The global generator outdoor enclosure market is experiencing steady growth, driven by increasing demand for reliable backup power solutions across residential, commercial, and industrial sectors. According to Grand View Research, the global generator market size was valued at USD 18.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, fueled by rising energy demands and infrastructure development in emerging economies. This surge in generator adoption has amplified the need for durable outdoor enclosures that protect equipment from environmental factors such as rain, dust, and extreme temperatures. As a result, manufacturers specializing in generator outdoor boxes are playing a critical role in enhancing operational efficiency and equipment longevity. In this landscape, a select group of nine manufacturers have emerged as industry leaders, combining innovation, material quality, and scalability to meet evolving market needs. This analysis highlights the top players shaping the future of protected power generation infrastructure.

Top 9 Generator Outdoor Box Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

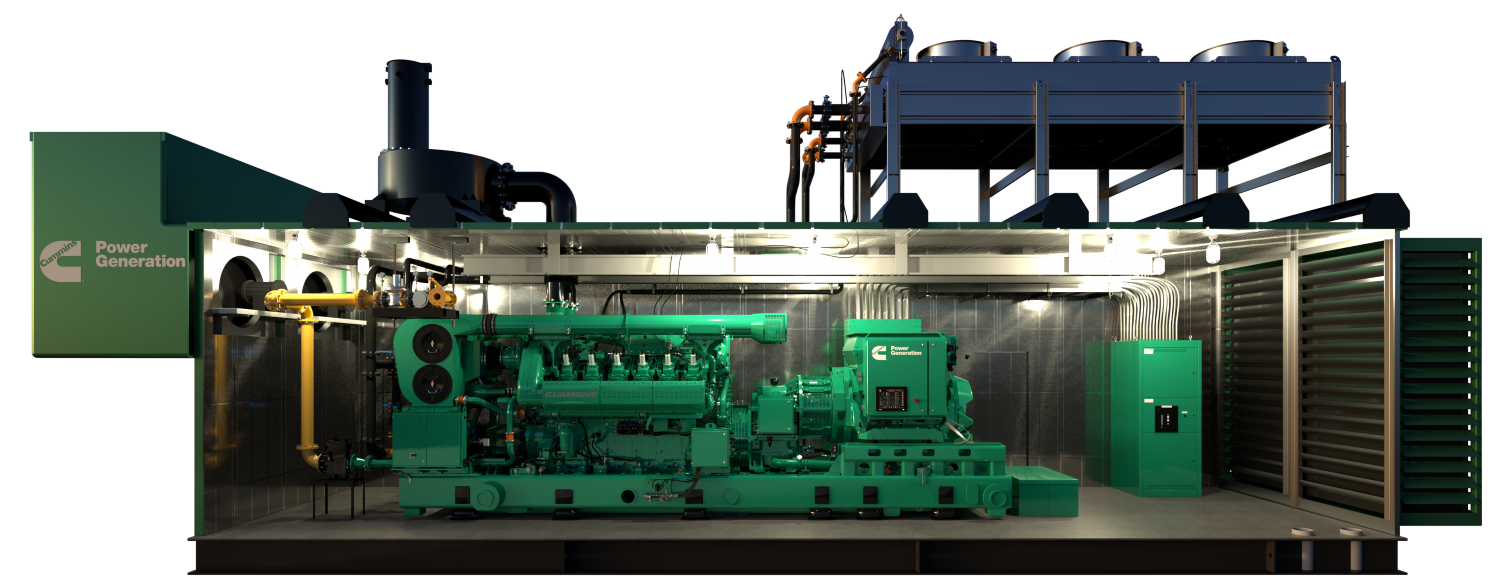

#1 Natural Gas Generator Enclosures

Domain Est. 1990

Website: cummins.com

Key Highlights: Cummins is offering market leading factory designed natural gas generator enclosure solutions for standby, peaking and combined heat and power (CHP) ……

#2 Phoenix Products

Domain Est. 1996

Website: phoenixprods.com

Key Highlights: Headquartered in Jacksonville, Florida, Phoenix Products is a manufacturer of custom generator enclosures, UL 142 and UL 2085 fuel tanks, and fueling systems.Missing: outdoor box…

#3 Generator Boxes, Enclosures, Sheds and Mufflers

Domain Est. 2006

Website: zombiebox.com

Key Highlights: ZombieBox is a portable, weatherproof, noise reducing enclosure for portable or standby generators, compressors, industrial equipment, pumps, vacuums, blowers….

