The global titanium alloys market is experiencing robust growth, driven by rising demand across aerospace, medical, and industrial sectors. According to Grand View Research, the market was valued at USD 7.8 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.4% from 2024 to 2030. A significant portion of this demand centers on two of the most widely used titanium grades: Grade 2 (commercially pure) and Grade 5 (Ti-6Al-4V), which together dominate applications requiring a balance of strength, corrosion resistance, and biocompatibility. As industries prioritize material efficiency and performance, sourcing from reliable manufacturers becomes critical. This analysis evaluates the top eight manufacturers excelling in the production of Grade 2 and Grade 5 titanium, leveraging capacity, innovation, and market reach to maintain competitive advantage in a rapidly expanding industry.

Top 8 Grade 2 Titanium Vs Grade 5 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Everything Manufacturers Need to Know About Titanium…

Domain Est. 1995

Website: ulbrich.com

Key Highlights: Grade 2 vs. Grade 9: While Grade 2 offers excellent corrosion … Grade 5 vs. Grade 9: Grade 5 offers higher strength and is commonly ……

#2 What are different titanium grades and why does it matter?

Domain Est. 2020

Website: bugatti-smartwatches.com

Key Highlights: For example, a manufacturer may choose Grade 2 titanium for its ease of machining and lower cost, while another may choose Grade 5 titanium ……

#3 6Al

Domain Est. 1995

Website: titanium.com

Key Highlights: Titanium Sheet Grade 2: Due to Grade 2 Titanium being 99% pure, this material is more corrosion resistant than 6Al-4V Grade 5, but not as strong as Grade 9 ……

#4 How to Choose the Right Grade

Domain Est. 2000

Website: titaniumprocessingcenter.com

Key Highlights: For slightly stronger metal, there is Grade 2 titanium. It is still very moldable, but has a higher tensile strength. Grade 2 titanium is very widely available, ……

#5 Titanium Grade 5 vs Titanium Grade 2 Comparison

Domain Est. 2012

Website: neonickel.com

Key Highlights: When compared with Titanium grade 5 (Ti 6Al-4V), Titanium grade 2 is generally selected where aqueous corrosion resistance and/or formability are required….

#6 Which is Better Grade 2 or Grade 5 Titanium? A Comprehensive …

Domain Est. 2017

Website: tsm-titanium.com

Key Highlights: A:Grade 5 is worth the higher cost when your application requires its superior strength, fatigue resistance, or elevated temperature performance ……

#7 Understanding the Different Grades of Titanium

Domain Est. 2018

Website: aemmetal.com

Key Highlights: Pure titanium grades like Grade 2 tend to be more cost-effective compared to titanium alloys such as Grade 5 (Ti-6Al-4V), which may be more ……

#8 Titanium Grades • A Selection Guide

Domain Est. 1998

Website: continentalsteel.com

Key Highlights: Commercially Pure Titanium Grade 2 has moderate strength and excellent cold forming properties. It provides excellent welding properties and has excellent ……

Expert Sourcing Insights for Grade 2 Titanium Vs Grade 5

H2: 2026 Market Trends: Grade 2 vs. Grade 5 Titanium

As the global demand for high-performance materials continues to rise across aerospace, medical, automotive, and industrial sectors, titanium alloys remain at the forefront of advanced material selection. By 2026, the market dynamics between commercially pure Grade 2 titanium and the widely used Grade 5 titanium (Ti-6Al-4V) are expected to reflect evolving technological needs, supply chain considerations, and sustainability pressures. Here’s an analysis of the key trends shaping the competition and coexistence of these two titanium grades in the 2026 market landscape.

1. Aerospace and Defense Driving Demand for Grade 5 Titanium

The aerospace and defense sectors will remain the dominant consumers of Grade 5 titanium, accounting for over 50% of its global demand by 2026. The alloy’s high strength-to-density ratio, excellent performance at elevated temperatures, and fatigue resistance make it indispensable for critical components such as jet engine parts, airframes, and landing gear. With increased aircraft production (e.g., Boeing, Airbus backlogs) and the growth of next-generation defense platforms and hypersonic systems, demand for Grade 5 is projected to grow at a CAGR of 6.8% through 2026.

2. Medical and Industrial Applications Favoring Grade 2 Titanium

In contrast, Grade 2 titanium is expected to see strong growth in the medical device and industrial sectors due to its excellent corrosion resistance, formability, and biocompatibility. The global expansion of minimally invasive surgeries, dental implants, and prosthetics is fueling demand for biocompatible, corrosion-resistant materials—areas where Grade 2 excels. Additionally, its use in chemical processing, desalination plants, and marine applications remains steady. By 2026, the medical segment alone could represent nearly 30% of Grade 2 titanium consumption, growing at a CAGR of approximately 5.5%.

