The global demand for automated shading solutions, including grill shutter actuators used in automotive and industrial applications, has seen steady growth driven by increasing vehicle production, emphasis on fuel efficiency, and rising adoption of smart thermal management systems. According to Grand View Research, the global automotive motor market—under which grill shutter actuators fall—was valued at USD 27.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. This growth is further fueled by regulatory pressure to reduce emissions and improve aerodynamics, prompting widespread integration of active grill shutter systems in modern vehicles. As a result, manufacturers specializing in precision actuation technology are scaling innovation and production capacity to meet OEM demands. In this competitive landscape, eight key players have emerged as leading suppliers of reliable, high-performance grill shutter actuators, combining engineering expertise with data-backed quality control and global reach.

Top 8 Grill Shutter Actuator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

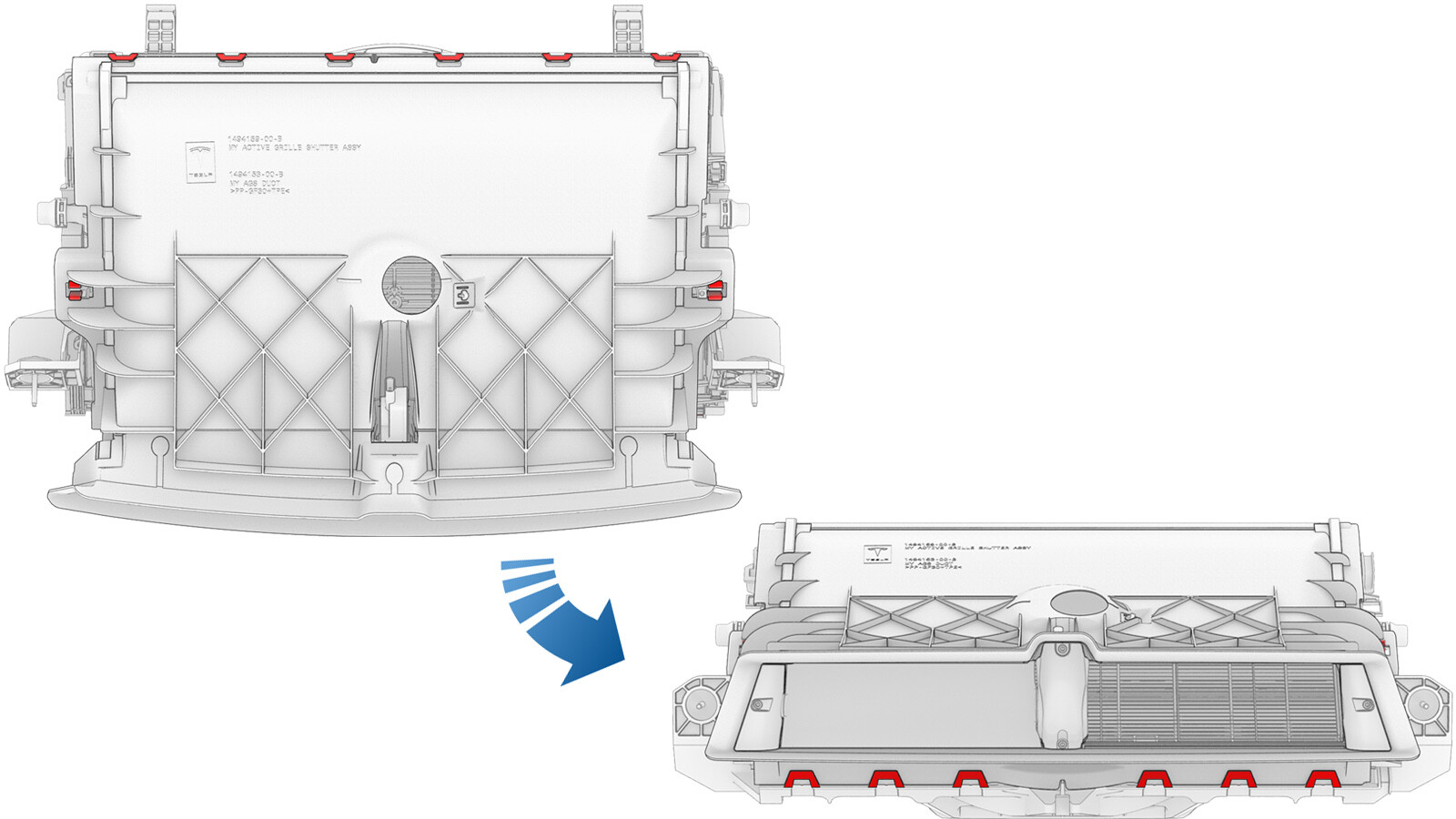

#1 [PDF] Active Grille Shutter

Domain Est. 1991

Website: magna.com

Key Highlights: • Global Manufacturing Capability. Active Grille Shutter. (Non-Visible). Regulates frontal airflow to reduce aerodynamic drag. Page 2. Application: • Pickup ……

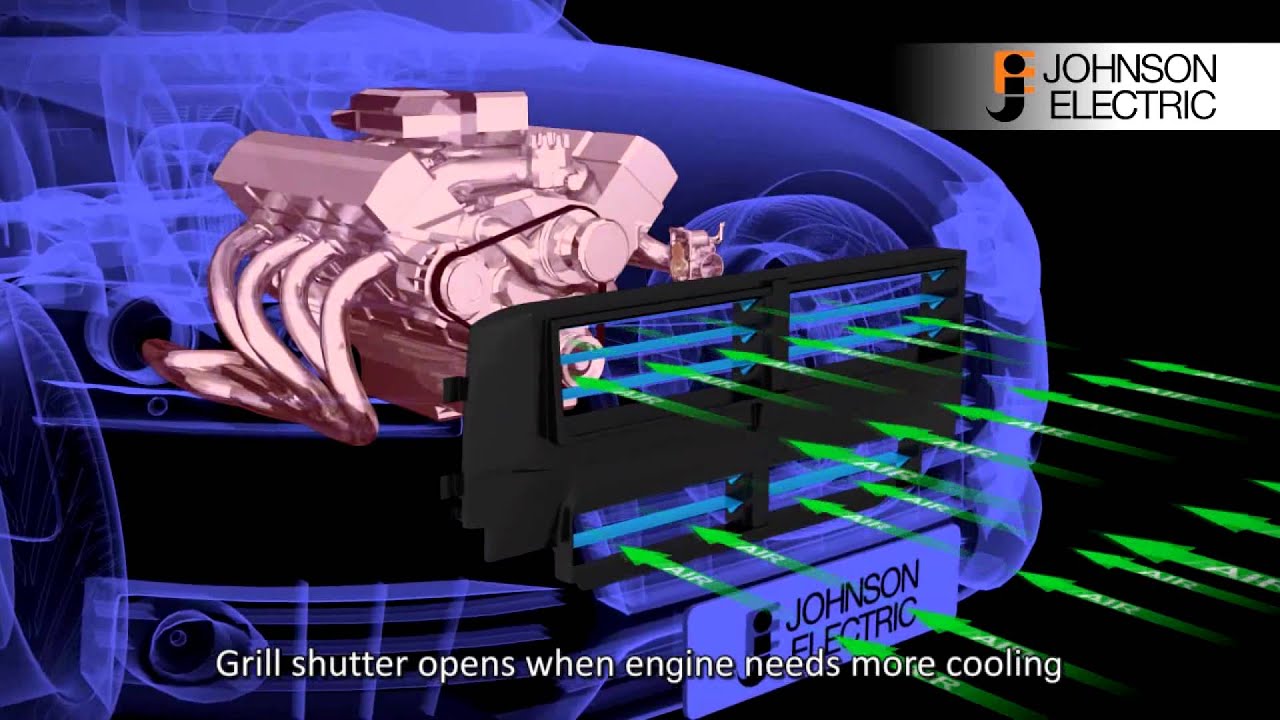

#2 Grill Shutter Actuators

Domain Est. 1996

Website: johnsonelectric.com

Key Highlights: The saia-burgess GS grill shutters are custom engineered to operate with high torque, high operating reliability and a low power budget and support LIN bus, ……

