The global market for graphite casting molds is experiencing robust growth, driven by increasing demand from industries such as automotive, aerospace, and metal processing. According to a report by Grand View Research, the global graphite market size was valued at USD 26.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, fueled by rising adoption of advanced materials in high-temperature applications. Similarly, Mordor Intelligence projects steady growth in graphite-based industrial components, citing advancements in material science and expanding manufacturing capabilities in emerging economies. As precision and thermal stability become critical in metal casting processes, graphite molds have emerged as a preferred choice due to their excellent thermal conductivity, resistance to thermal shock, and long service life. This growing demand has led to the rise of specialized manufacturers worldwide, establishing a competitive landscape of innovation and scalability. In this report, we examine the top nine graphite casting mold manufacturers leading the industry through technological expertise, global reach, and a commitment to quality-driven production.

Top 9 Graphite Casting Molds Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Leading Graphite Mold Manufacturers

Domain Est. 2000

Website: machinedgraphite.com

Key Highlights: Immediately discover graphite mold manufacturers and suppliers in the US who are leading ISO certified companies that have teams of experienced engineers….

#2 Graphite Permanent Mold Casting

Domain Est. 2004

Website: albco.com

Key Highlights: We provide a superior alternative to traditional casting techniques by utilizing graphite permanent mold technology (GPMT) to produce net and near shape parts….

#3 Graphite Permanent Molds

Domain Est. 2004 | Founded: 1984

Website: forestcitycastings.com

Key Highlights: Graphite Permanent Mold Technology (GPMT) began in the late 1970’s and our professional team has been working with this technology since 1984. With this ……

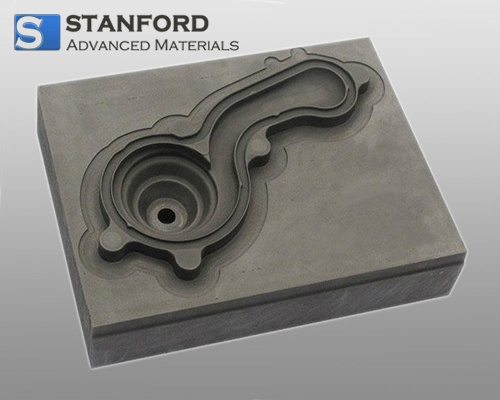

#4 China Graphite Mold, Graphite Block, Graphite Plate Manufacturers …

Domain Est. 2019

Website: graphitemolds.com

Key Highlights: We are engaged in manufacturing, researching and selling all kinds of graphite products, such as EDM graphite mold, graphite rod, graphite block, graphite ……

