The global graphite gasket material market is experiencing steady growth, driven by rising demand across critical industries such as oil & gas, power generation, chemical processing, and automotive. According to Grand View Research, the global flexible graphite market—key to high-performance gasketing—was valued at USD 1.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by increasing requirements for leak-proof, heat-resistant sealing solutions in extreme operating environments. Additionally, Mordor Intelligence projects heightened demand due to stringent environmental regulations and the ongoing expansion of industrial infrastructure in emerging economies. As performance standards evolve, manufacturers specializing in graphite gasket materials are investing in advanced material engineering and expanded production capacities. In this competitive landscape, ten companies have emerged as leaders, combining innovation, quality, and scalability to meet global industry demands.

Top 10 Graphite Gasket Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Soft Gaskets

Domain Est. 2004

Website: robco.com

Key Highlights: Low pressure applications. A homogenous graphite gasket sheet for use in sealing conditions where low internal pressures exist. High quality industrial-grade ( ……

#2 Packing and Gaskets

Domain Est. 1995

Website: chesterton.com

Key Highlights: Chesterton offers a full line of packing and gasketing technology for rotating and stationary equipment….

#3 Lamons

Domain Est. 2002

Website: lamons.com

Key Highlights: Lamons is one of the largest custom gasket, bolt, & seal manufacturers globally, committed to providing industry leading sealing solutions. Call us today!…

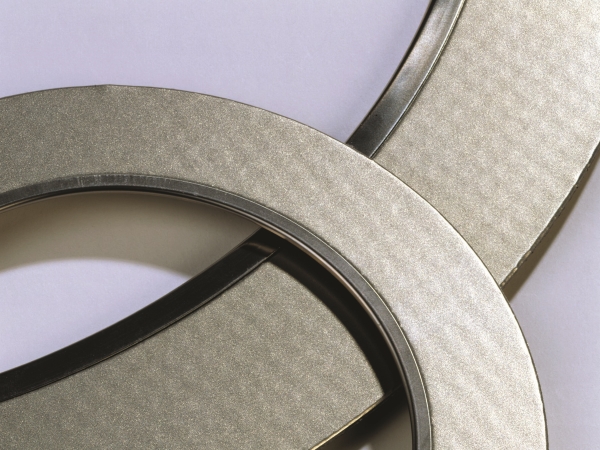

#4 Flexible Graphite Gasket Sheet Material

Domain Est. 1995

Website: garlock.com

Key Highlights: Available with or without metal inserts, perfect for applications requiring chemical resistance or high temperatures….

#5 Gaskets

Domain Est. 1996

Website: nuclear.curtisswright.com

Key Highlights: Style 6300E is a graphite sheet manufactured from 97% pure graphite flakes containing a stainless steel tanged insert. These flakes are treated and processed ……

#6 50 years of SIGRAFLEX®

Domain Est. 1997

Website: sglcarbon.com

Key Highlights: The SIGRAFLEX story begins in 1972 with the inauguration of our first flexible graphite foil line in Meitingen, Germany, and the SIGRAFLEX brand registration….

#7 Graphite Gaskets & Seals

Domain Est. 1999

Website: henniggasket.com

Key Highlights: Graphite Gasket Sheet Material. Hennig Gasket & Seals is a stocking distributor of a wide variety of graphite sheets and flexible homogenous graphite rolls….

#8 GrafTech International Ltd.

Domain Est. 2000

Website: graftech.com

Key Highlights: A global graphite electrode leader delivering highly engineered services, customer-first solutions and essential products – all backed by an exceptional history ……

#9 Gaskets and Seals

Domain Est. 2012

Website: klinger-international.com

Key Highlights: Products on this page. CNAF gaskets; Compression packings; Elastomere gaskets; Graphite gaskets; Insulation sets; Metallic gaskets; PTFE gaskets; SEALEX….

#10 Flexible Graphite Laminate Gasket Materials

Domain Est. 2020

Website: klinger-thermoseal.com

Key Highlights: Our graphite materials are available with an anti-stick coating that avoids sticking, aides in easy gasket removal, and keeps the flanges cleaner….

