The global washing machine market is witnessing robust expansion, driven by rising urbanization, increasing disposable incomes, and growing demand for energy-efficient appliances. According to Mordor Intelligence, the washing machine market is projected to grow at a CAGR of over 5.5% between 2023 and 2028, with Asia-Pacific emerging as the fastest-growing region due to rapid household electrification and infrastructure development. As critical components of washing machines, motors significantly influence performance, durability, and energy consumption. With General Electric sourcing high-efficiency motors for its premium appliance lines, understanding the key manufacturers behind these components becomes essential. These suppliers are not only meeting stringent performance standards but are also integrating advanced technologies like brushless DC (BLDC) motors to enhance efficiency and reduce noise. The following analysis identifies the top seven motor manufacturers supplying or compatible with General Electric washing machines, evaluated based on technical capabilities, production scale, innovation in motor design, and market presence.

Top 7 General Electric Washing Machine Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Official General Electric Washer Parts

Domain Est. 1999

Website: partselect.com

Key Highlights: Shop for authentic General Electric Washer parts today! Find genuine OEM replacement parts along with expert repair help, video tutorials, and same–day ……

#2 Official General Electric Washer Motors

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: Find Motors to repair your General Electric Washer at eReplacementParts.com. Great prices on all factory–authorized General Electric Motors….

#3 Contact Us

Domain Est. 1986

Website: ge.com

Key Highlights: General Electric Company 1 Neumann Way Cincinnati, OH 45215 Verification of Employment Vault Verify vaultverify.com Phone: +001 407 378 6203*…

#4 https://geappliances.com/ge/service

Domain Est. 1996

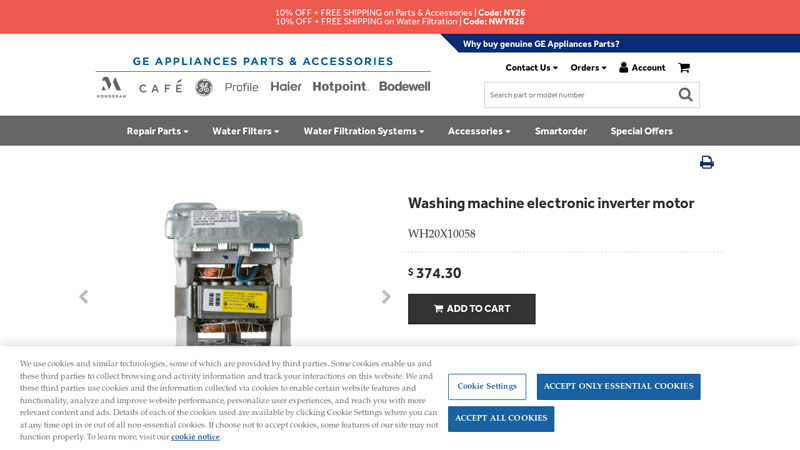

#5 Washing machine electronic inverter motor

Domain Est. 1999

Website: geapplianceparts.com

Key Highlights: $7.95 delivery 30-day returnsGE’s motor / inverter electronic (WH20X10058) determines the load and controls the rate at which the washer moves through cycles such as fill, agitate,…

#6 GE Appliances

Domain Est. 2020

Website: geappliancesco.com

Key Highlights: Our largest manufacturing site with five facilities making washers, dryers, dishwashers and refrigerators. … GE is a trademark of the General Electric Company….

#7 NIDEC MOTOR CORPORATION

Domain Est. 1997

Website: nidec.com

Key Highlights: NIDEC MOTOR is a manufacturer of motors and control equipment for home appliances, industrial use, and consumer use….

Expert Sourcing Insights for General Electric Washing Machine Motor

H2: Market Trends Forecast for General Electric Washing Machine Motors in 2026

As we approach 2026, the market for General Electric (GE) washing machine motors is expected to evolve significantly due to technological innovation, regulatory shifts, and changing consumer preferences. Below is an analysis of the key trends likely to shape this segment:

-

Increased Adoption of Brushless DC (BLDC) Motors

By 2026, BLDC motors are projected to dominate GE’s washing machine motor portfolio. Their superior energy efficiency, quieter operation, and longer lifespan align with global energy standards and consumer demand for sustainable appliances. GE is expected to continue integrating BLDC technology across its product lines, especially in premium and smart washer models. -

Integration with Smart Home Ecosystems

With the proliferation of IoT-enabled home appliances, GE is likely to enhance motor control systems to support real-time diagnostics, adaptive wash cycles, and remote monitoring via mobile apps. Motors will increasingly feature embedded sensors and connectivity modules, allowing for predictive maintenance and improved user experience. -

Focus on Energy Efficiency and Regulatory Compliance

Stringent energy regulations—such as updated U.S. Department of Energy (DOE) standards and global initiatives like the EU’s Ecodesign Directive—are pushing manufacturers to optimize motor efficiency. GE is expected to meet or exceed these standards, leveraging advanced motor designs to reduce energy consumption and support ENERGY STAR® certification. -