#4 Containerized Generator Enclosures

Domain Est. 2014

Website: bmarkostructures.com

Key Highlights: BMarko Structures is a leading containerized generator enclosures manufacturer with vast experience in producing high-quality modular structures….

#5 Power Systems

Domain Est. 2024

Website: powersystems.rehlko.com

Key Highlights: Rehlko Power Industrial Generators provide backup, prime and continuous power solutions you need, available in diesel, gas and LP configurations….

#6 Generators

Website: denyo.co.jp

Key Highlights: Our generators produce the optimal power to meet user needs. Offering high-performance power generation and durability as well as energy conservation and noise ……

#7 Standby Generators

Domain Est. 1995

Website: generac.com

Key Highlights: Free deliveryA Generac standby generator protects your home and gives you peace of mind. When the power fails, you’ll be ready. With automatic operation and 24/7/365 support ……

#8 Custom Power Generator Enclosures

Domain Est. 1999

Website: ekmachine.com

Key Highlights: EK Power Products division specializes in the design and build of weatherproof and sound attenuated, custom power generator enclosures….

#9 Generator Enclosure

Domain Est. 2014

Website: pdgenerators.com

Key Highlights: PDG specializes in generator noise-reduction enclosures that mitigate the sound made by your diesel generator during operation….

Expert Sourcing Insights for Generator Outdoor Box

H2: 2026 Market Trends for Generator Outdoor Boxes

The global market for generator outdoor boxes is poised for significant transformation by 2026, driven by technological innovation, evolving energy demands, and increasing emphasis on resilience and sustainability. These enclosures—critical for protecting backup and primary power generators from environmental and security threats—are seeing a shift in design, materials, and deployment strategies.

One of the key trends shaping the 2026 landscape is the rising demand for energy resilience in both residential and commercial sectors. With climate change contributing to more frequent and severe weather events, businesses and homeowners are investing in reliable backup power systems. As a result, generator outdoor boxes are being designed for enhanced durability, with weather-resistant materials such as galvanized steel, aluminum, and advanced composites that withstand extreme temperatures, moisture, and corrosion.

Another dominant trend is the integration of smart technologies. By 2026, generator enclosures are increasingly equipped with IoT-enabled monitoring systems that provide real-time data on temperature, humidity, noise levels, and generator performance. These smart boxes improve maintenance efficiency, reduce downtime, and support remote diagnostics—especially vital for off-grid or remote installations.

Sustainability is also influencing design and material choices. Manufacturers are adopting eco-friendly production methods and recyclable materials to meet green building standards and regulatory requirements. Acoustic insulation technologies are being improved to reduce noise pollution, aligning with urban zoning laws and community standards.

The growing adoption of renewable energy hybrids—such as solar-plus-storage systems with backup generators—is reshaping enclosure requirements. These hybrid systems often necessitate multifunctional outdoor boxes that integrate not only the generator but also inverters, transfer switches, and battery management units, leading to modular and scalable enclosure designs.

Regionally, North America and Europe are leading in demand due to strict safety regulations and high infrastructure investment, while the Asia-Pacific region is expected to see the fastest growth, fueled by urbanization, industrial expansion, and grid instability in emerging economies.

In conclusion, by 2026, the generator outdoor box market will be characterized by smarter, more sustainable, and highly resilient solutions. Innovation in materials, connectivity, and integration capabilities will define competitive advantage, positioning advanced enclosures as essential components of modern energy infrastructure.

