The global granite tool supplies market is experiencing robust growth, driven by increasing demand from construction, mining, and stone processing industries. According to Grand View Research, the global stone tools market was valued at USD 5.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030, fueled by advancements in tooling technology and rising infrastructure investments worldwide. Similarly, Mordor Intelligence projects steady expansion in the stone cutting and processing tools sector, with particular growth in Asia-Pacific due to urbanization and industrialization trends. As granite remains a preferred material for countertops, flooring, and architectural elements, the need for high-performance tooling—such as diamond blades, grinding pads, and cutting saws—has intensified. This convergence of market dynamics has elevated the prominence of specialized manufacturers who combine innovation, durability, and precision in their product offerings. The following list highlights the top 10 granite tool supplies manufacturers shaping this evolving landscape.

Top 10 Granite Tool Supplies Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 GranQuartz

Domain Est. 1997

Website: granquartz.com

Key Highlights: The largest distributor of stone fabrication tools, equipment and supplies in the U.S., and provider of top quality products to the concrete, tile and ……

#2 The Eastern Marble And Granite Supplies, New Jersey

Domain Est. 1997

Website: easternmarble.com

Key Highlights: The Eastern Marble And Granite Supply Company, New Jersey – The Authentic Provider Of Stone Tool Supplies and Machinery. Learn More….

#3 Granite City Tool Co.

Domain Est. 1999

Website: granitecitytoolvt.com

Key Highlights: Granite City Tool Company of Vermont is an international distributor of Granite Tools, Stone Tools and Monument Supplies for the fabrication of stone….

#4 Granite Tools Fabrication Installation Supplies Abaco Lifters Forklift …

Domain Est. 2002

#5 Direct Stone Tool Supply, Inc

Domain Est. 2012

Website: stonetoolsupply.com

Key Highlights: Looking for high-quality epoxy and stone tooling supplies? Our store offers a wide range of products such as diamond blades, core bits, stone polishers and ……

#6 USA Granite Tools

Domain Est. 2014

#7 Granite Design

Domain Est. 2016

Website: granite-design.com

Key Highlights: Discover Granite Design: premium tools and storage solutions for bike and MTB. Shop tool kits, mounts, and accessories designed for performance and durability….

#8 Universal Stone Solutions

Domain Est. 2019

Website: universalstonesolutions.com

Key Highlights: We are the distributor of tools, equipment, chemicals, and everything in between for granite or stone fabrication, construction, restoration, and more….

#9 All World Stone Supply, granite tools for contractors installers

Domain Est. 2020

Website: granitetoolssupply.com

Key Highlights: Ggranite tools for installation, fabrication and materials handling, Diamond Blades, Polishing Pads, Grinding Diamond cup wheels, Power tools, ……

#10 Granite Tool Supply

Website: granitetoolsupply-store.com

Key Highlights: top of page. Your One-Stop Shop for Quality Granite and Marble Tools. We’re Here to Help! Call Us at (888) 385-5316….

Expert Sourcing Insights for Granite Tool Supplies

H2: 2026 Market Trends Forecast for Granite Tool Supplies

Based on current industry trajectories, technological advancements, and macroeconomic indicators, Granite Tool Supplies can expect a dynamic and evolving market landscape in 2026. Success will hinge on strategic adaptation to key trends:

1. Accelerated Digital Transformation & E-Commerce Dominance

- Trend: B2B procurement, including industrial tools, will increasingly shift online. Customers (contractors, manufacturers, maintenance teams) will expect seamless digital experiences comparable to B2C.

- Impact on Granite: Expect heightened demand for a robust, user-friendly e-commerce platform with advanced search (by tool type, brand, application, compatibility), real-time inventory, personalized recommendations, and integrated procurement tools (e.g., punchout catalogs for large clients). Mobile optimization will be non-negotiable.

- Opportunity: Invest in platform capabilities, data analytics for customer insights, and digital marketing (SEO, targeted ads). Offer value-added digital services like online tool selection guides or AR/VR for product visualization.