Expert Sourcing Insights for Graphite Gasket Material

H2: 2026 Market Trends for Graphite Gasket Material

The global market for graphite gasket materials is poised for significant transformation by 2026, driven by evolving industrial demands, technological advancements, and sustainability initiatives. As industries increasingly prioritize high-performance, reliable sealing solutions, graphite gasket materials—particularly flexible graphite—are expected to witness robust growth. Below is an analysis of key market trends shaping the graphite gasket material landscape in 2026:

-

Rising Demand from Key End-Use Industries

The oil & gas, chemical processing, power generation, and automotive sectors remain primary consumers of graphite gasket materials. By 2026, increased investments in refinery upgrades, petrochemical expansion in Asia-Pacific, and the global push for cleaner energy infrastructure (including hydrogen and biofuels) will bolster demand. High-temperature and corrosion-resistant properties of graphite make it ideal for sealing applications in extreme environments, supporting its adoption in next-generation industrial equipment. -

Growth in Renewable Energy and Power Applications

The expansion of renewable energy infrastructure—especially concentrated solar power (CSP) and geothermal systems—will drive the need for reliable high-temperature sealing. Graphite gaskets are favored in these applications due to their thermal stability and performance under cyclic temperature conditions. Additionally, nuclear power plant maintenance and life extension projects will continue to rely on graphite-based sealing solutions, supporting market growth. -

Technological Advancements and Composite Innovations

By 2026, manufacturers are expected to focus on developing advanced composite graphite gasket materials that combine enhanced mechanical strength, reduced creep, and improved chemical resistance. Innovations such as graphite reinforced with PTFE, ceramic fibers, or metal inserts will address limitations in traditional flexible graphite, expanding application scope in aerospace, semiconductor manufacturing, and high-pressure systems. -

Sustainability and Regulatory Pressures

Environmental regulations targeting emissions and fugitive leaks (e.g., EPA and EU directives) are pushing industries to adopt low-emission sealing technologies. Graphite gaskets, especially those certified under TA-Luft or ISO 22013 standards, are increasingly specified in compliance-driven projects. Additionally, the recyclability and long service life of graphite contribute to its appeal in sustainable manufacturing practices. -

Geographic Shifts and Supply Chain Dynamics

Asia-Pacific, led by China, India, and South Korea, is expected to dominate the graphite gasket market by 2026 due to rapid industrialization and infrastructure development. However, supply chain vulnerabilities—such as reliance on natural graphite sourced from limited geographic regions (e.g., China and Madagascar)—may prompt investment in synthetic graphite production and vertical integration by key players to ensure material security. -

Competitive Landscape and Market Consolidation

The market is anticipated to see consolidation among mid-tier manufacturers, with larger players expanding their product portfolios through R&D and strategic partnerships. Emphasis on customization, technical support, and digital supply chain integration will differentiate leading suppliers. Companies are also investing in digital twin technologies and predictive maintenance tools to support gasket performance monitoring in critical applications. -

Price Volatility and Raw Material Challenges

Fluctuations in natural graphite prices, driven by mining output, geopolitical factors, and EV battery demand (for graphite in anodes), may impact gasket material costs. Manufacturers are responding by optimizing material usage, developing low-loading formulations, and exploring recycled graphite sources to mitigate input cost volatility.

Conclusion

By 2026, the graphite gasket material market will be characterized by innovation, regulatory alignment, and strategic adaptation to global energy transitions. While challenges related to raw materials and competition from alternative sealing materials (e.g., PTFE or mica-based composites) persist, the unique performance benefits of graphite ensure its continued relevance across critical industrial sectors. Companies that invest in sustainable production, advanced materials, and application-specific solutions will be best positioned to capture growth in this evolving market.

Common Pitfalls When Sourcing Graphite Gasket Material (Quality & Intellectual Property)

Sourcing graphite gasket material—especially flexible graphite or expanded graphite—requires careful attention to both material quality and intellectual property (IP) risks. Overlooking these aspects can lead to performance failures, legal disputes, and supply chain disruptions.

