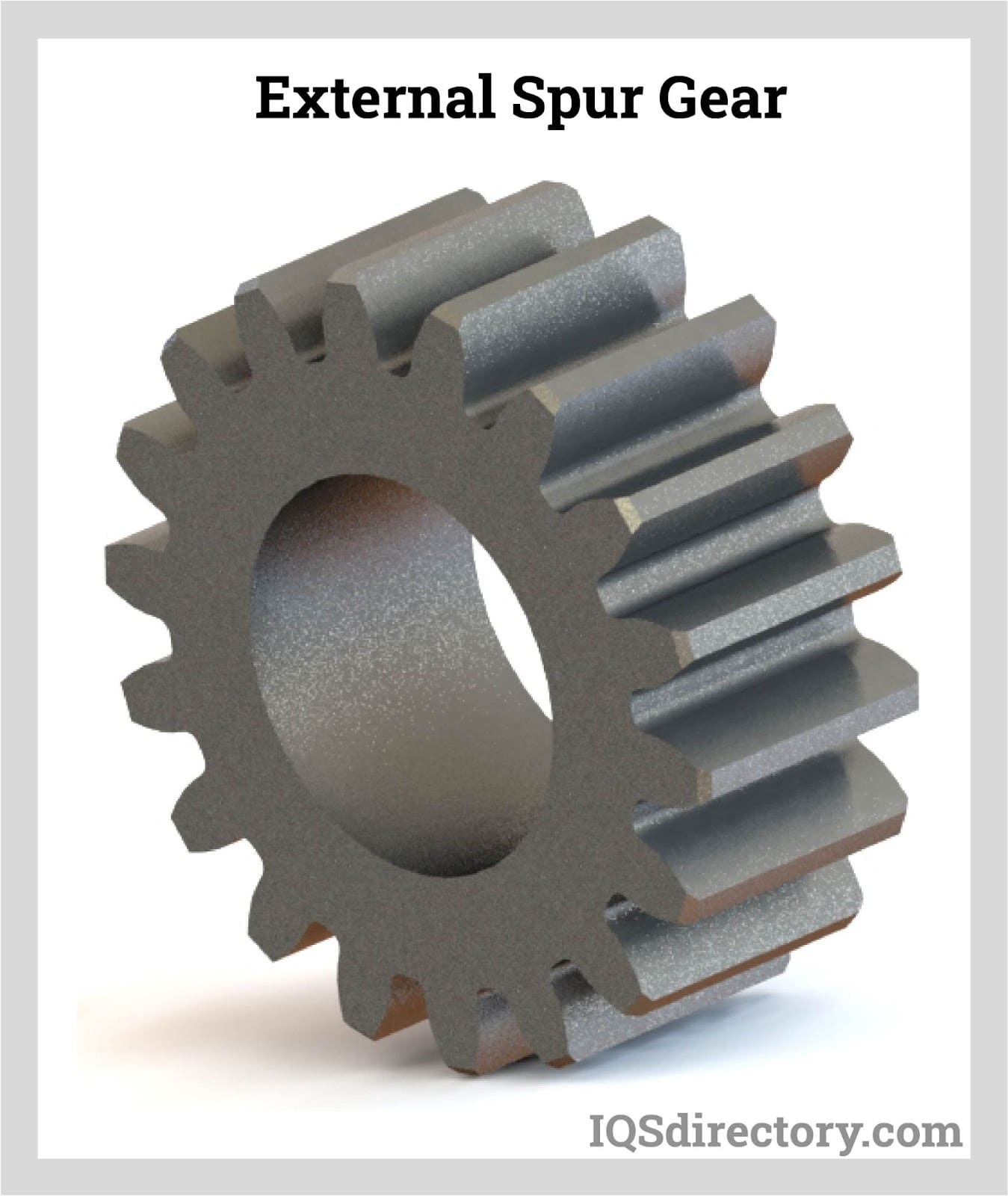

The global spur gear market is experiencing robust growth, driven by increasing demand across industrial machinery, automotive, aerospace, and renewable energy sectors. According to Grand View Research, the global gear market size was valued at USD 68.9 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. Similarly, Mordor Intelligence projects a CAGR of over 6% during the forecast period 2023–2028, citing rising automation and the expansion of wind energy applications as key growth catalysts. As precision and reliability become critical in power transmission systems, spur gears—renowned for their simplicity, efficiency, and cost-effectiveness—continue to dominate gear selection in countless mechanical applications. With market dynamics favoring innovation in materials, manufacturing processes, and customization, identifying the leading manufacturers has become essential for engineering and procurement decision-makers. Here’s a data-informed look at the top 9 spur gear manufacturers shaping the future of motion control and industrial performance.

