The global rotameter market is experiencing steady growth, driven by increasing demand for flow measurement devices across industries such as chemical, pharmaceutical, water treatment, and oil & gas. According to Grand View Research, the global rotameter market was valued at USD 427.8 million in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This growth is fueled by industrial automation trends, the need for precise flow monitoring, and advancements in measurement technologies. Within this landscape, glass tube rotameters remain a preferred choice for their reliability, cost-effectiveness, and visual flow indication—particularly in low-to-medium pressure applications. As demand rises, a competitive ecosystem of manufacturers has emerged, combining legacy engineering expertise with innovation in materials and design. Based on market presence, product range, and technological capabilities, we spotlight the top 9 glass tube rotameter manufacturers shaping the industry today.

Top 9 Glass Tube Rotameter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 74612345W King Instruments Flow

Domain Est. 1999

Website: rhfs.com

Key Highlights: $1,000 deliveryGlass Tube Rotameter. Manufacturer, King Instruments. Manufacturer’s part number, 74612345W. Type, Rotameter. Function, Monitor. Configuration, In-line Mount….

#2 Glass tube variable area flowmeter FGM1190

Domain Est. 1990

Website: new.abb.com

Key Highlights: Designed for flowrate measurements in many industries including system manufacture, food, water treatment plants and chemical….

#3 Glass Tube Variable Area Flow Meters

Domain Est. 1996

Website: brooksinstrument.com

Key Highlights: Glass tube variable area flow meters (rotameters) from Brooks Instrument combine accuracy with robust borosilicate-glass body construction….

#4 ABB Series 10A4600 Glass Tube Rotameter with PVC End Fittings

Domain Est. 1996

Website: bucksales.com

Key Highlights: ABB Series 10A4600 is a glass tube rotameter (variable area flow meter) similar to the 10A4500 model but with PVC end fittings….

#5 Glass Tube Rotameter

Domain Est. 2014

Website: labotronics.com

Key Highlights: Rating 5.0 (502) · Free delivery · 30-day returns…

#6 Glass Tube Rotameter FA20S

Domain Est. 2015

Website: trinityissb.com

Key Highlights: FA20S Glass Tube Rotameter is one of economy model to measure flow rate manually. Max working pressure is 9 bar, max temperature is 120degC….

#7 Glass Tube Rotameter

Domain Est. 2016

Website: psinstruments.net

Key Highlights: These rota meters are useful for measuring flow of air, common gases, water, alkalies, oil & organic chemicals….

#8 Heta Glass And Polymers PVT. LTD.

Domain Est. 2018

Website: hetaglass.com

Key Highlights: Glasstube Rotameter. Manufactures Variable Area Flowmeters (Rotameters) which are mainly used for Liquid & Gas applications for measurement of Rate of Flow ……

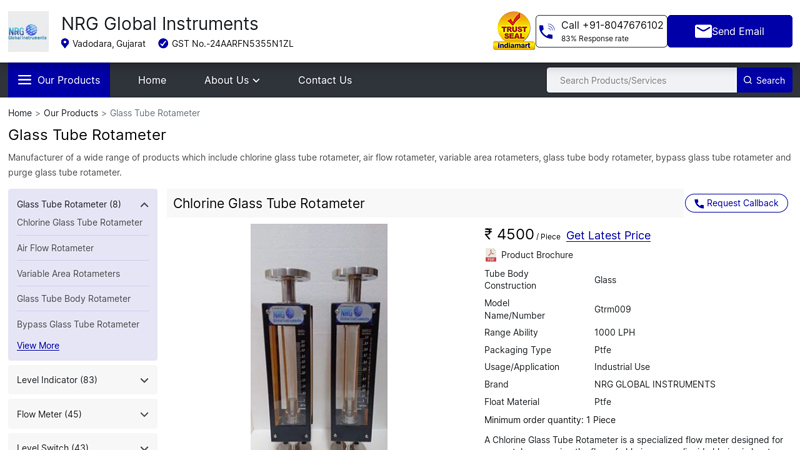

#9 Chlorine Glass Tube Rotameter

Domain Est. 2023

Website: nrgglobalinstruments.com

Key Highlights: A Chlorine Glass Tube Rotameter is a specialized flow meter designed for accurately measuring the flow of chlorine gas or liquid chlorine in low to medium ……