3. Sustainability and Recycling Pressures

Environmental regulations and ESG (Environmental, Social, Governance) mandates are pushing manufacturers to adopt more sustainable practices. Both Grade 2 and Grade 5 titanium are 100% recyclable, but Grade 5’s complex alloying elements (vanadium, aluminum) pose higher challenges in sorting and remelting. As closed-loop recycling systems improve, Grade 2 may benefit from simpler reprocessing, potentially lowering lifecycle costs and carbon footprints. This could give Grade 2 a competitive edge in markets prioritizing sustainability, such as green energy and consumer medical devices.

4. Cost and Supply Chain Dynamics

Grade 5 titanium typically commands a 30–50% price premium over Grade 2 due to its alloying elements and more complex manufacturing process. However, geopolitical disruptions in vanadium and aluminum supply chains could exacerbate price volatility for Grade 5 by 2026. In response, some industries—particularly in automotive and consumer goods—are exploring design optimizations to use lighter Grade 2 in non-structural applications or hybrid material systems. Meanwhile, advancements in additive manufacturing (AM) are reducing waste and enabling more efficient use of both grades, though Grade 5 remains dominant in high-strength AM parts.

5. Technological Innovation and Material Substitution

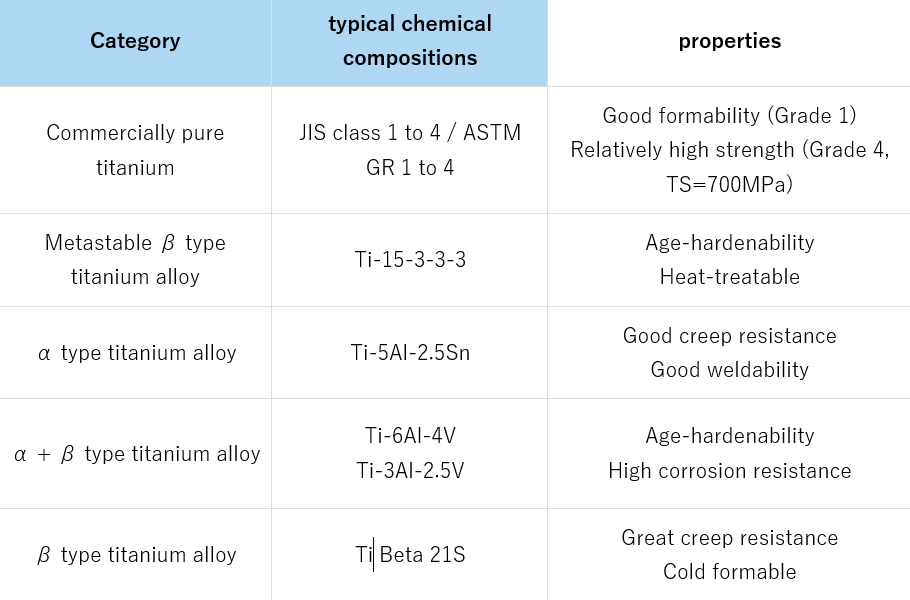

Emerging technologies such as titanium powder bed fusion and near-net-shape manufacturing are narrowing the processing gap between the two grades. While Grade 5 continues to dominate in high-performance AM, research into Grade 2 variants with enhanced strength through nanostructuring or surface treatments could challenge Grade 5 in mid-tier applications. Additionally, competition from alternative materials—such as high-strength aluminum alloys, composites, and beta-titanium alloys—may limit growth in certain segments, particularly where weight savings outweigh the need for extreme strength.

Conclusion

By 2026, Grade 5 titanium will maintain its leadership in high-stress, high-temperature applications, especially in aerospace and defense, driven by performance requirements. In contrast, Grade 2 titanium will see robust growth in medical, industrial, and sustainability-focused markets, benefiting from its purity, biocompatibility, and lower processing complexity. While both grades will coexist and grow, their market trajectories will diverge based on application-specific demands, cost efficiency, and environmental considerations. Strategic investments in recycling, material science, and manufacturing innovation will determine which grade gains incremental market share in emerging sectors.

