The global demand for sustainable and durable fencing solutions has surged in recent years, driven by increasing urbanization, infrastructure development, and a growing emphasis on eco-friendly construction materials. According to Grand View Research, the global construction fencing market size was valued at USD 29.1 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A significant portion of this growth is attributed to rising demand for green mesh fencing—lightweight, recyclable, and UV-resistant solutions widely used in temporary site enclosures, erosion control, and environmental protection. Mordor Intelligence corroborates this trend, noting that heightened focus on safety compliance and environmental sustainability in both public and private construction projects is accelerating the adoption of high-performance mesh products. As the market evolves, a select group of manufacturers has emerged as leaders, combining innovation, scalability, and environmental responsibility to meet expanding global needs. Here, we spotlight the top 10 green mesh fencing manufacturers shaping the future of sustainable construction infrastructure.

Top 10 Green Mesh Fencing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Custom Green Mesh Fencing Manufacturer,China Green Mesh …

Domain Est. 2012

Website: artsignenergy.com

Key Highlights: Customized green mesh fencing at factory price from Artsignenergy.com.We are best green mesh fencing supplier,focus on solar mounting system products ……

#2 AMICO Global

Domain Est. 2014

Website: amicoglobal.com

Key Highlights: Amico global, manufacturer & distributor of building products, industrial, architectural , and expanded metal and high security fencing….

#3 Metal panels

Domain Est. 1997

Website: moreda.com

Key Highlights: MRT’s metal panels are rigid residential and professional type panels. The fences are made with welded galvanized wires….

#4 Fencing companies, manufacturers, contractors India, & Installation …

Domain Est. 2009

Website: a-1fenceproducts.com

Key Highlights: A-1 Fence is the best fencing companies near me, offering perimeter security fence and woven wire solutions. Trusted fence manufacturers & suppliers in ……

#5 358 Mesh Fence

Domain Est. 2014

Website: 358meshfence.com

Key Highlights: We are specialized company operating in the design, manufacture and installation of high security fencing systems for civil, industrial and military projects….

#6 Bekaert Fencing

Domain Est. 1993

Website: fencing.bekaert.com

Key Highlights: Bekaert is a leading fencing supplier in the agriculture industry who takes pride in creating strong, durable fencing so you can build a fence that lasts….

#7 Garden Fence

Domain Est. 2000

Website: tenaxus.com

Key Highlights: Versatile garden fencing for DIY and home garden projects. Tenax Garden Fence is the ideal way to establish a protective border around your gardens….

#8 Wire Mesh Fence

Domain Est. 2005

Website: wiremesh-fencing.com

Key Highlights: Huaguang is professionally engaged in production and sales of wire mesh fencing, security fences, wire mesh grating, welded wire mesh, barbed wire tapes….

#9 Trident Fence

Domain Est. 2012

Website: tridentfence.com

Key Highlights: Trident Fence has been a leading wholesale fence supplier for effective wildlife control. Customers in the US and Canada will find quality fence supplies and ……

#10 International Mesh Group

Domain Est. 2020

Website: internationalmeshgroup.com

Key Highlights: The leading supplier of all types of Wire Mesh Fencing, Gates and Fencing Accessories. World Class Quality Fencing Products. Extensive Gate and Fencing Ranges….

Expert Sourcing Insights for Green Mesh Fencing

H2: Projected 2026 Market Trends for Green Mesh Fencing

The green mesh fencing market is poised for significant evolution by 2026, driven by converging forces in sustainability, urbanization, technology, and consumer preferences. Key trends shaping the market include:

1. Accelerated Demand for Sustainable & Recycled Materials: Environmental consciousness will be a primary market driver. Consumers and businesses will increasingly favor green mesh fencing made from recycled plastics (especially post-consumer HDPE and PP) and bio-based polymers. Transparency in sourcing and end-of-life recyclability will become critical differentiators, pushing manufacturers toward closed-loop systems and enhanced product labeling (e.g., recycled content percentages). Regulations targeting single-use plastics and extended producer responsibility (EPR) schemes will further incentivize this shift.

