The global thermal interface materials (TIMs) market, driven by rising demand for efficient thermal management in electronics, is witnessing robust growth, with a projected CAGR of 9.2% from 2023 to 2028, according to Mordor Intelligence. Within this expanding sector, graphite thermal pads have emerged as a critical solution due to their superior thermal conductivity, flexibility, and thin-profile design—making them ideal for smartphones, tablets, wearable devices, and high-performance computing. Valued at USD 1.8 billion in 2022, the graphite-based TIMs segment is gaining traction as manufacturers seek reliable alternatives to traditional thermal pastes and pads. As innovation accelerates and device miniaturization continues, the demand for high-efficiency thermal dissipation solutions has propelled investment and competition among material engineers and component suppliers. In this evolving landscape, a select group of manufacturers leads the charge in delivering advanced graphite thermal pads, combining precision engineering with scalable production. Here are the top 9 companies shaping the future of thermal management through cutting-edge graphite-based solutions.

Top 9 Graphite Thermal Pad Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Suzhou thermal pad manufacturer

Domain Est. 2023

Website: en.szzh-t.com

Key Highlights: Suzhou Zhiteng Electronic Technology Co., Ltd. is a strong thermal pad manufacturer, mainly selling thermal gel, thermal grease and other products….

#2 Aavid, Thermal Division of Boyd Corporation is now Boyd

Domain Est. 1996

Website: boydcorp.com

Key Highlights: Aavid is now part of Boyd’s comprehensive portfolio of thermal management solutions and design engineering services for electronics cooling, ……

#3 thermal pads

Domain Est. 2009

Website: hala-tec.com

Key Highlights: GRAPHITE FOILS. Graphite foils consist of more than 98% pure natural graphite or are processed of synthetic pyrolytic graphite. TYPES: Sheet or ……

#4 Reliable cooling expertise.

Domain Est. 2011

Website: carbice.com

Key Highlights: Carbice products are the building blocks for game-changing solutions, cutting thermal gradients by 2x and mechanical stress gradients by 3x for unmatched ……

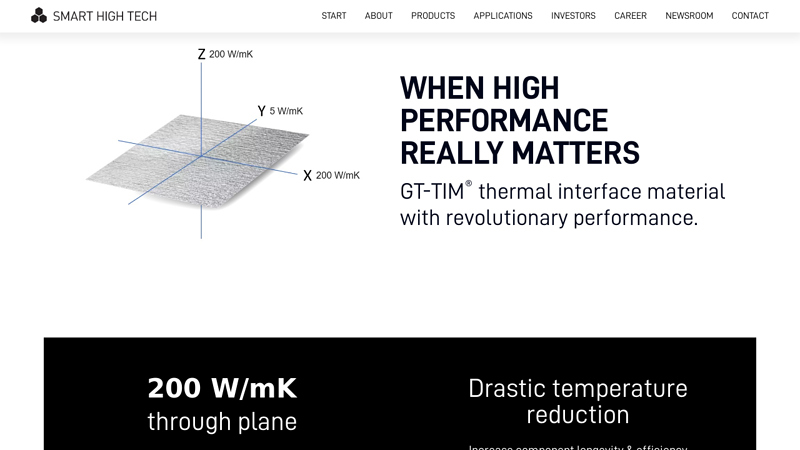

#5 Start

Domain Est. 2012

Website: smarthightech.com

Key Highlights: GT-TIM® thermal pads can decrease the temperature up to 10 °C in your hardware which can double your hardwares lifetime. INDUSTRIES. Servers. Cooling ……

#6 Thermal Grizzly KryoSheet Thermal Pads

Domain Est. 2013

Website: thermal-grizzly.com

Key Highlights: In stockThe KryoSheet Graphene Thermal Pads are an excellent alternative to thermal pastes and have an adaptable surface with very high thermal conductivity….

