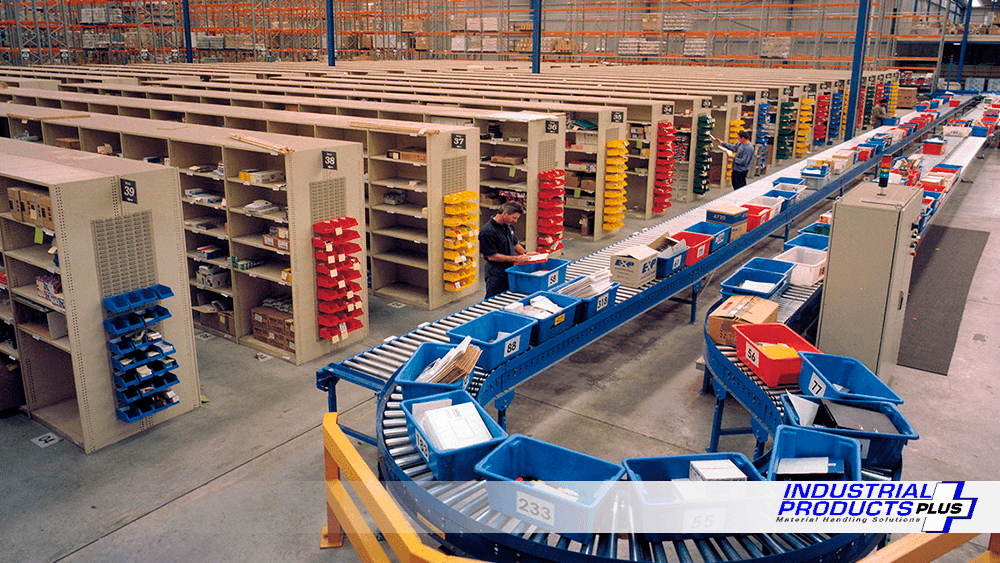

The global conveyor systems market is experiencing robust growth, driven by rising demand for automation across industries such as logistics, e-commerce, automotive, and food & beverage. According to a report by Mordor Intelligence, the global conveyor belt market was valued at USD 6.25 billion in 2023 and is projected to grow at a CAGR of over 6.5% from 2024 to 2029. Similarly, Grand View Research estimates that the global conveyor systems market size surpassed USD 13.3 billion in 2023 and is expected to expand at a CAGR of 6.7% through 2030, fueled by increased adoption of material handling solutions in manufacturing and distribution centers. Within this expanding landscape, gravity roller conveyor systems—valued for their energy efficiency, low maintenance, and cost-effective transport of unit loads—have become a cornerstone of modern material handling infrastructure. As industries prioritize operational efficiency and scalable logistics solutions, the demand for high-quality gravity roller conveyors continues to rise, prompting a competitive field of manufacturers offering innovative, durable, and customizable systems. This list highlights the top 10 gravity roller conveyor systems manufacturers leading the market through technological advancement, global reach, and customer-centric design.

Top 10 Gravity Roller Conveyor Systems Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

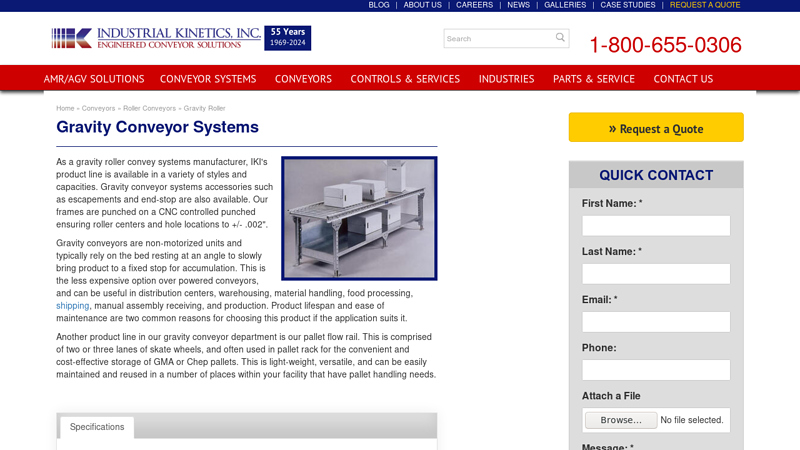

#1 Gravity Roller Conveyor Systems Manufacturer

Domain Est. 1996

Website: iki.com

Key Highlights: As a gravity roller convey systems manufacturer, IKI’s product line is available in a variety of styles and capacities….

