The global graffiti and street art market has evolved from an underground movement to a recognized form of urban expression, fueling demand for high-performance tools like graffiti paint sprayers. According to Grand View Research, the global spray paint market was valued at USD 5.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. This expansion is driven by increasing urbanization, rising investments in public art projects, and growing adoption by both professional artists and hobbyists. Additionally, advancements in aerosol technology—focusing on precision nozzles, eco-friendly formulations, and ergonomic designs—are reshaping the competitive landscape. As demand surges, manufacturers are scaling innovation to meet the needs of a global creative community. In this context, the following eight companies have emerged as leading graffiti paint sprayer manufacturers, combining engineering excellence with artistic functionality to dominate the market.

Top 8 Graffiti Paint Sprayer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Graco Inc.

Domain Est. 1994

Website: graco.com

Key Highlights: Graco is one of the world’s leading suppliers of fluid management products and packages. We manufacture equipment to move, measure, mix, control, ……

#2

Domain Est. 2009

Website: flame-paint.com

Key Highlights: Carbon-neutral graffiti spray with recycled packaging materials, innovative aerosols and modernized production system including photovoltaic technology….

#3 Fuji Spray

Domain Est. 1996

Website: fujispray.com

Key Highlights: Fuji Spray is a leader in the spray paint industry with its high performance array of products designed for woodworking, automotive body work and spray ……

#4 Graffiti Spray Paint

Domain Est. 1998

Website: montanacolors.com

Key Highlights: A specialized aerosol for the world of graffiti. A paint whose quality would meet the needs of graffiti writers, at the most affordable price possible….