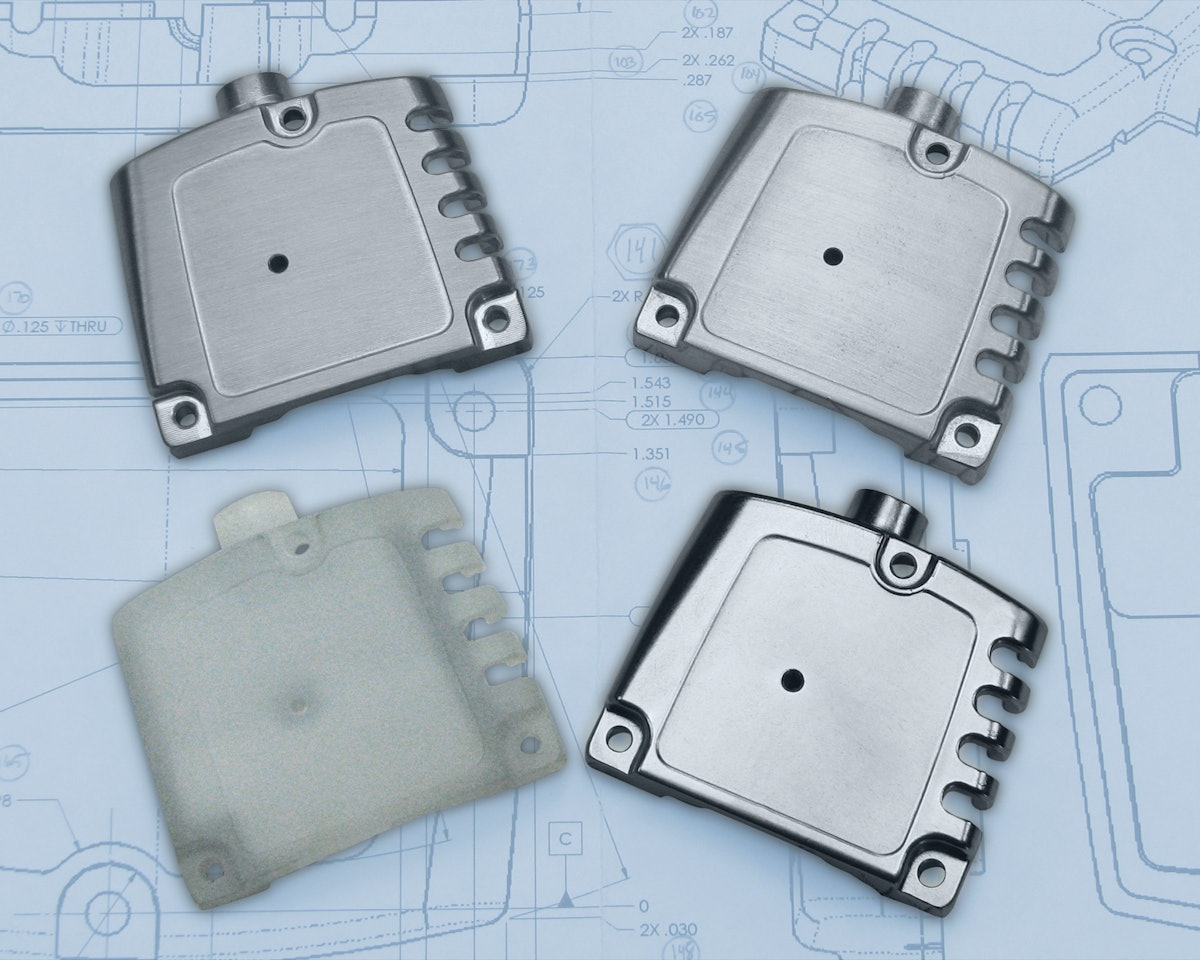

#5 Graphicast

Domain Est. 1999

Website: graphicast.com

Key Highlights: Our graphite mold casting process combines with zinc-aluminum alloy to produce metal castings with tighter tolerances, better finishes, & lower costs….

#6 Graphite Ingot Molds, 3D Molds & Other Accessories

Domain Est. 2013

#7 Graphite Customs

Domain Est. 2014

Website: graphitecustoms.com

Key Highlights: Graphite Customs creates high quality graphite molds for all glass and silver arts….

#8 Masterwork Graphite

Domain Est. 2020

Website: masterworkproducts.com

Key Highlights: Custom Graphite Molds. Made In The USA. Superior Quality. Great For Silver, Gold, Aluminum. Cast Your Coins, Bars, Jewelry & More!…

#9 Gontermann Peipers – Foundry since 1825

Website: gontermann-peipers.de

Key Highlights: We manufacture cast components using a wide range of processes, including chill casting, spincasting, continuous casting and classical hand-mold casting….