Sustainability and Circular Economy Initiatives

GE Appliances, a Haier subsidiary since 2016, is emphasizing sustainability in product design. By 2026, motors may incorporate more recyclable materials and modular designs to facilitate repair and recycling. This aligns with growing consumer and regulatory pressure to reduce e-waste and extend product lifecycles. -

Supply Chain Resilience and Localization

Ongoing geopolitical and logistical challenges are prompting GE to strengthen domestic and regional supply chains. Increased production of motor components in North America could reduce lead times and mitigate risks, supporting faster innovation cycles and responsive manufacturing. -

Competition and Market Differentiation

GE faces growing competition from both traditional appliance makers and emerging smart home brands. To maintain market share, GE is expected to differentiate through motor reliability, integration with its proprietary smart platform (e.g., GE SmartHQ), and customer-centric innovation. -

Growing Demand in Emerging Markets

While North America remains a core market, GE may expand motor production and design adaptations for emerging markets in Asia, Latin America, and Africa. This includes developing cost-optimized, durable motors suitable for variable power supplies and diverse usage patterns.

Conclusion:

By 2026, the General Electric washing machine motor market will be characterized by advanced motor technologies, smart integration, and sustainability. GE’s strategic focus on innovation, energy efficiency, and supply chain agility will be critical to maintaining competitiveness in a rapidly evolving global appliance landscape.

Common Pitfalls When Sourcing General Electric Washing Machine Motors (Quality & IP)

Sourcing General Electric (GE) washing machine motors, whether genuine, replacement, or compatible units, presents several critical challenges related to product quality and intellectual property (IP). Overlooking these pitfalls can lead to operational failures, legal risks, and damage to brand reputation.

Quality-Related Pitfalls

Procuring Counterfeit or Substandard Motors

A major risk is inadvertently sourcing counterfeit motors falsely labeled as genuine GE products. These units often use inferior materials, lack proper quality control, and fail prematurely. Buyers may experience reduced efficiency, increased noise, or complete motor failure, leading to higher warranty claims and customer dissatisfaction.

Inconsistent Performance from Third-Party Suppliers

Many suppliers offer “GE-compatible” motors that are not manufactured by GE. While some meet OEM standards, others cut corners to reduce costs. Inconsistencies in torque, speed control, and durability can result in poor washing performance and increased appliance downtime.

Lack of Certification and Testing Documentation

Genuine GE motors undergo rigorous testing for safety, efficiency, and longevity (e.g., UL, CSA, or IEC certification). Suppliers may fail to provide valid test reports or certifications, making it difficult to verify compliance with regional electrical and safety standards.

Poor Thermal and Moisture Resistance

Washing machine motors operate in high-humidity environments and must withstand temperature fluctuations. Low-quality motors may lack proper sealing or insulation, leading to corrosion, short circuits, or insulation breakdown—especially in humid climates.

Intellectual Property (IP)-Related Pitfalls

Unauthorized Use of GE Branding and Logos

Sourcing motors that bear the GE name, logo, or part numbers without authorization constitutes trademark infringement. Even if the motor functions adequately, using GE’s brand without a licensing agreement exposes the buyer to legal action, product seizures, and reputational damage.

Patented Technology Violations

GE holds patents on specific motor designs, control algorithms, and integration features (e.g., direct drive systems or proprietary mounting configurations). Sourcing compatible motors that replicate these patented elements without permission can lead to patent infringement lawsuits, especially in markets with strong IP enforcement.

Grey Market Sourcing Risks

Purchasing genuine GE motors through unauthorized distributors or grey market channels may seem cost-effective but often violates GE’s distribution agreements. These motors may lack warranty coverage, come from expired inventory, or be diverted from other regions, raising both quality and legal concerns.

Inadequate Due Diligence on Supplier IP Compliance

Buyers may fail to audit suppliers for IP compliance, assuming that product labeling equates to legitimacy. Without verifying supplier authorization, supply chain transparency, and IP clearance, companies risk importing infringing goods, particularly at customs in IP-sensitive jurisdictions like the EU or U.S.

Conclusion

To mitigate these risks, buyers should verify supplier credentials, request certification documents, conduct product testing, and consult legal counsel on IP rights. Partnering with authorized distributors or certified OEMs ensures both quality assurance and compliance with intellectual property laws.

Logistics & Compliance Guide for General Electric Washing Machine Motor

This guide outlines the essential logistics and compliance considerations for the transportation, handling, and regulatory adherence related to General Electric (GE) washing machine motors. Proper management ensures product integrity, regulatory compliance, and efficient supply chain operations.

Product Classification & Identification

GE washing machine motors are classified as electrical components used in major home appliances. Accurate identification using part numbers (e.g., WH12X10120, WH12X10115) and Harmonized System (HS) codes is critical for customs clearance and regulatory compliance. The typical HS code for such motors falls under 8501.10 (Motors of an output not exceeding 37.5 W) or 8501.31 (Single-phase AC motors > 37.5 W but ≤ 1 kW), depending on motor specifications. Confirm the exact code based on technical data for each motor model.

