The global desiccant market is experiencing robust growth, driven by increasing demand for moisture control across pharmaceuticals, food and beverage, electronics, and logistics industries. According to Mordor Intelligence, the desiccants market was valued at USD 1.5 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. A key contributor to this expansion is the rising adoption of gel silica desiccants—valued for their high moisture absorption capacity, chemical stability, and compliance with safety standards. Grand View Research further underscores this trend, noting that the global silica gel market accounted for a significant share of the overall desiccant segment in 2022, with pharmaceutical packaging alone driving substantial demand due to strict regulatory requirements for product integrity. As supply chains become more globalized and climate-controlled storage gains importance, the need for reliable, high-performance desiccants has never been greater—making the leading gel silica manufacturers pivotal players in safeguarding product quality across industries.

Top 10 Gel Silica Desiccant Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 DryTec Industries Pvt. Ltd

Domain Est. 2014 | Founded: 2006

Website: drytecindustries.com

Key Highlights: DryTec Industries Pvt. Ltd., established in 2006, is a prominent OEM Manufacturer specializing in a wide array of desiccants and adsorbents such as Silica Gel, ……

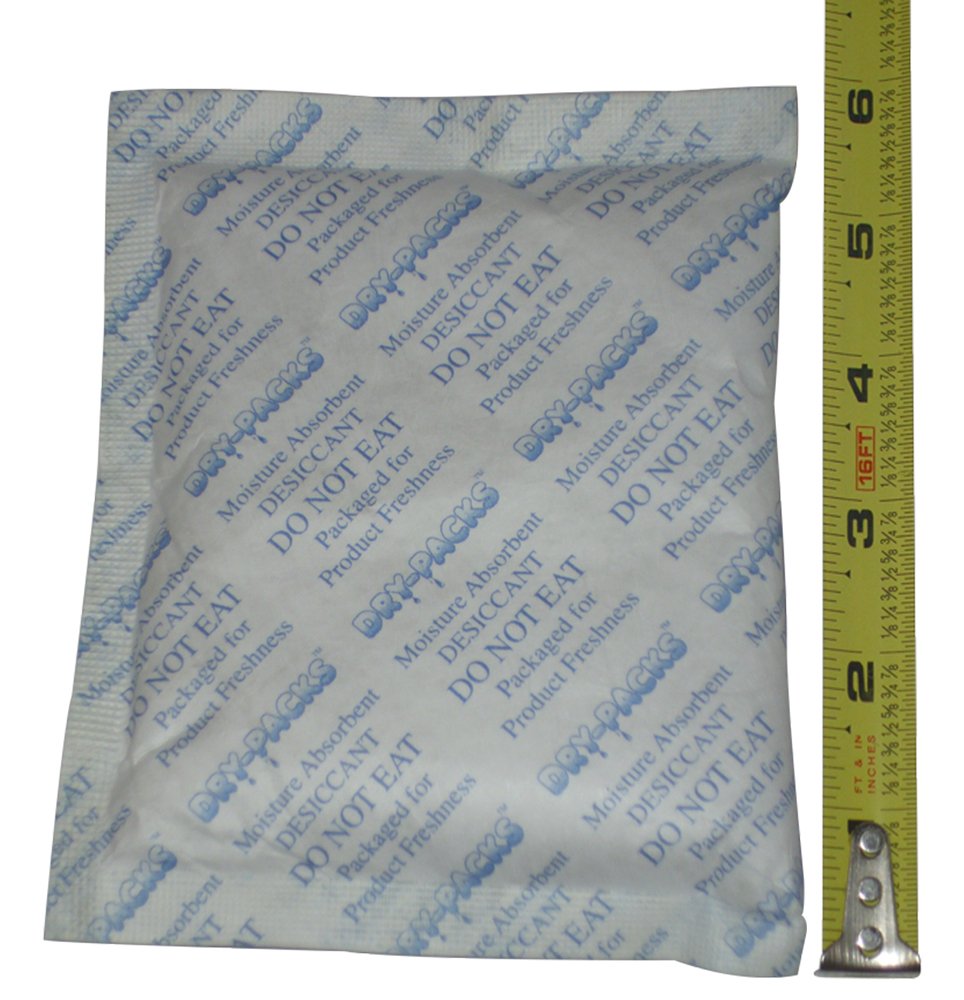

#2 Silica Gel 4 Unit Packs

Domain Est. 2002

Website: deltaadsorbents.com

Key Highlights: In stock $35.79 deliveryProtects against deterioration even in extreme climates. Government agencies, the military, and electronics manufacturers trust our desiccants to protect….

#3 Silica Gel Desiccant Manufacturer

Domain Est. 2011

Website: cilicant.com

Key Highlights: CILICANT is a qualified silica gel desiccants packets manufacturer in India. Helps to keep moisture away from your valuable computers and equipment….

#4 Silica Gel Desiccant

Domain Est. 2014 | Founded: 1973

Website: silicagel-desiccant.com

Key Highlights: We have been manufacturing high-quality silica gel desiccants, beads, and crystals since 1973. Our extensive range of silica gel and allied products caters to ……

#5 Silica Gel Desiccant

Domain Est. 2016

Website: wisesorbent.com

Key Highlights: WiseSorb® Silica Gel Desiccant utilizes silica gel as raw material. Silica gel has a strong moisture absorption capacity, is physically and chemically ……

#6 Desiccant Packets

Domain Est. 1995

Website: clariant.com