Expert Sourcing Insights for Graphite Casting Molds

H2: 2026 Market Trends for Graphite Casting Molds

The global market for graphite casting molds is poised for significant transformation by 2026, driven by advancements in material science, rising demand from high-growth industries, and a shift toward sustainable manufacturing practices. Graphite’s unique properties—such as high thermal conductivity, resistance to thermal shock, and excellent machinability—make it an ideal material for casting molds in sectors like aerospace, automotive, semiconductor, and renewable energy. Below are key trends expected to shape the graphite casting mold market in 2026:

-

Increased Demand from the Semiconductor Industry

The semiconductor sector is a primary growth driver for graphite casting molds, particularly in the production of silicon ingots used in solar panels and electronic components. As global investments in chip manufacturing expand—fueled by digitalization and AI development—demand for high-purity graphite molds used in directional solidification and Czochralski processes will rise significantly by 2026. -

Growth in Electric Vehicle (EV) and Battery Manufacturing

The EV revolution is increasing the need for advanced battery materials, including silicon anodes. Graphite molds are essential in producing silicon wafers and battery-grade materials. With automakers ramping up EV production targets for 2026, the demand for precision graphite molds in metallurgical-grade casting and forming processes is expected to grow steadily. -

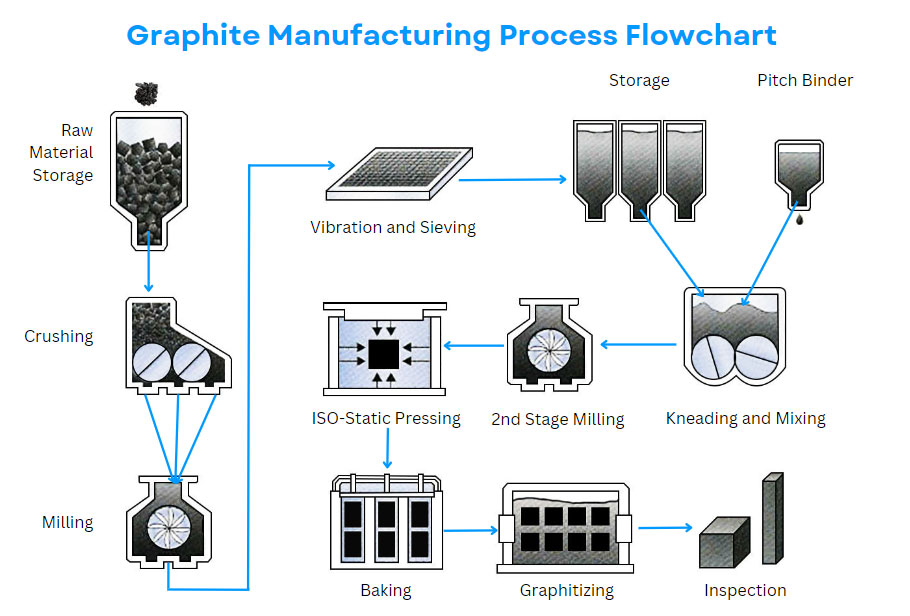

Adoption of Isostatically Pressed and High-Purity Graphite

Manufacturers are increasingly favoring isostatically pressed graphite due to its uniform structure and enhanced thermal stability. By 2026, high-purity and fine-grained graphite grades will dominate the casting mold market, especially in applications requiring tight tolerances and minimal contamination, such as in aerospace turbine blade casting. -

Regional Manufacturing Shifts and Supply Chain Localization

Geopolitical factors and supply chain resilience concerns are prompting companies to localize production. In 2026, North America and Europe are expected to increase domestic graphite mold manufacturing, reducing reliance on traditional suppliers in Asia. However, China will remain a key player due to its established graphite production infrastructure and cost advantages. -

Sustainability and Recycling Initiatives

Environmental regulations are pushing manufacturers to adopt greener practices. Graphite is recyclable, and by 2026, closed-loop recycling systems for spent molds are expected to become more common. Innovations in reprocessing used graphite into secondary molds will support circular economy goals and reduce raw material dependency. -

Integration of Digital Design and Additive Manufacturing

The use of CAD/CAM systems and 3D printing (additive manufacturing) for custom graphite molds is gaining traction. By 2026, digital twin technologies and AI-driven mold design optimization are expected to enhance precision, reduce lead times, and lower production costs, particularly for complex mold geometries. -

Price Volatility and Raw Material Constraints

Fluctuations in the prices of petroleum coke and coal tar pitch—key raw materials for synthetic graphite—may impact production costs. In 2026, companies are likely to invest in alternative raw materials and synthetic graphite alternatives to mitigate supply risks and maintain profitability.