Common Pitfalls When Sourcing Generator Outdoor Boxes (Quality and IP Rating)

When sourcing outdoor enclosures for generators, overlooking key quality factors and Ingress Protection (IP) ratings can lead to equipment failure, safety hazards, and costly repairs. Below are common pitfalls to avoid:

Inadequate IP Rating for Environmental Conditions

Choosing a generator box with an insufficient IP rating for the installation environment is a frequent mistake. For example, selecting an IP54-rated enclosure for coastal or heavy industrial areas may allow salt spray or dust ingress, leading to corrosion and generator malfunction. Always match the IP rating (e.g., IP55, IP65, or higher) to site-specific conditions like rain exposure, dust levels, and humidity.

Poor Material Quality and Corrosion Resistance

Low-cost enclosures often use thin-gauge steel or substandard coatings that rust quickly, especially in humid or salty environments. This compromises both the generator’s protection and structural integrity. Avoid boxes made from non-galvanized or poorly painted materials—opt for hot-dip galvanized steel or marine-grade aluminum with durable powder coating.

Insufficient Ventilation and Heat Dissipation

Overlooking proper ventilation design can cause overheating, reducing generator efficiency and lifespan. Some enclosures prioritize weather protection over airflow, leading to inadequate heat dissipation. Ensure the box includes engineered ventilation with weatherproof louvers or ducting that maintains IP integrity while allowing sufficient cooling.

Compromised Noise Attenuation Due to Poor Construction

Acoustic performance often suffers in low-quality boxes due to thin walls, poor sealing, or lack of sound-damping materials. This results in excessive noise pollution, especially in residential or commercial zones. Verify that the enclosure meets specified dB reduction levels and uses proper insulation and sealing techniques.

Incomplete or Misleading IP Certification

Some suppliers claim high IP ratings without third-party testing or certification. This “IP rating inflation” can leave generators vulnerable to water and dust ingress. Always request certified test reports from accredited laboratories and inspect seals, gaskets, and cable entry points for compliance.

Neglecting Ease of Maintenance and Accessibility

Poorly designed enclosures may lack proper access points, making routine maintenance difficult or unsafe. Overly tight spaces or missing inspection hatches hinder servicing and increase downtime. Ensure the box features lockable doors, removable panels, and adequate internal clearance.

Overlooking Customization and Installation Challenges

Standard boxes may not fit specific generator models or site constraints, leading to on-site modifications that compromise IP ratings and structural integrity. Avoid one-size-fits-all solutions; work with suppliers who offer customization while maintaining quality and certification standards.

By addressing these pitfalls early in the procurement process, buyers can ensure reliable, long-lasting protection for their generator investments.

Logistics & Compliance Guide for Generator Outdoor Box

This guide outlines key considerations for the safe and compliant logistics, handling, and deployment of Generator Outdoor Boxes. Adhering to these guidelines ensures regulatory compliance, operational safety, and equipment longevity.

Transportation and Handling

Ensure proper procedures are followed during transit and installation to prevent damage and maintain safety.

- Secure Mounting on Transport Vehicle: The Generator Outdoor Box must be firmly secured to the transport trailer using rated straps, chains, or twist locks compatible with the container’s lifting and securing points.

- Lifting Procedures: Use certified lifting equipment and rigging appropriate for the box’s total weight. Lift only from designated lifting points (e.g., corner castings or integrated lifting lugs). Never lift by handles, vents, or non-rated components.

- Center of Gravity Awareness: Confirm the center of gravity is balanced, especially if the generator is mounted off-center. Asymmetric loads can cause tipping during transport or lifting.

- Ground Clearance and Route Planning: Verify adequate ground clearance and route feasibility (bridges, overhead lines, road width). Avoid rough terrain that may damage the undercarriage or vibration-sensitive components.

- Weather Protection: If the unit is not fully sealed or during extended transport, cover exposed areas (e.g., exhaust, air intakes) with waterproof caps or tarps to prevent ingress of rain, snow, or debris.

Site Preparation and Placement

Proper site setup ensures safety, regulatory compliance, and optimal generator performance.

- Level and Stable Foundation: Install on a level, load-bearing surface such as a concrete pad, compacted gravel, or approved steel base. Uneven surfaces can lead to oil leakage, vibration, or operational faults.