#7 UPSIREN

Domain Est. 2023

Website: upsiren.cn

Key Highlights: Provide high-quality graphics cooling, development, production and sales solutions. U6 100g 12.8W Thermal Putty. 3D Graphite Thermal Pad … brand in the heat ……

#8 FRD

Domain Est. 2024

Website: frd-corp.com

Key Highlights: FRD – The Global Leading Provider for EMI shielding materials, Thermal management materials & Supporting electronic materials….

#9 The Ultimate Guide to Buying Thermal Pads

Domain Est. 2020

Website: fehonda.com

Key Highlights: Other specialized materials include graphite pads, known for high thermal … Fehonda Official Website (Fehonda.com / Feihongda Technology). The corporate ……

Expert Sourcing Insights for Graphite Thermal Pad

H2: 2026 Market Trends for Graphite Thermal Pads

The global graphite thermal pad market is poised for significant evolution by 2026, driven by escalating thermal management demands across high-growth electronics sectors. Key trends shaping the market include:

-

Surging Demand from Advanced Electronics: The proliferation of high-performance computing (HPC), 5G infrastructure, electric vehicles (EVs), and next-generation consumer electronics (smartphones, AR/VR, gaming consoles) will be the primary growth engine. These applications generate intense heat in compact spaces, demanding superior thermal solutions where graphite pads excel due to their high in-plane thermal conductivity and thin profile.

-

Performance Enhancement and Hybridization: Intense competition will push manufacturers towards developing higher-performance pads. Key trends include:

- Increased Thermal Conductivity: R&D will focus on achieving thermal conductivity values exceeding 1000 W/mK through advanced purification, alignment techniques, and composite formulations.

- Hybrid Solutions: Integration of graphite with other materials (e.g., metal foils, phase change materials, ceramic fillers) will create hybrid pads offering superior performance (e.g., better through-plane conductivity, enhanced mechanical properties, electrical insulation) tailored for specific applications like EV power modules or advanced processors.

-

Miniaturization and Form Factor Innovation: The relentless drive for thinner, lighter, and smaller devices will necessitate ultra-thin graphite pads (<0.1mm) with exceptional conformability. Expect innovations in handling ultra-thin films, improving tear resistance, and developing pads with precise cut-outs and adhesive patterns for complex assemblies.

-

Focus on Sustainability and Supply Chain Resilience: Growing environmental regulations (e.g., REACH, RoHS) and corporate sustainability goals will increase demand for:

- Recyclable/Recyclable-Backed Pads: Development of pads using more sustainable substrates or processes.

- Responsible Sourcing: Transparency in graphite sourcing (especially natural flake graphite) and reduced environmental impact of production will become critical competitive factors.

- Supply Chain Diversification: Geopolitical tensions may accelerate efforts to diversify graphite supply chains away from heavy reliance on specific regions.

-

Cost Optimization and Material Substitution Pressures: While high performance is key, cost remains a significant factor, especially in high-volume consumer electronics. This will drive:

- Process Efficiency: Manufacturers will focus on improving yield and reducing waste in the calendering and expansion processes.

- Alternative Materials: Competition from advanced thermal interface materials (TIMs) like high-performance thermal greases, gap fillers, and metal-based solutions will pressure graphite pad pricing, pushing innovation towards higher value-added, irreplaceable applications.

-

Regional Growth Dynamics: Asia-Pacific (particularly China, South Korea, Japan, and Taiwan) will remain the dominant market and manufacturing hub due to its massive electronics and EV production. However, growth in North America and Europe will accelerate, driven by EV adoption, data center expansion, and government investments in semiconductor and clean tech manufacturing, potentially reshaping the regional production landscape.

In conclusion, the 2026 graphite thermal pad market will be characterized by high performance, hybridization, miniaturization, and sustainability, driven by the insatiable thermal demands of cutting-edge technologies. Success will depend on continuous innovation, cost-effective manufacturing, and navigating complex supply chains and environmental regulations.

