The global trailer components market is experiencing steady growth, driven by rising demand in the recreational vehicle (RV), logistics, and construction sectors. According to Mordor Intelligence, the global trailer market was valued at USD 56.3 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2029, with North America and Europe remaining key contributors. A critical component within this ecosystem is the gooseneck electric trailer jack—valued for its convenience, load capacity, and integration with modern towing systems. As consumer preference shifts from manual to electric jacks for improved safety and ease of use, manufacturers are responding with innovative, high-performance models. Based on market presence, product innovation, customer reviews, and distribution reach, the following nine companies have emerged as leading manufacturers of gooseneck electric trailer jacks, shaping the future of towing technology.

Top 9 Gooseneck Electric Trailer Jack Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Powered Jacks

Domain Est. 1995

#2 FULTON

Domain Est. 1996

Website: fultonperformance.com

Key Highlights: XLT Trailer Jack Uses TruTurn 360 system that delivers a best in class castering performance….

#3 Trailer Jacks

Domain Est. 1997

Website: buyersproducts.com

Key Highlights: 12 Volt Electric Jack. A convenient electric way to raise, lower and level your parked RV or trailer. Color: Black; Finish: Powder-Coat; Square/Round: Round….

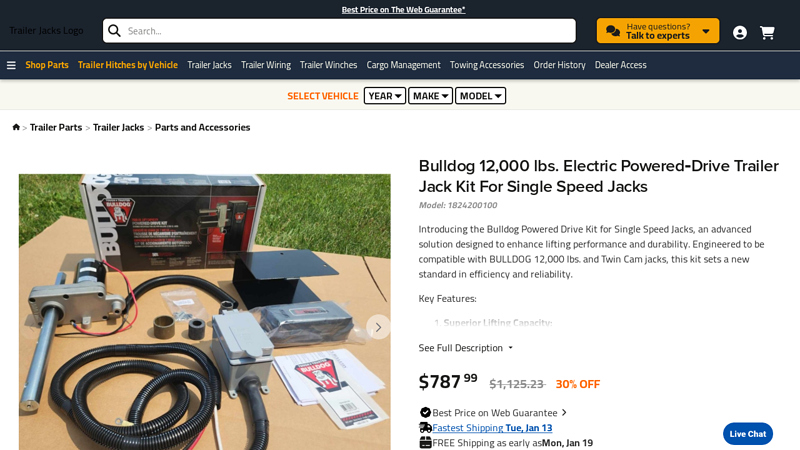

#4 Bulldog Electric & Gooseneck Trailer Jacks

Domain Est. 2002

Website: trailerjacks.com

Key Highlights: In stock Free deliveryUpgrade with Bulldog Electric Trailer Jacks: 12000 lbs capacity, gooseneck trailer, and square tube designs for ultimate towing ease and reliability….

#5 Magnum Lift Systems

Domain Est. 2006

Website: magnumliftsystems.com

Key Highlights: At Magnum Lift Systems, we build high-quality trailer jacks designed to make trailer setup faster, easier, and hassle-free….

#6 Pop Up Gooseneck Hitches & Couplers

Domain Est. 2009

Website: hitchescouplers.com

Key Highlights: The Flip-Over Ball Gooseneck Hitch converts your pickup bed to a smooth bed in seconds by just rotating the handle and flipping the ball over….

#7 Electric Hydraulic Gooseneck Trailer Jack Landing Gear

Domain Est. 2011

Website: popupgooseneckhitch.com

Key Highlights: The Magnum electric/hydraulic gooseneck trailer jacks have a manual override that can be operated with an electric or cordless drill. Also available are models ……

