The global wire mesh market is experiencing robust growth, driven by increasing demand across construction, agriculture, and industrial sectors. According to Grand View Research, the global welded wire mesh market size was valued at USD 58.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This surge is fueled by rising infrastructure development, stricter safety regulations, and the need for durable protective fencing solutions—particularly in agricultural and residential applications where gopher wire mesh plays a critical role in pest control and soil stabilization. As demand grows, manufacturers are enhancing production efficiency, expanding product lines, and investing in corrosion-resistant technologies to meet evolving customer requirements. In this competitive landscape, identifying leading gopher wire mesh manufacturers becomes essential for buyers seeking quality, reliability, and innovation. Based on market presence, production capacity, and customer reviews, the following seven companies stand out as top performers in the gopher wire mesh sector.

Top 7 Gopher Wire Mesh Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Seboss Hardware Cloth Store

Domain Est. 2022 | Founded: 2009

Website: sebossfence.com

Key Highlights: SEBOSS Metal Industry Company was established in 2009, manufacturer and … wire mesh/rabbit fencing/chicken wire for coop/gopher netting/garden mesh/tree…

#2 Gophers Limited Inc

Domain Est. 2003

Website: gopherslimited.com

Key Highlights: We are proud to have offered high-quality stainless steel gopher baskets and wire rolls to our loyal customers over the past two decades. Due to the excessive ……

#3 Digger’s Products Gopher Baskets & Wire

Domain Est. 2008

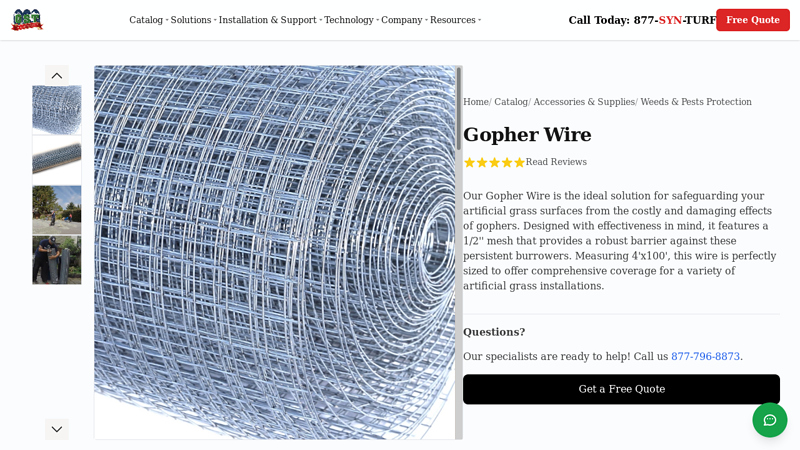

#4 Gopher Wire

Domain Est. 2010

Website: globalsynturf.com

Key Highlights: Rating 5.0 (17) Our Gopher Wire is the ideal solution for safeguarding your artificial grass surfaces from the costly and damaging effects of gophers….

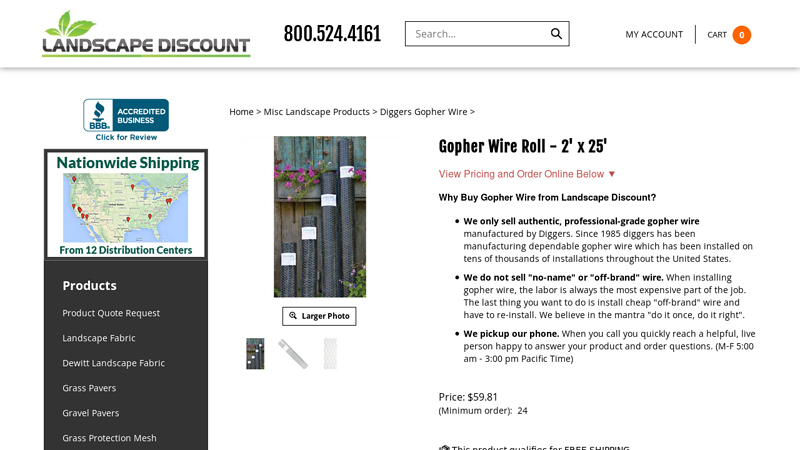

#5 Gopher Wire Roll

Domain Est. 2014 | Founded: 1985

Website: landscapediscount.com

Key Highlights: In stock Rating 5.0 (2) We only sell authentic, professional-grade gopher wire manufactured by Diggers. Since 1985 diggers has been manufacturing dependable gopher wire….