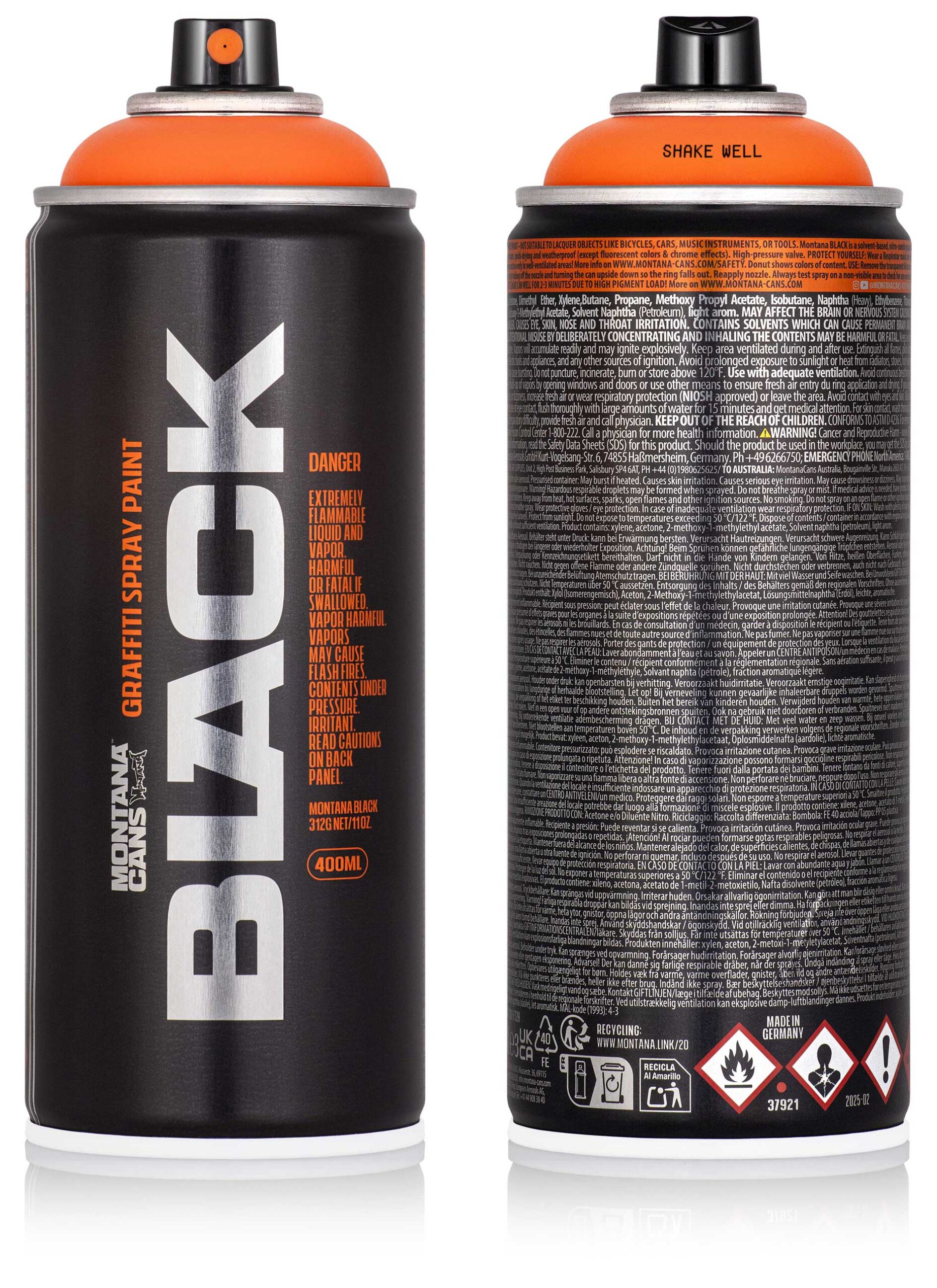

#5 Montana BLACK Spray Paint

Domain Est. 1999

Website: montana-cans.com

Key Highlights: Montana BLACK 50ml high-pressure Nitro-Combi-based graffiti spray paint. Small, high-covering, and quick-drying for instant overpainting….

#6 Spray Planet by Montana Colors

Domain Est. 2001

#7 Banna Sprays

Domain Est. 2017

Website: bannasprays.com

Key Highlights: Discover Banna Spray Paints – Your go-to solution for vibrant graffiti, durable automotive finishes, high-temperature sprays, and DIY creativity….

#8 World’s Best Graffiti Removal Products

Domain Est. 2009

Website: graffitiremovalinc.com

Key Highlights: 2–7 day delivery 90-day returnsWorld’s Best Graffiti Removal Products are trusted by over 1000 cities to safely remove all types of graffiti without damaging surfaces or the enviro…