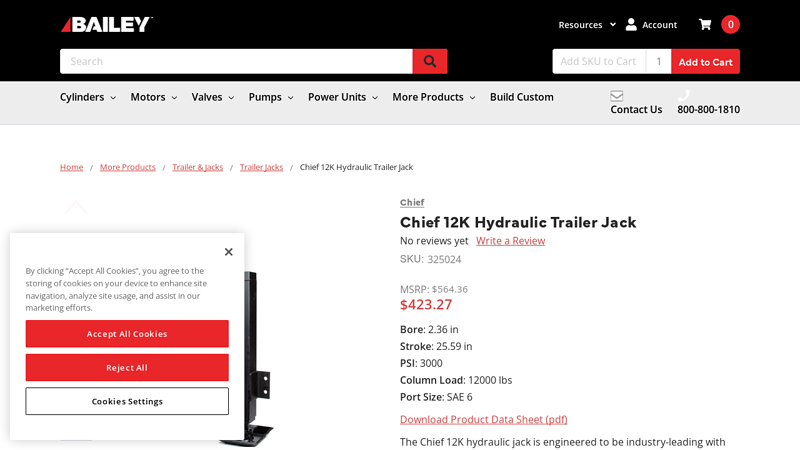

#8 Chief 12K Hydraulic Trailer Jack

Domain Est. 2013

#9 Horse Trailers

Domain Est. 2021

Expert Sourcing Insights for Gooseneck Electric Trailer Jack

H2: 2026 Market Trends for Gooseneck Electric Trailer Jacks

The market for gooseneck electric trailer jacks is poised for notable evolution by 2026, driven by advancements in technology, growing consumer demand for convenience, and expansion in the towing and recreational vehicle sectors. This analysis outlines the key trends expected to shape the industry in the coming years.

-

Increased Demand from Recreational and Commercial Sectors

By 2026, the recreational vehicle (RV) market is projected to continue its growth trajectory, particularly in North America. As gooseneck trailers remain a preferred choice for heavy-duty hauling and fifth-wheel RVs, the demand for reliable and user-friendly electric trailer jacks will rise. Simultaneously, commercial users in agriculture, construction, and equipment transport are adopting electric jacks to improve operational efficiency and reduce physical strain. -

Technological Advancements and Smart Integration

A major trend in 2026 will be the integration of smart technology into gooseneck electric trailer jacks. Features such as Bluetooth connectivity, smartphone app control, real-time load monitoring, and automatic leveling systems are expected to become standard in mid-to-high-end models. These innovations enhance user experience, safety, and precision during hitching and unhitching operations. -

Focus on Durability and Weather Resistance

Manufacturers are increasingly prioritizing rugged designs to meet the demands of heavy-duty use in diverse environmental conditions. By 2026, expect wider adoption of corrosion-resistant materials (e.g., stainless steel, marine-grade aluminum) and enhanced sealing against dust and moisture, especially in premium models targeting off-road and all-weather applications. -

Expansion of Battery and Power Efficiency Options

As electric systems become more sophisticated, so does the need for reliable power sources. The 2026 market will likely see more models featuring dual-power options (12V DC and onboard battery packs), faster charging systems, and energy-efficient motors. This reduces dependency on vehicle batteries and increases usability in remote locations. -

Growing Emphasis on Safety and Load Capacity

Safety standards are becoming stricter, prompting manufacturers to design jacks with higher weight capacities (up to 10,000+ lbs) and built-in overload protection. Anti-sway mechanisms and emergency stop features are expected to be more prevalent, aligning with broader trends in vehicle safety technology. -

Regional Market Growth and E-Commerce Influence

North America will remain the dominant market, but growth is also expected in Europe and parts of Asia-Pacific due to increasing RV ownership and infrastructure development. Online retail platforms will play a crucial role in product distribution, with detailed comparisons, customer reviews, and installation guides influencing purchasing decisions. -

Sustainability and Eco-Friendly Manufacturing

Environmental concerns are pushing manufacturers toward sustainable production methods. By 2026, eco-conscious brands may differentiate themselves through recyclable packaging, energy-efficient manufacturing, and product longevity, appealing to environmentally aware consumers.

