The global natural stone market, driven by rising demand for premium architectural materials in residential and commercial construction, is experiencing steady growth. According to Mordor Intelligence, the natural stone market was valued at USD 38.5 billion in 2023 and is projected to grow at a CAGR of 6.2% through 2029. Granite, prized for its durability, aesthetic appeal, and resistance to weathering, represents a significant share of this demand—particularly in high-traffic structural applications such as stairs. As urban development accelerates and luxury design trends favor timeless materials, granite stairs have become a hallmark of high-end construction. This growing demand has elevated the importance of reliable, precision-focused manufacturers capable of blending craftsmanship with scalable production. In response, a select group of producers have emerged as leaders in quality, innovation, and global reach. The following list highlights the top nine granite stairs manufacturers shaping the industry through technical expertise, sustainability initiatives, and consistent delivery of high-performance stone solutions.

Top 9 Granite Stairs Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

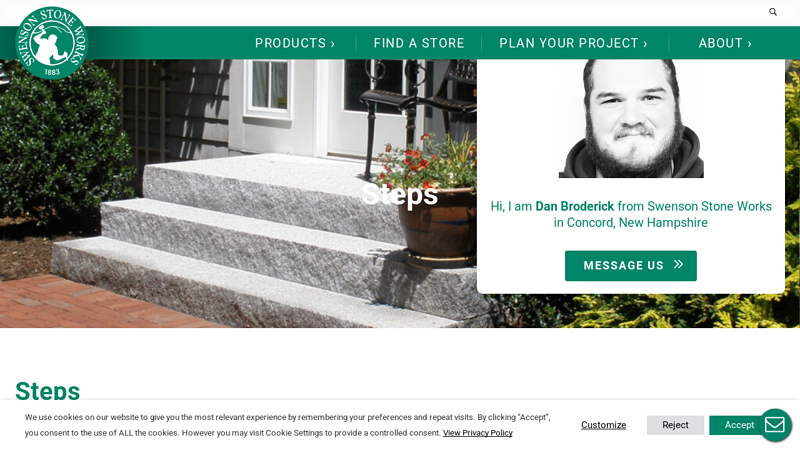

#1 Steps

Domain Est. 1999

Website: swensongranite.com

Key Highlights: These natural stone steps. With their impressive density, stone steps do not experience the effects of spalling and cracking associated with concrete steps….

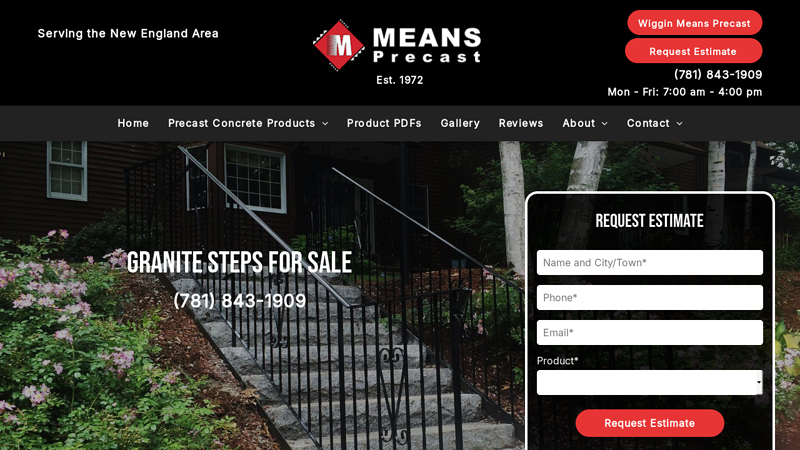

#2 Granite Steps Sales

Domain Est. 2001 | Founded: 1972

Website: meansprecast.com

Key Highlights: Discover the beauty of granite steps from Means Precast in New England. Unmatched durability, non-slip surface, salt & weather-resistant. Since 1972….