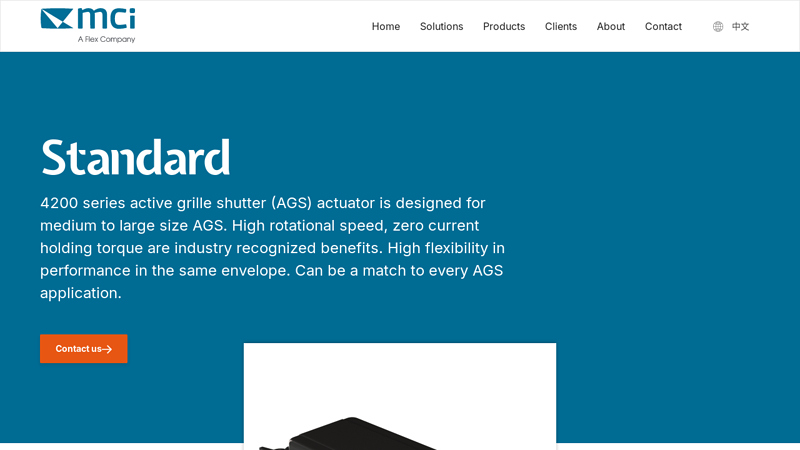

#3 Standard

Domain Est. 1996

Website: motioncontrols.com

Key Highlights: 4200 series active grille shutter (AGS) actuator is designed for medium to large size AGS. High rotational speed, zero current holding torque are industry ……

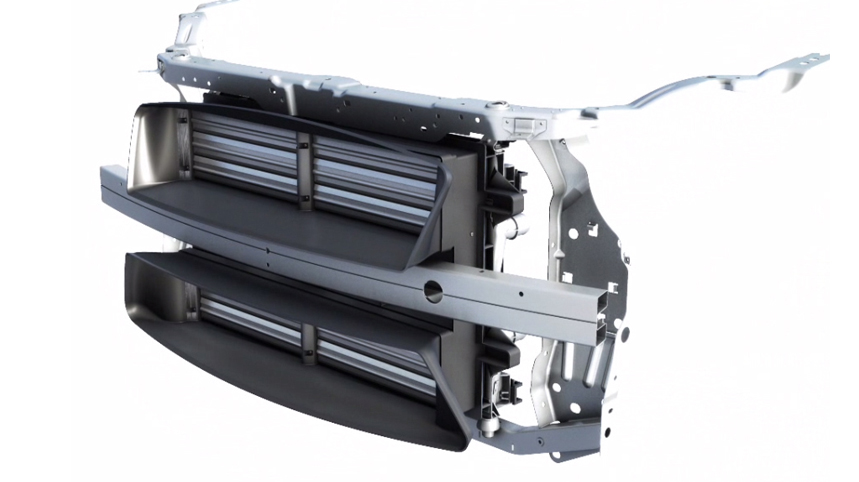

#4 Active Grill Shutters: enhanced performance and comfort

Domain Est. 1997

Website: valeo.com

Key Highlights: Valeo’s Active Grill Shutter controls and adjusts air flow to improve the vehicle’s aerodynamics and thermal performance using a system of controlled shutters….

#5 Active Grille Shutters

Domain Est. 2000

Website: standardbrand.com

Key Highlights: Active Grille Shutters open and close automatically to control airflow that cools the engine, reducing aerodynamic drag and improving fuel efficiency….

#6 Active Grille Shutters

Domain Est. 2005

Website: bwdbrand.com

Key Highlights: Active Grille Shutters open and close automatically to control airflow, reducing aerodynamic drag and improve fuel efficiency….