In summary, the 2026 market for gooseneck electric trailer jacks will be characterized by innovation, enhanced user experience, and expanded application across both personal and commercial domains. Companies that invest in smart features, durability, and customer-centric design will be well-positioned to lead this evolving market.

Common Pitfalls When Sourcing a Gooseneck Electric Trailer Jack (Quality and Intellectual Property)

Sourcing a gooseneck electric trailer jack involves more than just finding the lowest price. Key pitfalls related to quality and intellectual property (IP) can lead to performance failures, safety issues, and legal risks. Being aware of these challenges helps ensure a reliable, compliant, and cost-effective procurement process.

Poor Build Quality and Materials

Many low-cost electric trailer jacks use substandard materials such as thin-gauge steel, inferior welds, or weak motors. This compromises durability, leading to premature failure under load or exposure to weather. Components like gears, housings, and mounting brackets may lack proper heat treatment or corrosion resistance, reducing lifespan—especially in harsh environments.

Inadequate Weather and Environmental Protection

Gooseneck jacks operate in demanding conditions, yet some models lack sufficient Ingress Protection (IP) ratings. Units without at least an IP65 rating may allow dust and water ingress, damaging internal electronics and motors. This can cause electrical shorts, corrosion, or complete jack failure, posing safety hazards during use.

Overstated Load Capacity and Performance Claims

Suppliers—especially from unverified manufacturers—may exaggerate lifting capacity, speed, or duty cycle. Units tested under ideal conditions may fail under real-world loads, leading to motor burnout or structural collapse. Always verify performance claims with third-party testing data or certifications.

Lack of Safety and Compliance Certifications

Reputable electric trailer jacks should meet safety standards such as CE, RoHS, or UL. Sourcing from manufacturers without these certifications increases the risk of non-compliant products that may fail inspections or violate regional regulations, resulting in liability or shipment rejections.

Intellectual Property Infringement Risks

Some low-cost suppliers replicate branded designs (e.g., Atwood, Lippert) without authorization. Sourcing such counterfeit or knock-off products exposes buyers to IP litigation, customs seizures, and reputational damage. Always verify that the design and branding do not infringe on existing patents or trademarks.

Insufficient Warranty and After-Sales Support

Cheaply sourced jacks often come with limited or no warranty. When failures occur, lack of spare parts, technical support, or service networks leads to costly downtime and replacements. Reliable suppliers offer comprehensive warranties and accessible customer service.

Hidden Costs from Frequent Failures

While initial pricing may be attractive, poor quality leads to higher total cost of ownership through repairs, replacements, and operational delays. Investing in a higher-quality, IP-compliant jack with strong manufacturer backing reduces long-term expenses and enhances safety.

To avoid these pitfalls, conduct thorough due diligence: request product samples, validate certifications, audit suppliers, and ensure IP compliance before finalizing procurement.

Logistics & Compliance Guide for Gooseneck Electric Trailer Jack

Product Overview

The Gooseneck Electric Trailer Jack is a motorized lifting device designed to raise and lower the front end of gooseneck trailers for hitching, unhitching, and leveling. It replaces manual crank jacks with convenient electric operation, typically powered by a 12V DC battery system. This guide outlines key logistics and compliance considerations for distribution, installation, and use.

Shipping & Handling Requirements

- Packaging: Units must be shipped in sturdy, manufacturer-approved packaging with internal foam or plastic supports to prevent damage during transit.

- Weight & Dimensions: Confirm crate weight and dimensions for accurate freight classification (typically Class 150–225 NMFC). Average unit weight: 30–50 lbs (13–23 kg).

- Hazardous Materials: No hazardous components; standard ground or freight shipping applies. Avoid exposure to moisture during transport.

- Storage Conditions: Store in a dry, temperature-controlled environment (32°F–120°F / 0°C–49°C). Avoid prolonged exposure to direct sunlight or corrosive atmospheres.

Import & Export Compliance

- HS Code: Typically classified under 8425.42 (hoists and winches) or 8716.90 (parts and accessories for trailers). Confirm with local customs authority.