Common Pitfalls Sourcing Graphite Thermal Pads (Quality, IP)

Sourcing graphite thermal pads requires careful evaluation to avoid performance issues, supply chain disruptions, and intellectual property (IP) risks. Overlooking key pitfalls can lead to product failures, increased costs, and legal exposure.

Inadequate Quality Verification

Many suppliers claim high thermal conductivity (e.g., 1,000–1,500 W/mK), but actual performance often falls short due to inconsistent manufacturing. Buyers may accept samples without rigorous third-party testing, leading to thermal bottlenecks in end products. Variability in thickness uniformity, compressibility, and electrical isolation also impacts reliability—especially in high-density electronics. Without proper incoming quality checks or material certifications (e.g., RoHS, REACH), companies risk field failures and warranty claims.

Lack of IP Protection and Transparency

Graphite thermal pad technology often involves proprietary formulations or lamination processes protected by patents. Sourcing from suppliers who do not disclose IP ownership or freedom-to-operate (FTO) status exposes buyers to infringement risks. Some manufacturers may reverse-engineer solutions or use unlicensed technology, especially in regions with weaker IP enforcement. Without clear contractual terms on IP indemnification and know-how protection, companies risk litigation or being locked into non-compliant supply chains.

Overreliance on Unverified Supply Chains

Procurement teams may prioritize cost and lead time over supplier vetting, selecting vendors without auditing their production facilities or raw material traceability. This increases the risk of counterfeit or substandard graphite materials—such as pads with insufficient purity or inconsistent layer alignment. Additionally, undisclosed subcontracting can compromise quality control and IP security, especially when manufacturing shifts occur without notification.

Insufficient Application-Specific Validation

Graphite pads perform differently based on pressure, temperature, and interface materials. A common mistake is qualifying a pad based on generic specs without validating performance in the actual thermal stack-up. This leads to unexpected thermal resistance in real-world conditions, reducing product lifespan or requiring costly redesigns late in development.

Failure to Secure Long-Term Supply and Scalability

Graphite is a strategic material with fluctuating availability. Suppliers without secured raw material sources or scalable capacity may struggle during demand surges, disrupting production. Relying on single-source vendors without alternative qualification increases supply chain vulnerability and reduces negotiation leverage.

Avoiding these pitfalls requires due diligence: conduct performance testing, audit suppliers, validate IP rights, and establish dual-sourcing strategies—ensuring reliable, compliant, and high-performance thermal management solutions.

H2: Logistics & Compliance Guide for Graphite Thermal Pads

H2: Overview

Graphite thermal pads are thermally conductive materials commonly used in electronics for heat dissipation. While generally safe and non-hazardous, proper logistics handling and regulatory compliance are essential due to their material composition and international shipping requirements. This guide outlines key considerations for the safe and compliant transportation, storage, and documentation of graphite thermal pads.

H2: Regulatory Classification

- UN Number: Not regulated as dangerous goods under ADR/RID/IMDG/IATA when in solid, non-powder form. Typically shipped as “Not Restricted” or “Not Subject to Regulations.”

- IATA/ICAO: Generally exempt from dangerous goods regulations for air transport (refer to Packing Instruction 965, Section II, if lithium batteries are attached; otherwise, not applicable).

- IMDG Code: Not classified as hazardous for sea freight in standard form.

- REACH & RoHS Compliance: Confirm that the graphite thermal pad is free from SVHC (Substances of Very High Concern) and complies with RoHS (Restriction of Hazardous Substances) directives, especially regarding lead, cadmium, mercury, and certain flame retardants.

- TSCA (USA): Ensure compliance with U.S. Toxic Substances Control Act; graphite is listed and generally compliant.

H2: Packaging & Handling

- Primary Packaging: Individually wrapped or sheet-stacked with protective film to prevent surface damage.