#7 Active Grille Shutters

Domain Est. 2010

Website: continental-aftermarket.com

Key Highlights: Active grill shutters play an important part in improving vehicle fuel efficiency by maintaining ideal engine operating temperatures. They open at lower speeds ……

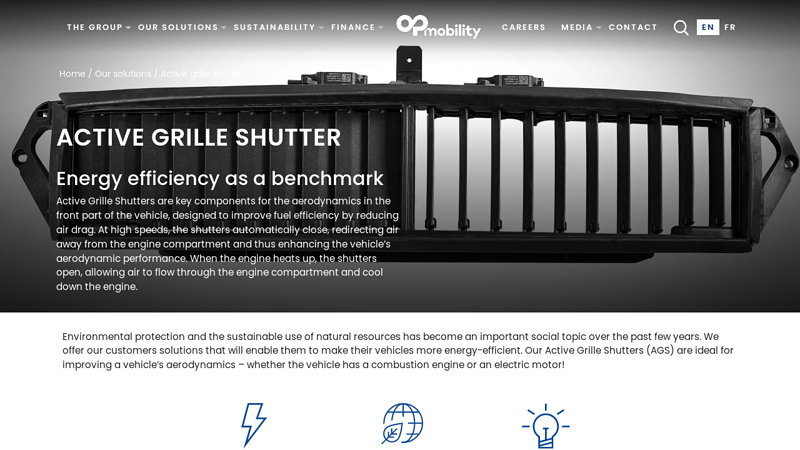

#8 Active grille shutter

Domain Est. 2021

Website: opmobility.com

Key Highlights: Active Grille Shutters are key components for the aerodynamics in the front part of the vehicle, designed to improve fuel efficiency by reducing air drag….

Expert Sourcing Insights for Grill Shutter Actuator

H2: 2026 Market Trends for Grill Shutter Actuators

The global market for grill shutter actuators is poised for significant evolution by 2026, driven by advancements in automotive technology, stricter emissions regulations, and the rising demand for fuel-efficient and thermally optimized vehicles. As a critical component of active grille shutter (AGS) systems, grill shutter actuators play a pivotal role in managing airflow to the engine radiator, thereby improving aerodynamics, reducing fuel consumption, and enhancing engine thermal management.

-

Growing Adoption in Passenger Vehicles

By 2026, the penetration of grill shutter actuators is expected to increase significantly in passenger vehicles, especially in mid-to-high-end models. OEMs are increasingly integrating AGS systems into compact and mid-size sedans and SUVs to meet fuel efficiency standards in key markets such as North America, Europe, and China. The expansion into more affordable vehicle segments will drive volume growth for actuator manufacturers. -

Stringent Emission and Fuel Economy Regulations

Regulatory pressure remains a primary growth driver. Governments worldwide are tightening CO₂ emission norms—such as the Euro 7 standards in Europe and CAFE standards in the U.S.—pushing automakers to adopt technologies that improve fuel efficiency. AGS systems, enabled by reliable actuators, contribute directly to reducing aerodynamic drag, particularly at highway speeds, making them a cost-effective solution for compliance. -

Electrification and Thermal Management in EVs

With the acceleration of electric vehicle (EV) adoption, grill shutter actuators are finding new applications beyond internal combustion engines. In EVs, AGS systems help manage battery and powertrain thermal performance while optimizing aerodynamics to extend driving range. By 2026, an increasing number of electric SUVs and premium EVs are expected to feature intelligent AGS systems, creating a dual-market demand from both ICE and EV platforms. -

Advancements in Actuator Technology

The demand for smarter, lighter, and more durable actuators is driving innovation. By 2026, brushless DC motors, integrated sensors, and position feedback systems are expected to become standard in next-generation actuators. Enhanced connectivity with vehicle control units (VCUs) enables predictive actuation based on driving conditions, weather, and traffic patterns, improving system efficiency. -

Regional Market Dynamics

Asia-Pacific, particularly China and India, will emerge as high-growth markets due to increasing vehicle production and localization of AGS technology. Meanwhile, North America and Europe will maintain strong demand due to existing regulatory frameworks and consumer preference for advanced driver-assistance and efficiency features. -

Consolidation and Strategic Partnerships

The competitive landscape is expected to witness consolidation, with Tier-1 suppliers such as Bosch, Magna International, and Denso strengthening their offerings through R&D investments and partnerships with startups specializing in smart actuation and thermal management systems. Localization of production will also be a key strategy to reduce costs and respond swiftly to OEM demands.