2. Growth in Urban Greening & Infrastructure Projects: Urbanization continues to fuel demand for solutions that integrate nature into cities. Green mesh fencing will see expanded use in vertical gardens, green walls, noise barriers along highways, and erosion control on urban slopes. Municipalities and developers will prioritize these applications for their dual benefits: aesthetic improvement and environmental functionality (air quality, temperature regulation, biodiversity support). Public infrastructure grants and green building certifications (like LEED, BREEAM) will boost adoption.

3. Technological Integration & Smart Features: While still emerging, the integration of technology will gain traction. Expect developments in “smart” mesh systems incorporating:

* Sensors: Embedded sensors for monitoring structural integrity, soil moisture (in green wall applications), or air quality.

* Enhanced Durability: Advanced UV stabilizers and nano-coatings will extend lifespan and maintain color integrity, reducing long-term costs and waste.

* Connectivity: Potential for integration with building management systems for automated irrigation in green wall setups.

4. Dominance of High-Density Polyethylene (HDPE) & Material Innovation: HDPE will remain the dominant material due to its proven durability, weather resistance, and recyclability. However, competition will intensify from:

* Polypropylene (PP) Blends: Offering lighter weight and potentially lower cost.

* Composite Materials: Blends incorporating wood fibers or natural fillers to enhance sustainability profile and aesthetics.

* Improved Recycled Content: Advancements in recycling technology will enable higher percentages of recycled content without compromising strength, meeting stricter environmental standards.

5. Focus on Aesthetic Customization & Design Flexibility: Beyond basic functionality, demand for visually appealing solutions will rise. Manufacturers will offer wider ranges of colors (beyond standard green), textures (simulating wood or stone), and weave patterns. Customizable panel sizes and modular designs will cater to diverse architectural styles and complex site requirements, particularly in residential and commercial landscaping.

6. Regional Market Diversification & Supply Chain Resilience: While established markets (North America, Western Europe) will grow steadily, emerging economies in Asia-Pacific, Latin America, and parts of Africa will show higher growth rates due to rapid urbanization and infrastructure development. This will drive regional manufacturing expansion to reduce logistics costs and carbon footprint. Supply chain resilience, focusing on local sourcing of recycled materials and manufacturing, will become a strategic priority.

7. Competitive Landscape Intensification & Consolidation: The market will become increasingly competitive, with established players investing in R&D for sustainable materials and differentiation, while new entrants focus on niche innovations. This could lead to consolidation as companies seek economies of scale, broader material portfolios, and enhanced distribution networks to capture market share.

In conclusion, the 2026 green mesh fencing market will be defined by a strong emphasis on sustainability, urban integration, and technological enhancement. Success will depend on manufacturers’ ability to innovate with recycled and eco-friendly materials, meet the demands of urban infrastructure projects, offer aesthetically pleasing and durable products, and build resilient, transparent supply chains.

Common Pitfalls When Sourcing Green Mesh Fencing (Quality & Intellectual Property)

Sourcing green mesh fencing—commonly used in construction, agriculture, and erosion control—can present several challenges, especially concerning product quality and intellectual property (IP) risks. Being aware of these pitfalls helps ensure you receive durable, compliant, and legally sound materials.

Poor Material Quality and Durability

One of the most frequent issues is receiving fencing made from substandard materials. Low-quality polyethylene or inadequate UV stabilization can lead to rapid degradation when exposed to sunlight, reducing the product’s lifespan from years to months. Buyers may also encounter inconsistent mesh density, weak weave patterns, or insufficient tensile strength, compromising safety and performance.

Inadequate UV and Weather Resistance

Not all green mesh fencing is equally resistant to UV radiation and harsh weather. Some suppliers cut costs by using inferior additives or insufficient UV inhibitors. This results in brittleness, color fading, and structural failure over time—especially problematic in outdoor and long-term installations.