Common Pitfalls Sourcing Grade 2 vs Grade 5 Titanium (Quality, IP)

Sourcing titanium—especially distinguishing between commercially pure Grade 2 and high-strength Grade 5 (Ti-6Al-4V)—poses significant challenges related to material quality and intellectual property (IP) protection. Missteps can lead to performance failures, safety risks, and legal exposure. Below are key pitfalls to avoid:

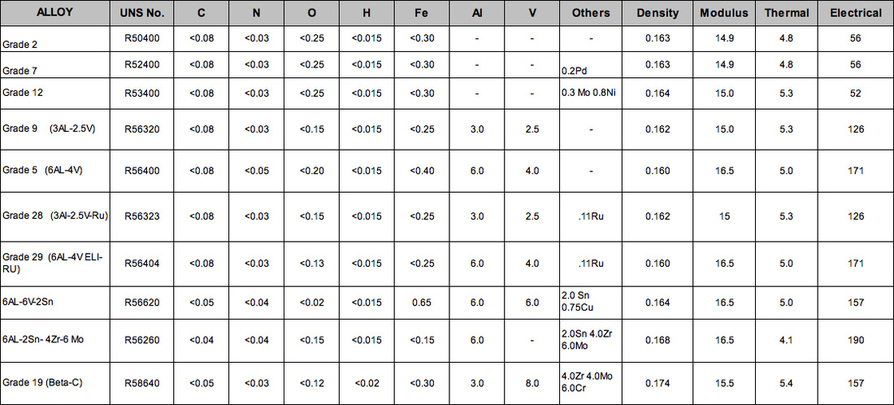

Misunderstanding Material Specifications and Performance Requirements

A frequent error is selecting the wrong grade due to confusion about application demands. Grade 2 offers excellent corrosion resistance and formability but lower strength, making it ideal for chemical processing or marine environments. In contrast, Grade 5 provides superior strength-to-density ratio, suited for aerospace and medical implants. Sourcing Grade 2 for a high-stress application—or vice versa—can result in premature failure or unnecessary cost. Always verify mechanical property requirements (e.g., tensile strength, yield strength) against ASTM or AMS standards before procurement.

Inadequate Supplier Qualification and Certification

Both grades require strict process controls, but Grade 5’s alloy composition (6% aluminum, 4% vanadium) is more sensitive to variations. Unqualified suppliers may deliver substandard material with incorrect chemistry or poor microstructure, especially in forged or welded components. Relying on suppliers without proper certifications (e.g., NADCAP, AS9100) increases the risk of receiving non-conforming product. Always demand full material test reports (MTRs) traceable to heat/lot numbers and validate third-party testing when feasible.

Risk of Material Substitution and Counterfeiting

Grade 5 titanium commands a premium price, making it a target for fraudulent substitution—sometimes with lower-grade alloys or even non-titanium materials. Grade 2 is less prone to counterfeiting but can still be misrepresented in terms of purity or mechanical properties. Without rigorous incoming inspection (e.g., PMI—Positive Material Identification), counterfeit or mislabeled stock may enter the supply chain, jeopardizing product integrity and compliance.

Intellectual Property and Traceability Gaps

Grade 5 is commonly used in patented or proprietary applications (e.g., aerospace components, medical devices), where traceability and IP protection are critical. Sourcing from suppliers lacking robust documentation systems can result in incomplete or falsified trace records, undermining regulatory compliance (e.g., FAA, FDA) and exposing your organization to IP infringement claims. Ensure supply agreements include clauses on data transparency, chain of custody, and confidentiality.

Overlooking Processing History and Consistency

The performance of both grades depends heavily on processing—annealing, forging, and heat treatment. Grade 5, in particular, requires precise thermal processing to achieve desired mechanical properties and microstructure (e.g., alpha-beta phase balance). Sourcing from vendors with inconsistent process controls may lead to variable quality between batches. Always audit processing history and insist on documented process parameters.

Insufficient Due Diligence in Global Sourcing

Offshore suppliers may offer lower prices but often lack adherence to international standards or face challenges in IP enforcement. For Grade 5, this risk is amplified due to its strategic importance and technical complexity. Engaging suppliers without site audits or independent verification increases exposure to quality lapses and IP theft, especially in jurisdictions with weak enforcement of material standards and trade secrets.

By addressing these pitfalls through rigorous supplier vetting, material verification, and contractual safeguards, organizations can ensure they receive the correct titanium grade with assured quality and protected intellectual property.

Logistics & Compliance Guide: Grade 2 Titanium vs Grade 5 Titanium

Material Overview

Grade 2 Titanium

Grade 2 titanium is commercially pure (un-alloyed) titanium, known for its excellent corrosion resistance, good formability, and moderate strength. It is widely used in chemical processing, marine environments, and medical applications due to its biocompatibility and weldability.

Grade 5 Titanium (Ti-6Al-4V)

Grade 5 titanium is an alpha-beta alloy composed of 6% aluminum and 4% vanadium. It offers high strength-to-density ratio, excellent performance at elevated temperatures, and good fatigue resistance. It is commonly used in aerospace, high-performance automotive, and medical implant applications.

Manufacturing & Processing Considerations

Grade 2 Titanium

– Easier to form and weld due to lower strength and higher ductility.

– Minimal post-weld heat treatment required.

– Can be cold-formed with standard tooling; less tool wear.

– Suitable for seamless tubing, sheet metal fabrication, and deep drawing.

Grade 5 Titanium

– Requires more energy for forming due to higher strength.