#6 Diggers 5′ x 100′ Root Guard Gopher Wire Roll

Domain Est. 2022

#7 Gopher Wire Roll

Domain Est. 2023

Website: gopherblock.com

Key Highlights: In stock Rating 5.0 (1) Designed specifically to block gophers from damaging lawns and planting areas, Gopher Block® wire is a heavy duty galvanized-steel wire mesh which typical…

Expert Sourcing Insights for Gopher Wire Mesh

2026 Market Trends for Gopher Wire Mesh

Growing Demand in Residential Landscaping and Gardening

By 2026, the residential sector is expected to remain a dominant driver of gopher wire mesh demand. Increasing homeowner interest in sustainable gardening, edible landscapes, and native plant restoration will boost the need for effective underground pest control. As urban and suburban areas expand into rural zones, human-wildlife conflicts, particularly with burrowing rodents like gophers and moles, are on the rise. This trend will prompt more homeowners to invest in preventative solutions such as gopher wire mesh for raised garden beds, tree protection, and flower beds, supporting steady market growth.

Expansion in Agricultural and Horticultural Applications

The agricultural sector is poised for increased adoption of gopher wire mesh in 2026, especially in high-value crop production. Orchards, vineyards, and nurseries are increasingly using the mesh to protect root systems and young saplings from rodent damage. With rising emphasis on crop yield optimization and reduced reliance on chemical repellents, physical barriers like gopher wire offer an eco-friendly and long-term solution. Government incentives promoting sustainable farming practices may further accelerate its integration into agricultural infrastructure.

Shift Toward Durable and Corrosion-Resistant Materials

Market demand in 2026 will favor gopher wire mesh made from galvanized steel or with PVC coating due to enhanced durability and longer lifespan. Consumers and commercial users are prioritizing products that withstand harsh soil conditions and moisture, reducing replacement frequency and lifecycle costs. Innovations in coating technologies and higher-grade steel alloys are expected to gain traction, differentiating premium offerings in a competitive landscape.

E-Commerce Growth and Accessibility

Online retail channels will play a pivotal role in shaping the gopher wire mesh market by 2026. DIY consumers and small-scale farmers are increasingly purchasing mesh rolls and kits through e-commerce platforms, attracted by competitive pricing, customer reviews, and home delivery. Major online marketplaces and specialized gardening suppliers are likely to expand product listings, including pre-cut kits and installation accessories, making the product more accessible and user-friendly.

Sustainability and Environmental Regulations

Environmental awareness will influence material sourcing and disposal practices in the gopher wire mesh industry. Recyclable steel content and reduced environmental impact during manufacturing may become key selling points. Additionally, regions with strict regulations on rodenticides may see a regulatory push toward non-toxic pest control methods, indirectly boosting demand for physical barriers like gopher wire mesh as a compliant alternative.

Regional Market Variations and Climate Impact

Geographic trends will remain significant, with higher demand expected in western U.S. states (e.g., California, Oregon, Washington), where gopher populations are prevalent and agriculture is robust. Climate change-induced shifts in rodent migration patterns could expand the effective use zone of gopher wire into new regions by 2026, opening untapped markets in areas previously less affected by burrowing pests.

Competitive Landscape and Product Innovation

The market will see increased competition among manufacturers, leading to product differentiation through improved mesh designs (e.g., finer gauges, flexible weaves) and bundled solutions (e.g., mesh with stakes, installation tools). Private-label brands and big-box retailers may introduce cost-effective alternatives, pressuring traditional suppliers to innovate or reduce prices to maintain market share.

Common Pitfalls Sourcing Gopher Wire Mesh (Quality, IP)

Sourcing gopher wire mesh for agricultural, construction, or landscaping purposes requires careful attention to quality standards and intellectual property (IP) considerations. Below are common pitfalls buyers encounter, particularly concerning material quality and IP risks.