Misrepresentation of Specifications

Suppliers may exaggerate product specifications such as tensile strength, mesh size, or weight per square meter. Without third-party testing or verifiable certifications (e.g., ISO, ASTM), buyers risk receiving products that don’t meet project requirements, potentially leading to safety hazards or contract non-compliance.

Lack of Traceability and Compliance Documentation

Reputable green mesh fencing should come with documentation proving compliance with industry standards and environmental regulations. Sourcing from manufacturers who cannot provide traceability, test reports, or material safety data sheets (MSDS) increases the risk of using non-compliant or unsafe products.

Intellectual Property Infringement

Some suppliers may offer fencing that copies patented designs, logos, or proprietary weaving techniques from established brands. Purchasing such products—even unknowingly—can expose your business to legal liability, shipment seizures, or reputational damage, particularly in markets with strict IP enforcement like the EU or the U.S.

Use of Counterfeit or Branded-Impersonating Products

Counterfeit fencing that mimics well-known brands can appear cost-effective but often fails to meet performance standards. These products may carry fake certifications or misleading labels, making it difficult to verify authenticity without detailed supplier vetting and product inspection.

Insufficient Supplier Vetting and Due Diligence

Relying solely on online listings or third-party marketplaces without verifying a supplier’s manufacturing capabilities, quality control processes, or legal standing increases exposure to both quality and IP risks. Skipping factory audits or sample testing can result in costly mistakes post-purchase.

Hidden Costs from Rejection or Recalls

Poor quality or IP-infringing fencing may be rejected at customs, during site inspections, or under contract review. This leads to project delays, replacement costs, and potential penalties—costs that often exceed initial savings from choosing a low-priced supplier.

By addressing these pitfalls through rigorous supplier evaluation, requesting verifiable certifications, and conducting pre-shipment inspections, buyers can secure reliable, high-quality green mesh fencing while minimizing legal and operational risks.

Logistics & Compliance Guide for Green Mesh Fencing

This guide outlines key logistics considerations and compliance requirements for the transportation, handling, and installation of green mesh fencing. Adhering to these guidelines ensures efficient operations, regulatory compliance, and product integrity.