In conclusion, the 2026 market for grill shutter actuators will be shaped by regulatory mandates, electrification trends, and technological innovation. As vehicles become more intelligent and efficient, the role of the grill shutter actuator will expand beyond basic functionality to become an integral part of holistic vehicle thermal and aerodynamic management systems.

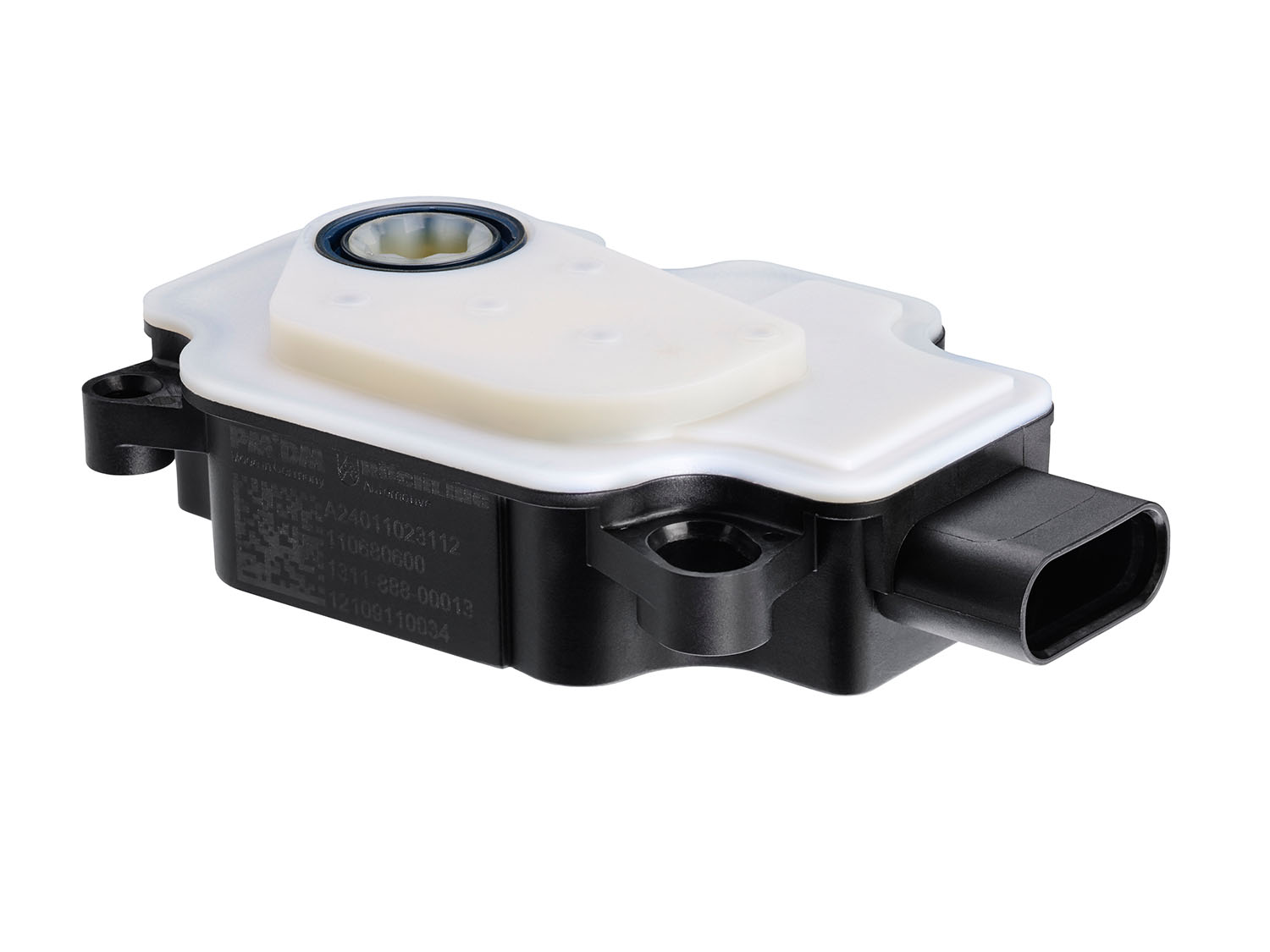

Common Pitfalls Sourcing a Grill Shutter Actuator (Quality, IP)

Sourcing a reliable Grill Shutter Actuator (GSA) is critical for effective thermal management in vehicles, particularly in modern ICE and hybrid powertrains. However, several common pitfalls related to quality and Ingress Protection (IP) rating can compromise performance, durability, and safety if not carefully addressed.

Inadequate IP Rating for Operating Environment

One of the most frequent mistakes is selecting a GSA with an insufficient IP rating for the harsh under-hood or front-end environment. The actuator is exposed to water spray, dust, road debris, and cleaning agents. Opting for a unit rated below IP6K9K (especially in high-pressure wash zones) or IP67/IP68 can lead to internal contamination, electrical short circuits, or motor failure. Always verify that the specified IP rating matches the actual installation location and environmental exposure conditions.

Poor Material Quality and Construction

Low-cost GSAs often use substandard plastics, weak gears, or undersized motors that degrade rapidly under thermal cycling and vibration. This results in premature mechanical failure, gear stripping, or inconsistent shutter positioning. Avoid suppliers offering unusually low prices, as this often indicates compromises in material quality. Look for actuators using high-temperature resistant engineering plastics (e.g., PBT, Nylon) and metal-reinforced gear trains.

Lack of Environmental and Durability Testing

