The global PVC pipe market is experiencing robust growth, driven by rising demand in construction, infrastructure development, and water management systems. According to a report by Mordor Intelligence, the global PVC pipes market was valued at approximately USD 56.7 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. Increasing urbanization, government investments in smart city projects, and the need for durable, corrosion-resistant piping solutions are key factors fueling this expansion. A significant portion of this growth is supported by advancements in solvent cements and adhesives—commonly known as glue—specifically formulated for PVC pipe joints, ensuring leak-proof and long-lasting connections. As the industry scales, a select group of manufacturers have emerged as leaders in producing high-performance PVC pipe and compatible bonding solutions, setting benchmarks in quality, innovation, and global reach. Here’s a look at the top 8 glue and PVC pipe manufacturers shaping the industry’s present and future.

Top 8 Glue Pipe Pvc Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

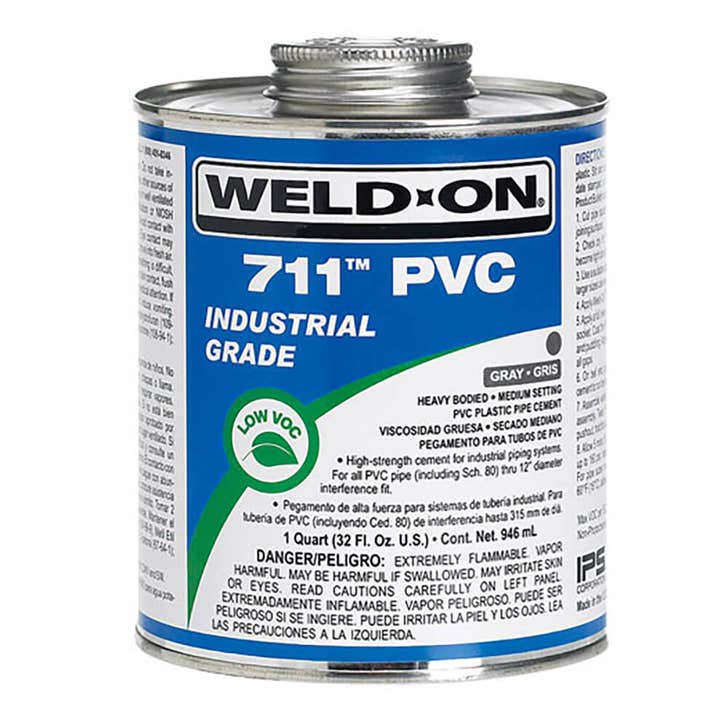

#1 Weld

Domain Est. 2002

Website: weldon.com

Key Highlights: Weld-On Adhesives, Inc. is the pioneer and leading manufacturer of Weld-On® solvent cements, primers and cleaners for PVC, CPVC, ABS and other plastic piping ……

#2 PVC Piping Adhesives

Domain Est. 2004

Website: distributioninternational.com

Key Highlights: 30-day returnsDistribution International supplies PVC adhesives from major manufacturers such as Johns Manville Zeston and Proto. View our selection of PVC piping ……

#3 JM Eagle™

Domain Est. 2007

Website: jmeagle.com

Key Highlights: JM Eagle · Delivering life’s essentials through the most eco-friendly plastic pipe products on the market. · Express Service Trucks (ESTs) Deliver within 24 hours ……

#4 IPS Corporation

Domain Est. 1996

Website: ipscorp.com

Key Highlights: We are a global leader in Water & Flow Management and Specialty Adhesive Solutions. When your job is holding the world together, success is the only option….

#5 PVC & CPVC Solvent Cements

Domain Est. 1997

Website: sluyter.com

Key Highlights: Heavy bodied cement for all PVC pipe and fittings. Medium setting. Flows freely and provides a thick layer of cement on the pipe….

#6 PVC Cements

Domain Est. 1999

Website: arrowadhesives.com

Key Highlights: ARROW manufactures a complete line of PVC Cement products that are uniquely formulated for virtually all types of plastic pipe applications….

#7 to Tangit

Website: tangit.ae

Key Highlights: Welcome to Tangit, the professional brand for construction specialists. Tangit is a leader in the bonding and repair of rigid PVC pipe systems….