Key Highlights: Desiccant packets are a simple, dependable, and economical solution for preventing moisture damage in properly enclosed packages, or containers….

#7 Silica gel, Humidity indicators, Molecular sieves, Activated Aluminas …

Domain Est. 2000

Website: silicagelco.com

Key Highlights: Desiccant Bags provide the static dehumidification needed for the protection of many materials and packaged items to prevent corrosion, mold and mildew….

#8 Silica Gel

Domain Est. 2012

Website: impakcorporation.com

Key Highlights: Silica gel keeps photos safe and important documents from deteriorating, keeps silver shiny, and absorbs excess moisture in your basement, garage, safe, or ……

#9 Pharmaceutical Desiccants

Domain Est. 2014

Website: pharmadesiccants.com

Key Highlights: We offers high-quality pharmaceutical desiccants, including silica gel, molecular sieve desiccant, montmorillonite clay, carbon, pharmaceutical coils, ……

#10 Buy Silica Gel and Desiccant Products Online at SilicaGelProducts …

Website: silicagelproducts.co.nz

Key Highlights: SILICA GEL PRODUCTS are New Zealand’s supplier of Silica Gel and Desiccant products, a 100% Kiwi owned and operated company….

Expert Sourcing Insights for Gel Silica Desiccant

H2: Market Trends for Gel Silica Desiccant in 2026

The global gel silica desiccant market is poised for steady growth through 2026, driven by increasing demand across key industries, technological advancements, and expanding applications in emerging markets. This analysis explores the primary trends shaping the gel silica desiccant landscape in 2026 under the H2 framework.

-

Rising Demand in Pharmaceuticals and Healthcare

By 2026, the pharmaceutical sector continues to be a dominant consumer of gel silica desiccants. With stringent regulatory requirements for moisture control in drug packaging, manufacturers are increasingly adopting high-purity silica gel to ensure product stability and shelf life. Growth in biologics, vaccines, and temperature-sensitive medications further accentuates the need for reliable desiccants, particularly in regions with humid climates. -

Expansion in Food and Beverage Packaging

The food industry is witnessing a surge in the use of silica gel desiccants to maintain freshness and prevent spoilage. Growing consumer awareness regarding food safety and longer shelf life is pushing packaged food producers to integrate moisture-control solutions. In 2026, innovations such as food-grade, non-toxic silica gels with indicator dyes (e.g., cobalt-free alternatives) are gaining traction, aligning with sustainability and safety standards. -