Poor Material Quality and Specifications

One of the most frequent issues when sourcing gopher wire mesh is receiving substandard materials that fail to meet required durability or safety standards. Common quality-related pitfalls include:

- Incorrect Wire Gauge: Suppliers may provide mesh with thinner wires than specified, reducing its effectiveness in preventing gopher intrusion. Always verify the gauge (e.g., 19 AWG or 2.3 mm) before purchase.

- Low Zinc Coating on Galvanized Mesh: Inadequate galvanization leads to rust and premature degradation, especially in moist environments. Ensure compliance with ASTM A641 or equivalent standards for coating weight.

- Inconsistent Mesh Size: A deviation from the specified opening size (commonly 1/2 inch) can allow pests to penetrate. Request sample testing or third-party inspection.

- Weak Weld Points or Weaving: Poorly welded or woven joints compromise structural integrity. Look for ISO or ASTM-certified manufacturing processes.

Lack of Compliance with Industry Standards

Buyers often assume that all gopher wire mesh meets regional construction or agricultural codes. However, non-compliant products may not pass inspection or perform as expected. Always confirm conformity with relevant standards such as:

- ASTM A474 (for welded steel mesh)

- CSA standards (in Canada)

- Local building or agricultural codes

Intellectual Property (IP) Infringement Risks

When sourcing from manufacturers, especially overseas, there’s a risk of inadvertently purchasing products that infringe on proprietary designs or patented mesh configurations. Key IP pitfalls include:

- Counterfeit or Clone Products: Some suppliers replicate patented mesh patterns or branding without authorization. This exposes buyers to legal liability or supply chain disruptions.

- Unverified Supplier Credentials: Working with unauthorized distributors or factories that lack proper licensing agreements for branded products.

- Absence of IP Warranty: Many generic suppliers do not provide assurances that their products are free from IP claims. Insist on contractual IP indemnification clauses.

Mitigation Strategies

To avoid these pitfalls:

– Request material test reports and certifications.

– Conduct factory audits or use third-party inspection services.

– Verify supplier legitimacy through business licenses and customer references.

– Include IP protection terms in procurement contracts.

By addressing quality and IP concerns proactively, buyers can ensure reliable performance and legal compliance when sourcing gopher wire mesh.

