The HVAC components market has experienced steady expansion, driven by rising demand for energy-efficient cooling solutions and increased residential and commercial infrastructure development. According to Grand View Research, the global air conditioning market was valued at USD 111.7 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. As critical components in HVAC systems, contactors play a pivotal role in ensuring reliable operation of air conditioners, particularly in widely used brands like Goodman. With aging units requiring replacements and new installations on the rise, demand for high-quality, compatible contactors has surged. This growth trajectory, supported by industry reports from leading analytics firms such as Grand View Research, underscores the importance of dependable manufacturers in maintaining system performance and longevity. In this context, the top three Goodman air conditioner contactor manufacturers have emerged based on product reliability, market presence, and customer-centric innovation.

Top 3 Goodman Air Conditioner Contactor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 GoodmanParts.net

Domain Est. 2011

Website: goodmanparts.net

Key Highlights: Free delivery over $99 · 90-day returnsGet genuine Goodman factory OEM repair parts for your Goodman unit. All Goodman parts are brand new in the original factory packaging and ar…

#2 Customer Support

Domain Est. 1997

Website: goodmanmfg.com

Key Highlights: Standard Warranty. Our air conditioners and heat pumps feature our most comprehensive limited warranty coverage of any on the market. · Extended Service Plan….

#3 Air Conditioners

Domain Est. 1997

Website: gmc.goodmanmfg.com

Key Highlights: Every single GMC brand system designed, engineered and manufactured with pride. All employees follow strict quality driven process….

Expert Sourcing Insights for Goodman Air Conditioner Contactor

H2: 2026 Market Trends for Goodman Air Conditioner Contactors

As the HVAC industry continues to evolve, the market for Goodman air conditioner contactors is expected to experience several key trends in 2026 driven by technological advancements, regulatory changes, and shifting consumer demands. Goodman, a leading brand under Daikin America, is well-positioned to adapt to these shifts due to its reputation for reliability and cost-effective solutions. Below are the primary market trends expected to shape the demand and development of Goodman contactors in 2026:

-

Increased Demand for Energy Efficiency

With growing emphasis on energy conservation and sustainability, HVAC systems are being designed to meet higher efficiency standards. As a result, Goodman contactors—integral components that control the flow of electricity to compressors and fans—are being engineered for smoother, more reliable operation to support high-efficiency Goodman AC units. The push for ENERGY STAR®-certified systems and compliance with updated DOE efficiency rules will drive demand for precision contactors that minimize energy loss and reduce wear on system components. -

Integration with Smart HVAC Systems

Smart home technology is expanding rapidly, and HVAC systems are no exception. In 2026, Goodman is expected to further integrate its contactors with smart thermostats and IoT-enabled control boards. This trend will favor contactors that are compatible with variable-speed compressors and modulating systems, allowing for better load management and extended equipment lifespan. Enhanced diagnostics and remote monitoring capabilities may also require contactors with improved durability and signal responsiveness. -

Focus on Durability and Reliability

As climate change contributes to more extreme weather patterns—particularly longer and hotter summers—air conditioners are running longer and under more stress. This places greater strain on components like contactors, which are prone to pitting, welding, or failure due to frequent cycling. In response, Goodman is likely to emphasize contactors with higher amp ratings, improved arc suppression, and longer lifespans. OEM replacement demand is expected to grow, benefiting both original equipment manufacturers and the aftermarket. -

Growth in Replacement and Retrofit Markets

The existing base of aging HVAC systems in the U.S. continues to expand the replacement market. Many Goodman units installed in the 2010s will approach or exceed their expected service life by 2026, leading to increased demand for replacement contactors. Goodman’s broad compatibility across its product lines and standardized designs will support strong aftermarket performance. Additionally, contractors and technicians will prioritize genuine OEM parts like Goodman contactors for reliability and warranty compliance. -

Supply Chain and Manufacturing Localization

Ongoing global supply chain volatility and a push for domestic manufacturing may influence how Goodman sources and produces components. In 2026, there could be a greater emphasis on localized production of critical parts, including contactors, to reduce lead times and improve inventory availability. This trend may also encourage partnerships with U.S.-based component suppliers, enhancing supply resilience. -

Regulatory and Environmental Compliance

Environmental regulations, particularly those related to refrigerants (e.g., the phase-down of R-410A in favor of lower-GWP alternatives like R-32 and R-454B), will impact HVAC system design. While contactors are not directly affected by refrigerant changes, the shift toward next-generation systems may require updated electrical components capable of handling different operating pressures and temperatures. Goodman will likely adapt its contactor specifications to align with these new system requirements.