Expert Sourcing Insights for Graffiti Paint Sprayer

H2: 2026 Market Trends for Graffiti Paint Sprayers

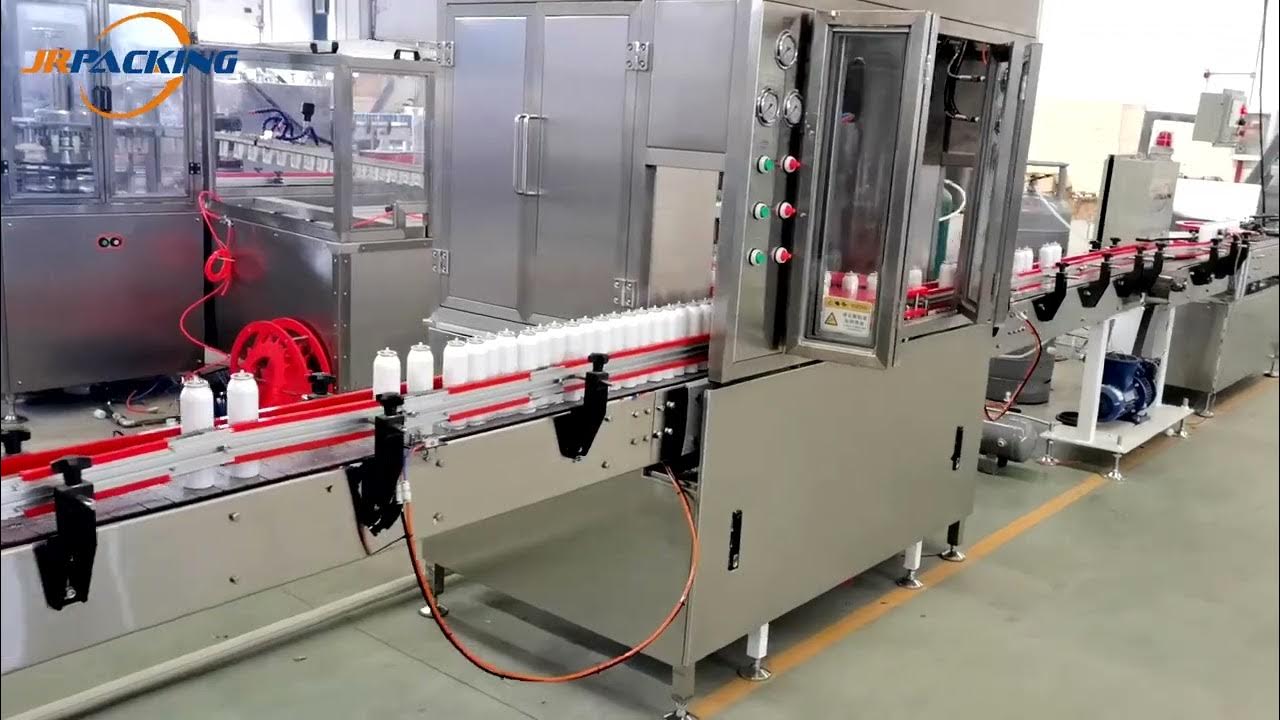

The graffiti paint sprayer market is poised for notable transformation by 2026, driven by technological advancements, evolving urban art culture, and increasing commercial applications. As cities globally embrace street art as a legitimate form of public expression, demand for high-performance, precision-focused paint sprayers continues to rise. Key trends shaping the market include:

-

Increased Demand from Urban Art and Legal Wall Projects

Municipalities and private developers are investing in urban revitalization projects that incorporate legal graffiti zones and commissioned murals. This shift fosters a growing need for professional-grade graffiti sprayers that offer control, durability, and consistent spray patterns. By 2026, partnerships between local governments and art collectives are expected to boost sprayer adoption. -

Advancements in Spray Technology and Ergonomics

Manufacturers are focusing on innovation in nozzle design, adjustable pressure control, and lightweight construction. Sprayers with variable flow settings and reduced overspray are becoming standard, improving efficiency and minimizing paint waste. These enhancements cater to both amateur artists and large-scale commercial muralists. -

Sustainability and Eco-Friendly Formulations

Environmental regulations and consumer awareness are pushing the industry toward low-VOC (volatile organic compound) paints and recyclable sprayer components. By 2026, leading brands are likely to launch eco-conscious product lines, including refillable and biodegradable aerosol alternatives, aligning with global sustainability goals. -

Growth in Online Sales and Direct-to-Consumer Channels

E-commerce platforms are becoming primary distribution channels for graffiti supplies. Customizable sprayer kits, subscription models for paint refills, and digital tutorials are enhancing customer engagement. Social media and influencer marketing continue to drive brand visibility and product adoption among younger demographics. -

Expansion into Commercial and Industrial Applications

Beyond street art, graffiti-style finishes are gaining popularity in retail, hospitality, and event design. Custom wall treatments and branded installations are creating new revenue streams for sprayer manufacturers. Industrial adaptations of graffiti sprayers—capable of covering large surfaces with artistic precision—are expected to enter niche markets. -

Regional Market Diversification

While North America and Western Europe remain dominant, emerging markets in Latin America, Southeast Asia, and Africa are witnessing rapid growth in street art scenes. Localized product offerings and affordable entry-level sprayers will be critical to capturing this expanding customer base by 2026.