Product Specifications and Packaging

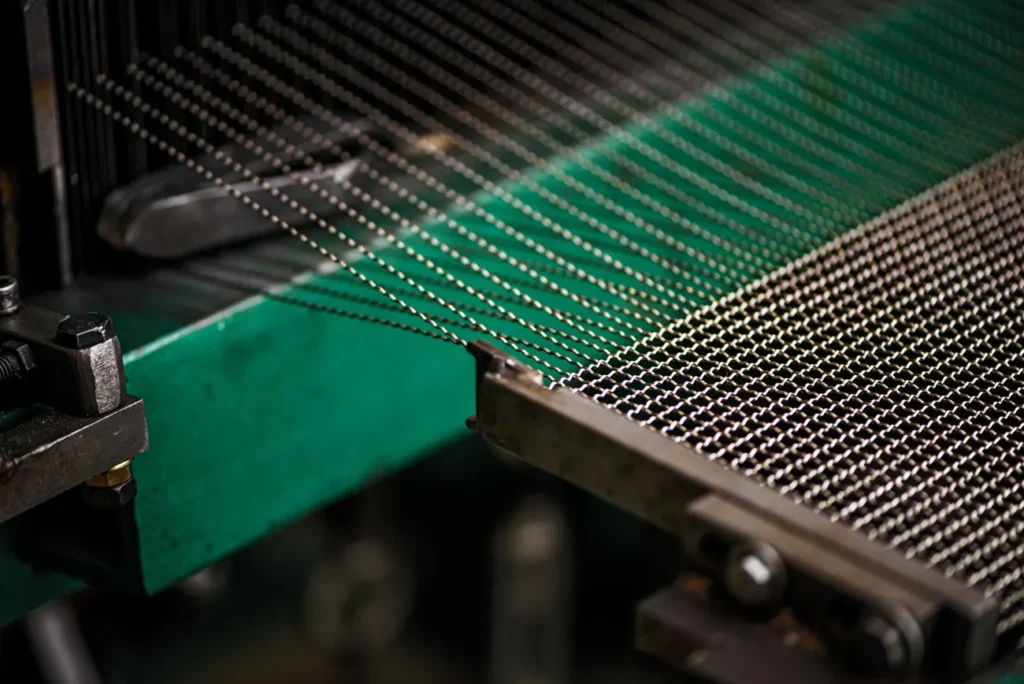

Green mesh fencing is typically supplied in rolls or panels made from galvanized steel wire coated with PVC or polyethylene for durability and corrosion resistance. Standard roll lengths range from 25 to 50 meters, with heights of 0.5m to 2.4m. Rolls are tightly wound and secured with plastic or metal strapping. Panels may be bundled with protective corner guards. All packaging must include product labeling with specifications, batch numbers, and manufacturer details for traceability.

Transportation and Handling

Transport green mesh fencing on flatbed or enclosed trucks, ensuring rolls are secured with straps to prevent rolling or shifting. Store products horizontally and off the ground on pallets or skids to avoid moisture exposure and deformation. Use forklifts or lifting slings with padded edges to prevent damage during loading/unloading. Avoid dragging rolls across surfaces to maintain mesh integrity and coating.

Storage Conditions

Store green mesh fencing in a dry, well-ventilated area, protected from direct sunlight, rain, and snow. Prolonged UV exposure can degrade the polymer coating over time. Keep rolls elevated on wooden pallets to prevent contact with standing water or damp ground. Maintain adequate spacing between stacks for airflow and easy access.

Import and Export Compliance

Ensure all shipments comply with destination country regulations. Key documentation includes commercial invoices, packing lists, certificates of origin, and material safety data sheets (MSDS) if required. Verify compliance with international standards such as ISO 9001 (quality management) and ISO 14001 (environmental management). For exports to the EU, confirm adherence to REACH and RoHS regulations regarding restricted substances.

Environmental and Safety Regulations

Green mesh fencing must comply with local environmental standards governing material composition and recyclability. The PVC/PE coatings should be free from heavy metals such as lead and cadmium. During installation, follow OSHA (or equivalent) safety protocols, including the use of gloves, eye protection, and proper lifting techniques to prevent injury.

Installation Standards and Best Practices

Install fencing in accordance with regional building codes and fencing standards (e.g., ASTM A392 for welded wire mesh). Ensure posts are securely set in concrete and aligned to maintain tension across the mesh. Overlap vertical joints by at least one mesh square and secure with tie wires or clips. Trim excess material with wire cutters, avoiding jagged edges.

Disposal and Recycling

At end-of-life, green mesh fencing can often be recycled. Separate the steel core from the polymer coating where recycling facilities allow. Dispose of non-recyclable components in accordance with local waste regulations. Avoid open burning, which may release hazardous fumes from the plastic coating.

Documentation and Traceability

Maintain complete records of product batches, shipping manifests, compliance certificates, and inspection reports. Implement a traceability system to quickly identify and address any product issues. This supports warranty claims, recalls, and quality audits.

Following this guide ensures safe, compliant, and efficient handling of green mesh fencing throughout its supply chain lifecycle.

In conclusion, sourcing green mesh fencing requires a strategic approach that balances durability, environmental sustainability, cost-effectiveness, and aesthetic appeal. By prioritizing suppliers that use recycled or eco-friendly materials, adhere to sustainable manufacturing practices, and offer long-term product warranties, businesses and individuals can make responsible purchasing decisions. Additionally, comparing various options—such as HDPE, PVC-coated, or bamboo-based mesh—ensures the selection of a solution suited to specific needs, whether for erosion control, construction site safety, agriculture, or landscaping. Evaluating certifications, customer reviews, and local availability further enhances sourcing success. Ultimately, choosing a green mesh fencing solution supports environmental stewardship while meeting functional requirements, contributing to a more sustainable built environment.