Many off-brand or non-OEM actuators lack proper validation testing for temperature extremes, salt spray resistance, vibration, and lifetime cycle testing. Without proof of compliance with standards like ISO 16750 or OEM-specific requirements, the actuator may fail prematurely in real-world conditions. Always request test reports and certifications to verify durability claims.

Inconsistent Performance and Position Feedback

Low-quality actuators may exhibit inconsistent torque output or unreliable position feedback signals (e.g., potentiometer drift or signal noise). This leads to inaccurate shutter control, reduced aerodynamic efficiency, and potential engine overheating or excessive fuel consumption. Ensure the actuator provides stable, repeatable feedback and meets OEM signal specifications.

Counterfeit or Non-Compliant Components

Sourcing from unreliable suppliers increases the risk of receiving counterfeit or non-compliant parts that mimic genuine components but lack proper IP sealing, thermal protection, or EMI shielding. These units can fail unexpectedly and may not support diagnostic systems correctly. Stick to reputable suppliers or authorized distributors with traceable supply chains.

Misalignment Between IP Rating and Connector Sealing

Even if the main housing has a high IP rating, the electrical connector may be a weak point. A common pitfall is assuming IP6K9K on the housing extends to the connector. Poorly sealed or incompatible connectors can allow moisture ingress along the cable harness. Verify that both the actuator body and the connector system meet the required IP rating and are designed for automotive-grade sealing.

By carefully evaluating these quality and IP-related factors during sourcing, procurement teams can avoid costly field failures and ensure reliable operation of the grill shutter system over the vehicle’s lifetime.

Logistics & Compliance Guide for Grill Shutter Actuator

Overview

The Grill Shutter Actuator is a precision automotive component responsible for controlling airflow through the vehicle’s grille. Efficient logistics and strict compliance are critical due to its role in vehicle performance, safety, and regulatory standards.