- Country-Specific Regulations:

- USA/Canada: Complies with FMVSS and CMVSS standards when installed on road-going trailers. No additional import restrictions for standalone components.

- EU: CE marking required. Must comply with Machinery Directive 2006/42/EC and Electromagnetic Compatibility (EMC) Directive 2014/30/EU.

- Australia/NZ: Complies with AS/NZS 4177 (caravan and light trailer standards).

- Documentation: Commercial invoice, packing list, and bill of lading required. Certificates of Conformity (CoC) may be needed for EU and other regulated markets.

Installation & Use Compliance

- Voltage Requirements: Designed for 12V DC systems. Verify compatibility with trailer battery and wiring (minimum 10-gauge wire recommended).

- Mounting Standards: Must be securely bolted or welded to the trailer frame per manufacturer specifications. Mounting strength should support 1.5x the trailer’s tongue weight.

- Safety Features: Equipped with automatic overload protection and thermal cutoff. Do not bypass or disable safety mechanisms.

- Operational Limits: Never exceed rated lifting capacity (typically 6,000–10,000 lbs). Use only on stable, level ground.

Electrical & EMC Compliance

- Certifications: UL/CSA listed (North America), CE marked (Europe), RCM compliant (Australia). Ensure product bears appropriate certification marks.

- EMI Protection: Built-in noise suppression to meet FCC Part 15 (USA) and CISPR 25 (automotive EMC) standards. Shielded wiring recommended.

- Grounding: Proper chassis grounding is required to prevent electrical faults and ensure reliable operation.

Maintenance & Inspection

- Routine Checks: Inspect for corrosion, loose bolts, and cable wear every 30 days or prior to long trips.

- Lubrication: Apply marine-grade grease to the screw shaft and moving parts every 6 months or after exposure to water/salt.

- Load Testing: Test lifting function under no load monthly. Never perform load tests in public areas or unstable environments.

Warranty & Liability

- Standard Warranty: Typically 1–2 years limited warranty covering defects in materials and workmanship. Excludes damage from misuse, improper installation, or lack of maintenance.

- User Responsibility: End users must follow installation manuals and safety warnings. Unauthorized modifications void warranty and may create liability risks.

- Recall Readiness: Distributors must maintain traceability (serial numbers, batch logs) and have a recall response plan aligned with local consumer safety regulations (e.g., CPSC in USA).

Environmental & Disposal Compliance

- RoHS/REACH (EU): Compliant with restrictions on hazardous substances. Contains no lead, cadmium, or restricted phthalates above threshold.

- End-of-Life Handling: Recycle through e-waste programs. Motors and metal housings are recyclable; electronic components must be disposed of per local WEEE regulations.

- Battery Disconnection: Always disconnect trailer battery before servicing to prevent short circuits.

Training & Documentation

- User Manuals: Must be provided in local language(s) for all markets. Include installation instructions, safety warnings, torque specs, and troubleshooting.

- Distributor Training: Provide technical training for installers on proper mounting, wiring, and load testing.

- Safety Labels: Ensure all units have durable warning labels indicating pinch points, electrical hazards, and maximum load.

Adherence to this guide ensures safe, legal, and efficient handling of Gooseneck Electric Trailer Jacks throughout the supply chain and end use. Always consult the manufacturer’s latest specifications and regional regulatory updates.

In conclusion, sourcing a gooseneck electric trailer jack requires careful consideration of load capacity, durability, ease of installation, and compatibility with your trailer setup. Opting for a reliable, corrosion-resistant model with remote operation enhances convenience, safety, and efficiency during hitching and unhitching. By prioritizing quality brands, verifying user reviews, and comparing features such as lift range and power source (12V or battery-operated), you can ensure a worthwhile investment that improves your towing experience. Ultimately, a well-chosen electric gooseneck jack simplifies trailer handling and provides peace of mind on every journey.