2. Sustainability & Circular Economy Integration

- Trend: Environmental, Social, and Governance (ESG) pressures and customer demand will intensify. Focus will shift towards sustainable sourcing, reduced packaging waste, energy-efficient tools, and end-of-life solutions.

- Impact on Granite: Customers will increasingly favor suppliers with transparent, sustainable practices. Demand for remanufactured/refurbished tools, tool take-back programs, and partnerships with eco-conscious brands will grow.

- Opportunity: Develop a clear sustainability strategy. Offer certified refurbished tools, promote energy-efficient product lines (e.g., battery-powered), audit supply chain sustainability, and implement recycling/reuse programs. Communicate these efforts effectively.

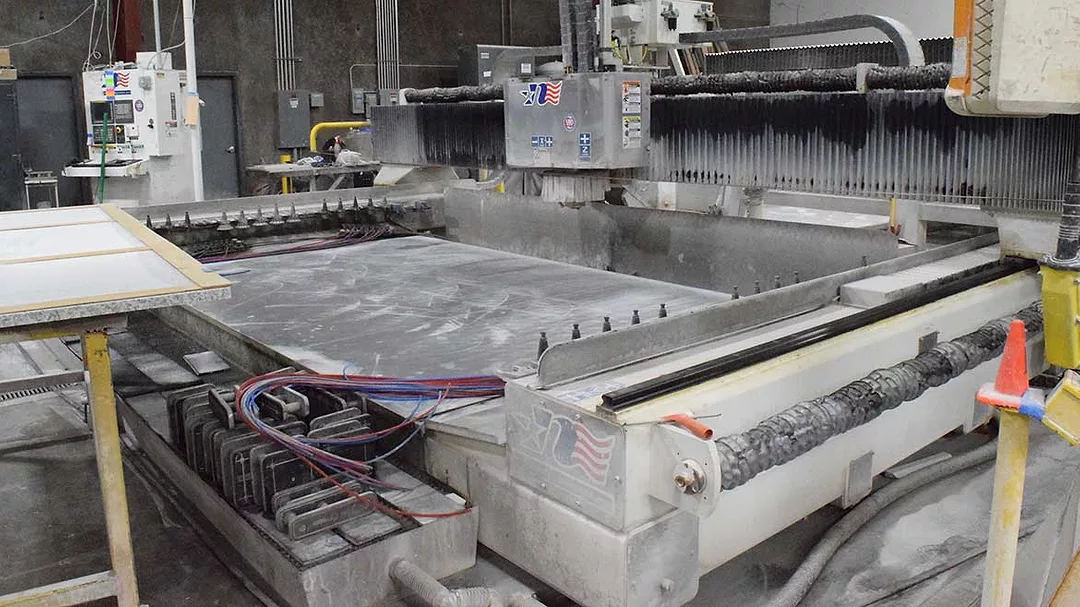

3. Advanced Tool Technology & Smart Equipment

- Trend: Integration of IoT, AI, and connectivity into tools (e.g., smart drills, torque wrenches with data logging, predictive maintenance sensors) will become mainstream, driven by Industry 4.0 and efficiency demands.

- Impact on Granite: Granite will need to expand expertise beyond traditional tool sales. Requires knowledge of data platforms, connectivity standards, and value proposition of smart tools (productivity, safety, maintenance).

- Opportunity: Become a solutions provider, not just a supplier. Offer bundled packages (tools + software + data services), provide training on smart tool utilization, and develop partnerships with leading tech-integrated tool manufacturers.

4. Supply Chain Resilience & Localization/Regionalization

- Trend: Geopolitical instability and past disruptions have made resilience paramount. Companies are diversifying suppliers, increasing inventory buffers for critical items, and exploring nearshoring/regional sourcing.

- Impact on Granite: Expect customer demand for guaranteed supply, shorter lead times, and transparency into supply chain risks. Reliance on single-source, distant suppliers will be a vulnerability.