Expert Sourcing Insights for Glass Tube Rotameter

2026 Market Trends for Glass Tube Rotameters

The global market for glass tube rotameters is poised for steady evolution by 2026, shaped by enduring strengths, technological integration, and shifting industrial demands. While facing competition from advanced flow measurement technologies, glass tube rotameters maintain a vital niche due to their inherent advantages. Key trends for 2026 include:

Growing Demand in Emerging Economies and Retrofit Projects

Developing regions in Asia-Pacific (particularly India, Southeast Asia), the Middle East, and Africa will drive significant market growth. Rapid industrialization in chemicals, water treatment, food & beverage, and pharmaceuticals creates demand for cost-effective, reliable flow monitoring. Glass tube rotameters, with their low initial cost and ease of installation, are ideal for budget-conscious projects and widespread deployment in process lines. Additionally, ongoing retrofitting and modernization of existing industrial infrastructure in mature markets will sustain demand, as rotameters offer a simple, proven solution for replacing aging flow indicators.

Focus on Enhanced Materials and Durability

To address traditional limitations like fragility and chemical compatibility, manufacturers will increasingly offer rotameters with improved materials. Borosilicate glass with enhanced thermal and mechanical resistance will become standard. Wider adoption of protective shields (metal or polycarbonate) and shatter-resistant coatings will improve safety and longevity, expanding their suitability into harsher industrial environments and reducing maintenance costs.

Integration with Digital Monitoring and IIoT

A pivotal trend is the hybridization of the simple glass tube design with digital technology. By 2026, expect significant growth in “smart” glass tube rotameters featuring integrated sensors (e.g., magnetic pickups, optical sensors) that convert the float position into a 4-20 mA signal or digital output (HART, Modbus). This allows seamless integration into Plant Asset Management (PAM) systems and Industrial Internet of Things (IIoT) platforms, enabling remote monitoring, data logging, predictive maintenance alerts, and improved process control while retaining local visual indication.

Niche Dominance in Specific Applications

Glass tube rotameters will solidify their dominance in applications where visual flow verification is critical. This includes laboratory settings, pilot plants, chemical dosing systems, and small-scale processes in pharmaceuticals and food & beverage. Their transparency, low pressure drop, and ability to handle a wide range of liquids and gases (with appropriate wetted materials) ensure continued relevance. Demand for specialized versions (e.g., with alarms, flow totalizers, or specific end connections) will grow to meet precise application needs.

Intensifying Competition and Price Pressure

The market will face persistent pressure from alternative technologies like electromagnetic, ultrasonic, and Coriolis flow meters, especially for high-accuracy or custody transfer applications. However, glass rotameters will maintain their edge on cost, simplicity, and ease of use. This will lead to intense competition among manufacturers, driving innovation in value-added features (like digital integration) while keeping base models highly price-competitive. Sustainability concerns may also influence material choices and manufacturing processes.

In conclusion, the 2026 glass tube rotameter market will be characterized by resilience through adaptation. Success will depend on manufacturers’ ability to enhance product durability, embrace digital connectivity, target growth sectors effectively, and leverage the technology’s core advantages of simplicity, visibility, and cost-effectiveness in a competitive landscape.

Common Pitfalls When Sourcing Glass Tube Rotameters (Quality and Intellectual Property)

Sourcing glass tube rotameters can be deceptively complex, with several critical pitfalls related to quality and intellectual property (IP) that can impact performance, safety, and compliance. Being aware of these risks is essential for making informed procurement decisions.

Quality-Related Pitfalls

Substandard Materials and Construction

One of the most prevalent quality issues is the use of low-grade materials. Inferior borosilicate glass may lack the necessary chemical and thermal resistance, increasing the risk of cracking or failure under normal operating conditions. Similarly, poor-quality gaskets, seals, or metal fittings (e.g., brass instead of 316 stainless steel) can lead to leaks, contamination, or premature degradation, especially in corrosive environments.

Inaccurate Calibration and Measurement Drift

Many low-cost suppliers do not perform individual calibration or use outdated calibration standards. This results in rotameters with poor accuracy and repeatability. Additionally, inadequate float design or poor manufacturing tolerances can lead to measurement drift over time, rendering process control unreliable and potentially causing safety or quality issues.

