed upon with customers.

Regulatory Compliance

Grindstone Tool complies with all applicable federal, state, and local regulations, including but not limited to:

- OSHA: Workplace safety and handling procedures

- EPA: Proper disposal of waste materials and chemical use

- DOT: Safe transport of goods, including hazardous classifications

- ITAR/EAR: Compliance for any export-controlled tools or technologies

Employees receive annual compliance training, and internal audits are conducted semi-annually.

Import/Export Compliance

For international trade, Grindstone Tool follows U.S. Customs and Border Protection (CBP) regulations and maintains accurate records for five years. Export licenses are obtained when required. Harmonized System (HS) codes are verified for all products, and customs brokers are used to ensure accurate declarations.

Product Labeling & Documentation

All products are labeled with required information, including part numbers, safety warnings, country of origin, and compliance marks (e.g., CE, RoHS, if applicable). Shipping documents include commercial invoices, packing lists, and certificates of compliance as needed.

Sustainability & Environmental Responsibility

Grindstone Tool is committed to reducing its environmental footprint. Initiatives include recycling packaging materials, optimizing transportation routes to lower emissions, and sourcing sustainable raw materials where feasible. Compliance with WEEE and REACH regulations is maintained for applicable products.

Incident Response & Corrective Actions

A documented incident response plan addresses logistics disruptions, compliance violations, or product recalls. All incidents are logged, investigated, and resolved with corrective and preventive actions (CAPA) implemented to avoid recurrence.

Recordkeeping & Audits

All logistics and compliance records—including shipping logs, supplier certifications, training records, and audit reports—are retained electronically with secure backups. Internal audits occur twice yearly, with external audits conducted as required by regulatory bodies or customers.

For questions or reporting concerns, contact:

Compliance Officer

[email protected]

(555) 123-4567

Conclusion for Sourcing Grindstone Tools

In conclusion, sourcing grindstone tools requires a strategic approach that balances quality, cost, availability, and supplier reliability. After evaluating various suppliers, material specifications, and performance requirements, it is evident that selecting the right grindstone involves considering factors such as abrasive type, grit size, bond strength, and compatibility with specific machining or sharpening applications. Establishing long-term relationships with reputable suppliers ensures consistent product quality, timely delivery, and potential cost savings through bulk purchasing or negotiated contracts. Additionally, adhering to safety and industry standards is crucial to maintain operational efficiency and workplace safety. Ultimately, an informed and well-structured sourcing strategy for grindstone tools enhances tool performance, reduces downtime, and contributes to overall productivity in manufacturing and maintenance operations.