The global welding equipment market is undergoing a transformative shift driven by increasing demand for energy-efficient and environmentally sustainable technologies. According to a 2023 report by Mordor Intelligence, the market was valued at USD 28.4 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.1% from 2023 to 2028, reaching an estimated USD 40.5 billion by the end of the forecast period. A key driver behind this growth is the rising adoption of green welding technologies—machines that offer lower energy consumption, reduced emissions, and improved operational efficiency. Regulatory pressures, corporate sustainability goals, and advancements in inverter and digital welding technologies are further accelerating this trend. As industries from automotive to renewable energy infrastructure prioritize eco-friendly manufacturing processes, leading welding machine manufacturers are responding with innovative, energy-smart solutions. This demand has catalyzed the emergence of a new generation of green welding systems, positioning sustainability at the core of modern fabrication. Below, we highlight the top 8 manufacturers at the forefront of this shift, recognized for their commitment to environmental performance, energy efficiency, and technological innovation.

Top 8 Green Welding Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Welding Booths & Equipment

Website: greenemfg.com

Key Highlights: Explore Greene Manufacturing’s welding booths and equipment, designed for safety and efficiency in welding environments….

#2 Everlast Inverter Welders Equipment

Website: everlastgenerators.com

Key Highlights: Everlast Power Equipment, manufacturers of MIG, TIG & Stick welders. For reliable welding machines and supplies shop Everlast Power Equipment….

#3 Migatronic

Website: migatronic.com

Key Highlights: Migatronic is a manufacturer of arc welding machines and welding equipment for professionals. We’ve been making welding easy for nearly half a century….

#4 Green’s Welding & Sales

Founded: 1983

Website: greenwelding.com

Key Highlights: Green’s Welding and Sales (GWS) was founded in 1983. It was originally named Green’s Welding Service. It is still owned and operated by Chris and Karen Green….

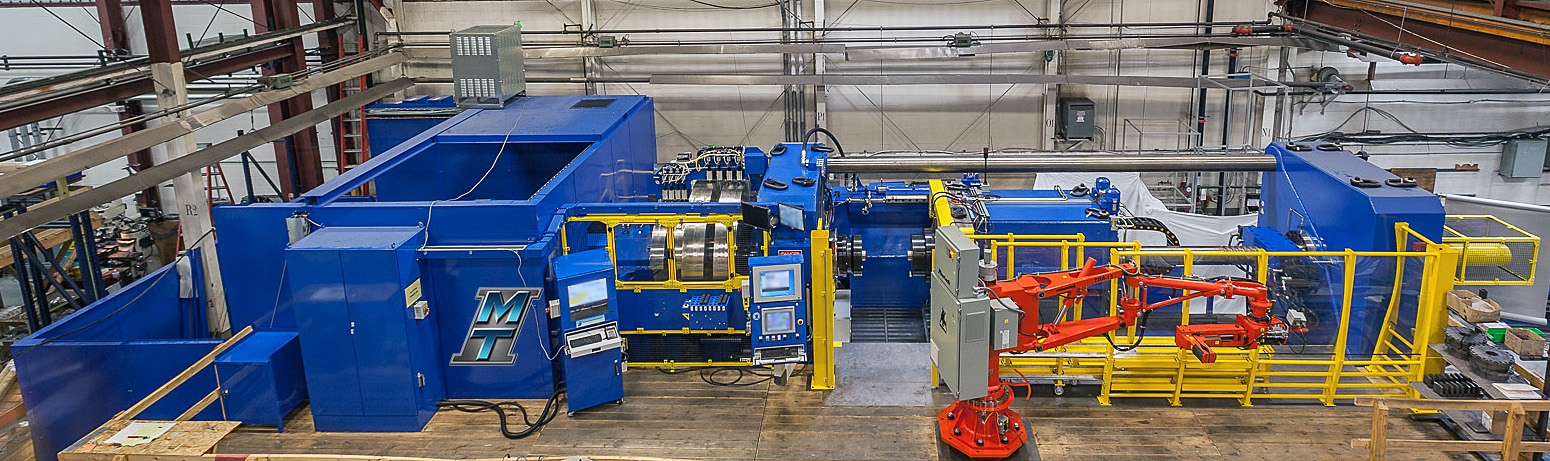

#5 MTI Friction Welding Solutions & Manufacturing Services

Website: mtiwelding.com

Key Highlights: An optimized form of traditional friction welding, Low Force Friction Welding touts smaller and smoother flash, faster cycle times, and reduced machine size….

#6 Laser Welding

Website: ipgphotonics.com

Key Highlights: Laser welding is the process of transferring a laser beam’s energy in the form of heat to fuse or join parts. This transferred heat melts the materials to ……

#7 Zeman Technologies

Website: zebau.com

Key Highlights: At Zeman Bauelemente we research, develop and produce the world’s best steel fab automation solutions. From welding and assembly robots to on-site logistics and ……

#8 Engine Driven Welders

Website: lincolnelectric.com

Key Highlights: Engine Driven Welders. Portable, multifunction equipment capable of providing welding output and auxiliary power to conquer your next job….