#2 Ashland Conveyor

Domain Est. 1999

Website: ashlandconveyor.com

Key Highlights: Ashland Conveyor Products is a leading conveyor manufacturer supplying the material handling, warehouse equipment, and factory automation markets for over ……

#3 Gravity Conveyor Roller

Domain Est. 2002

Website: conveyorrollers.com

Key Highlights: As the leading roller conveyor manufacturer, we have been creating gravity roller conveyors for warehouses and other facilities for over 35 years….

#4 Gravity Roller Conveyors

Domain Est. 2007

Website: dornerconveyors.com

Key Highlights: Dorner is a leading manufacturer of conveyors and other material handling solutions. We offer a wide range of products, including flexible gravity conveyors, ……

#5 Gravity Roller Conveyor Manufacturers

Domain Est. 2021

Website: convelinerollers.com

Key Highlights: Convelinerollers is the India’s largest heavy duty gravity roller conveyor manufacturers and suppliers. Get top-notch gravity roller conveyors. Call Now!…

#6 Gravity Roller Conveyor Systems

Domain Est. 1996

Website: hytrol.com

Key Highlights: Gravity conveyors are non-powered, transport solutions that use gravity or some external force to move products. Gravity conveyors may be chutes, rollers, or ……

#7 GRAVITY ROLLER CONVEYOR

Domain Est. 1996

Website: conveyors.lewcoinc.com

Key Highlights: Gravity Roller Conveyors are ideal for applications that require an economical, non-powered means for conveying material. This heavy-duty conveyor is used for ……

#8 Gravity Conveyor

Domain Est. 1997

Website: unex.com

Key Highlights: Eliminate costly malfunctions and equipment damage with durable, low-maintenance gravity conveyors engineered to keep your operations flowing seamlessly….

#9 Gravity Conveyor

Domain Est. 2005

Website: bastiansolutions.com

Key Highlights: Gravity conveyors may be used to move boxes, cartons and totes with firm, rigid bottoms. Roller or skatewheel sizes as well as spacing will vary. A good rule of ……

#10 Roller Conveyor Systems

Domain Est. 2009

Website: mknorthamerica.com

Key Highlights: mk’s offers a variety of roller conveyor systems, including gravity roller conveyors, chain driven roller conveyors, and powered roller conveyors….

Expert Sourcing Insights for Gravity Roller Conveyor Systems

H2: 2026 Market Trends for Gravity Roller Conveyor Systems

The gravity roller conveyor market is poised for steady evolution by 2026, shaped by broader industrial automation, e-commerce growth, and sustainability demands. While often overshadowed by powered systems, gravity conveyors maintain critical relevance due to their simplicity, cost-effectiveness, and reliability in specific applications. Key trends expected to define the market in 2026 include:

-

Resilient Demand Driven by E-Commerce and Warehousing Expansion:

- The continued surge in online retail necessitates efficient, flexible material handling within distribution centers (DCs), fulfillment centers, and last-mile hubs.

- Gravity conveyors remain fundamental for sorting, accumulation, staging, and order consolidation zones where powered movement isn’t required.

- Growth in automated storage and retrieval systems (AS/RS) often incorporates gravity sections for pre- and post-processing, sustaining demand.

-

Emphasis on Modularity and Flexibility:

- The need for rapid reconfiguration in dynamic warehouse environments (seasonal peaks, changing product mixes) drives demand for modular gravity conveyor systems.

- Suppliers will focus on standardized components (rollers, frames, supports) enabling easy assembly, disassembly, and reconfiguration without specialized tools.

- Lightweight aluminum frames will gain further traction over steel for easier handling and reduced installation time/cost.

-

Integration with Automation and Smart Systems (Hybrid Approaches):

- Pure gravity systems will increasingly act as components within larger automated material handling ecosystems.

- Seamless integration points with powered conveyors, sorters, automated guided vehicles (AGVs), and robotic picking/packing stations will be crucial.

- While gravity conveyors themselves remain passive, their design will focus on compatibility with sensors (e.g., photoelectric sensors for presence detection on accumulation zones) feeding data to warehouse control systems (WCS) for better flow management.

-

Focus on Ergonomics and Worker Safety:

- Regulatory pressures and a focus on reducing workplace injuries will drive design innovations.

- Features like adjustable height sections, improved roller end caps, and integrated guardrails will become standard.

- Designs minimizing manual pushing/pulling force (e.g., optimized roller pitch, low-friction rollers, incline/decline calculations) will be prioritized.