#8 Best Adhesives for Polyvinyl Chloride (PVC)

Domain Est. 1997

Website: gluegun.com

Key Highlights: Whether you are looking for an adhesive for PVC pipes, sheets, or something else, we are sharing the best adhesives for PVC applications of various kinds….

Expert Sourcing Insights for Glue Pipe Pvc

H2: 2026 Market Trends for Glue for PVC Pipes

The global market for glue used in polyvinyl chloride (PVC) pipe systems is expected to experience steady growth through 2026, driven by increasing construction activities, infrastructure development, and demand for durable, cost-effective plumbing solutions. This analysis explores key trends shaping the PVC pipe glue market in the lead-up to 2026.

1. Rising Demand in Construction and Infrastructure

One of the primary drivers of the PVC pipe glue market is the surge in residential, commercial, and industrial construction projects globally. Urbanization in emerging economies—particularly in Asia-Pacific, Africa, and Latin America—is fueling demand for water supply, sewage, and drainage systems, where PVC piping is a preferred choice due to its corrosion resistance and ease of installation. As a result, demand for high-quality solvent cements and adhesives to join PVC pipes continues to grow.

2. Technological Advancements in Adhesive Formulations

Manufacturers are investing in R&D to develop faster-curing, low-VOC (volatile organic compound), and environmentally friendly PVC pipe adhesives. By 2026, eco-conscious regulations in North America and Europe are expected to push the adoption of green adhesives. Innovations such as water-based or bio-solvent cements may gain traction, reducing environmental impact while maintaining strong bonding performance.

3. Regulatory Pressures and Safety Standards

Stringent environmental and occupational health regulations—such as those enforced by the U.S. Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA)—are influencing product formulations. Adhesives containing high levels of harmful solvents like tetrahydrofuran (THF) or cyclohexanone are being phased out or reformulated. By 2026, compliance with global safety standards will be a competitive differentiator for manufacturers.

4. Growth in Water and Wastewater Management Projects

Government-led initiatives to improve water infrastructure, especially in developing countries, are accelerating the use of PVC piping systems. Programs aimed at reducing water loss, expanding sanitation access, and modernizing aging networks are directly boosting demand for PVC pipe glue. For instance, India’s Jal Jeevan Mission and similar programs in Southeast Asia and Sub-Saharan Africa are expected to sustain market growth through 2026.

5. Regional Market Dynamics

- Asia-Pacific is projected to dominate the market due to rapid urbanization, industrialization, and government infrastructure spending. China, India, and Indonesia are key growth markets.

- North America will maintain steady demand, supported by residential renovations and strict building codes requiring reliable pipe joining solutions.

- Europe will see moderate growth, with emphasis on sustainable and low-emission adhesive products.

- Latin America and the Middle East offer expanding opportunities due to ongoing public and private construction projects.

6. Competitive Landscape and Supply Chain Shifts

The market is moderately consolidated, with key players such as Oatey Co., Henkel AG, 3M, and IPS Corporation leading innovation and distribution. By 2026, regional manufacturers are expected to gain market share through localized production and competitive pricing. Supply chain resilience, particularly after disruptions seen during the pandemic, will remain a focus, with companies diversifying sources of raw materials like PVC resins and solvents.

7. Impact of Alternative Piping Materials

Although PVC remains popular, competition from alternative materials such as cross-linked polyethylene (PEX) and HDPE could limit growth in certain applications. However, PVC’s cost advantage and proven performance in drainage and irrigation ensure continued relevance, sustaining demand for compatible adhesives.

Conclusion

By 2026, the glue for PVC pipe market will be shaped by infrastructure expansion, environmental regulations, and technological innovation. Market participants that prioritize sustainable formulations, regulatory compliance, and regional customization are likely to gain a strategic advantage. Overall, the global market is poised for moderate but consistent growth, with a compound annual growth rate (CAGR) estimated between 4% and 5% through the forecast period.

Common Pitfalls When Sourcing Glue for PVC Pipes (Quality and IP)

Sourcing the right adhesive for PVC piping systems is critical to ensure joint integrity, long-term performance, and compliance with safety standards. However, buyers often encounter several pitfalls related to quality and intellectual property (IP) that can compromise project outcomes. Being aware of these issues helps in making informed procurement decisions.