Expert Sourcing Insights for Green Welding Machine

H2: Market Trends for Green Welding Machines in 2026

By 2026, the global market for green welding machines is expected to experience significant transformation, driven by sustainability mandates, technological innovation, and evolving industrial demands. The term “green welding machines” refers to energy-efficient, low-emission welding equipment that incorporates eco-friendly technologies such as inverter-based power sources, regenerative energy systems, and reduced material waste during operations.

1. Rising Demand Driven by Environmental Regulations

Stringent environmental regulations across North America, Europe, and parts of Asia-Pacific are pushing manufacturing and construction sectors to adopt cleaner technologies. Governments are enforcing lower carbon emission targets, prompting industries to replace outdated, energy-intensive welding systems with green alternatives. In the EU, for example, the Green Deal and Energy Efficiency Directive are accelerating the adoption of energy-saving industrial equipment, including green welding machines.

2. Technological Advancements Enhancing Efficiency

The integration of smart technologies such as IoT-enabled monitoring, AI-driven process optimization, and real-time energy consumption tracking is making green welding machines more efficient and user-friendly. By 2026, manufacturers like Lincoln Electric, Fronius, and Miller Electric are expected to dominate the market with next-generation inverters that reduce energy loss by up to 40% compared to conventional transformers.

3. Growth in Renewable Energy and EV Infrastructure

The expansion of renewable energy projects (e.g., wind turbines, solar farms) and the electric vehicle (EV) manufacturing boom are creating robust demand for precision and sustainable welding solutions. Green welding machines, which offer higher arc stability and lower fume emissions, are becoming essential in producing high-integrity joints required in EV battery enclosures and wind tower assemblies.

4. Shift Toward Lightweight and Sustainable Materials

As industries adopt aluminum, magnesium, and advanced high-strength steels to reduce weight and improve efficiency, the need for precise, low-heat-input welding processes is increasing. Green welding technologies, particularly pulsed MIG and TIG systems, are well-suited for these materials, supporting their wider adoption in aerospace, automotive, and transportation sectors.

5. Cost Competitiveness and ROI Improvements

Although green welding machines often have a higher initial cost, their long-term operational savings—through reduced energy consumption, lower maintenance, and longer consumable life—are improving return on investment (ROI). By 2026, declining prices of power electronics and increased production scale are expected to make green models more accessible to small and medium-sized enterprises (SMEs).

6. Regional Market Dynamics

Asia-Pacific is projected to lead global market growth due to rapid industrialization in China and India, coupled with government incentives for green manufacturing. Meanwhile, North America and Western Europe will maintain high adoption rates due to established sustainability frameworks and skilled labor pools trained in advanced welding techniques.

Conclusion

By 2026, the green welding machine market will be shaped by regulatory pressures, technological innovation, and sector-specific demands for cleaner production. Companies that invest in R&D for energy-efficient, digitally integrated welding solutions will be best positioned to capture market share in this growing, sustainability-driven industry.

Common Pitfalls When Sourcing Green Welding Machines (Quality, IP)

Sourcing green welding machines—those designed for energy efficiency, reduced emissions, and sustainability—offers environmental and operational benefits. However, buyers often encounter significant challenges related to quality assurance and intellectual property (IP) risks. Avoiding these pitfalls is crucial to ensure long-term performance, compliance, and protection against legal or reputational damage.

Quality-Related Pitfalls

Overlooking Certification and Standards Compliance

A major mistake is assuming that “green” branding equates to high quality. Many suppliers market welding machines as eco-friendly without adhering to recognized industry standards such as ISO 14001 (environmental management), IEC 60974 (welding equipment safety), or ENERGY STAR ratings. Without verified certifications, machines may underperform, consume more energy than claimed, or pose safety hazards.

Inadequate Performance Validation

Green welding machines often emphasize energy savings or lower heat output, but real-world performance may differ. Buyers who skip field testing or third-party validation risk acquiring units with poor arc stability, inconsistent weld quality, or shorter lifespans. Always request performance data under actual operating conditions, not just laboratory results.

Compromising Core Components for Sustainability Claims

Some manufacturers substitute critical internal components (e.g., inverters, cooling systems) with lower-grade alternatives to cut costs while focusing marketing on recyclable casings or low-emission labels. This can lead to frequent breakdowns and higher total cost of ownership. Scrutinize component specifications and insist on transparency from suppliers.

Neglecting After-Sales Support and Spare Parts Availability

Even high-quality green machines require maintenance. Sourcing from suppliers without established service networks—especially for newer or niche eco-brands—can result in prolonged downtime. Ensure the vendor offers accessible technical support, training, and a reliable supply of spare parts.