Logistics & Compliance Guide for Gopher Wire Mesh

Product Overview

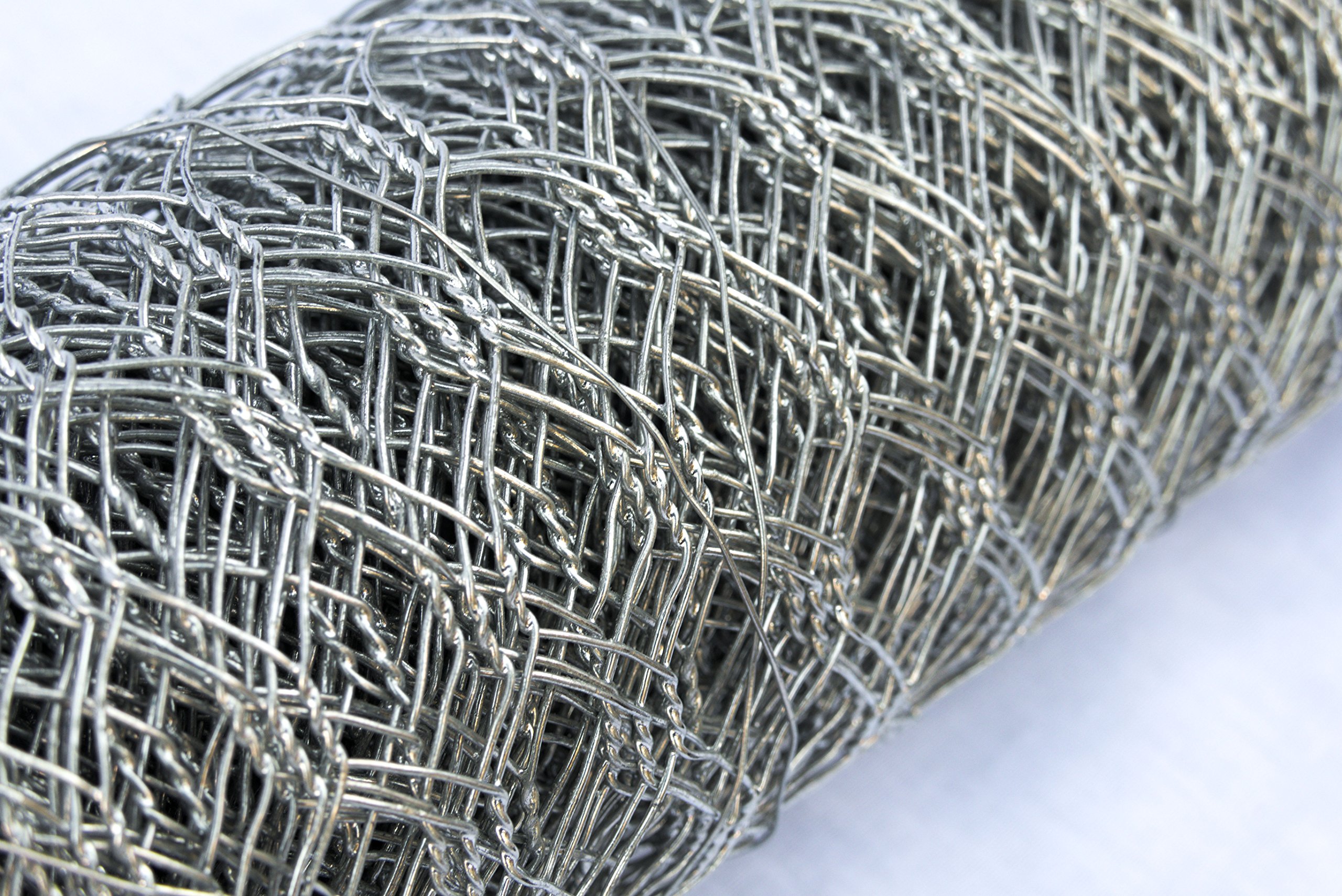

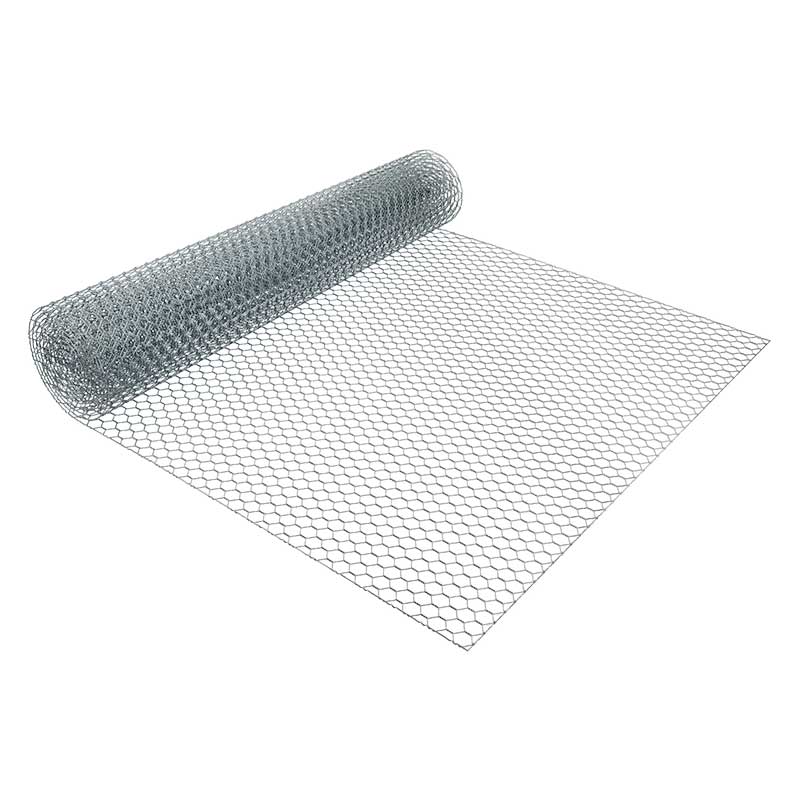

Gopher Wire Mesh, also known as hardware cloth or gopher mesh, is a welded or woven wire mesh typically made of galvanized steel. It is commonly used for garden protection, animal enclosures, and erosion control. This guide outlines key logistics and compliance considerations to ensure safe, efficient distribution and regulatory adherence.