-

Material and Design Optimization for Sustainability:

- Sustainability concerns will influence material choices and manufacturing processes.

- Increased use of recycled aluminum and steel, along with designs focused on longevity, repairability, and end-of-life recyclability, will be market differentiators.

- Energy efficiency remains a core advantage (zero operational energy), reinforcing their “green” appeal compared to powered alternatives for suitable tasks.

-

Regional Growth Variations:

- Asia-Pacific: Expected to be the fastest-growing region due to rapid industrialization, e-commerce boom (especially China, India, Southeast Asia), and expanding manufacturing/warehouse infrastructure.

- North America & Europe: Steady growth driven by warehouse automation upgrades, e-commerce fulfillment, and modernization of existing logistics networks. Focus will be on high-efficiency, modular solutions.

- Rest of World: Emerging markets will see growth linked to infrastructure development and increasing logistics sophistication.

-

Competition and Value Proposition:

- Competition will remain intense, particularly in the standard product segment. Differentiation will come through:

- Specialized Solutions: Customization for unique applications (e.g., heavy loads, specific product types, harsh environments).

- Value-Added Services: Faster delivery, comprehensive design support, installation services, and maintenance programs.

- Durability and Reliability: Proven performance in demanding 24/7 operations will be a key selling point.

- Competition will remain intense, particularly in the standard product segment. Differentiation will come through:

Conclusion for H2 2026:

Gravity roller conveyors will not experience revolutionary technological leaps, but their market will be shaped by strategic adaptation. Success will hinge on manufacturers’ ability to offer highly modular, easily integrable, ergonomic, and sustainable solutions that serve as the reliable, cost-effective backbone within increasingly automated and flexible material handling systems. Demand will remain robust, particularly in growing e-commerce logistics and manufacturing sectors, ensuring gravity conveyors retain a vital, albeit often unglamorous, role in the industrial landscape.

Common Pitfalls When Sourcing Gravity Roller Conveyor Systems (Quality, IP)

Sourcing gravity roller conveyor systems involves more than just selecting a basic design—overlooking key quality and intellectual property (IP) considerations can lead to long-term operational inefficiencies, safety risks, and legal complications. Below are common pitfalls to avoid:

Poor Material and Component Quality

One of the most frequent issues is selecting systems made from substandard materials. Low-grade steel rollers, inadequate tube wall thickness, or inferior bearings may appear cost-effective initially but lead to premature wear, increased maintenance, and system failure. Always verify material specifications and insist on industry-standard components to ensure durability and load capacity.

Inadequate Customization and Design Validation

Many suppliers offer “standard” conveyor solutions that don’t fully meet unique operational requirements. Failing to validate the design for your specific application—such as load weight, environmental conditions (e.g., washdown, temperature), or integration with existing systems—can result in performance issues. Ensure the supplier conducts a site assessment and provides engineered drawings for approval.

Lack of Compliance with Safety and Industry Standards

Conveyors that do not meet recognized safety standards (e.g., OSHA, ANSI, or CEMA) pose significant liability and safety risks. Avoid suppliers who cannot provide documentation confirming compliance. Also, ensure guarding, emergency stops, and ergonomic design elements are included where necessary.

Intellectual Property Infringement Risks

When sourcing from low-cost or offshore manufacturers, there’s a risk of inadvertently purchasing systems that infringe on patented designs or technologies. This can expose your company to legal action or supply chain disruptions. Always work with reputable suppliers who can confirm their designs are IP-compliant and offer warranties against infringement.

Insufficient Documentation and Technical Support

Poor documentation—including assembly instructions, maintenance guides, and spare parts lists—hampers installation and long-term maintenance. Additionally, lack of post-sale technical support can delay troubleshooting. Choose suppliers that provide comprehensive documentation and accessible customer service.

Hidden Costs from Poor Installation and Layout Planning

Underestimating installation complexity can lead to cost overruns and downtime. Some suppliers may quote low unit prices but lack in-house installation expertise or fail to account for site-specific challenges. Ensure the supplier offers layout engineering services and considers installation logistics during the sourcing process.

Overlooking Future Scalability and Maintenance Needs

Selecting a system without considering future expansion or ease of maintenance results in costly retrofits or downtime. Verify that the conveyor design allows for modular expansion and uses readily available, standardized components to simplify repairs and replacements.

By proactively addressing these quality and IP-related pitfalls, businesses can ensure they source reliable, compliant, and scalable gravity roller conveyor systems that deliver long-term value.