Poor Adhesive Quality Leading to Joint Failure

One of the most frequent issues is selecting low-quality PVC cement or solvent glue that fails to create a strong, durable bond. Substandard adhesives may have incorrect solvent formulations, insufficient viscosity, or inconsistent chemical composition, leading to weak joints prone to cracking, leaks, or disbonding under pressure or temperature fluctuations. These failures often manifest over time, resulting in costly repairs and system downtime.

Use of Non-Compliant or Off-Spec Formulations

Many regions require PVC pipe adhesives to meet specific standards (e.g., ASTM D2513, ISO 15493, or local building codes). Sourcing glue that does not comply with these standards—either due to lack of certification or mislabeling—poses a significant risk. Non-compliant adhesives may not cure properly or may degrade when exposed to certain environmental conditions, compromising the integrity of the entire piping system.

Counterfeit or Illegally Copied Brands

The PVC adhesive market is susceptible to counterfeit products that imitate well-known brands. These copies often use inferior raw materials and lack proper quality control. In addition to performance risks, purchasing counterfeit glue may inadvertently support IP infringement, exposing buyers to legal and reputational risks, especially in regulated industries or public infrastructure projects.

Lack of Intellectual Property Verification

When sourcing from lesser-known or overseas suppliers, there’s a risk of purchasing adhesives that use patented formulations without proper licensing. Even if the product performs adequately, unauthorized use of protected chemical compositions can lead to IP disputes, supply chain disruptions, or liability if the original patent holder takes legal action.

Inadequate Technical Support and Documentation

Low-cost suppliers may fail to provide essential technical data sheets (TDS), safety data sheets (SDS), or application guidelines. Without proper documentation, installers cannot ensure correct usage (e.g., proper cure time, joint preparation), increasing the likelihood of application errors and field failures. This also complicates compliance audits and quality assurance processes.

Inconsistent Batch-to-Batch Performance

Unreliable manufacturers may lack robust quality control systems, resulting in variations between adhesive batches. Differences in solvent concentration or resin content can affect bonding strength and curing time, leading to unpredictable performance and potential system failures, particularly in large-scale installations.

Short Shelf Life and Poor Storage Stability

Some low-quality PVC cements degrade quickly when stored improperly or beyond their shelf life. Buyers may receive products that are already past their effective use date or that lack proper labeling of manufacture and expiration dates. This reduces adhesive effectiveness and increases waste and rework costs.

Avoiding these pitfalls requires due diligence: sourcing from reputable suppliers, verifying certifications, checking for brand authenticity, and ensuring proper technical and legal compliance. Conducting sample testing and maintaining clear procurement documentation further safeguards against quality and IP risks.

Logistics & Compliance Guide for Glue Pipe PVC

Product Overview

Glue Pipe PVC refers to polyvinyl chloride (PVC) piping systems that are joined using solvent cement (commonly known as PVC glue). These systems are widely used in plumbing, drainage, and industrial applications. Proper logistics and compliance handling are essential due to the chemical nature of the adhesive and regulatory requirements for plastics and hazardous materials.

Regulatory Classification

PVC pipes themselves are generally non-hazardous and classified as inert plastic materials. However, the solvent cement (glue) used with PVC pipes often contains volatile organic compounds (VOCs) such as tetrahydrofuran (THF), cyclohexanone, or acetone. These substances may be classified as flammable or hazardous under transportation regulations including:

- DOT (Department of Transportation) – 49 CFR (US)

- IATA – Dangerous Goods Regulations (air transport)

- IMDG Code – International Maritime Dangerous Goods (sea transport)

- ADR – European Agreement concerning the International Carriage of Dangerous Goods by Road

Solvent cements may fall under UN1133, Adhesives, flammable (Class 3, Flammable Liquids) or similar classifications depending on flash point and composition.

Packaging & Labeling Requirements

- PVC Pipes: Typically bundled and secured on pallets with stretch wrap or strapping. Must be protected from UV exposure and physical damage.

- Solvent Cement (Glue): Must be shipped in UN-certified, leak-proof containers with secure closures. Outer packaging must be labeled with:

- Proper shipping name (e.g., “Adhesives, flammable, liquid, n.o.s.”)