In conclusion, the 2026 graffiti paint sprayer market will be defined by innovation, sustainability, and broader cultural acceptance of urban art. Companies that prioritize product performance, environmental responsibility, and digital engagement are best positioned to lead in this dynamic landscape.

Common Pitfalls When Sourcing Graffiti Paint Sprayers (Quality and Intellectual Property)

Sourcing graffiti paint sprayers, especially for commercial or large-scale use, comes with several risks related to product quality and intellectual property (IP) infringement. Being aware of these pitfalls can help avoid wasted investments, legal issues, and reputational damage.

Poor Build Quality and Material Deficiencies

Many low-cost sprayers, especially those from unverified suppliers, use substandard plastics and internal components that degrade quickly when exposed to harsh solvents in spray paint. This leads to nozzle clogs, inconsistent spray patterns, or complete failure after minimal use. Additionally, poorly machined valves and seals can cause leaks or pressure loss, reducing both performance and safety.

Inaccurate or Exaggerated Performance Claims

Suppliers may overstate key metrics like spray pressure, coverage area per minute, or battery life. Without third-party testing or verifiable data, buyers risk receiving a sprayer that underperforms compared to professional-grade tools. This is particularly common with online marketplaces where product descriptions are not rigorously vetted.

Lack of Compliance with Safety and Environmental Standards

Some sprayers may not meet regional safety standards (e.g., CE, UL, or RoHS compliance), posing health and fire hazards due to improper electrical components or volatile material handling. Non-compliant products may also be seized at customs or banned from sale, leading to shipment delays or financial losses.

Intellectual Property Infringement Risks

Sourcing from manufacturers that copy patented designs—such as trigger mechanisms, nozzle configurations, or battery systems—can expose buyers to legal liability. Even if unintentional, importing or selling IP-infringing products may result in lawsuits, customs seizures, or damage to brand reputation. This is especially prevalent with counterfeit versions of well-known brands.

Inadequate After-Sales Support and Spare Parts Availability

Low-cost sprayers often come from suppliers with limited customer service or no spare parts inventory. When components fail, users may find it impossible to repair the device, rendering it useless. This lack of support increases long-term costs and downtime.

Misrepresentation of Compatibility and Accessories

Some suppliers advertise compatibility with a wide range of paint types or brands, but in reality, the sprayer may only work optimally with specific formulations. Additionally, included accessories like nozzles, filters, or chargers may be missing, low-quality, or incompatible with regional power standards.

Failure to Verify Supplier Authenticity

Unverified suppliers, particularly on B2B platforms, may present themselves as manufacturers when they are merely resellers using stock images. This opacity makes it difficult to trace production methods, quality control processes, or IP ownership, increasing the risk of receiving counterfeit or non-compliant goods.

Avoiding these pitfalls requires thorough due diligence: requesting product samples, verifying certifications, conducting factory audits, and consulting legal experts on IP matters before finalizing procurement.

Logistics & Compliance Guide for Graffiti Paint Sprayer

Product Classification & Regulatory Overview

Graffiti paint sprayers, depending on their design and intended use, may fall under multiple regulatory categories including consumer products, aerosol devices, or industrial equipment. Understanding the classification is essential for compliance with transportation, safety, and environmental regulations. Key considerations include whether the sprayer uses compressed gas, flammable propellants, or is refillable. These factors influence labeling, packaging, and shipping requirements.

Hazardous Materials Classification

Many graffiti paint sprayers contain flammable solvents or pressurized components, potentially classifying them as hazardous materials under transportation regulations such as the U.S. Department of Transportation (DOT) 49 CFR, IATA Dangerous Goods Regulations (DGR), or ADR for road transport in Europe. If the product contains flammable liquids (e.g., alcohol-based paints) or is pressurized, it may be categorized under UN1950, Aerosols (Class 2.1 – Flammable Gas). Proper hazard classification must be confirmed through safety data sheets (SDS) and product testing.