– Prone to contamination during welding; requires inert gas shielding (e.g., argon).

– Often requires heat treatment (e.g., annealing or solution treating and aging) to achieve desired mechanical properties.

– Machining requires sharp tools and low cutting speeds due to work hardening.

Transportation & Handling

Common Logistics for Both Grades

– Store in dry, clean environments to prevent moisture-induced contamination.

– Use non-ferrous handling tools (e.g., plastic or stainless steel) to avoid iron pickup, which can compromise corrosion resistance.

– Protect surfaces with plastic wrap or protective film during transit to prevent scratches and contamination.

Special Considerations for Grade 5

– Higher value and critical applications may require tamper-evident packaging and temperature-controlled shipping.

– Traceability (e.g., lot/batch numbers, material test reports) is often mandatory, especially in aerospace or medical uses.

Regulatory & Compliance Requirements

ASTM Standards

– Grade 2: ASTM B265 (sheet, strip, plate), ASTM B338 (tubes), ASTM F67 (for surgical implants).

– Grade 5: ASTM B265, ASTM B338, and ASTM F136 (for surgical implants).

Industry-Specific Compliance

– Aerospace (Grade 5): Must comply with AMS 4911, NADCAP certification for heat treatment and non-destructive testing (NDT).

– Medical (Both Grades): FDA 21 CFR compliance; ISO 13485 quality management system required for manufacturers.

– Industrial/Chemical (Grade 2): May need to meet NACE MR0175/ISO 15156 for sour service environments.

Export Controls

– Both grades may be subject to export regulations (e.g., ITAR, EAR) when used in defense or aerospace applications.

– Grade 5 is more likely to be ITAR-controlled due to military applications.

– Proper ECCN (Export Control Classification Number) classification is essential:

– Grade 2: Typically EAR99 (low concern) unless specially processed.

– Grade 5: Often classified under ECCN 1C003 (titanium alloys for aerospace).

Quality Assurance & Documentation

Required Documentation

– Material Test Reports (MTRs) with chemistry and mechanical properties.

– Certificate of Conformance (CoC) traceable to heat number.

– For Grade 5: Additional NDT reports (e.g., ultrasonic or eddy current) may be required.

Traceability

– Full mill-to-fabricator traceability is required for Grade 5 in critical applications.

– Grade 2 may require less stringent tracking unless used in regulated industries.

Summary: Key Differences in Logistics & Compliance

| Factor | Grade 2 Titanium | Grade 5 Titanium |

|—————————|——————————————|———————————————-|

| Formability & Welding | Easier, low risk | Complex, requires strict controls |

| Handling | Standard non-ferrous precautions | Enhanced cleanliness and contamination control |

| Regulatory Oversight | Moderate (ASTM, ISO) | High (AMS, ITAR, NADCAP) |

| Export Controls | Usually EAR99 | Often ITAR or ECCN 1C003 |

| Traceability Requirements | Basic MTRs sufficient for most uses | Full traceability and batch documentation |

| Typical Applications | Chemical, medical, marine | Aerospace, defense, high-stress medical |

Conclusion

Selecting between Grade 2 and Grade 5 titanium involves not only mechanical and environmental performance but also significant differences in logistics and compliance. Grade 2 offers simpler handling and fewer regulatory hurdles, making it ideal for industrial and commercial uses. Grade 5, while stronger and more versatile in high-performance settings, demands rigorous process controls, traceability, and adherence to export and industry-specific standards. Proper planning in procurement, shipping, and documentation ensures compliance and operational efficiency.

Conclusion: Sourcing Grade 2 vs. Grade 5 Titanium

The decision to source Grade 2 versus Grade 5 titanium ultimately depends on the specific requirements of the application, balancing mechanical performance, fabrication needs, and cost considerations.

Grade 2 titanium offers excellent corrosion resistance, good formability, and weldability, making it ideal for applications in chemical processing, marine environments, and medical devices where moderate strength and high ductility are sufficient. Its lower cost and ease of fabrication make it a cost-effective choice for less demanding structural or non-load-bearing components.

In contrast, Grade 5 (Ti-6Al-4V) provides significantly higher strength, fatigue resistance, and performance at elevated temperatures, making it the preferred choice for aerospace, high-performance automotive, and critical biomedical implants such as joint replacements. However, its increased strength comes with greater machining difficulty, higher cost, and more complex welding requirements.

In summary, opt for Grade 2 titanium when corrosion resistance, formability, and cost-efficiency are priorities in low- to moderate-stress environments. Choose Grade 5 titanium when high strength-to-density ratio, durability under stress, and performance in extreme conditions are essential, despite higher material and processing costs. A clear understanding of operational demands and lifecycle requirements will guide the optimal sourcing decision between these two widely used titanium grades.