The global gold ratchet market is experiencing steady growth, driven by increasing demand across industrial, automotive, and construction sectors. According to Grand View Research, the global ratchet tools market was valued at USD 1.2 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. A key factor fueling this expansion is the rising need for precision-engineered, durable hand tools, with gold-finished ratchets gaining favor for their corrosion resistance and enhanced visibility in low-light environments. Additionally, Mordor Intelligence reports that growth in manufacturing and infrastructure development—especially in the Asia-Pacific region—is amplifying demand for high-quality hand tool solutions. As competition intensifies, a select group of manufacturers have emerged at the forefront, combining innovation, durability, and advanced coating technologies to lead the segment. Here are the top 8 gold ratchet manufacturers shaping the industry in 2024.

Top 8 Gold Ratchet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 DT Swiss: manufacturer of bicycle components

Domain Est. 1996

Website: dtswiss.com

Key Highlights: We develop high-end, lightweight bicycle wheels, forks and shocks which are known for their precision and durability….

#2 Milwaukee® Tool

Domain Est. 2000

Website: milwaukeetool.com

Key Highlights: Milwaukee Tool is the most respected manufacturer of heavy-duty power tools, hand tools, instruments, and accessories….

#3 Snap

Website: snapontools.com.au

Key Highlights: Snap-on is a leading manufacturer of hand tools, power tools, diagnostics, workshop equipment & tool storage solutions for automotive professionals….

#4 ICON 3/8 in. Drive Professional Special Edition Gold

Domain Est. 1996

Website: go.harborfreight.com

Key Highlights: The ICON™ special edition 24k gold-plated 3/8 in. Drive Professional Special Edition Gold Plated Ratchet has a low profile head for easy clearance cramped ……

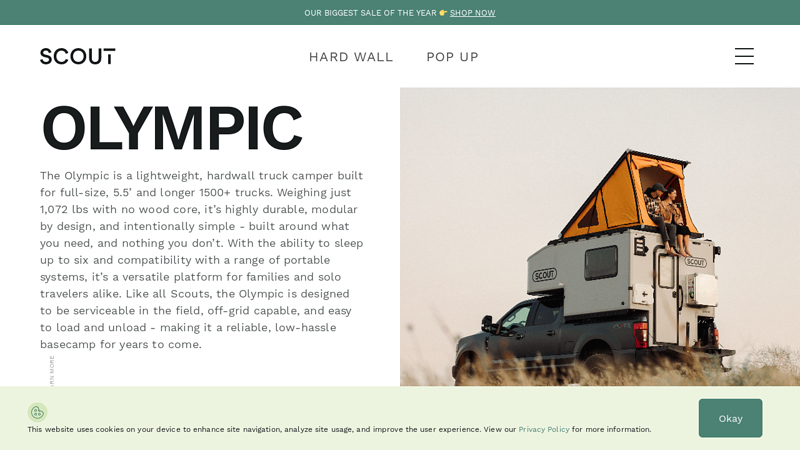

#5 Olympic

Domain Est. 2016

Website: scoutcampers.com

Key Highlights: The flagship model of the SCOUT fleet: Olympic. Experience truck camping at its finest, for both import and domestic trucks….

#6 1/4 in. Drive Professional Special Edition Gold Plated Ratchet

Domain Est. 2018

Website: solisdepot.com

Key Highlights: Rating 4.4 (61) Dec 1, 2025 · 1/4 in. Drive Professional Special Edition Gold Plated Ratchet ; Number in stock · 1 ; New $132.00 ; Product details · 1/4 in. Drive Professional …..

#7 XPO

Domain Est. 2018

Website: xpo.ru

Key Highlights: Mutual Index Funds! A smart platform for diversified, expert-managed investments in Forex, CFDs, and cryptocurrencies….

#8 Icon Gold Ratchet

Domain Est. 2024

Website: icon-tool.com

Key Highlights: This specialty ratchet is made by Icon, a tool brand sold through Harbor Freight that focuses on quality mechanics tools. The Gold Ratchet line features all ……

Expert Sourcing Insights for Gold Ratchet

H2 2026 Market Trends for Gold Ratchet

As we move into the second half of 2026, the market for Gold Ratchet—an innovative brand in the high-end hand tools and precision mechanics sector—reflects a convergence of technological advancement, sustainability demands, and evolving consumer preferences. Below is an analysis of key market trends shaping Gold Ratchet’s position and growth trajectory during this period.

1. Rising Demand for Smart Tools and IoT Integration

The industrial and professional DIY markets are increasingly embracing smart tools equipped with IoT (Internet of Things) capabilities. In H2 2026, Gold Ratchet continues to gain traction with its SmartRatchet™ line, which features Bluetooth connectivity, torque analytics, and mobile app integration. These tools appeal to automotive technicians, aerospace engineers, and construction professionals who require precision data tracking and predictive maintenance. Market adoption is particularly strong in North America and Western Europe, where labor efficiency and digital workflow integration are top priorities.