- UN number (e.g., UN1133)

- Hazard class label (Class 3 Flammable Liquid)

- Handling labels (e.g., “Flammable,” “Keep Away from Heat”)

- GHS-compliant hazard pictograms (if applicable)

Storage Guidelines

- Temperature Control: Store PVC pipes and solvent cement in a cool, dry, well-ventilated area. Avoid temperatures above 100°F (38°C) for solvent cements to prevent pressure build-up and leakage.

- Segregation: Flammable adhesives must be stored separately from oxidizers and ignition sources. PVC pipes should be stored off the ground and protected from direct sunlight to prevent degradation.

- Ventilation: Storage areas for solvent cement must have adequate ventilation to prevent accumulation of flammable vapors.

Transportation Considerations

- Mode-Specific Regulations:

- Road (DOT/ADR): Vehicles must display proper placards for flammable liquids if shipping in large quantities (>1,001 lbs gross weight of Class 3 materials).

- Air (IATA): Quantity limitations apply per package and aircraft. Requires Shipper’s Declaration for Dangerous Goods for regulated shipments.

- Sea (IMDG): Proper stowage and segregation from incompatible goods (e.g., oxidizing agents) required. Must be declared on the bill of lading.

- Documentation: Safety Data Sheets (SDS), shipping declarations, and permits (if required) must accompany shipments involving solvent cement.

Safety & Handling Procedures

- Personal Protective Equipment (PPE): Handlers should wear gloves, safety goggles, and respiratory protection when handling solvent cements.

- Spill Response: In case of leaks or spills, use absorbent materials and dispose of waste according to local hazardous waste regulations. Never dispose of solvent waste down drains.

- Fire Safety: Keep fire extinguishers (Class B rated) accessible in storage and handling areas. Prohibit smoking and open flames near flammable adhesives.

Environmental & Disposal Compliance

- Waste Disposal: Empty adhesive containers may be considered hazardous waste depending on residue. Follow RCRA (US) or local waste regulations for disposal.

- Recycling: PVC pipes are recyclable (Resin ID Code 3). Ensure proper sorting and processing through certified recycling facilities.

- VOC Emissions: Comply with EPA or regional air quality regulations regarding VOC content in adhesives, especially in construction and manufacturing settings.

International Trade Compliance

- Customs Documentation: Accurate HS (Harmonized System) codes required:

- PVC Pipes: Typically 3917.32 or 3917.33

- PVC Cement: May fall under 3506.91 or 3214.90 depending on formulation

- Import/Export Controls: Check for restrictions or tariffs on PVC products and chemical adhesives in destination countries. Some regions regulate phthalates or certain solvents.

- REACH & RoHS (EU): Ensure PVC formulations and adhesives comply with EU chemical regulations, especially regarding restricted substances.

Recordkeeping & Training

- Maintain records of SDS, shipping documents, training logs, and incident reports for at least 3 years.

- Train employees on:

- Hazard communication (HazCom)

- Spill response procedures

- Proper use of PPE

- Emergency protocols

Summary

The logistics and compliance requirements for Glue Pipe PVC systems hinge largely on the solvent cement component. While PVC pipes are straightforward to handle, the flammable nature of the adhesive demands strict adherence to hazardous materials regulations across storage, transport, and disposal. Proactive compliance ensures safety, avoids fines, and supports smooth international operations.

Conclusion for Sourcing PVC Glue (Cement) for Pipes:

Sourcing the right PVC glue (also known as PVC cement or solvent cement) is crucial for ensuring durable, leak-free joints in PVC piping systems. After evaluating various suppliers, product specifications, and application requirements, it is evident that selecting a high-quality, code-compliant adhesive—such as those meeting ASTM D-2513 standards—is essential for long-term system integrity. Factors such as bonding strength, cure time, compatibility with pipe diameter and schedule (e.g., Schedule 40 or 80), and environmental resistance must be considered. Additionally, sourcing from reputable manufacturers and certified distributors ensures product authenticity and reliability. Cost-effectiveness should not compromise quality, especially in plumbing, irrigation, or industrial applications where failure can lead to significant damage. Ultimately, a balanced approach that prioritizes quality, compliance, and supplier reliability will ensure successful installation and performance of PVC piping systems.