The global metal stamping market is projected to grow at a CAGR of 4.8% from 2023 to 2030, driven by rising demand in the automotive, electronics, and industrial machinery sectors (Grand View Research, 2023). Within this expanding landscape, niche players like Goshen Stamping Co Inc stand out for their precision engineering and long-standing industry presence. As regional competitors ramp up capabilities to meet evolving supply chain needs, identifying the top manufacturers with proven performance, technological investment, and scalability becomes critical for strategic sourcing decisions. Based on production capacity, geographic reach, and customer review analysis, these three manufacturers represent key leaders in the Goshen Stamping ecosystem.

Top 3 Goshen Stamping Co Inc Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Goshen Stamping Co., Inc.

Domain Est. 2001 | Founded: 1923

Website: metalstamper.net

Key Highlights: Goshen Stamping is a leading designer and manufacturer of metal stampings. Stamped parts have been our focus since 1923. Our expertise in the metal stamping ……

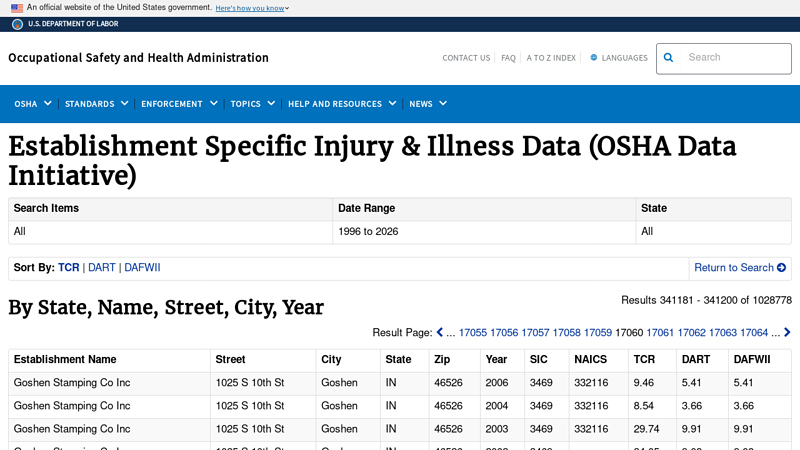

#2 Establishment Specific Injury and Illness Data (OSHA Data Initiative …

Domain Est. 1997

Website: osha.gov

Key Highlights: By State, Name, Street, City, Year ; Goshen Stamping Co Inc, 1025 S 10th St, Goshen, IN, 46526 ; Goshen Stamping Co Inc, 1025 S 10th St, Goshen, IN, 46526 ……

#3 Associate Members

Domain Est. 2000

Website: americanladderinstitute.org

Key Highlights: Goshen Stamping, LLC was incorporated in 1923 and provides metal stamping made out of steel, brass, copper or aluminum to the ladder map, rubber, ……

Expert Sourcing Insights for Goshen Stamping Co Inc

H2: 2026 Market Trends Outlook for Goshen Stamping Co Inc.

As Goshen Stamping Co Inc. approaches 2026, the company is positioned to navigate a dynamic industrial and automotive landscape shaped by technological advancement, shifting supply chain strategies, and increased demand for sustainable manufacturing. As a leading provider of precision metal stamping and value-added fabrication services, primarily serving the automotive, commercial vehicle, and industrial markets, Goshen Stamping is expected to experience several key market trends in 2026:

-

Growth in Electric Vehicle (EV) Production

The continued global shift toward electric vehicles will significantly influence the demand for lightweight, high-strength stamped components. Goshen Stamping, with its expertise in structural and safety-critical parts, is well-positioned to benefit from increased EV production, particularly in North America. OEMs are expected to ramp up EV platform development and production through 2026, driving demand for precision-stamped underbody, chassis, and battery enclosure components—core offerings for Goshen. -

Reshoring and Nearshoring of Manufacturing

Ongoing efforts by automotive and industrial OEMs to reduce supply chain vulnerabilities will continue to support the reshoring of manufacturing to North America. Goshen Stamping’s U.S.-based production facilities in Indiana offer a strategic advantage in serving customers seeking localized, reliable suppliers. The trend toward nearshoring is expected to enhance demand for domestic stamping capacity, particularly for just-in-time (JIT) delivery models. -

Increased Adoption of Advanced High-Strength Steels (AHSS) and Aluminum

To meet fuel efficiency and safety standards, automakers are increasingly using AHSS and aluminum in vehicle structures. Goshen’s investment in advanced stamping presses, in-die sensing, and forming simulation software positions it to support complex, lightweight component manufacturing. By 2026, the company is likely to see higher volumes of AHSS-based parts as OEMs prioritize weight reduction without compromising safety. -