- Opportunity: Strengthen relationships with multiple suppliers, consider strategic regional warehousing for high-demand items, invest in supply chain visibility technology, and develop contingency plans. Offer supply chain security as a key differentiator.

5. Skilled Labor Shortage & Focus on Productivity/Training

- Trend: The shortage of skilled tradespeople (welders, machinists, technicians) will persist, driving demand for tools and solutions that maximize productivity and reduce skill barriers.

- Impact on Granite: Customers will prioritize tools that are easier to use, require less setup, and enhance output per worker. Demand for training resources and support will increase.

- Opportunity: Promote tools known for ease of use, durability, and productivity gains. Expand value-added services: comprehensive online training videos, downloadable guides, application engineering support, and on-site training partnerships. Position Granite as a productivity partner.

6. Consolidation & Competitive Pressure

- Trend: The industrial distribution sector may see continued consolidation. Competition will come from large national/international distributors, specialized online players, and direct-from-manufacturer sales.

- Impact on Granite: Pricing pressure will remain significant. Differentiation through service, expertise, and relationships will be critical for survival.

- Opportunity: Double down on customer relationships and personalized service (especially for regional accounts). Leverage local presence for faster delivery and support. Focus on niche expertise or specific high-demand sectors where personal touch matters most.

Conclusion for Granite Tool Supplies:

The 2026 market will demand agility, technological adoption, and a shift towards value-added services. Granite’s success will depend on embracing digitalization, embedding sustainability, building expertise in smart tools, ensuring supply chain robustness, and supporting customers in overcoming the skills gap. Moving beyond transactional relationships to become a trusted advisor and productivity partner will be essential to thrive in this competitive and evolving landscape. Proactive investment in these areas now is crucial for 2026 readiness.

Common Pitfalls When Sourcing Granite Tool Supplies (Quality, IP)

Sourcing granite tool supplies—such as precision surface plates, inspection tables, or granite components for machinery—requires careful attention to both quality and intellectual property (IP) concerns. Overlooking these aspects can lead to performance issues, safety risks, and legal complications. Below are key pitfalls to avoid:

Poor Material Quality and Specifications

One of the most frequent issues is receiving granite that does not meet required standards for flatness, hardness, or grain structure. Suppliers may use lower-grade stone that wears quickly or lacks thermal stability, compromising measurement accuracy. Always verify compliance with international standards like ISO 8512 or ASTM E240.

Inadequate Certification and Traceability

Reputable suppliers provide material certification, including source quarry information and test reports for flatness and stability. Lack of documentation can indicate questionable sourcing practices and make it difficult to trace defects or ensure consistency across batches.

Misrepresentation of Grade and Tolerance

Some suppliers misleadingly label commercial-grade granite as “precision-grade” to cut costs. This can result in tools that fail under rigorous industrial use. Ensure clear specifications are provided and independently verified through third-party inspection when necessary.

Ignoring Intellectual Property in Tool Design

When sourcing custom-designed granite tooling (e.g., fixtures or gauges), there is a risk of inadvertently using designs protected by patents or copyrights. Working with suppliers who copy existing OEM designs without licensing exposes your company to IP infringement claims, litigation, and product recalls.

Lack of IP Agreements in Contracts

Failing to define IP ownership in sourcing agreements is a major oversight. Without clear contracts, the supplier may retain rights to custom tool designs, limiting your ability to reproduce or modify the tooling. Always include IP clauses that assign ownership to your organization for custom work.

Counterfeit or Replica Components

In global markets, counterfeit granite tools or replica calibration fixtures may be sold as genuine. These often use substandard materials and replicate trademarked designs, violating IP laws. Source from vetted suppliers and conduct factory audits to mitigate this risk.

Insufficient Due Diligence on Suppliers

Choosing suppliers based solely on cost without evaluating their manufacturing processes, quality control systems, or legal compliance increases exposure to both quality failures and IP violations. Conduct thorough supplier audits and request references from other industrial clients.

By addressing these pitfalls proactively—through rigorous supplier vetting, clear contractual terms, and independent quality verification—companies can ensure reliable performance and legal compliance when sourcing granite tool supplies.