- Secondary Packaging: Use sturdy corrugated cardboard boxes with internal dividers or foam inserts to prevent shifting.

- Palletization: Secure boxes on standard pallets using stretch wrap. Max load height: 1.8 m (6 ft). Use edge protectors for stability.

- Labeling: Include product name, part number, batch/lot number, net weight, manufacturer details, and handling symbols (e.g., “Fragile,” “This Side Up”).

- Static Sensitivity: Although not typically ESD-sensitive, avoid excessive dust generation and store away from static-prone environments if integrated with EMI shielding materials.

H2: Storage Conditions

- Temperature: Store between 15°C and 30°C (59°F to 86°F).

- Humidity: Maintain relative humidity below 60% to prevent moisture absorption (particularly relevant for adhesive-backed variants).

- Shelf Life: Typically 12–24 months when stored properly; check manufacturer specifications.

- Location: Store indoors, away from direct sunlight, heat sources, and corrosive chemicals. Keep flat to avoid warping.

H2: Transportation Requirements

- Mode of Transport: Suitable for air, sea, and ground freight without special permits in standard form.

- Documentation:

- Commercial Invoice

- Packing List

- Certificate of Compliance (RoHS, REACH)

- SDS (Safety Data Sheet) – often classified as “Not Classified” under GHS, but provide upon request

- Customs Classification (HS Code): Typical HS code: 3819.00 (Prepared binders for foundry moulds or cores; chemical products for industrial processing). Confirm with local customs authority—alternatives may include 8547.20 (Insulating fittings for electrical machines) depending on form and use.

- Export Controls: Generally not subject to ITAR or EAR restrictions. Verify if modified with controlled materials (e.g., carbon composites in defense applications).

H2: Safety & Environmental

- SDS Requirements: While graphite pads are inert and non-toxic, provide an SDS if requested. Highlight:

- No significant health hazards under normal handling.

- Avoid inhalation of dust if cut or machined (use PPE).

- Non-flammable, but may char at very high temperatures (>400°C).

- Disposal: Dispose of as non-hazardous industrial waste in accordance with local regulations. Recycle if possible through e-waste or carbon material recovery programs.

H2: Special Notes

- Adhesive Variants: If the thermal pad includes acrylic or silicone adhesive, ensure compliance with VOC regulations in regions like the EU (e.g., EU Ecolabel criteria).

- Customer Requirements: Some OEMs may require conflict minerals reporting (e.g., CMRT) if integrated into consumer electronics—verify supply chain transparency.

- Testing Documentation: Maintain thermal conductivity, electrical insulation, and flame resistance (e.g., UL 94 V-0) test reports for compliance audits.

H2: Summary

Graphite thermal pads are low-risk for logistics and compliance when handled correctly. Key actions include verifying material compliance (RoHS/REACH), using proper packaging, providing accurate documentation, and confirming HS codes with freight forwarders. Always consult the manufacturer’s technical data and safety sheets for product-specific guidance.

Note: Regulations may vary by country and product formulation. Consult a compliance specialist or freight forwarder for high-volume or international shipments.

Conclusion for Sourcing Graphite Thermal Pads:

After evaluating various suppliers and material specifications, sourcing graphite thermal pads presents a compelling solution for efficient heat dissipation in compact and high-performance electronic devices. Graphite’s high thermal conductivity, flexibility, and thin profile make it ideal for applications where space and weight are critical constraints. Key factors in successful sourcing include ensuring material purity, consistency in thickness and performance, and supplier reliability.

It is recommended to partner with established manufacturers or suppliers who provide certified material testing data, adhere to international quality standards (such as ISO), and offer scalable production capabilities. Additionally, conducting sample testing and long-term reliability assessments under real-world operating conditions will help validate performance and durability.

In conclusion, graphite thermal pads are a technologically advanced thermal management solution, and strategic sourcing—prioritizing quality, consistency, and technical support—will ensure optimal thermal performance and product reliability in end applications.