Logistics & Compliance Guide for Gravity Roller Conveyor Systems

Overview of Gravity Roller Conveyor Systems

Gravity roller conveyor systems are a cost-effective and efficient solution for transporting goods using gravity to move items along a controlled path. These systems are commonly used in warehouses, distribution centers, manufacturing facilities, and loading docks. Proper logistics planning and compliance adherence are essential to ensure safe, efficient, and legal operations.

Design and Installation Requirements

When designing and installing gravity roller conveyors, consider slope, load capacity, roller spacing, and material compatibility. The incline should not exceed manufacturer recommendations—typically 5–15 degrees—to prevent uncontrolled movement. Ensure the conveyor structure is level laterally to avoid product skewing. Install safety guards, end stops, and warning signs where appropriate, especially near drop-offs or intersections.

Load and Material Specifications

Verify that the conveyor is rated for the maximum expected load per linear foot and overall weight. Match roller diameter and spacing to the size and weight of conveyed items—smaller items require closer roller spacing. Avoid conveying fragile, hazardous, or irregularly shaped loads unless specifically designed for such use. Comply with material handling standards such as ANSI/ASME B20.1 for safety and performance.

Workplace Safety and OSHA Compliance

Adhere to OSHA regulations (29 CFR 1910.212 and 1910.176) regarding machine guarding, material storage, and safe work practices. Install guarding where rollers pose pinch-point hazards. Ensure clear walkways and emergency stop mechanisms are accessible. Train personnel on safe handling practices, including not riding on conveyors and using proper push tools for manual item movement.

Transportation and Shipping Considerations

For shipping gravity roller conveyors, secure components to prevent shifting during transit. Use protective packaging for rollers and frames to avoid damage. Label packages with handling instructions (e.g., “Fragile,” “This Side Up”). When transporting assembled sections, ensure compliance with road vehicle size and weight limits. Coordinate with carriers experienced in handling industrial equipment.

International Trade and Customs Compliance

For cross-border shipments, ensure accurate Harmonized System (HS) code classification—typically under 8428.90 for conveyor equipment. Prepare commercial invoices, packing lists, and certificates of origin. Comply with import/export regulations, including REACH (EU) or TSCA (U.S.) if applicable. Verify that materials meet regional environmental or chemical restrictions.

Maintenance and Operational Compliance

Establish a routine maintenance schedule to inspect rollers, frames, and structural integrity. Lubricate rollers if specified by the manufacturer. Remove debris to prevent jamming. Document inspections and repairs to demonstrate compliance with internal safety policies and insurance requirements. Update operational procedures as needed to reflect changes in workflow or regulations.

Environmental and Sustainability Practices

Dispose of damaged conveyor components in accordance with local waste regulations. Recycle metal frames and rollers where possible. Consider energy-efficient design principles—even though gravity conveyors require no power, optimizing layout reduces manual handling effort and supports sustainable warehouse operations.

Documentation and Recordkeeping

Maintain complete records including installation manuals, compliance certifications (e.g., CE, UL), inspection logs, and training records. These documents support audits, insurance claims, and regulatory inspections. Provide operators with accessible safety and operating instructions in the appropriate language(s).

Emergency Procedures and Risk Mitigation

Develop and communicate emergency procedures for jams, falling loads, or injuries. Ensure employees know how to safely disengage or stop the conveyor. Conduct regular safety drills and update risk assessments to reflect changes in operations. Implement measures such as anti-static rollers if handling sensitive materials in explosive atmospheres (ATEX compliance may apply).

Conclusion: Sourcing Gravity Roller Conveyor Systems

Sourcing gravity roller conveyor systems is a strategic decision that can significantly enhance material handling efficiency, reduce operational costs, and improve workflow flexibility in warehouses, distribution centers, and manufacturing facilities. These systems offer a cost-effective, low-maintenance solution for moving goods using gravity, requiring no external power source and minimizing energy consumption.

When sourcing, it is essential to consider factors such as load capacity, roller spacing, material type (steel or aluminum), frame construction, and compatibility with existing operations. Working with reputable suppliers who offer customizable options, reliable technical support, and quality assurance ensures long-term durability and seamless integration.

Additionally, evaluating total cost of ownership—beyond the initial purchase price—helps identify systems that deliver optimal value through longevity, ease of maintenance, and adaptability to future needs. Proper installation and staff training further maximize system performance and safety.

In conclusion, investing in a well-sourced gravity roller conveyor system not only streamlines material flow but also supports scalable and sustainable operations. With careful selection and planning, businesses can achieve improved productivity and operational agility, making gravity conveyors a smart choice for efficient material handling.