Lack of Compliance with Industry Standards

Reputable rotameters should comply with international standards such as ISO 11784, DIN 11864, or ASTM D3713. Sourcing from suppliers who do not adhere to these standards may result in instruments unsuitable for regulated industries (e.g., pharmaceuticals, food and beverage). Absence of certification (e.g., CE, ATEX, or NSF) can also lead to non-compliance and operational shutdowns.

Poor Packaging and Fragility

Glass tube rotameters are inherently fragile. Suppliers who neglect proper packaging—such as inadequate cushioning or absence of protective end caps—significantly increase the risk of breakage during shipping, leading to costly replacements and project delays.

Intellectual Property (IP) Risks

Counterfeit or Cloned Products

A significant IP concern is the proliferation of counterfeit rotameters that mimic well-known brands in design and labeling. These clones often replicate patented float geometries, scale markings, or housing designs without authorization. While they may appear identical, their performance and durability are typically subpar, and their use can expose the buyer to legal liability.

Unauthorized Use of Patented Technologies

Some rotameter designs incorporate patented innovations in float stabilization, scale readability, or connection interfaces. Sourcing from manufacturers who infringe on these patents not only supports unethical practices but may also result in supply chain disruptions if legal actions halt production or distribution.

Lack of Traceability and Documentation

IP violations often go hand-in-hand with poor documentation. Suppliers may fail to provide certificates of conformance, material traceability, or proof of legitimate design rights. This lack of transparency complicates audits, quality assurance processes, and regulatory compliance, especially in highly controlled environments.

Risk of Infringement Liability for End Users

In some jurisdictions, end users can be held liable for using equipment that infringes on IP rights, particularly if they knowingly source counterfeit or unauthorized replicas. This risk is heightened when procurement is driven solely by price without due diligence on the supplier’s legitimacy.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Source from authorized distributors or directly from reputable manufacturers.

– Request and verify certifications, calibration reports, and material test certificates.

– Conduct supplier audits or request factory quality management system certifications (e.g., ISO 9001).

– Perform due diligence on IP rights, including checking for brand authenticity and patent status.

– Prioritize total cost of ownership over initial purchase price, considering reliability and lifecycle costs.

By addressing both quality and IP concerns proactively, organizations can ensure the safe, reliable, and legally compliant operation of their flow measurement systems.

Logistics & Compliance Guide for Glass Tube Rotameter

This guide outlines the essential logistics and compliance considerations for the safe and legal handling, transport, storage, and use of Glass Tube Rotameters, which are fragile glass instruments used for measuring the flow rate of liquids and gases.

Packaging and Handling

Glass Tube Rotameters are highly susceptible to breakage due to their glass construction. Proper packaging and careful handling are critical to prevent damage during transit.

- Original Packaging: Always ship and store rotameters in their original manufacturer-provided packaging, which includes protective foam, rigid outer boxes, and secure fittings.

- Secondary Packaging: If original packaging is unavailable, use double-walled cardboard boxes with ample cushioning (e.g., bubble wrap, foam inserts) to immobilize the device and absorb shocks.

- Labeling: Clearly mark packages with “Fragile,” “Handle with Care,” “This Side Up,” and “Do Not Stack” labels to alert handlers.

- Handling Procedures: Train personnel to avoid dropping, bumping, or applying pressure to the glass tube. Use two hands when carrying and avoid gripping the glass portion directly.

Transportation Requirements

Adherence to transportation regulations ensures safe delivery and avoids regulatory penalties.

- Mode of Transport: Suitable for road, air, and sea freight. For air transport, comply with IATA Dangerous Goods Regulations if fluids (e.g., calibration media) remain in the device.

- Temperature Control: Avoid exposure to extreme temperatures (typically below 0°C or above 50°C), which can crack glass or affect internal components. Use climate-controlled transport when necessary.

- Vibration and Shock Protection: Secure cargo to prevent movement during transit. Use shock-absorbing pallets and avoid loading near heavy or unstable items.