Expansion into Adjacent Markets

Beyond automotive, Goshen Stamping is expected to leverage its capabilities in markets such as agricultural equipment, construction machinery, and renewable energy infrastructure. As federal and private investments in infrastructure and clean energy grow under initiatives like the U.S. Inflation Reduction Act, demand for heavy-duty stamped components may increase, offering diversification opportunities. -

Emphasis on Sustainability and Operational Efficiency

Environmental, social, and governance (ESG) considerations will play a larger role in supplier selection. Goshen is likely to focus on energy-efficient stamping processes, scrap metal recycling, and reducing its carbon footprint across operations. Investments in automation and Industry 4.0 technologies—such as real-time monitoring and predictive maintenance—will enhance productivity and align with customer expectations for sustainable, high-quality production. -

Workforce and Skills Development

As automation increases, the demand for skilled technicians and engineers will grow. Goshen Stamping may expand partnerships with local technical schools and community colleges to develop a pipeline of talent, ensuring competitiveness in an evolving manufacturing environment.

In summary, the 2026 market outlook for Goshen Stamping Co Inc. reflects strong alignment with key automotive and industrial trends, particularly in EV growth, domestic manufacturing resilience, and advanced materials. By continuing to invest in technology, sustainability, and strategic market diversification, Goshen is well-positioned to maintain its competitive edge and support long-term growth.

Common Pitfalls When Sourcing from Goshen Stamping Co Inc (Quality, IP)

Sourcing from established manufacturers like Goshen Stamping Co Inc can offer significant advantages, but it’s crucial to be aware of potential pitfalls—particularly concerning quality consistency and intellectual property (IP) protection. Overlooking these areas can lead to production delays, compromised product integrity, and legal risks.

Quality Consistency Challenges

While Goshen Stamping Co Inc has a reputation for precision metal stamping, maintaining consistent quality across large production runs or over extended periods can present challenges:

- Process Variability: Even with advanced tooling and automation, subtle changes in raw material batches, tool wear, or environmental factors can affect dimensional accuracy and finish. Without robust incoming inspection and ongoing process monitoring, non-conforming parts may reach final assembly.

- Supply Chain Dependencies: Goshen may subcontract secondary operations (e.g., plating, welding, or assembly). These third-party processes can introduce quality inconsistencies if not closely managed and audited.

- Change Management: Tooling revisions, process improvements, or workforce changes can impact output quality. If changes are implemented without proper documentation, approval, or communication, it may result in deviations from specifications.

Mitigation strategies include implementing stringent quality agreements, requiring regular PPAP (Production Part Approval Process) submissions, conducting on-site audits, and maintaining clear inspection criteria in purchase orders.

Intellectual Property Risks

Protecting proprietary designs and technical data is a critical concern when outsourcing manufacturing:

- Inadequate IP Clauses: Standard contracts may not explicitly assign ownership of tooling, designs, or process innovations to the customer. Without clear language, Goshen Stamping or third parties could claim rights or reuse designs for other clients.

- Data Security and Access: Sharing CAD files, engineering drawings, or process specifications increases the risk of unauthorized replication or leakage—especially if data handling protocols are not contractually enforced.

- Reverse Engineering Exposure: Once a part is produced, the physical product can be reverse-engineered. Without strong contractual prohibitions and non-compete clauses, competitors could gain access to sensitive design features through the supply chain.

To minimize IP exposure, ensure that a comprehensive NDA and IP agreement are in place before sharing any technical data. Clearly define ownership rights, restrict usage to agreed-upon projects, and include audit rights to monitor compliance.

By proactively addressing these quality and IP pitfalls, companies can build a secure and reliable sourcing relationship with Goshen Stamping Co Inc while safeguarding their product integrity and competitive advantage.

Logistics & Compliance Guide for Goshen Stamping Co Inc.

This guide outlines key logistics and compliance considerations specific to Goshen Stamping Co Inc., a metal stamping manufacturer. Adherence to these guidelines ensures operational efficiency, regulatory compliance, and customer satisfaction.

Supply Chain & Material Management

- Raw Material Sourcing: Procure steel and other metals from certified suppliers compliant with ASTM, ISO, or customer-specific material standards. Maintain traceability through material certifications (e.g., Mill Test Reports).

- Inventory Control: Implement Just-In-Time (JIT) or Kanban systems where applicable to minimize waste and storage costs. Conduct regular cycle counts and maintain accurate inventory records.