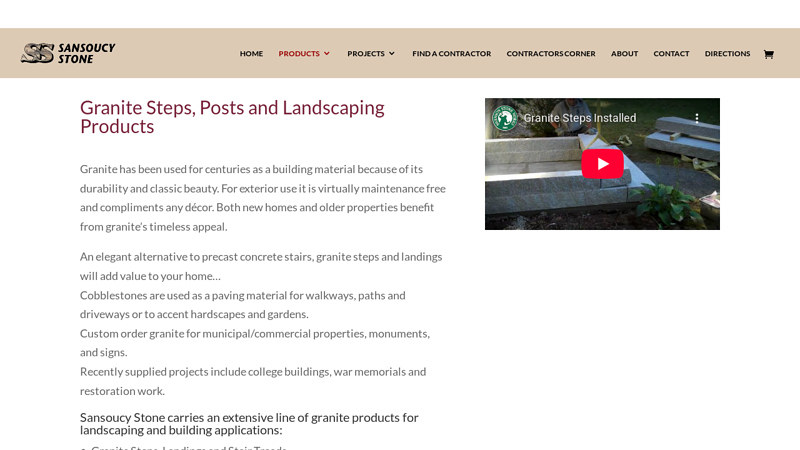

#3 Granite Steps & Landscape Products

Domain Est. 2003

Website: sansoucystone.com

Key Highlights: An elegant alternative to precast concrete stairs, granite steps and landings will add value to your home….

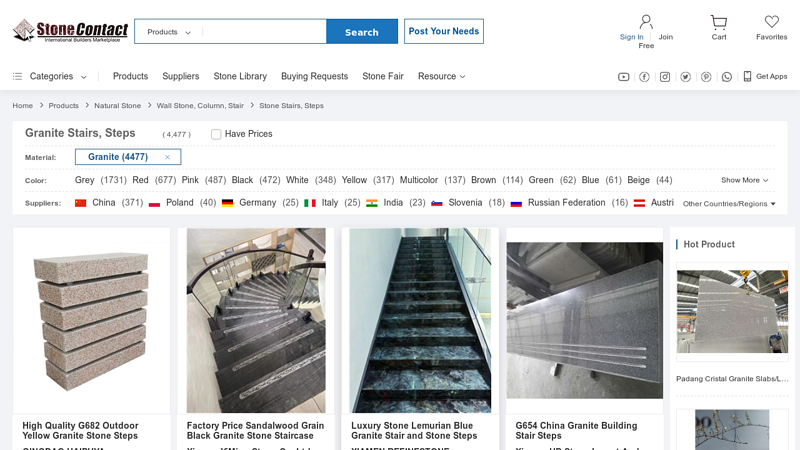

#4 Granite Stairs, Steps

Domain Est. 2003

Website: stonecontact.com

Key Highlights: Natural stone stairs are available in different colours, designs, shapes, materials and styles to custom fit any interior decor and requirement. Treads(Steps) – ……

#5 Stone Steps + Treads

Domain Est. 2006

#6 Granite Steps Design in Durham, CT

Domain Est. 2007

Website: torrisonstone.com

Key Highlights: Enhance your home’s entrance with custom granite steps from Torrison Stone & Garden in Durham, CT. Expert design & installation….

#7 Coldspring

Domain Est. 2012

Website: coldspringusa.com

Key Highlights: Coldspring | Over 125 years of experience quarrying and fabricating granite and natural stone for stunning memorial and commercial projects….

#8 GraniteShares YieldBOOST NVDA (NVDA) ETF

Domain Est. 2016

Website: graniteshares.com

Key Highlights: GraniteShares YieldBOOST NVDA ETF (NVYY) aims to generate weekly income by selling options on leveraged NVDA ETFs. NVYY is available on the NASDAQ….

#9 Chinese Granite Steps Supplier

Domain Est. 2020

Website: externalgranite.com

Key Highlights: Yantai External Granite supplies a wide range of granite steps that meet both private and commercial purposes. Our offerings include cast stone steps, curved ……

Expert Sourcing Insights for Granite Stairs

2026 Market Trends for Granite Stairs

As the construction and interior design industries evolve, granite stairs continue to hold a prominent place in high-end residential and commercial projects. Looking ahead to 2026, several key trends are expected to shape the demand, design, and distribution of granite staircases. This analysis explores major market dynamics, technological advancements, consumer preferences, and sustainability factors influencing the granite stairs sector.

Rising Demand in Luxury Residential Construction

The luxury housing market is projected to grow steadily through 2026, particularly in urban centers and high-net-worth regions such as North America, Western Europe, and parts of Asia. Granite stairs, known for their durability and elegance, remain a preferred choice in upscale homes. Custom-designed granite staircases with intricate finishes—such as flamed, honed, or polished surfaces—are increasingly sought after to enhance aesthetic appeal. Architects and designers are integrating granite stairs as focal points in open-concept layouts, further boosting demand.

Shift Toward Sustainable and Ethically Sourced Materials

Environmental awareness is reshaping consumer behavior. By 2026, buyers are expected to prioritize sustainability in building materials. The granite industry is responding by adopting more transparent supply chains and promoting responsibly quarried stone. Certifications such as ISO 14001 and adherence to green building standards (e.g., LEED, BREEAM) will become significant differentiators for suppliers. Additionally, water recycling in polishing plants and reduced carbon footprints in transportation are becoming essential competitive advantages.