- Documentation: Include packing lists, safety data sheets (SDS) if applicable, and commercial invoices with consignment details. For international shipments, ensure Harmonized System (HS) code accuracy (typically 9026.10 or 9026.20 for flow meters).

Storage Conditions

Proper storage preserves the integrity and accuracy of the rotameter before installation.

- Environment: Store in a clean, dry, temperature-stable indoor area (recommended: 10–35°C) with low humidity and minimal dust.

- Positioning: Keep upright in original packaging to prevent stress on the glass tube or float mechanism.

- Shelf Life: While the device has no strict expiration, prolonged storage in suboptimal conditions may affect seals or calibration. Inspect before use after long-term storage.

Regulatory Compliance

Ensure adherence to international and regional standards applicable to measurement devices and instrumentation.

- Measurement Standards: Comply with ISO 4084 (Rotameters – Principles of operation and construction) and ISO 20764 (Measurement of fluid flow – Rotameters).

- Regional Approvals:

- EU: CE marking under the Measuring Instruments Directive (MID 2014/32/EU) if used for custody transfer or regulated applications.

- USA: May require NIST traceability for calibration; compliance with OSHA and EPA regulations if used in hazardous environments.

- Canada: Compliance with Measurement Canada requirements for legal-for-trade use.

- Hazardous Locations: If used in explosive atmospheres, ensure the model is certified to ATEX (EU) or IECEx standards, even if the main body is non-electrical.

Import/Export Documentation

International trade requires accurate documentation to clear customs efficiently.

- HS Code: Confirm correct classification (e.g., 9026.10.00 – Devices for measuring flow of liquids; 9026.20.00 – Devices for measuring flow of gases).

- Certificates of Conformity: Provide test reports, calibration certificates, and declarations of conformity as required by the destination country.

- Export Controls: Verify that the device does not fall under dual-use or ITAR restrictions. Most glass tube rotameters are non-controlled, but confirm based on model and specifications.

- Customs Declarations: Include detailed product descriptions, value, country of origin, and end-use to prevent delays.

Installation and Use Compliance

Ensure end-user compliance with operational and safety standards.

- Calibration: Perform initial and periodic calibration traceable to national standards (e.g., NIST, DAkkS) for accurate measurements.

- Safety Protocols: Install in accordance with manufacturer instructions. Use protective shields or guards in high-traffic or high-risk areas to prevent breakage.

- Fluid Compatibility: Verify chemical compatibility of wetted parts (glass, float material, seals) with the process media to avoid degradation or hazardous reactions.

- Leak Prevention: Ensure proper pipe alignment and avoid mechanical stress on the rotameter connections.

Disposal and Environmental Considerations

Dispose of damaged or obsolete units responsibly.

- Glass Waste: Recycle broken glass according to local regulations for laboratory or industrial glass waste.

- Hazardous Components: If the rotameter contains mercury floats or process fluids, handle as hazardous waste in compliance with EPA, REACH, or local environmental regulations.

- Documentation: Maintain records of disposal, especially for regulated or environmentally sensitive materials.

By following this guide, organizations can ensure the safe, compliant, and efficient logistics management of Glass Tube Rotameters throughout their lifecycle.

Conclusion for Sourcing Glass Tube Rotameter:

After a thorough evaluation of technical specifications, supplier capabilities, quality standards, cost considerations, and lead times, sourcing glass tube rotameters from reliable manufacturers proves to be a practical and cost-effective solution for low to medium pressure flow measurement applications. These rotameters offer advantages such as simplicity in design, ease of installation and maintenance, clear visual flow indication, and compatibility with a wide range of non-corrosive and chemically compatible fluids.

Key factors in the sourcing decision include ensuring compliance with international standards (e.g., ISO, ASTM), material quality (borosilicate glass, suitable float materials), customization options for specific flow ranges, and the supplier’s track record for after-sales support and technical service. Sourcing from manufacturers with strong quality management systems (e.g., ISO 9001 certified) further ensures product reliability and consistency.

In conclusion, selecting a reputable supplier for glass tube rotameters—balancing performance, durability, and cost—enables efficient flow monitoring in industrial, water treatment, chemical, and HVAC systems. Ongoing supplier evaluation and potential for long-term partnerships will help ensure a continuous supply of accurate, dependable instrumentation while supporting operational efficiency and process control.