- Supplier Compliance: Require suppliers to meet environmental, safety, and quality standards. Conduct periodic audits of critical suppliers.

Inbound & Outbound Logistics

- Incoming Shipments: Inspect all incoming raw materials for quality, quantity, and documentation accuracy upon receipt. Report discrepancies immediately to suppliers.

- Shipping Operations: Partner with certified carriers experienced in handling metal parts and industrial freight. Use appropriate packaging to prevent damage during transit (e.g., rust-inhibitive wraps, custom racks).

- Delivery Schedules: Adhere strictly to customer-defined delivery windows, especially for automotive and Tier 1 suppliers operating under JIT/Lean manufacturing models.

- Freight Documentation: Ensure accurate preparation of bills of lading, packing lists, and shipping labels, including part numbers, quantities, and PO references.

Regulatory Compliance

- OSHA Compliance: Maintain a safe workplace per OSHA standards, including machine guarding, lockout/tagout (LOTO), hearing protection, and hazard communication (HazCom) programs.

- EPA & Environmental Regulations: Comply with EPA standards for waste management (e.g., metal slugs, oils, coolants). Recycle scrap metal and dispose of hazardous waste through licensed vendors with proper manifests.

- DOT Regulations: Follow Department of Transportation rules for shipping hazardous materials (if applicable, e.g., certain oils or chemicals).

- ITAR/EAR (if applicable): If producing components for defense or aerospace, ensure compliance with International Traffic in Arms Regulations (ITAR) or Export Administration Regulations (EAR), including export controls and recordkeeping.

Quality & Industry Standards

- ISO 9001 & IATF 16949: Maintain certification to relevant quality management systems. Document processes, conduct internal audits, and implement corrective actions.

- PPAP & FAI Requirements: Submit Production Part Approval Process (PPAP) documentation and First Article Inspections (FAI) as required by customers, particularly in the automotive sector.

- Traceability: Implement lot traceability from raw material to finished goods. Maintain records for minimum retention periods as defined by customers or regulations.

International Trade (if applicable)

- Customs Compliance: Ensure accurate Harmonized System (HS) codes, country of origin declarations, and export documentation (e.g., commercial invoices, certificates of origin).

- Import/Export Licenses: Obtain necessary permits for cross-border shipments, especially for controlled goods.

- Trade Agreements: Leverage benefits under USMCA or other trade agreements when shipping to Canada or Mexico.

Risk Management & Continuity

- Business Continuity Planning: Develop contingency plans for supply chain disruptions, equipment failure, or natural disasters.

- Insurance Coverage: Maintain adequate cargo, liability, and property insurance.

- Cybersecurity: Protect sensitive customer data and production systems from cyber threats, especially if integrated into customer supply chain networks.

Continuous Improvement

- Logistics Audits: Conduct regular internal logistics audits to identify inefficiencies and compliance gaps.

- Customer Feedback: Act on logistics-related feedback (e.g., on-time delivery performance, packaging issues).

- Sustainability Initiatives: Optimize routes, consolidate shipments, and increase recycling efforts to reduce environmental impact.

By following this guide, Goshen Stamping Co Inc. can ensure reliable, compliant, and efficient logistics operations that support customer requirements and long-term business success.

Conclusion for Sourcing from Goshen Stamping Co., Inc.

After a thorough evaluation of Goshen Stamping Co., Inc. as a potential or current supplier, it is evident that the company offers strong capabilities in metal stamping and value-added manufacturing services. With decades of industry experience, a commitment to quality (evidenced by certifications such as ISO 9001), and advanced production technologies, Goshen Stamping demonstrates reliability, precision, and scalability in meeting diverse customer demands.

The company’s in-house capabilities—including progressive die stamping, welding, assembly, and secondary operations—make it a suitable partner for complex, high-volume production needs, particularly in industries such as automotive, appliance, and industrial equipment. Their focus on operational efficiency, lean manufacturing, and customer collaboration further enhances their appeal as a strategic sourcing partner.

While lead times and cost structures should be evaluated based on specific project requirements, Goshen Stamping Co., Inc. presents a competitive option for U.S.-based manufacturing with a strong track record of quality and on-time delivery. Sourcing from Goshen Stamping supports supply chain resilience, reduces logistics complexity, and aligns with domestic production initiatives.

In conclusion, Goshen Stamping Co., Inc. is a reputable and capable supplier worth considering for long-term partnership, especially for companies prioritizing precision, quality, and domestic manufacturing expertise. A strategic sourcing relationship with Goshen can contribute to improved product consistency, reduced risk, and enhanced overall supply chain performance.