Growth in Electronics and Precision Instruments

As electronic devices become smaller and more complex, moisture protection remains critical. The proliferation of IoT devices, wearable technology, and 5G infrastructure drives demand for high-performance desiccants. In 2026, gel silica desiccants are increasingly used in circuit boards, sensors, and semiconductor packaging to prevent corrosion and ensure long-term reliability, especially during global supply chain transit. -

Sustainability and Eco-Friendly Innovations

Environmental concerns are reshaping the market. By 2026, manufacturers are focusing on recyclable packaging, regenerable silica gels, and reduced chemical additives. Regulatory pressure and ESG (Environmental, Social, and Governance) initiatives encourage the shift toward cobalt-free color-indicating gels and biodegradable sachets. Companies investing in green production processes are gaining competitive advantage. -

Regional Market Development

Asia-Pacific remains the fastest-growing region due to robust industrialization, expanding pharmaceutical and electronics manufacturing in China, India, and Southeast Asia. North America and Europe maintain strong demand driven by advanced healthcare systems and stringent packaging regulations. Meanwhile, Latin America and Africa present untapped potential, with rising infrastructure and consumer goods production boosting desiccant usage. -

Technological Advancements and Customization

In 2026, the market sees increased customization of silica gel products—tailored granule sizes, controlled absorption rates, and integration with smart packaging (e.g., humidity indicators). Advances in nano-silica and hybrid desiccant materials are enhancing performance in extreme environments, opening new applications in aerospace and automotive sectors. -

Supply Chain Resilience and Raw Material Sourcing

Post-pandemic supply chain adjustments continue to influence the market. Players are diversifying silica sources and investing in localized production to mitigate disruptions. The cost and availability of sodium silicate, a key raw material, remain critical factors affecting pricing and scalability.

Conclusion

By 2026, the gel silica desiccant market is characterized by innovation, regulatory compliance, and sustainability. Growth is underpinned by cross-industry demand, especially in healthcare, food, and electronics. Companies that adapt to environmental standards, embrace digital integration, and expand regionally are best positioned to lead in this evolving landscape.

Common Pitfalls When Sourcing Gel Silica Desiccant (Quality & IP)

Sourcing gel silica desiccant may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to product failure, reputational damage, compliance issues, and legal risks. Avoid these common pitfalls:

1. Assuming All Silica Gel is the Same (Quality Variability)

A major mistake is treating silica gel as a commodity without assessing critical quality differences. Not all silica gels perform equally. Key pitfalls include:

– Inconsistent Moisture Adsorption Capacity: Low-grade silica may not meet required adsorption rates (e.g., failing to reach 30–40% weight gain at 100% RH), compromising product protection.

– Poor Physical Integrity: Substandard materials may powderize during transit or handling, leading to contamination—especially critical in pharmaceuticals or electronics.

– Inadequate Additives or Indicators: Color-indicating silica (e.g., blue-to-pink cobalt chloride) may use banned substances (cobalt is carcinogenic; restricted under REACH). Suppliers may omit compliance documentation.

– Lack of Certification: Failure to request or verify ISO 9001, USP-NF, or FDA compliance for regulated industries (e.g., medical devices, food packaging).

2. Overlooking Packaging Integrity and Compatibility

Even high-quality desiccant fails if improperly packaged:

– Non-Breathable or Permeable Packaging: Using polyethylene instead of Tyvek or porous filter paper limits moisture access, reducing effectiveness.

– Contamination Risk: Inferior packaging materials may leach chemicals or shed fibers into sensitive environments.

– Incorrect Sizing or Form Factor: Mismatched sachet size, shape, or placement reduces efficiency and may interfere with product assembly.