Growth in Prefabricated and Modular Granite Stair Systems

Technological advancements in CNC machining and 3D modeling are enabling the rise of prefabricated granite stair systems. These modular solutions offer faster installation, reduced labor costs, and higher precision. In 2026, the market will see increased adoption of factory-cut granite stair components, especially in commercial developments and multi-unit residential buildings. This trend supports just-in-time delivery models and minimizes on-site waste, aligning with lean construction practices.

Influence of Design Trends and Color Preferences

Design trends continue to favor neutral and earth-toned palettes. In 2026, popular granite varieties for stairs are expected to include Absolute Black, Imperial Red, Baltic Brown, and White Galaxy. Textured finishes that improve slip resistance without compromising aesthetics are gaining favor, especially for outdoor and high-traffic installations. Integration with complementary materials—such as glass railings, stainless steel balusters, or wooden handrails—will enhance visual appeal and functionality.

Expansion in Emerging Markets

While mature markets in North America and Europe remain strong, emerging economies in Southeast Asia, the Middle East, and parts of Latin America are showing growing interest in premium building materials. Urbanization, rising disposable incomes, and the proliferation of luxury real estate developments are driving demand for granite stairs in hotels, villas, and high-end retail spaces. Local fabrication capabilities are improving, reducing reliance on imports and supporting regional market growth.

Challenges and Competitive Pressures

Despite positive trends, the granite stairs market faces challenges. Competition from engineered stone (e.g., quartz) and alternative natural stones like marble and limestone is intensifying. Price volatility in raw granite due to geopolitical factors and supply chain disruptions remains a concern. Moreover, skilled labor shortages in stone fabrication could impact delivery timelines and customization capabilities.

Conclusion

By 2026, the granite stairs market is poised for steady growth, driven by luxury construction, technological innovation, and evolving design preferences. Success will depend on a supplier’s ability to balance aesthetics with sustainability, embrace digital fabrication, and adapt to regional market dynamics. Companies that invest in eco-friendly practices, modular solutions, and design versatility are likely to lead the market in the coming years.

Common Pitfalls When Sourcing Granite Stairs (Quality and Intellectual Property)

Sourcing granite stairs for architectural or construction projects involves more than just selecting an aesthetically pleasing stone. Quality inconsistencies and intellectual property (IP) concerns can lead to significant project delays, cost overruns, and legal complications. Being aware of the following pitfalls can help mitigate risks.

Quality-Related Pitfalls

Inconsistent Material Quality and Grading

Granite varies widely in density, hardness, and mineral composition. Suppliers may provide stones that appear visually similar but differ in structural integrity. Without standardized grading, lower-quality granite may be prone to chipping, cracking, or wear—especially in high-traffic stair applications.

Lack of Certifications and Testing Documentation

Reputable granite should come with certification for physical properties such as compressive strength, water absorption, and slip resistance. Failing to verify these documents can result in sourcing material unsuitable for stair use, posing safety hazards and potential code violations.

Poor Surface Finishing and Dimensional Accuracy

Granite stairs require precise cutting and polishing to ensure uniform tread depth, riser height, and edge profiles. Inaccurate fabrication can lead to uneven steps, tripping hazards, and costly on-site modifications. Some suppliers may cut corners on finishing to reduce costs, compromising both safety and aesthetics.

Inadequate Sealing and Treatment

Untreated granite is porous and vulnerable to staining, moisture penetration, and freeze-thaw damage—particularly in outdoor or high-moisture environments. If the supplier does not apply or verify proper sealing, long-term durability may be compromised.

Unreliable Supply Chain and Lead Times

Granite sourcing often involves international logistics. Delays due to quarry availability, shipping issues, or customs can disrupt project timelines. Relying on suppliers without proven track records increases the risk of missed deadlines.

Intellectual Property (IP) Pitfalls

Use of Copycat or Imitation Designs

Some suppliers replicate patented stair designs, custom profiles, or architectural details without authorization. Using such components may expose architects, contractors, or developers to IP infringement claims, even if unintentional.

Lack of Design Ownership Clarity

Custom granite stairs often involve unique CAD models, tooling, or fabrication techniques. If contracts do not clearly assign ownership or usage rights to these designs, disputes may arise—especially if the supplier reuses the design for other clients.