Logistics & Compliance Guide for Granite Tool Supplies

This guide outlines the essential logistics and compliance procedures to ensure efficient operations, legal adherence, and customer satisfaction at Granite Tool Supplies. All employees involved in shipping, receiving, inventory management, and regulatory compliance must follow these protocols.

Order Fulfillment Process

All customer orders must be processed within 24 hours of receipt. Orders are prioritized based on delivery deadlines and shipping method. Each order undergoes a three-step verification: product selection, quantity check, and packing slip validation. Only after quality assurance approval can the shipment proceed to dispatch.

Inventory Management Standards

Maintain real-time inventory records using the company’s ERP system. Conduct monthly cycle counts and annual full audits. Report discrepancies exceeding 2% variance immediately to the Logistics Manager. Store hazardous materials (e.g., cutting fluids) in designated, labeled zones with appropriate safety measures.

Domestic Shipping Procedures

Use approved carriers (FedEx, UPS, and regional freight partners) based on destination, weight, and delivery urgency. All packages must be double-checked for correct labeling, proper packaging, and freight classification. Retain shipping documentation for a minimum of three years.

International Shipping & Export Compliance

Comply with U.S. Department of Commerce Export Administration Regulations (EAR) and Bureau of Industry and Security (BIS) guidelines. Obtain required export licenses for controlled items. Accurately complete commercial invoices, packing lists, and Shipper’s Letters of Instruction. Sanctioned countries (e.g., Cuba, Iran, North Korea, Syria, and Crimea) are off-limits for shipments without explicit legal authorization.

Import Regulations & Customs Clearance

Ensure all imported tools and raw materials comply with U.S. Customs and Border Protection (CBP) requirements. Provide accurate Harmonized Tariff Schedule (HTS) codes, country of origin, and declared values. Retain import records, including bills of lading and entry filings, for five years as mandated by 19 CFR § 163.102.

Hazardous Materials Handling

Any product classified as hazardous (e.g., flammable liquids, compressed gases) must be stored, labeled, and shipped in compliance with OSHA Hazard Communication Standard (29 CFR 1910.1200) and DOT 49 CFR regulations. Employees must complete HAZMAT training annually and wear appropriate PPE when handling such materials.

Recordkeeping & Audit Readiness

Maintain organized electronic and physical records for all logistics transactions, compliance certifications, training logs, and safety data sheets (SDS). The compliance team conducts bi-annual internal audits. All departments must be audit-ready at all times with documentation accessible within 24 hours of request.

Environmental & Sustainability Compliance

Follow EPA guidelines for waste disposal, including used oil, metal shavings, and packaging materials. Recycle whenever possible and document waste management practices. Granite Tool Supplies commits to reducing carbon emissions by optimizing delivery routes and using recyclable packaging materials.

Incident Reporting & Corrective Actions

Immediately report logistics errors, compliance violations, or safety incidents to the Compliance Officer. Complete an Incident Report Form within 48 hours. A root cause analysis will be conducted, and corrective actions implemented to prevent recurrence.

Training & Responsibilities

All logistics and warehouse staff must complete onboarding training covering compliance policies, safety protocols, and ERP usage. Supervisors are responsible for ensuring team adherence and updating staff on regulatory changes. Training certifications are valid for one year and must be renewed annually.

In conclusion, sourcing granite tool supplies requires a strategic approach that balances quality, cost, reliability, and long-term sustainability. By carefully evaluating suppliers based on their material quality, manufacturing standards, certifications, and track record, businesses can ensure they obtain durable and precision-engineered tools suited for demanding applications. Establishing strong partnerships with reputable suppliers, considering both domestic and international options, and conducting regular performance assessments contribute to a resilient supply chain. Additionally, prioritizing ethical sourcing and environmental responsibility aligns with modern industry standards and enhances brand reputation. Ultimately, a well-executed sourcing strategy for granite tool supplies not only supports operational efficiency and product reliability but also provides a competitive advantage in the market.