Inconsistent Material Quality and Performance

One of the most frequent challenges is variability in the quality of sourced graphite gasket material. Poor or inconsistent quality can lead to gasket failure under pressure, temperature, or chemical exposure.

- Purity and Ash Content: Low-grade graphite often contains high levels of ash (inorganic residue), which reduces thermal stability and chemical resistance. Sourcing from suppliers without strict quality control can result in batches failing specifications.

- Density and Compressibility: Inconsistent density affects sealing performance. Under-compressed or over-compressed gaskets may leak or damage flanges.

- Tensile Strength and Reinforcement: Unreliable tensile strength—especially in foil or sheet forms—can cause tearing during installation. Reinforcement (e.g., with stainless steel) must be properly bonded and corrosion-resistant.

- Lack of Certification: Suppliers may fail to provide material test reports (MTRs), ASTM/EN compliance documentation (e.g., ASTM F149, EN 12566), or traceability data, making quality assurance difficult.

Intellectual Property (IP) Infringement Risks

Graphite gasket technologies, especially proprietary manufacturing processes or composite formulations, are often protected by patents and trade secrets. Sourcing from unauthorized or non-compliant suppliers exposes companies to legal liability.

- Patented Manufacturing Processes: Leading suppliers (e.g., GrafTech, SGL Carbon, John Crane) hold patents on methods like controlled intercalation and rapid expansion of graphite. Sourcing from manufacturers using similar processes without licensing can lead to infringement claims.

- Branded Materials and Formulations: Some graphite materials are trademarked or associated with specific performance grades (e.g., “Flexitallic Pyrosoft”). Copycat materials may mimic appearance but underperform or violate IP rights.

- Reverse Engineering and Knock-offs: Suppliers in certain regions may produce near-identical copies of patented materials. While appealing due to lower cost, these products can carry significant IP risk and lack performance validation.

- Supply Chain Transparency: Opaque supply chains make it difficult to verify the origin of materials and whether proper IP licenses are held by intermediate suppliers.

Mitigation Strategies

To avoid these pitfalls:

– Require full material certifications and conduct third-party testing for critical applications.

– Audit suppliers for quality systems (e.g., ISO 9001) and traceability.

– Perform IP due diligence, including patent landscape reviews and supplier declarations of freedom to operate.

– Source from reputable, licensed manufacturers and avoid unusually low-cost alternatives with unclear origins.

By proactively addressing both quality consistency and IP compliance, organizations can ensure reliable gasket performance and avoid costly legal and operational setbacks.

Logistics & Compliance Guide for Graphite Gasket Material

Overview

Graphite gasket materials, known for their excellent thermal stability, chemical resistance, and sealing performance in high-temperature and high-pressure environments, are widely used across industries such as oil & gas, power generation, and chemical processing. Proper logistics handling and regulatory compliance are essential to ensure safety, maintain material integrity, and meet international and regional standards.

Classification & Regulatory Identification

- Chemical Name: Natural or expanded graphite (often in flexible or foil form)

- CAS Number: 7782-42-5

- UN Number: Not regulated as hazardous under normal conditions (UN3077, Class 9 may apply if in dust form or mixed with binders)

- HS Code: 3801.10 (for artificial graphite); may vary by country and form (e.g., sheets, rolls, cut gaskets)

Note: If graphite is combined with elastomers, binders, or PTFE, classification may change—verify based on exact composition.

Safety & Handling (OSHA & GHS)

- GHS Classification: Generally not classified as hazardous. However, graphite dust may be irritating to respiratory system and eyes.

- Hazard Statements (if applicable):

- H319: Causes serious eye irritation

- H335: May cause respiratory irritation

- Precautionary Measures:

- Use in well-ventilated areas

- Wear safety goggles and dust masks when handling powdered or cut materials

- Avoid creating airborne dust

- OSHA Compliance: Follow general industry practices for particulate matter; no specific PEL (Permissible Exposure Limit) for graphite, but control dust per 29 CFR 1910.1000 (General Air Contaminants).