Top 9 Gear Spur Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Spur Gears

Domain Est. 1998

Website: traceygear.com

Key Highlights: Tracey Gear & Precision Shaft is an experienced gear manufacturer, specializing in spur gears. We utilize cutting-edge technology to manufacture spur gears….

#2 American Gear Manufacturers Association

Domain Est. 1997

Website: agma.org

Key Highlights: AGMA is the global network for technical standards, education, and business information for manufacturers, suppliers, and users of gears and mechanical power ……

#3 KHK Gears

Domain Est. 2015

Website: khkgears.net

Key Highlights: KHK Gears (Kohara Gear Industry) is a leading manufacturer of stock gears handling production and distribution of a large variety of stock gears….

#4 Gears, Racks, Pinions & Differentials

Domain Est. 1995

Website: sdp-si.com

Key Highlights: At SDP/SI, we offer high-quality gear blanks used to manufacture a wide variety of gear types, including spur gears and internal gears. In spur gears, teeth ……

#5 Spur Gears

Domain Est. 1996

Website: qtcgears.com

Key Highlights: Our spur gears are made in a variety of configurations, modules and materials, including: ground, hubless, plastic, stainless steel, injection molded, and brass ……

#6 Spur Gears

Domain Est. 1997

Website: bostongear.com

Key Highlights: Boston Gear’s spur gears, which are designed to transmit motion and power between parallel shafts, are the most economical gears in the power transmission ……

#7 to rushgears.com

Domain Est. 1997

Website: rushgears.com

Key Highlights: Welcome to rushgears.com. We manufacture all types of gears and machine parts in just about any material to suit your needs….

#8 Spur Gears

Domain Est. 1999

Website: bbman.com

Key Highlights: As a trusted supplier of quality spur gears, B&B Manufacturing® offers aluminum, stainless steel and custom spur gears.. Call us and request a quote today!…

#9 Supplier of Metric Spur Gears

Domain Est. 2015

Website: khkgears.us

Key Highlights: KHK’s spur gears are made in a variety of styles. Our spur gears are offered in many materials, configurations, modules and numbers of teeth….

Expert Sourcing Insights for Gear Spur

H2: Market Trends for Spur Gears in 2026

The global spur gear market is poised for steady growth through 2026, driven by advancements in industrial automation, electric mobility, and sustainable manufacturing. As a fundamental component in power transmission systems, spur gears remain critical across industries such as automotive, aerospace, industrial machinery, robotics, and renewable energy. This analysis explores key market trends shaping the spur gear sector in the second half (H2) of 2026.

-

Increased Demand from Electric Vehicles (EVs)

The expansion of the electric vehicle market continues to be a major growth driver. Spur gears are widely used in EV transmissions, onboard chargers, and auxiliary systems due to their simplicity, efficiency, and cost-effectiveness. As global EV adoption accelerates—supported by government incentives and declining battery costs—automotive manufacturers are investing in high-precision, lightweight spur gears. In H2 2026, demand is particularly strong in North America, Europe, and China, where EV production capacity is expanding rapidly. -

Advancements in Materials and Manufacturing

Material innovation is transforming spur gear performance and durability. By H2 2026, high-strength polymers, powder metallurgy alloys, and surface-treated steels are increasingly replacing traditional materials to reduce weight, noise, and wear. Additive manufacturing (3D printing) is being adopted for prototyping and low-volume production of complex gear geometries, enabling faster design iterations and customization. Additionally, Industry 4.0 technologies such as AI-driven quality control and digital twins are improving manufacturing precision and reducing waste. -

Growth in Industrial Automation and Robotics

With factories worldwide embracing smart manufacturing, the demand for compact, reliable spur gears in robotic joints, conveyors, and automated assembly systems has surged. In H2 2026, collaborative robots (cobots) and modular automation platforms are key markets. Spur gears are favored for their high torque transmission and ease of integration, especially in servo-driven systems. The Asia-Pacific region, led by Japan, South Korea, and China, remains the largest market for automation-driven gear demand. -

Sustainability and Energy Efficiency Regulations

Environmental regulations are pushing industries to adopt energy-efficient components. Spur gears with optimized tooth profiles, reduced friction coatings, and precision alignment contribute to higher system efficiency. In H2 2026, OEMs across Europe and North America are increasingly specifying gears that comply with ISO 14001 and Energy Star standards. Recyclable materials and closed-loop manufacturing processes are also gaining traction, aligning with corporate ESG goals. -

Regional Market Dynamics

- Asia-Pacific: Continues to dominate the spur gear market, fueled by manufacturing growth in India, Vietnam, and Indonesia. Local production of machinery and EVs is reducing import dependency.