Intellectual Property (IP) Pitfalls

Sourcing from Suppliers with Questionable IP Ownership

A significant risk involves purchasing machines that infringe on patented technologies. Some manufacturers, especially in regions with weak IP enforcement, replicate energy-efficient circuit designs, control algorithms, or cooling technologies without licensing. Buyers may face legal liability or product seizures if third parties assert IP claims.

Lack of IP Documentation and Due Diligence

Failing to require proof of IP ownership or freedom-to-operate (FTO) documentation exposes companies to litigation risks. Always request evidence such as patent registrations, licensing agreements, or legal opinions confirming that the green technology used in the welding machine does not violate existing IP rights.

Counterfeit or Clone Products Marketed as Green

The growing demand for sustainable equipment has led to counterfeit versions of reputable green welding machines. These clones may mimic branding and eco-features but lack the original engineering, safety, and IP legitimacy. Conduct supplier audits and use authorized distributors to mitigate this risk.

Ambiguous Technology Licensing Agreements

When integrating proprietary green technologies (e.g., AI-driven energy optimization), unclear licensing terms can restrict usage, upgrades, or resale. Ensure contracts specify IP rights, permitted modifications, and data ownership to avoid future disputes.

Conclusion

Sourcing green welding machines requires a balanced focus on both sustainability claims and tangible quality and legal safeguards. Conduct thorough due diligence, prioritize certified suppliers with transparent supply chains, and verify both technical performance and IP integrity before procurement. This proactive approach ensures that environmental benefits are not achieved at the expense of reliability or legal exposure.

Logistics & Compliance Guide for Green Welding Machine

Product Classification and Documentation

Ensure the Green Welding Machine is accurately classified under the appropriate Harmonized System (HS) code, typically falling within Chapter 85 (Electrical Machinery). Prepare essential shipping documents including commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Include detailed technical specifications such as power rating, input voltage, duty cycle, and safety certifications to support customs clearance.

Regulatory Compliance and Safety Standards

Verify that the Green Welding Machine complies with international safety and environmental standards such as IEC 60974 (welding equipment safety), CE marking for European markets, UL/CSA for North America, and PSE for Japan. Confirm adherence to RoHS (Restriction of Hazardous Substances) and REACH regulations, particularly due to the product’s “Green” designation, ensuring no restricted materials are used in manufacturing.

Packaging and Handling Requirements

Use robust, environmentally sustainable packaging that secures the welding machine during transit and protects sensitive components. Clearly label packages with handling instructions (e.g., “Fragile,” “Keep Dry”), proper orientation arrows, and compliance marks. Include all necessary user manuals, warranty cards, and regulatory leaflets in the local language of the destination country.

Import/Export Controls and Permits

Check for export restrictions or licensing requirements based on the destination country. Some regions may regulate the export of industrial equipment with specific power or technological features. Similarly, confirm any import duties, taxes, or local registration requirements, such as BIS certification in India or INMETRO in Brazil, prior to shipment.

Transportation and Shipping Modes

Select appropriate transportation methods—sea freight for bulk shipments, air freight for urgent deliveries—considering the machine’s weight, dimensions, and delivery timeline. Ensure proper crating and use of anti-vibration materials. Coordinate with freight forwarders experienced in handling industrial electrical equipment to minimize transit risks.

Environmental and Sustainability Compliance

As a “Green” product, emphasize compliance with environmental directives. Provide documentation on energy efficiency, recyclability, and low-emission operation. Maintain records supporting eco-friendly claims for marketing and regulatory purposes. Ensure disposal and end-of-life guidelines are included in product documentation per WEEE (Waste Electrical and Electronic Equipment) directives where applicable.

Post-Shipment Support and Tracking

Implement a shipment tracking system to monitor logistics in real time. Prepare for after-sales logistics, including spare parts distribution and warranty service coordination. Maintain compliance records for a minimum of five years to support audits or customs inquiries.

Conclusion: Sourcing Green Welding Machines

Sourcing green welding machines represents a strategic and sustainable step toward reducing environmental impact while enhancing operational efficiency in manufacturing and fabrication processes. These energy-efficient machines—designed with advanced inverter technology, reduced emissions, lower power consumption, and recyclable components—align with global environmental standards and corporate sustainability goals.

By prioritizing green welding equipment, organizations not only contribute to a cleaner environment but also benefit from long-term cost savings through improved energy efficiency, reduced maintenance, and compliance with environmental regulations. Additionally, adopting eco-friendly technologies strengthens a company’s reputation, supports ESG (Environmental, Social, and Governance) initiatives, and positions the business as a responsible industry leader.

In conclusion, investing in green welding machines is not merely a response to environmental concerns, but a forward-thinking business decision that combines economic, operational, and ecological advantages. As sustainability becomes increasingly integral to industrial practices, sourcing green welding technology is a critical move toward building a resilient and responsible manufacturing future.