Storage & Shelf Life

- Storage Conditions:

- Dry, indoor environment (relative humidity < 60%)

- Avoid exposure to moisture, oils, or corrosive chemicals

- Store flat to prevent warping or creasing

- Shelf Life: Indefinite if stored properly; inspect for contamination or physical damage before use

- Packaging: Typically vacuum-sealed or wrapped in moisture-resistant film; protect from physical damage during storage

Transportation & Shipping

- Domestic (USA – DOT): Generally non-hazardous; no special labeling required unless in fine powder form (may fall under Class 9, UN3077).

- International (IMDG, IATA, ADR):

- Not classified as dangerous goods when in solid sheet or roll form

- If shipped as graphite powder or dust, may require Class 9 labeling (Miscellaneous Dangerous Goods) due to potential respiratory hazard

- Packaging Requirements:

- Secure in sturdy cardboard or wooden crates

- Use edge protectors for rolls to prevent deformation

- Label with product name, batch number, and handling instructions (e.g., “Fragile,” “Keep Dry”)

- Documentation: Commercial invoice, packing list; SDS required under WHMIS (Canada), REACH/CLP (EU), and OSHA HAZCOM (USA)

Environmental & Regulatory Compliance

- REACH (EU): Graphite is listed on the EINECS (231-955-3); no SVHC (Substances of Very High Concern) identified. Declaration may still be required in supply chain.

- RoHS & WEEE (EU): Not applicable—graphite gaskets are typically not electronic components

- TSCA (USA): Graphite is listed on the TSCA Inventory; no significant restrictions

- Prop 65 (California): Graphite is not listed as a carcinogen under Prop 65

- Export Controls: Generally not subject to ITAR or EAR restrictions unless part of a controlled system

Material Safety Data Sheet (MSDS/SDS) Requirements

- Maintain up-to-date SDS (per GHS standards) for each graphite gasket product

- SDS must include:

- Composition/information on ingredients

- First-aid measures

- Fire-fighting measures

- Accidental release measures

- Handling and storage

- Exposure controls/personal protection

- Physical and chemical properties

- Regulatory information

Import & Customs Considerations

- Verify correct HS Code for duty assessment (e.g., 3801.10.0000 in the U.S.)

- Some countries may require import permits or conformity assessments (e.g., INMETRO in Brazil, KC in Korea)

- Ensure invoices include full product description, country of origin, and weight/volume

Disposal & Recycling

- Disposal: Non-hazardous waste in most jurisdictions; dispose of per local solid waste regulations

- Recycling: Graphite is recyclable—return offcuts or used gaskets to supplier or certified recycler where feasible

- Landfill: Permissible in non-hazardous landfills if recycling not available

Best Practices Summary

- Label all shipments clearly with product details and handling instructions

- Train personnel in safe handling, especially when cutting or machining graphite

- Maintain SDS access for all products and ensure availability to customers and emergency responders

- Verify compliance with destination country regulations before export

- Use protective packaging to prevent moisture absorption and physical damage

By following this guide, companies can ensure safe, compliant, and efficient logistics handling of graphite gasket materials across global supply chains.

Conclusion for Sourcing Graphite Gasket Material:

After a thorough evaluation of suppliers, material specifications, performance requirements, and cost considerations, sourcing high-quality flexible graphite gasket material is critical to ensuring reliable sealing performance in high-temperature and high-pressure applications. The selected graphite material should meet industry standards (such as ASTM F149 or EN 1256), offer excellent thermal stability, chemical resistance, and compressibility, and be compatible with the operating environment.

It is recommended to partner with reputable suppliers who provide certified materials, consistent quality control, and technical support. Factors such as lead times, availability of custom fabrication, and long-term supply chain stability should also be considered. Sourcing domestically or from geographically stable regions may reduce logistical risks and enhance sustainability.

In conclusion, prioritizing material quality, supplier reliability, and application-specific performance will ensure optimal gasket performance, reduce downtime, and contribute to the overall safety and efficiency of the system. Establishing a qualified supplier list and conducting periodic performance reviews will further support a robust sourcing strategy for graphite gasket materials.