2. Sustainability and Circular Economy Focus

Environmental regulations and corporate ESG (Environmental, Social, and Governance) goals are pushing tool manufacturers toward sustainable practices. Gold Ratchet has responded with its “GreenGear” initiative, launched in Q2 2026, emphasizing recycled alloy construction, modular designs for easy repair, and a take-back program for end-of-life tools. By H2 2026, over 40% of Gold Ratchet’s product line is certified carbon-neutral, enhancing brand loyalty among eco-conscious businesses and government procurement programs.

3. Expansion in Emerging Markets

Gold Ratchet is strategically expanding distribution in Southeast Asia, Latin America, and parts of Africa, where infrastructure development and industrialization are accelerating. Partnerships with local distributors and vocational training centers have helped establish Gold Ratchet as a premium yet reliable brand. In H2 2026, emerging markets contribute nearly 25% of global sales, up from 15% in 2024, driven by demand for durable, high-torque ratchets in energy, transportation, and manufacturing sectors.

4. Competitive Pressure from Low-Cost Brands

Despite its premium positioning, Gold Ratchet faces growing competition from technologically capable but lower-priced alternatives from China and India. These brands are rapidly improving quality and incorporating smart features, squeezing mid-tier margins. In response, Gold Ratchet is focusing on brand differentiation through superior ergonomics, extended warranties, and proprietary anti-slip gear mechanisms—key factors in customer retention.

5. Supply Chain Resilience and Nearshoring

Ongoing geopolitical tensions and logistics volatility have prompted Gold Ratchet to accelerate its nearshoring efforts. By H2 2026, the company has opened a new manufacturing facility in Monterrey, Mexico, serving the North American market, reducing lead times and import costs. This shift improves inventory responsiveness and aligns with U.S. government incentives for domestic industrial production.

6. Growing Influence of B2B E-Commerce Platforms

Procurement via digital marketplaces like Amazon Business, ToolBarn Pro, and specialized industrial hubs has surged. Gold Ratchet’s direct-to-business (D2B) e-commerce platform, enhanced with AI-driven inventory suggestions and bulk pricing tools, now accounts for 35% of total sales. Integration with ERP systems used by large contractors further streamlines purchasing, reinforcing Gold Ratchet’s presence in enterprise supply chains.

Conclusion

In H2 2026, Gold Ratchet is well-positioned to capitalize on the digitalization of manual trades, sustainability mandates, and global industrial growth. While competitive and cost pressures persist, the company’s focus on innovation, environmental responsibility, and strategic market expansion supports sustained growth. Continued investment in R&D and customer-centric digital services will be crucial to maintaining its leadership in the premium ratchet tools segment.

Common Pitfalls Sourcing Gold Ratchet (Quality, IP)

Sourcing Gold Ratchet, a high-performance thermoplastic known for its chemical resistance and mechanical strength, presents several critical challenges—particularly concerning quality consistency and intellectual property (IP) protection. Failing to address these pitfalls can lead to product failures, supply chain disruptions, and legal exposure.

Quality Inconsistencies

One of the most significant risks when sourcing Gold Ratchet is variability in material quality. Not all suppliers adhere to the same production standards, leading to inconsistencies in:

- Material Purity: Impurities or deviations in polymer composition can affect thermal stability and mechanical performance.

- Batch-to-Batch Variability: Differences in melt flow index, tensile strength, or impact resistance can compromise part reliability.

- Additive Formulation: Unauthorized or inconsistent use of fillers, stabilizers, or colorants may degrade performance or cause regulatory non-compliance.

Using substandard or inconsistently produced Gold Ratchet can result in premature product failure, especially in demanding applications like automotive or medical devices.

Intellectual Property Risks

Gold Ratchet is often a proprietary material developed and trademarked by specific chemical manufacturers (e.g., Solvay, though “Gold Ratchet” may be a placeholder or fictional name for illustrative purposes). Sourcing from unauthorized suppliers increases exposure to IP violations:

- Counterfeit Materials: Some suppliers may falsely label inferior or generic PPS (polyphenylene sulfide) as Gold Ratchet to command a premium price.

- Unauthorized Resins: Distributors without proper licensing may unlawfully repackage or resell genuine material, voiding warranties and traceability.

- Lack of Documentation: Absence of material test reports (MTRs), certificates of conformance (CoC), or chain-of-custody records makes it difficult to verify authenticity and invites legal liability.

Using counterfeit or IP-infringing materials can result in lawsuits, recalls, and damage to brand reputation.

Mitigation Strategies

To avoid these pitfalls:

– Source exclusively from authorized distributors or directly from the IP holder.

– Require full material traceability and certification with every shipment.

– Conduct third-party testing to verify resin identity and performance.

– Include IP indemnification clauses in supplier contracts.

Proactive due diligence ensures both material integrity and legal compliance when sourcing high-performance polymers like Gold Ratchet.

Logistics & Compliance Guide for Gold Ratchet

This guide outlines the essential logistics and compliance considerations for Gold Ratchet, a product likely involving valuable materials and stringent regulatory requirements. Adherence to these guidelines ensures smooth operations, legal compliance, and protection against financial and reputational risks.