Packaging & Handling Requirements

Motors must be packaged to prevent mechanical damage, corrosion, and contamination during transit. Standard packaging includes:

– Protective inner wrapping (anti-static or moisture-resistant film)

– Rigid corrugated cardboard boxes with cushioning (foam or molded inserts)

– Palletization with stretch-wrapping for stability

– Clearly labeled outer packaging with handling instructions (e.g., “Fragile,” “Do Not Stack,” “Keep Dry”)

Avoid exposure to moisture, extreme temperatures, and direct sunlight. Handle with care to prevent damage to windings, shafts, and mounting components.

Transportation & Shipping

Shipments must comply with domestic and international transport regulations:

– Domestic (U.S.): Follow Department of Transportation (DOT) guidelines for non-hazardous freight. Use common carriers with experience in handling electrical components.

– International: Adhere to International Maritime Dangerous Goods (IMDG) or IATA regulations if applicable. GE motors are typically non-hazardous but verify based on materials (e.g., presence of lubricants or coatings).

– Use sealed, weatherproof containers for ocean freight and climate-controlled transport when necessary.

– Maintain proper shipping documentation: commercial invoice, packing list, bill of lading/air waybill.

Import/Export Compliance

Ensure compliance with U.S. and destination country regulations:

– Export Controls: Verify if motors require an Export Control Classification Number (ECCN). Most GE washing machine motors fall under EAR99 (low-risk, non-controlled items), but confirm through the Commerce Control List (CCL).

– Import Requirements: Provide accurate tariff classification, country of origin (typically U.S. or Mexico for GE), and certification of conformity where required (e.g., CE for Europe, CCC for China).

– Trade Agreements: Leverage benefits under USMCA (United States-Mexico-Canada Agreement) when shipping between member countries, provided rules of origin are met.

Regulatory & Certification Standards

GE motors must comply with relevant safety and performance standards:

– Electrical Safety: UL 60730 (Automatic Electrical Controls) or UL 1004 (Electric Motors) in North America.

– Energy Efficiency: Comply with U.S. DOE (Department of Energy) standards for residential clothes washers, which indirectly govern motor efficiency.

– Electromagnetic Compatibility (EMC): FCC Part 18 (U.S.) and CISPR 14-1 (international) for electromagnetic interference.

– RoHS Compliance: Ensure motors are free of restricted substances (lead, mercury, cadmium, etc.) in accordance with EU RoHS and similar regulations in other markets.

– REACH: Confirm no use of Substances of Very High Concern (SVHC) above threshold levels.

Documentation & Recordkeeping

Maintain comprehensive records for traceability and audits:

– Certificate of Conformity (CoC) or Declaration of Conformity (DoC)

– Technical specifications and test reports (safety, efficiency, EMC)

– Bill of Materials (BOM) for RoHS and REACH compliance

– Shipping and customs documentation (retained for minimum of 5 years)

– Export records if subject to EAR or ITAR (typically not applicable)

Environmental & Sustainability Considerations

GE motors should be managed in accordance with environmental regulations:

– Label for proper end-of-life disposal (WEEE compliance in Europe).

– Use recyclable packaging materials and minimize waste.

– Follow local regulations for disposal of defective or obsolete motors.

Key Contacts & Support

For compliance or logistics issues, contact:

– GE Appliances Regulatory Affairs: [Insert contact]

– GE Supply Chain Logistics Team: [Insert contact]

– Customs Broker (for international shipments): [Insert contracted provider]

Adherence to this guide ensures safe, compliant, and efficient handling of GE washing machine motors across the supply chain. Regularly review updates to regulations and internal procedures to maintain compliance.

Conclusion: Sourcing General Electric Washing Machine Motors

In conclusion, sourcing General Electric (GE) washing machine motors requires a strategic approach that balances quality, authenticity, cost, and reliability. While GE motors are known for their durability, efficiency, and performance in household appliances, direct procurement from GE may be limited due to the company’s phased exit from the consumer appliance market, which was finalized with the sale of GE Appliances to Haier in 2016. As a result, current authentic GE-branded motors are often available through authorized distributors, OEM suppliers, or reputable aftermarket parts suppliers.

Key considerations when sourcing include verifying the authenticity of the motor, ensuring compatibility with specific washing machine models, and evaluating warranty and technical support offerings. Alternative sourcing options such as remanufactured or compatible third-party motors may provide cost-effective solutions, but thorough due diligence is required to maintain performance and safety standards.

Ultimately, successful sourcing involves establishing relationships with trusted suppliers, staying informed about brand transitions and part availability, and prioritizing long-term reliability over short-term savings. For businesses and repair services, maintaining a supply chain for genuine or high-quality equivalent GE motors ensures customer satisfaction and upholds the reputation for quality service.