In conclusion, the 2026 graphite casting mold market will be shaped by technological innovation, industry-specific demands, and sustainability imperatives. Companies that invest in high-performance materials, digital manufacturing tools, and eco-friendly practices are expected to lead the market in this evolving landscape.

Common Pitfalls Sourcing Graphite Casting Molds: Quality and Intellectual Property Risks

Sourcing graphite casting molds involves critical considerations beyond cost and lead time. Two major pitfalls—compromised quality and intellectual property (IP) exposure—can significantly impact production efficiency, product integrity, and competitive advantage. Understanding and mitigating these risks is essential for successful procurement.

Quality-Related Pitfalls

Poor quality in graphite casting molds directly affects casting integrity, tool life, and operational costs. Key quality pitfalls include:

-

Inconsistent Material Purity and Grain Structure: Low-grade or inconsistently processed graphite can lead to mold cracking, poor thermal shock resistance, and surface defects in castings. Impurities or uneven grain distribution increase the risk of premature mold failure.

-

Inadequate Machining Precision: Molds that lack dimensional accuracy or surface finish consistency result in flawed castings requiring rework or causing production downtime. Poor CNC machining or lack of quality control leads to deviations from design specifications.

-

Insufficient Testing and Certification: Suppliers who do not provide material certifications (e.g., ASTM standards), density testing, or thermal stability reports make it difficult to verify mold performance under real operating conditions.

-

Unreliable Supplier Quality Control Processes: Sourcing from manufacturers without robust in-house quality assurance systems increases the risk of receiving defective or non-conforming molds, especially in high-volume orders.

Intellectual Property (IP) Risks

Graphite mold designs often embody proprietary engineering and process know-how. When outsourcing, IP exposure becomes a significant concern:

-

Lack of IP Protection Agreements: Engaging suppliers without signed Non-Disclosure Agreements (NDAs) or IP ownership clauses leaves design data vulnerable to misuse or replication.

-

Unsecured Design File Transfers: Sending CAD or CAM files to suppliers without encryption or access controls increases the risk of data leaks or unauthorized duplication.

-

Supplier Subcontracting Without Oversight: Some suppliers outsource mold fabrication to third parties without informing the buyer, potentially exposing designs to unveted entities with weak IP safeguards.

-

Risk of Reverse Engineering or Market Competition: In regions with lax IP enforcement, there is a heightened risk that mold designs could be copied and sold to competitors or used to manufacture and sell similar cast products.

Mitigation Strategies

To avoid these pitfalls, implement a structured sourcing approach:

- Vet suppliers based on material traceability, quality certifications (e.g., ISO 9001), and in-house machining capabilities.

- Require sample testing and conduct on-site or third-party audits when possible.

- Establish legal agreements that clearly define IP ownership and confidentiality obligations.

- Use secure data-sharing platforms and limit access to critical design information.

- Consider dual-sourcing or maintaining in-house core mold designs to reduce dependency and exposure.

By proactively addressing quality and IP concerns, companies can ensure reliable performance from graphite casting molds while protecting their competitive innovations.

Logistics & Compliance Guide for Graphite Casting Molds

This guide outlines key considerations for the safe, efficient, and compliant handling, transportation, and regulatory management of graphite casting molds throughout the supply chain.

Packaging and Handling

Graphite casting molds are fragile and susceptible to chipping, cracking, or contamination. Proper packaging and handling are critical to prevent damage during transit and storage.

- Use rigid, crush-resistant outer packaging (e.g., wooden crates or heavy-duty corrugated boxes with edge protection).

- Secure each mold individually using custom-cut foam inserts, bubble wrap, or molded pulp to prevent movement.