Conclusion:

The 2026 market for Goodman air conditioner contactors will be shaped by a convergence of efficiency mandates, smart technology integration, and increasing system reliability demands. As a trusted name in residential HVAC, Goodman is expected to maintain a strong market presence by offering durable, compatible, and increasingly intelligent contactor solutions. The replacement market, in particular, will remain a key growth driver, supported by the brand’s widespread installation base and focus on quality components.

Common Pitfalls When Sourcing Goodman Air Conditioner Contactors (Quality & IP)

Sourcing replacement contactors for Goodman air conditioning units seems straightforward, but several pitfalls related to quality and intellectual property (IP) can lead to system failures, safety hazards, and warranty issues. Being aware of these common problems helps ensure you get a reliable, compatible, and legitimate part.

Choosing Low-Quality or Counterfeit Contactors

One of the biggest risks is purchasing contactors made with inferior materials or poor manufacturing standards. These often appear cheaper but can lead to premature failure, arcing, overheating, or even fire hazards. Counterfeit parts may mimic branding or packaging but lack the durability and safety certifications of genuine components.

Assuming Generic Parts Are Always Equivalent

While some third-party contactors meet OEM specifications (e.g., same coil voltage, amperage rating, and terminal configuration), not all do. Using a generic part that doesn’t precisely match the original can result in improper operation, increased wear on the compressor or fan motor, or failure to handle inrush current—potentially voiding system warranties.

Overlooking IP and Trademark Infringement

Goodman and its parent company, Daikin, hold trademarks and design patents on specific parts, including contactors. Sourcing parts that illegally replicate Goodman’s branding, part numbers, or design elements risks purchasing counterfeit goods. Distributors or suppliers selling such items may be violating intellectual property laws, and users could face liability or receive unreliable components.

Ignoring Environmental and Safety Ratings (IP Code)

The “IP” (Ingress Protection) rating indicates a contactor’s resistance to dust and moisture—critical for outdoor HVAC units. A common mistake is selecting a contactor with insufficient IP protection (e.g., IP20 instead of IP54/55), leading to corrosion, short circuits, and early failure in harsh environments. Always verify the correct IP rating for the installation location.

Failing to Verify Compatibility with Goodman Control Systems

Goodman systems may have specific electrical characteristics or control logic. A contactor that physically fits but isn’t electrically matched can disrupt the sequence of operation, cause nuisance tripping, or damage control boards. Always cross-reference the contactor part number with Goodman’s official documentation or approved equivalents.

Relying Solely on Online Marketplaces Without Vetting Sellers

Platforms like Amazon or eBay often host third-party sellers offering contactors at attractive prices. However, without vetting the seller’s reputation and part authenticity, buyers risk receiving substandard, used, or counterfeit contactors. Look for authorized distributors or suppliers with verifiable credentials.

Logistics & Compliance Guide for Goodman Air Conditioner Contactor

This guide outlines the key logistics considerations and compliance requirements for handling, transporting, storing, and installing Goodman air conditioner contactors. Adherence to these guidelines ensures product integrity, safety, and regulatory compliance.

Product Identification & Specifications

- Part Number: Verify the correct contactor model number (e.g., GMVC24A125, GMVC24B075) as specified by Goodman Manufacturing.

- Voltage Rating: Typically 24V coil with line voltage ratings of 208–230V AC.

- Ampere Rating: Ranges from 20A to 100A depending on model; confirm load compatibility.

- Certifications: UL Listed, CSA Certified, RoHS compliant. Look for marks on the device housing.

Packaging & Handling Requirements

- Original Packaging: Store and transport contactors in original anti-static packaging to prevent damage and contamination.

- Handling Instructions: Avoid dropping or applying mechanical stress. Do not touch electrical terminals with bare hands to prevent corrosion.

- Labeling: Ensure all packages are clearly labeled with part number, quantity, and handling symbols (e.g., “Fragile,” “Do Not Stack”).