Material Specifications & Standards

- Wire Gauge: Typically ranges from 19 to 23 gauge (0.0359″ to 0.0239″ diameter)

- Mesh Size: Commonly 1/2 inch, 1 inch, or 1/4 inch openings

- Coating: Hot-dip galvanized (HDG) after welding for corrosion resistance; meets ASTM A641 or ASTM A123 standards

- Tensile Strength: Minimum 50,000 psi for structural integrity

- Compliance: Conforms to ASTM A474 (Standard Specification for Zinc-Coated Steel Wire for Wire Fabric)

Packaging & Handling Requirements

- Rolls: Supplied in standard roll lengths (25 ft, 50 ft, 100 ft) and widths (24″, 36″, 48″)

- Core Material: Cardboard or plastic cores to prevent deformation

- Wrapping: Waterproof plastic or UV-resistant shrink wrap to prevent moisture damage and corrosion

- Labeling: Each roll must display product specifications, batch number, manufacturer, and safety warnings

- Handling: Use mechanical lifting equipment for large rolls; avoid dragging to prevent edge deformation

Transportation & Shipping

- Load Securing: Rolls must be strapped and braced on pallets to prevent shifting during transit

- Stacking: Limit vertical stacking to 3–4 layers depending on roll weight to avoid crushing

- Environmental Protection: Keep covered during transport to minimize exposure to rain, snow, or salt spray

- International Shipments: Comply with ISPM 15 for wooden pallets (heat-treated or fumigated)

Storage Guidelines

- Indoor Storage Recommended: Store in a dry, well-ventilated area away from moisture and corrosive chemicals

- Elevation: Keep rolls off the ground using pallets to prevent contact with standing water

- Shelf Life: Galvanized mesh can last 10–15 years when stored properly; inspect periodically for white rust or coating damage

Regulatory & Environmental Compliance

- REACH & RoHS: Confirm zinc coating complies with EU regulations on restricted substances

- Proposition 65 (California): Label products containing lead or cadmium if applicable (rare in modern galvanizing)

- EPA & OSHA: Adhere to workplace safety standards during handling and cutting; use PPE to prevent cuts and zinc exposure

- Recycling: Steel wire mesh is 100% recyclable; provide end-of-life disposal guidance to customers

Import/Export Documentation

- HS Code: 7314.31.10 (Galvanized steel wire mesh, welded) – verify per country

- Certificates Required: Certificate of Conformance (CoC), Mill Test Report (MTR), and Material Safety Data Sheet (MSDS)

- Customs Declarations: Accurate product descriptions, country of origin, and value declarations

Customer Compliance Support

- Provide detailed installation and safety instructions

- Offer technical support for code-compliant applications (e.g., agricultural fencing codes)

- Maintain traceability through batch tracking and quality records

Sustainability & ESG Considerations

- Source from mills with environmental management systems (e.g., ISO 14001)

- Minimize packaging waste through recyclable materials

- Support circular economy via take-back or recycling programs where feasible

By adhering to this logistics and compliance guide, distributors and end-users can ensure the safe, legal, and sustainable use of Gopher Wire Mesh across residential, agricultural, and commercial applications.

In conclusion, sourcing gopher wire mesh requires careful consideration of several key factors to ensure effectiveness, durability, and value. It is essential to select a mesh with the appropriate gauge (typically 1/4 inch openings and 9-11 gauge wire) to effectively deter gophers and other burrowing pests. Material quality, such as galvanized or PVC-coated steel, contributes to longevity and resistance to corrosion, especially in moist or acidic soils. Buyers should evaluate suppliers based on product consistency, pricing, availability, and customer reviews to ensure reliability.

Additionally, understanding the specific application—whether for garden beds, under raised planters, or around tree trunks—will guide the appropriate size, roll dimensions, and installation method. Sourcing from reputable agricultural or hardware suppliers, or directly from manufacturers, can yield cost-effective solutions while ensuring compliance with pest control standards. Ultimately, investing in high-quality gopher wire mesh and proper installation technique offers long-term protection for landscaping and agricultural investments, reducing maintenance costs and preventing damage from persistent underground pests.