- North America: Reshoring of industrial production and investments in clean energy infrastructure (e.g., wind turbines) are boosting demand.

-

Europe: Stringent emissions standards and strong R&D in mechatronics are driving innovation in high-efficiency gear systems.

-

Challenges and Competitive Landscape

Despite growth, the market faces challenges including raw material price volatility (especially steel and rare earths), supply chain disruptions, and rising competition from helical and planetary gears in high-performance applications. However, spur gears maintain a cost advantage and reliability in moderate-speed, parallel-shaft applications. Leading players such as Bosch Rexroth, SEW-Eurodrive, and Sumitomo Heavy Industries are focusing on modular designs and digital services (e.g., predictive maintenance) to differentiate offerings.

Conclusion

In H2 2026, the spur gear market reflects a blend of traditional reliability and modern innovation. While facing competition from alternative gear types, spur gears are adapting through material science, digital manufacturing, and alignment with green technology trends. Their role in EVs, automation, and sustainable industry ensures continued relevance and growth, positioning the market for robust expansion through the late 2020s.

Common Pitfalls Sourcing Gear Spur (Quality, IP)

Sourcing spur gears—especially for critical applications—can be fraught with challenges related to both quality consistency and intellectual property (IP) risks. Being aware of these pitfalls helps in selecting reliable suppliers and protecting your design integrity.

Poor Material and Manufacturing Quality

One of the most prevalent issues in sourcing spur gears is inconsistent or substandard material quality and manufacturing precision. Low-cost suppliers may use inferior steel or non-certified alloys that compromise gear strength, wear resistance, and fatigue life. Inadequate heat treatment processes—such as improper case hardening or lack of tempering—can lead to premature tooth failure or brittleness. Additionally, poor gear tooth profile accuracy due to imprecise hobbing or grinding results in increased noise, vibration, and reduced efficiency.

Inadequate Tolerance and Dimensional Control

Spur gears require tight tolerances in pitch diameter, tooth profile, runout, and backlash to ensure proper meshing and performance. Suppliers lacking advanced metrology equipment or quality control systems may deliver gears with dimensional deviations. These inconsistencies can cause misalignment, accelerated wear, and system failure, especially in high-speed or high-torque applications.

Lack of Traceability and Certification

Many suppliers, particularly in low-cost regions, fail to provide proper material certifications (e.g., mill test reports) or process documentation. Without traceability, it becomes difficult to verify compliance with industry standards (such as AGMA, DIN, or ISO) or conduct root-cause analysis in case of failure. This lack of documentation also complicates regulatory compliance in industries like aerospace or medical devices.

Intellectual Property Infringement Risks

Sourcing spur gears based on proprietary designs carries significant IP risks. Unauthorized replication of patented gear profiles, tooth geometries, or custom modifications by suppliers can expose the buyer to legal liability. Some manufacturers may claim to produce “equivalent” gears but actually reverse-engineer patented components without licensing, leading to potential infringement lawsuits.

Reverse Engineering and Unauthorized Production

Suppliers may use provided samples or technical drawings to produce and sell identical gears to competitors. This is particularly concerning when sourcing custom or high-value gear designs. Without strong contractual agreements and non-disclosure provisions, your design could be replicated and distributed without consent, undermining competitive advantage.

Inconsistent Quality Across Production Batches

Even if initial samples meet specifications, long-term sourcing can reveal inconsistencies between production batches. Variations in raw materials, tooling wear, or process controls can result in performance differences over time. A lack of robust quality management systems (e.g., ISO 9001) increases the likelihood of such variability.

Misrepresentation of Capabilities and Standards Compliance

Some suppliers claim compliance with international standards or possession of advanced manufacturing capabilities without proper validation. Buyers may receive gears labeled as AGMA Quality Class 10, for example, that do not meet the required inspection criteria. Third-party audits or independent testing may be necessary to verify such claims.