Unauthorized Use of Trademarked Finishes or Brand Names

Certain granite finishes (e.g., “honed,” “flamed,” “brushed”) or branded stone names may be trademarked. Suppliers might mislabel products or use protected terms improperly, potentially implicating buyers in false advertising or trademark violations.

Inadequate Contractual IP Protections

Many procurement agreements fail to include clauses addressing IP rights, confidentiality, and liability for infringement. Without these safeguards, the buyer may bear legal and financial responsibility if the sourced stairs infringe on third-party IP.

Mitigation Strategies

To avoid these pitfalls, conduct thorough due diligence: verify supplier credentials, request material test reports, inspect samples in person, and ensure contracts include explicit quality standards and IP indemnification clauses. Engaging legal and technical experts during the procurement process can further reduce exposure to quality and intellectual property risks.

Logistics & Compliance Guide for Granite Stairs

Overview

Granite stairs, due to their weight, fragility, and material classification, require careful planning throughout the logistics and compliance process. This guide outlines key considerations for safe transportation, handling, and regulatory adherence when moving granite stairs from manufacturer to installation site.

Material Characteristics & Handling

Granite is a dense, heavy natural stone prone to chipping, cracking, or staining if mishandled. Each stair tread or riser can weigh several hundred pounds, requiring specialized equipment and trained personnel for lifting and positioning. Use padded slings, forklifts with stone clamps, or vacuum lifters to avoid direct contact and surface damage. Always store granite stairs horizontally on wooden skids in a dry, covered area to prevent moisture absorption and edge damage.

Packaging & Crating

Granite stairs must be securely crated using marine-grade plywood or heavy-duty wooden frames. Each piece should be individually wrapped in foam or bubble wrap and separated with wooden spacers inside the crate to prevent movement during transit. Clearly label crates with “Fragile,” “This Side Up,” and “Heavy Stone” indicators. Include handling instructions and a detailed packing list with item dimensions and weights.

Transportation Logistics

Use flatbed trucks or enclosed trailers with sufficient weight capacity (typically 26,000+ lbs GVWR for large orders). Secure crates with ratchet straps and edge protectors to prevent shifting. Avoid sharp turns and rough roads to minimize vibration. For international shipments, coordinate with freight forwarders experienced in stone transport and ensure compliance with export/import documentation, including commercial invoices, packing lists, and certificates of origin.

Import & Export Compliance

Granite is subject to international trade regulations. Verify CITES (Convention on International Trade in Endangered Species) requirements if the stone contains protected mineral components—though rare, some rare granites may be restricted. Comply with customs regulations in both origin and destination countries, including tariff codes (HS Code 6802.91 or 6802.92 for worked granite). Provide accurate weight, value, and origin declarations to avoid delays or penalties.

Safety Regulations

Adhere to OSHA (Occupational Safety and Health Administration) standards for material handling, including proper lifting techniques and use of personal protective equipment (PPE) such as steel-toed boots, gloves, and eye protection. On construction sites, ensure stair installations meet local building codes for tread depth, riser height, slip resistance, and handrail requirements (e.g., IBC – International Building Code or ADA standards where applicable).

Environmental & Sustainability Considerations

Source granite from quarries that follow responsible extraction practices. Request documentation such as Environmental Product Declarations (EPDs) or LEED compliance information if required for green building projects. Minimize waste by optimizing cut patterns and recycling stone offcuts when possible.

Insurance & Liability

Obtain comprehensive cargo insurance covering damage, loss, or delay during transit. Verify that carriers have adequate liability coverage for high-value stone shipments. Clearly define responsibility (FOB origin vs. destination) in contracts to avoid disputes over damaged goods.

Final Inspection & Documentation

Conduct a thorough inspection upon delivery. Document any damage with photos and file claims immediately with the carrier and insurer. Maintain records of all compliance documents, safety certifications, and delivery confirmations for audit and warranty purposes.

Conclusion

Proper logistics and compliance management are critical for the successful delivery and installation of granite stairs. By following industry best practices and regulatory requirements, stakeholders can ensure safety, minimize risk, and maintain product integrity from quarry to site.

In conclusion, sourcing granite stairs requires careful consideration of quality, durability, aesthetics, cost, and supplier reliability. Granite remains an excellent choice for both interior and exterior staircases due to its strength, timeless appearance, and resistance to wear. When selecting a supplier, it is essential to evaluate their experience, material origin, customization capabilities, and post-installation support. Proper measurement, design planning, and professional installation are equally critical to ensure safety and longevity. By thoroughly researching and partnering with reputable suppliers, you can achieve a high-quality, visually striking staircase that enhances the overall value and appeal of your property.