Packaging Requirements

- Use anti-static, moisture-resistant packaging to protect electronic components.

- Include cushioning materials (e.g., foam inserts) to prevent mechanical damage during transit.

- Clearly label each package with part number, batch/lot number, and handling symbols (e.g., “Fragile,” “This Side Up”).

- Ensure packaging complies with ISTA 3A or equivalent standards for transportation safety.

Shipping & Transportation

- Ship via temperature-controlled carriers if actuator contains sensitive electronics or materials.

- Maintain traceability using serialized barcodes or RFID tags.

- Store and transport at temperatures between -20°C and 60°C unless otherwise specified.

- Avoid exposure to extreme humidity, vibration, or direct sunlight.

- Use sealed, tamper-evident containers for international shipments.

Import/Export Compliance

- Obtain Harmonized System (HS) code: Typically 8537.10 or 8708.29 (verify per country).

- Comply with export regulations such as EAR (Export Administration Regulations) if technology is of U.S. origin.

- Ensure proper documentation: Commercial invoice, packing list, bill of lading, and Certificate of Origin.

- Confirm compliance with destination country’s automotive import standards (e.g., INMETRO in Brazil, KC in South Korea).

Regulatory & Safety Standards

- Ensure conformity with ISO 16750 (road vehicle environmental conditions) and ISO 20653 (ingress protection).

- Comply with automotive EMC standards such as CISPR 25 and ISO 11452.

- Meet RoHS and REACH regulations for restricted substances.

- Validate compliance with vehicle-specific OEM requirements (e.g., Ford WSS, GM GMW).

Certifications & Documentation

- Provide Declaration of Conformity (DoC) for CE, UKCA (if applicable), and other regional marks.

- Maintain product test reports (vibration, temperature cycling, electrical performance).

- Keep material disclosure data (IMDS submission for EU automotive supply chain).

- Audit trail for ISO/TS 16949 or IATF 16949 quality management system compliance.

Customs Clearance

- Pre-clear shipments using electronic filing systems (e.g., AES in the U.S., ATLAS in Germany).

- Verify tariff classification and duty rates with local customs brokers.

- Address potential delays by ensuring complete and accurate Harmonized Code and product descriptions.

End-of-Life & Environmental Compliance

- Support WEEE (Waste Electrical and Electronic Equipment) directives where applicable.

- Provide take-back or recycling guidance per customer or regional requirements.

- Document environmentally sound disposal methods for hazardous materials, if any.

Supplier & OEM Coordination

- Align logistics schedules with Just-In-Time (JIT) or Kanban delivery models.

- Report any changes in manufacturing location, materials, or design that may affect compliance.

- Participate in automotive industry audit programs (e.g., VDA 6.3, CQI-9).

Contact & Support

For compliance inquiries, logistics issues, or documentation requests, contact:

[Insert Company Name] Compliance & Logistics Team

Email: [email protected]

Phone: +1 (XXX) XXX-XXXX

Conclusion for Sourcing Grill Shutter Actuator

After a comprehensive evaluation of potential suppliers, technical specifications, cost structures, and quality standards, the sourcing strategy for the grill shutter actuator has been finalized. The selected supplier demonstrates strong capabilities in automotive component manufacturing, consistent product quality, compliance with industry standards (such as ISO/TS 16949), and competitive lead times. The chosen actuator meets all technical requirements, including thermal performance, durability, and integration compatibility with the vehicle’s thermal management system.

Additionally, the total cost of ownership—factoring in unit price, logistics, warranty support, and after-sales service—positions the supplier as a sustainable and reliable partner. Risk mitigation measures, including dual sourcing options and rigorous incoming quality checks, have been incorporated to ensure supply chain resilience.

In conclusion, proceeding with the recommended supplier ensures optimal performance, cost-efficiency, and long-term reliability of the grill shutter actuator within the vehicle platform, supporting overall product quality and customer satisfaction.

![[PDF] Active Grille Shutter](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-active-grille-shutter-884.png)