3. Ignoring Regulatory and Environmental Compliance

Many buyers fail to verify that desiccants meet regional and industry standards:

– REACH, RoHS, or Prop 65 Violations: Use of restricted substances (e.g., cobalt chloride) without disclosure.

– Food or Pharma-Grade Requirements: Using industrial-grade silica in food contact or sterile medical packaging without appropriate certification (e.g., FDA 21 CFR, USP <670>).

– Sustainability Claims: Vague “eco-friendly” labels without proof (e.g., recyclability, biodegradability) can mislead and expose buyers to greenwashing allegations.

4. Neglecting Intellectual Property (IP) Rights

Desiccant technology and branding can be protected, leading to IP risks:

– Patented Formulations or Technologies: Using specialized silica (e.g., molecular sieve hybrids, nano-porous variants) without licensing can result in infringement claims.

– Branded Desiccants: Reputable brands (e.g., indicating sachets with proprietary dyes or packaging designs) may be trademarked. Unauthorized replication—even in private labeling—can trigger legal action.

– Counterfeit or Grey Market Goods: Sourcing from unauthorized distributors may provide non-genuine products that appear authentic but lack performance guarantees or IP clearance.

5. Failing to Audit Suppliers and Verify Claims

Relying solely on supplier-provided data sheets is risky:

– No On-Site Audits: Skipping facility inspections may miss poor manufacturing practices or contamination risks.

– Unverified Test Reports: Accepting COAs (Certificates of Analysis) without third-party validation or batch traceability.

– Lack of Supply Chain Transparency: Inability to trace raw material sources increases risk of adulteration or forced labor exposure.

6. Underestimating Long-Term Performance and Shelf Life

Some suppliers exaggerate performance:

– Pre-Loaded Desiccants: Desiccant exposed to humidity before use (e.g., poor warehouse storage) loses capacity.

– No Accelerated Aging Data: Absence of testing under real-world conditions (temperature, humidity cycles) leads to premature failure in the field.

Best Practices to Avoid Pitfalls:

– Require full material disclosure and regulatory compliance documentation.

– Conduct third-party lab testing on sample batches.

– Audit suppliers and confirm IP freedom-to-operate.

– Use contractual quality agreements with performance KPIs.

– Prefer suppliers with industry-specific certifications (e.g., IATF 16949 for automotive).

By proactively addressing these quality and IP concerns, companies can ensure reliable desiccant performance and mitigate legal and operational risks.

Logistics & Compliance Guide for Gel Silica Desiccant

Overview

Gel silica desiccant, also known as silica gel, is a highly porous, inert desiccant commonly used to control humidity and protect moisture-sensitive goods during storage and transportation. Proper logistics handling and regulatory compliance are essential to ensure product integrity, safety, and adherence to international shipping standards.

Classification & Identification

- Chemical Name: Silica gel (amorphous silicon dioxide)

- CAS Number: 63231-67-4

- UN Number: Not regulated as hazardous when in non-indicating (non-toxic) form (UN 3077 may apply if packaged under certain conditions for environmental hazards)

- IMDG/ADR/IATA Status: Generally not classified as dangerous goods when non-indicating and non-hazardous

- Common Forms: Beads, granules, or in sachets/packets made from breathable materials (e.g., Tyvek, paper, non-woven fabric)

Storage Requirements

- Environment: Store in a cool, dry, and well-ventilated area

- Packaging: Keep in original sealed containers to prevent premature moisture absorption

- Shelf Life: Typically 6–12 months if unopened and stored properly

- Precautions: Avoid exposure to high humidity, direct sunlight, and contamination with liquids or dust

Transportation Guidelines

- Mode of Transport: Suitable for air, sea, and land freight

- Packaging: Must be packed in moisture-resistant, sealed outer packaging (e.g., polyethylene bags inside fiber drums or cartons)

- Stacking: Do not exceed manufacturer-recommended stacking heights to prevent package compression and desiccant damage

- Segregation: Keep away from liquid cargoes, strong oxidizers, and hygroscopic materials