- Clearly label packages with “Fragile,” “This Side Up,” and “Handle with Care” markings.

- Avoid stacking excessive weight on packed molds.

- Handle molds with clean gloves to prevent oil and moisture transfer from skin, which can affect performance.

Storage Conditions

Maintain optimal storage environments to preserve mold integrity and performance.

- Store in a dry, climate-controlled area with stable temperature and humidity (ideally 20–25°C and <60% RH).

- Keep molds off the floor on pallets or shelves to avoid moisture absorption and physical damage.

- Protect from dust, dirt, and chemical vapors by storing in sealed plastic bags or containers when not in use.

- Avoid exposure to direct sunlight or heat sources that may cause thermal stress or degradation.

Transportation Requirements

Ensure safe and compliant shipping across domestic and international routes.

- Use freight carriers experienced in handling industrial ceramics and fragile materials.

- For air freight, comply with IATA Dangerous Goods Regulations—graphite itself is non-hazardous, but check for any impregnated resins or coatings that may have classification implications.

- For ocean or ground transport, secure packages to prevent shifting; use stretch wrap and load-locking methods in containers or trailers.

- Provide clear shipping documentation including item description, weight, dimensions, and handling instructions.

Regulatory Compliance

Adhere to international, national, and regional regulations governing the shipment and use of graphite products.

- Export Controls: Verify if molds meet criteria under export control regimes such as the Wassenaar Arrangement, especially if used in aerospace, defense, or advanced manufacturing. High-precision or custom graphite molds may require export licenses.

- Customs Documentation: Include accurate Harmonized System (HS) codes (commonly 8105.20 or 8105.90 for semi-finished or finished graphite products) on commercial invoices and packing lists.

- REACH & RoHS (EU): Confirm that molds are free from restricted substances. Graphite is typically compliant, but verify any binders, coatings, or impregnants used in manufacturing.

- TSCA (USA): Ensure compliance with the Toxic Substances Control Act—carbon-based materials like graphite are generally exempt, but documentation may be required upon import.

Safety and Environmental Considerations

Address workplace safety and environmental responsibilities related to graphite mold handling.

- Implement dust control measures when machining or repairing molds, as graphite dust can be combustible and pose respiratory risks. Use local exhaust ventilation and approved respirators.

- Provide Material Safety Data Sheets (MSDS/SDS) for molds, particularly if they contain resins, metals, or other additives.

- Dispose of damaged or spent molds in accordance with local waste regulations. Graphite is non-toxic but may be classified as industrial waste; recycling through specialized facilities is recommended.

Quality Assurance and Traceability

Maintain documentation to support compliance and quality control.

- Implement batch tracking and serialization for molds to enable traceability.

- Retain records of material certifications, manufacturing processes, and compliance checks.

- Conduct regular inspections upon receipt and before use to verify dimensional accuracy and structural integrity.

By following this guide, companies can ensure reliable logistics performance and full compliance when managing graphite casting molds across global operations.

Conclusion for Sourcing Graphite Casting Molds

Sourcing graphite casting molds requires a strategic approach that balances quality, cost, and reliability. Graphite molds are essential in various high-temperature casting processes due to their excellent thermal stability, resistance to thermal shock, and machinability. When selecting suppliers, it is crucial to evaluate factors such as material purity, dimensional accuracy, machining capabilities, and the supplier’s experience in serving similar industries—such as metal casting, semiconductor manufacturing, or aerospace.

Prioritizing suppliers that offer consistent quality control, customization options, and technical support ensures long-term performance and reduced downtime. Additionally, considering lead times, pricing, and after-sales service contributes to a more efficient supply chain. Whether sourcing domestically or internationally, establishing strong vendor relationships and conducting regular performance assessments will help maintain the integrity and efficiency of casting operations.

In conclusion, a well-informed sourcing strategy for graphite casting molds—one that emphasizes material quality, supplier reliability, and total cost of ownership—will significantly enhance production efficiency, mold lifespan, and overall product quality.