- Clearance Requirements: Maintain minimum clearance around the unit as specified by the manufacturer and local codes (e.g., 3–5 feet on all sides). Ensure adequate space for cooling airflow, exhaust dispersion, and maintenance access.

- Ventilation and Airflow: Confirm intake and exhaust vents are unobstructed. Avoid placing near walls, vegetation, or other structures that may restrict airflow or recirculate hot exhaust gases.

- Drainage and Flood Prevention: Position the box to avoid water pooling. Elevate if necessary. Ensure drainage paths are clear to prevent water accumulation around fuel tanks or electrical components.

- Security and Access Control: Locate in a secure area to prevent unauthorized access. Use locks or fencing where required by site policy or regulation.

Environmental and Regulatory Compliance

Adhere to environmental standards and local regulations to prevent violations and reduce environmental impact.

- Emissions Compliance: Verify the generator meets applicable emissions standards (e.g., EPA Tier 4, EU Stage V). Maintain records of emissions certification and perform required testing.

- Noise Restrictions: Confirm sound attenuation of the outdoor box meets local noise ordinances (e.g., <75 dB at 7 meters). Install additional acoustic barriers if needed.

- Spill Containment: Implement secondary containment measures (e.g., bunded base or drip tray) capable of holding 110% of the largest fuel tank capacity to comply with spill prevention regulations (e.g., EPA Spill Prevention, Control, and Countermeasure – SPCC).

- Stormwater Protection: Prevent fuel, oil, or coolant leaks from entering storm drains. Use absorbent pads and immediate spill response protocols.

- Local Permits and Zoning: Obtain required permits for installation and operation. Confirm zoning allows for stationary generator use and fuel storage.

Electrical and Fuel System Safety

Ensure safe integration of power and fuel systems in accordance with national and local codes.

- Electrical Grounding: Bond the generator frame and outdoor enclosure to a proper grounding electrode system per NEC (NFPA 70) or local electrical code.

- Wiring and Conduit Protection: Use weatherproof, UV-resistant conduits and connections. All electrical work must be performed by licensed personnel.

- Fuel Line Installation: Install fuel supply lines according to NFPA 30 (Flammable and Combustible Liquids Code) or equivalent. Use double-walled or protected piping where required. Include emergency shut-off valves.

- Fuel Storage Compliance: If storing fuel onsite, adhere to volume-based regulations (e.g., aboveground storage tanks > 55 gallons may require secondary containment and registration).

Documentation and Inspection

Maintain records and conduct regular checks to ensure ongoing compliance and safety.

- Compliance Documentation: Keep on file: generator certification, emissions reports, electrical permits, fuel storage approvals, and SPCC plans (if applicable).

- Pre-Operational Inspection: Before commissioning, inspect for transport damage, verify fluid levels, test grounding, and confirm all vents and doors operate correctly.

- Routine Maintenance Logs: Document all maintenance, fuel deliveries, and spill response actions as required by environmental and safety regulations.

- Regulatory Audits: Schedule periodic compliance reviews to ensure adherence to evolving local, state, and federal requirements.

Following this guide ensures safe, legal, and efficient deployment of Generator Outdoor Boxes across diverse operational environments.

Conclusion: Sourcing an Outdoor Generator Enclosure

After evaluating various options for sourcing an outdoor generator enclosure, it is clear that selecting the right enclosure is crucial for ensuring the longevity, performance, and safety of the generator. Key factors such as weather resistance, noise reduction, proper ventilation, security, and ease of maintenance must be carefully considered. Both pre-fabricated enclosures and custom-built solutions offer advantages depending on budget, generator specifications, and environmental conditions.

Sourcing from reputable manufacturers or suppliers ensures compliance with industry standards and local regulations, while also providing warranties and technical support. Additionally, investing in a high-quality enclosure can prevent costly repairs and downtime due to environmental exposure or unauthorized access.

In conclusion, a well-sourced outdoor generator box not only protects the equipment but also enhances operational efficiency and safety. It is recommended to conduct a thorough assessment of site-specific requirements and engage with reliable vendors to achieve a durable, code-compliant, and cost-effective solution.