- Labeling: Mark packages with “Keep Dry,” “Protect from Moisture,” and “Silica Gel – Desiccant” for clarity

Regulatory Compliance

International Regulations

- REACH (EU): Silica gel is registered under REACH; no SVHCs (Substances of Very High Concern) are present in standard non-indicating forms

- RoHS/ELV (EU): Compliant for use in electronics and automotive applications

- FDA (USA): Non-indicating silica gel is Generally Recognized As Safe (GRAS) for indirect food contact (21 CFR 172.480)

- Proposition 65 (California): Silica gel (amorphous) is not listed; crystalline silica is regulated—ensure product is amorphous only

- TSCA (USA): Listed on the TSCA Inventory

Hazard Communication

- SDS (Safety Data Sheet): Required under GHS standards. Non-indicating silica gel typically classified as:

- Hazard Statement: H319 (Causes serious eye irritation)

- Precautionary Statements: P264, P280, P305+P351+P338

- Not classified for flammability, acute toxicity, or environmental hazards

- Labeling: GHS-compliant labels required for bulk shipments

Environmental & Disposal Considerations

- Environmental Impact: Non-toxic and non-reactive under normal conditions

- Disposal: Dispose of in accordance with local regulations. Non-hazardous waste in most jurisdictions if uncontaminated

- Recycling: Silica gel can often be regenerated by heating (120–150°C) and reused, though this is uncommon in consumer applications

- Landfill: Permissible in non-hazardous landfills in most regions

Special Considerations

- Indicating Silica Gel: Contains moisture-sensitive dyes (e.g., cobalt chloride—restricted in EU under REACH Annex XVII). Prefer cobalt-free alternatives (e.g., methyl violet) for compliance

- Food & Pharma Grade: Must meet additional standards (e.g., USP, BP, or food-grade certifications) and be packaged in FDA-compliant materials

- Electronics & Military Use: May require MIL-DTL-3464 or equivalent compliance with strict moisture capacity and packaging standards

Best Practices Summary

- Verify regulatory status based on formulation (indicating vs. non-indicating)

- Use sealed, moisture-resistant packaging for transport and storage

- Provide GHS-compliant SDS and labels

- Avoid mixing with reactive or sensitive goods

- Train personnel on safe handling (avoid inhalation of dust, eye contact)

- Confirm compliance with destination country regulations (e.g., EU REACH, China REACH, K-REACH)

References

- UN Model Regulations on the Transport of Dangerous Goods

- IATA Dangerous Goods Regulations (for air)

- IMDG Code (for sea)

- ADR (for road in Europe)

- OSHA Hazard Communication Standard (29 CFR 1910.1200)

- REACH Regulation (EC) No 1907/2006

- FDA 21 CFR § 172.480

Note: Always consult the manufacturer’s SDS and local regulatory authorities for the most current compliance requirements.

Conclusion: Sourcing Gel Silica Desiccant

In conclusion, sourcing gel silica desiccant requires a strategic approach that balances quality, cost-effectiveness, reliability, and compliance with industry standards. As a highly effective moisture absorber, silica gel plays a critical role in preserving the integrity of products across pharmaceuticals, electronics, food packaging, and logistics. When selecting a supplier, it is essential to evaluate factors such as product specifications (indicators, mesh size, packaging forms), material purity, regulatory compliance (e.g., FDA, REACH, RoHS), and sustainability practices.

Establishing relationships with reputable manufacturers or distributors—preferably those with certifications like ISO 9001—ensures consistent product quality and supply chain reliability. Additionally, considering packaging customization, lead times, and logistics support can enhance operational efficiency. With increasing environmental awareness, exploring options for recyclable or non-indicating silica gel may also support sustainability goals.

Ultimately, a well-informed sourcing strategy for gel silica desiccant not only protects sensitive goods from moisture damage but also contributes to overall product quality, customer satisfaction, and cost optimization in the long term.