Product Classification and Regulatory Oversight

Gold Ratchet must be classified according to international and domestic regulations. Given its gold content, it falls under both precious metals regulations and general product safety standards. Key classifications include:

– HS Code: 7108.12 (Unwrought gold, unwrought or in powder form) or relevant category based on final form.

– ITAR/EAR: Verify if the product contains any dual-use components that may require export licensing under the Export Administration Regulations (EAR).

– Country-Specific Regulations: Comply with local laws in both origin and destination countries regarding precious metal trade, such as registration with national bullion associations or financial authorities.

Export and Import Compliance

All shipments of Gold Ratchet must comply with export control and customs regulations:

– Export Licenses: Determine if export licenses are required based on destination country and product specifications. Sanctioned countries (e.g., Iran, North Korea) are strictly prohibited.

– Customs Documentation: Prepare accurate commercial invoices, packing lists, certificates of origin, and, if applicable, export declarations (e.g., AES filing in the U.S.).

– Import Duties and Taxes: Research and calculate applicable import duties, VAT, or GST in the destination country. Misclassification may lead to penalties or shipment delays.

Transportation and Secure Logistics

Due to the high value and security risks associated with gold-containing products:

– Insured Freight: Use fully insured, trackable shipping services with real-time GPS monitoring.

– Chain of Custody: Maintain a documented chain of custody from manufacturing to final delivery, including tamper-evident packaging and access logs.

– Carrier Selection: Partner with logistics providers experienced in handling high-value cargo, preferably with armored transport options for domestic legs.

– Routing: Avoid high-risk transit zones; use secure ports and airports with strong anti-theft protocols.

Anti-Money Laundering (AML) and Know Your Customer (KYC)

Gold Ratchet transactions may be subject to AML regulations:

– Customer Due Diligence: Implement KYC procedures for all buyers, including verification of business licenses, registration documents, and beneficial ownership.

– Transaction Monitoring: Report any suspicious activity or unusually large/structured transactions to relevant financial intelligence units (e.g., FinCEN in the U.S.).

– Record Keeping: Retain transaction records, contracts, and identification documents for a minimum of five years as required by most AML regimes.

Environmental and Ethical Sourcing Compliance

Ensure gold used in Gold Ratchet is sourced responsibly:

– Conflict Minerals: Confirm gold is not sourced from conflict-affected or high-risk areas, in line with OECD Due Diligence Guidance.

– Certifications: Use gold from refiners certified under the Responsible Jewellery Council (RJC) or London Bullion Market Association (LBMA) Good Delivery standards.

– Sustainability Reporting: Maintain documentation of sourcing practices for ESG reporting and customer transparency.

Product Labeling and Safety Standards

Gold Ratchet must meet labeling and safety requirements:

– Material Disclosure: Clearly label gold content (e.g., karat weight, purity) as per FTC guidelines or EU REACH regulations.

– Safety Warnings: Include handling instructions if applicable (e.g., sharp edges, electrical components).

– Country of Origin: Label the product with the country where final assembly or substantial transformation occurred.

Recordkeeping and Audit Preparedness

Maintain comprehensive records to support compliance:

– Logistics Logs: Track all shipments, including dates, carrier details, tracking numbers, and delivery confirmations.

– Compliance Files: Archive export licenses, AML checks, sourcing certificates, and customs filings.

– Internal Audits: Conduct regular internal audits to verify adherence to all regulatory requirements and identify improvement areas.

Incident Response and Contingency Planning

Prepare for potential disruptions:

– Theft or Loss: Activate insurance claims immediately and report incidents to law enforcement and customs authorities.

– Regulatory Inquiry: Designate a compliance officer to manage audits or investigations by customs, financial regulators, or law enforcement.

– Supply Chain Disruptions: Maintain alternative logistics routes and backup suppliers for critical components.

By following this guide, Gold Ratchet operations can maintain legal compliance, ensure secure logistics, and uphold ethical standards across the supply chain. Regular training and updates to compliance policies are recommended to adapt to evolving regulations.

Conclusion for Sourcing Gold Ratchet:

Sourcing a gold ratchet—whether referring to a ratcheting tool with gold plating, a component in electronics, or a specialized part in aerospace or luxury applications—requires careful consideration of quality, authenticity, supplier reliability, and cost-effectiveness. It is essential to engage with reputable suppliers who provide verifiable material certifications, such as purity standards (e.g., 24K gold plating) and compliance with industry regulations like RoHS or MIL-SPEC where applicable.

Given the high value and potential for counterfeit materials, due diligence in vetting suppliers through audits, sample testing, and background checks is crucial. Additionally, evaluating total cost of ownership—including procurement, maintenance, and performance longevity—often outweighs focusing solely on upfront price.

In conclusion, successful sourcing of a gold ratchet hinges on balancing material integrity, supplier credibility, and application-specific requirements. Establishing long-term partnerships with trusted vendors, leveraging market intelligence, and maintaining rigorous quality control processes will ensure reliable supply and optimal performance in the intended application.