Storage Conditions

- Temperature Range: Store between 32°F (0°C) and 104°F (40°C).

- Humidity: Maintain relative humidity below 80%, non-condensing.

- Environment: Keep in a clean, dry, and well-ventilated area away from corrosive substances, direct sunlight, and electromagnetic interference.

Transportation Guidelines

- Mode of Transport: Suitable for ground and air freight; ensure compliance with IATA/IMDG regulations if shipping internationally.

- Stacking: Do not exceed manufacturer-recommended stack height to avoid crushing lower units.

- Shock & Vibration: Use cushioning materials and secure loads to minimize vibration during transit.

Import/Export Compliance

- HTS Code: Confirm Harmonized Tariff Schedule code (e.g., 8536.50 for electrical contactors) for customs declarations.

- Documentation: Include commercial invoice, packing list, and Certificate of Origin where required.

- Regulatory Approvals: Ensure contactors meet destination country standards (e.g., CE for Europe, RCM for Australia).

Environmental & Safety Compliance

- RoHS Compliance: Product complies with Restriction of Hazardous Substances Directive (EU 2011/65/EU).

- WEEE Directive: At end-of-life, contactors must be disposed of via authorized electronic waste recycling facilities in applicable regions.

- Safety Standards: Complies with UL 508 and CSA C22.2 No. 14 for industrial control equipment.

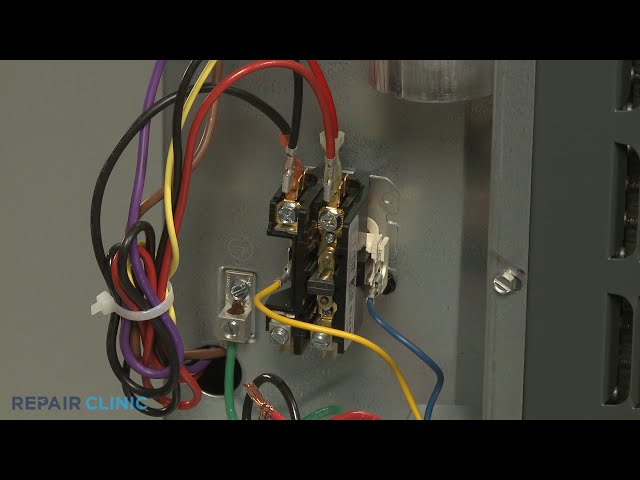

Installation & Field Use Compliance

- Qualified Personnel Only: Installation must be performed by licensed HVAC technicians in accordance with NEC (NFPA 70) and local electrical codes.

- Torque Specifications: Tighten terminal screws to manufacturer-specified torque (e.g., 14–18 in-lbs) to prevent arcing or overheating.

- System Compatibility: Verify compatibility with specific Goodman air handler or condenser unit model.

Warranty & Traceability

- Warranty Period: Typically 10-year limited parts warranty from Goodman; registration may be required.

- Serial Tracking: Record serial numbers for traceability and warranty validation.

- Defective Unit Handling: Return failed units following Goodman’s return material authorization (RMA) process.

Disposal & Recycling

- Hazardous Materials: Contains no significant hazardous materials beyond standard electronic components.

- Recycling: Partner with certified e-waste recyclers to ensure proper recovery of metals and plastics.

- Local Regulations: Follow municipal and federal disposal regulations for electrical components.

Adhering to this guide ensures efficient logistics operations and full compliance with safety, environmental, and regulatory standards for Goodman air conditioner contactors. Always consult the latest product documentation and manufacturer guidelines for updates.

In conclusion, sourcing a Goodman air conditioner contactor requires careful attention to compatibility, quality, and reliability. It is essential to select a contactor that matches the specific voltage, amperage, and coil specifications of your Goodman unit to ensure optimal performance and safety. Purchasing from reputable suppliers—such as HVAC specialty stores, authorized Goodman distributors, or trusted online retailers—helps guarantee that you receive an authentic, high-quality component. Additionally, considering factors like warranty, customer reviews, and technical support can further ensure long-term satisfaction. By taking these steps, you can confidently source the correct contactor, maintain the efficiency of your HVAC system, and extend the lifespan of your air conditioning unit.