Packaging & Labeling Requirements

Compliant packaging must be UN-certified for hazardous materials if applicable, featuring:

– Proper hazard labels (e.g., flammable gas, environmental hazard)

– UN number and proper shipping name

– Manufacturer/importer contact information

– GHS-compliant pictograms and precautionary statements

– Child-resistant packaging if required by jurisdiction (e.g., U.S. Poison Prevention Packaging Act)

Non-hazardous variants must still comply with general consumer product safety labeling, including usage instructions, warnings, and age restrictions.

Transportation & Shipping Compliance

- Air Transport (IATA DGR): Aerosol cans and pressurized sprayers are generally restricted or limited in passenger and cargo aircraft. Quantity limits, packaging standards, and documentation (Shipper’s Declaration for Dangerous Goods) are mandatory.

- Ground Transport (DOT/ADR): Requires placarding for large shipments, segregation from oxidizers, and trained personnel for handling.

- Maritime (IMDG Code): Similar classification and stowage requirements apply; proper container ventilation and segregation are critical.

Always verify carrier-specific restrictions, as some may prohibit aerosol shipments entirely.

Import/Export Documentation

International shipments require:

– Commercial invoice with detailed product description

– Bill of lading or air waybill

– Safety Data Sheet (SDS) compliant with local regulations (e.g., OSHA HazCom, REACH, CLP)

– Certificate of Origin

– Import permits (if required by destination country)

– Customs classification (HS Code) – typically under 8424.81 (hand-operated mechanical appliances for projecting paint)

Environmental & Safety Compliance

- VOC Regulations: Many regions (e.g., U.S. EPA, EU Solvents Directive) limit volatile organic compound (VOC) content in paints and sprays. Ensure formulations comply with local VOC limits.

- REACH & RoHS (EU): Verify substances in the sprayer and paint are not restricted under REACH SVHC or RoHS hazardous substances.

- Prop 65 (California): Label products containing listed chemicals (e.g., toluene, xylene) with appropriate warnings.

Age Restrictions & Sales Compliance

Graffiti sprayers may be subject to age restrictions due to misuse potential or chemical exposure risk. For example:

– Sale to minors may be restricted under local anti-vandalism or inhalant abuse laws

– Retailers may require age verification at point of sale

– Clear warning labels about inhalant abuse (e.g., “Intentional misuse may be hazardous or fatal”)

Storage & Handling Guidelines

- Store in cool, well-ventilated areas away from heat and ignition sources

- Keep upright to prevent leakage

- Follow fire code requirements for flammable liquid storage (e.g., NFPA 30)

- Provide appropriate personal protective equipment (PPE) for handlers

Disposal & End-of-Life Compliance

Dispose of used or empty sprayers in accordance with local hazardous waste regulations. Do not puncture or incinerate aerosol cans. Encourage consumers to use recycling programs for metal components and return expired or unused products to designated collection points.

Recordkeeping & Audits

Maintain records of:

– SDS and compliance certifications

– Shipping documentation and hazardous materials training

– Product testing reports (e.g., pressure, flammability)

– Regulatory correspondence

Regular internal audits help ensure ongoing compliance with evolving regulations across jurisdictions.

Conclusion

Successfully managing the logistics and compliance of graffiti paint sprayers requires a proactive approach to classification, documentation, and safety. Partnering with certified testing labs, legal counsel, and experienced freight forwarders can help mitigate risks and ensure market access across global regions.

In conclusion, sourcing a graffiti paint sprayer requires careful consideration of factors such as spray precision, portability, paint compatibility, durability, and ease of maintenance. Whether intended for street art, legal murals, or professional design projects, selecting the right sprayer enhances both creative expression and efficiency. Evaluating options—from standard aerosol cans to refillable spray systems or airbrush kits—based on budget, usage frequency, and desired finish will ensure optimal performance. Additionally, sourcing from reputable suppliers guarantees quality and reliability. Ultimately, investing in the right graffiti paint sprayer empowers artists to bring their visions to life with control, consistency, and style.