Mitigation Strategies

To avoid these pitfalls:

– Require full material and process certifications.

– Conduct supplier audits and request evidence of quality systems.

– Use legally binding NDAs and IP protection clauses in contracts.

– Perform incoming inspection and batch sampling.

– Partner with reputable manufacturers with proven track records in precision gearing.

By addressing these common issues proactively, sourcing spur gears can be both reliable and secure from both a quality and intellectual property standpoint.

Logistics & Compliance Guide for Gear Spur

This guide outlines the essential logistics and compliance considerations for Gear Spur, a manufacturer or distributor of spur gears and mechanical components. Adhering to these standards ensures operational efficiency, regulatory compliance, and customer satisfaction.

Supply Chain Management

Establish a reliable network of suppliers for raw materials such as alloy steels, plastics, and specialty coatings. Implement vendor qualification processes to ensure material consistency and traceability. Maintain safety stock levels based on demand forecasting and lead times. Utilize just-in-time (JIT) inventory practices where feasible to reduce carrying costs while ensuring production continuity.

Inventory Control & Warehousing

Implement an inventory management system (e.g., ERP or WMS) to track stock levels, batch numbers, and shelf life. Store materials and finished goods in a controlled environment to prevent corrosion, contamination, or physical damage. Segregate non-conforming products and maintain documented quarantine procedures. Conduct regular cycle counts and annual physical inventories to ensure accuracy.

Transportation & Distribution

Select carriers compliant with transportation regulations (e.g., FMCSA in the U.S., ADR in Europe). Package spur gears appropriately to prevent damage during transit—use protective wrapping, anti-corrosion agents, and secure palletization. Label shipments with product identifiers, handling instructions, and safety warnings. Optimize shipping routes and modes (air, sea, road) to balance cost, speed, and environmental impact.

Export Compliance

Adhere to international trade regulations when shipping outside domestic markets. Ensure proper classification of spur gears under the Harmonized System (HS) codes. Obtain required export licenses if products fall under dual-use or strategic goods controls (e.g., ITAR, EAR). Complete accurate commercial invoices, packing lists, and certificates of origin. Maintain records for a minimum of five years as required by most jurisdictions.

Product Compliance & Certification

Ensure all spur gears meet relevant industry standards such as AGMA (American Gear Manufacturers Association), ISO (e.g., ISO 1328 for accuracy), or DIN. Maintain documentation for material certifications (e.g., mill test reports), heat treatment records, and quality inspection reports. Apply appropriate CE, UKCA, or other regional conformity markings where required. Conduct regular internal audits to verify compliance.

Environmental & Safety Regulations

Comply with environmental regulations (e.g., EPA, REACH, RoHS) regarding the use of hazardous substances in manufacturing and packaging. Properly manage waste oils, metal shavings, and chemical byproducts through certified disposal or recycling channels. Ensure workplace safety in accordance with OSHA or local occupational health standards. Provide employees with necessary training and protective equipment.

Documentation & Traceability

Maintain comprehensive records for full product traceability—from raw material sourcing to final delivery. Include batch/lot numbers, production dates, inspection results, and shipping details. Use barcodes or RFID tags where applicable to streamline tracking. Make documentation available for customer audits, regulatory inspections, or recall scenarios.

Continuous Improvement & Audit Preparedness

Conduct regular internal compliance audits and logistics performance reviews. Address non-conformances through corrective and preventive actions (CAPA). Stay updated on regulatory changes and industry best practices. Train staff regularly on compliance protocols and emergency response procedures to ensure ongoing readiness.

Conclusion for Sourcing Spur Gears

In conclusion, sourcing spur gears requires a strategic approach that balances quality, cost, lead time, and technical specifications. Critical factors such as material selection, module (or diametral pitch), pressure angle, precision grade, and tooth finish must align with the intended application to ensure optimal performance and longevity. Whether sourcing domestically or internationally, evaluating supplier credibility, manufacturing capabilities, and quality control processes is essential to avoid potential failures or downtime.

Additionally, considering total cost of ownership—beyond just the purchase price—helps in making informed decisions that support reliability and efficiency in mechanical systems. Collaboration with suppliers during the design phase can also lead to custom solutions that improve functionality and reduce assembly time. Ultimately, a well-structured sourcing strategy for spur gears enhances system performance, reduces maintenance costs, and supports overall operational success.