The global gate latch parts market is experiencing steady growth, driven by rising demand in residential, commercial, and industrial construction sectors. According to Grand View Research, the global door and window hardware market—of which gate latch components are a critical segment—was valued at USD 57.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. Increasing urbanization, infrastructure development, and a growing emphasis on security and automation in building access systems are key factors fueling this expansion. Additionally, Mordor Intelligence forecasts continued momentum in the construction hardware sector, with heightened adoption of durable, corrosion-resistant materials like stainless steel and powder-coated zinc in latch manufacturing. As demand evolves, manufacturers are focusing on innovation, scalability, and global supply chain integration to meet rigorous quality standards and regional regulatory requirements. In this expanding landscape, identifying leading gate latch parts manufacturers becomes essential for sourcing reliable, high-performance components. The following list highlights the top 10 companies shaping the market through engineering excellence, consistent product quality, and strategic market presence.

Top 10 Gate Latch Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ace Gate Hardware

Domain Est. 2003

Website: acegatehardware.com

Key Highlights: Specialist Australian manufacturers of robust gate hardware. Barrel electro-zinc plating, custom machining & manufacturing….

#2 Gate Latch Suppliers

Domain Est. 2015

Website: latchmanufacturers.com

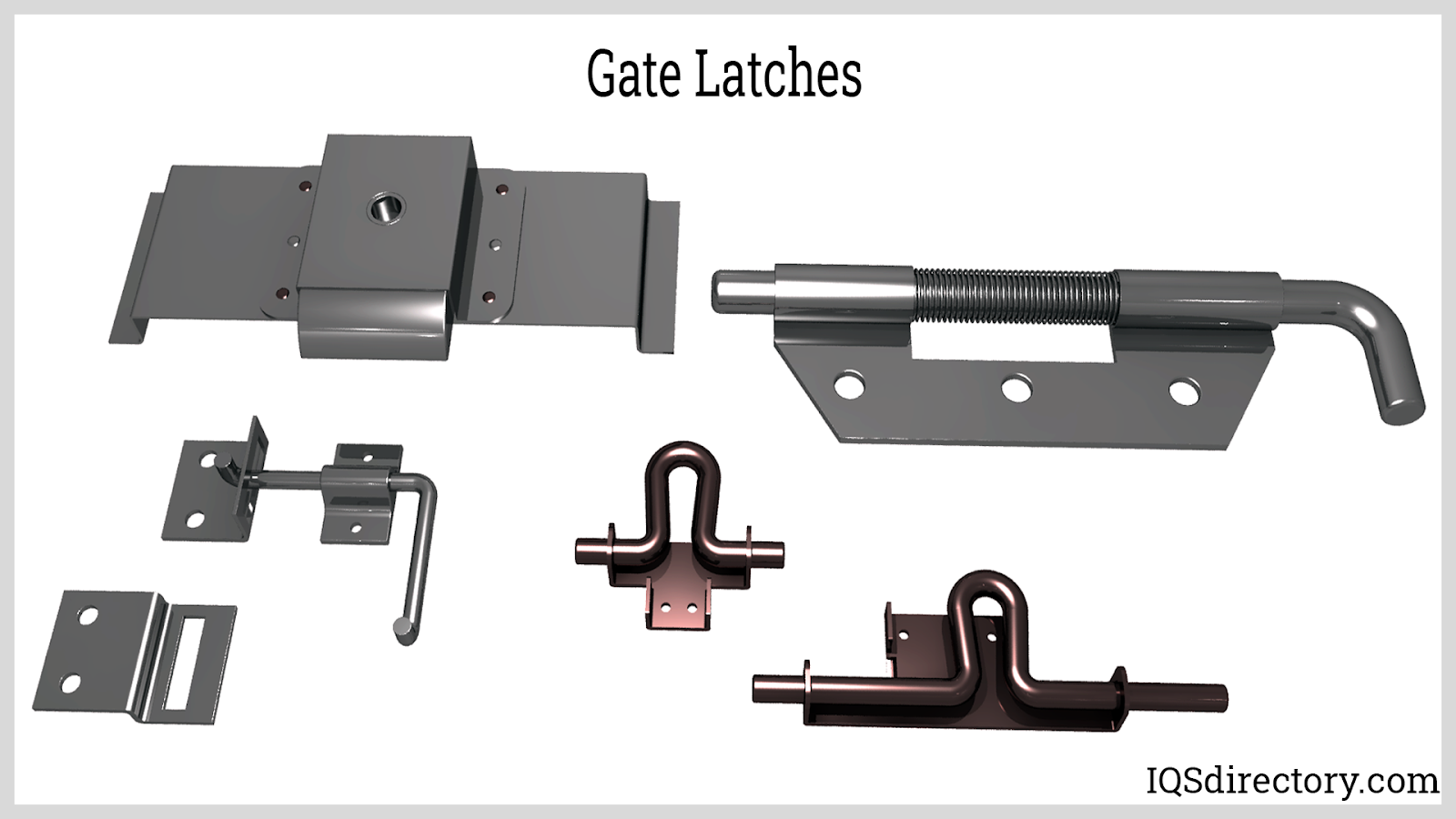

Key Highlights: Components of Gate Latches. Gate latches typically consist of a handle or knob, latch mechanism, strike plate, screws or bolts, and a spring or tension system….

#3 Gate Latches

Domain Est. 1996

#4 Gate Latches

Domain Est. 1996

Website: acornmfg.com

Key Highlights: Free delivery 120-day returnsHome · Gate Hardware; Gate Latches. Checkout as a new customer. Creating an account has many benefits: See order and shipping status; Track order histo…

#5 D&D Technologies US

Domain Est. 1998

Website: us.ddtech.com

Key Highlights: D&D Technologies is a company dedicated to the design and manufacture of top-quality, state-of the-art gate hardware products….

#6 Nationwide Industries

Domain Est. 2000

Website: nationwideindustries.com

Key Highlights: Magnetic Gate Latch for Wood, Vinyl, and Metal Applications. Illuminate Safety. Amplify Awareness….

#7 Sure-Latch

Domain Est. 2000

Website: colinemfg.com

Key Highlights: Sure-Latch has created eight durable and easy-to-use Sure-Latch™ products used on residential, commercial and livestock gates worldwide….

#8 Gate Hardware

Domain Est. 2002

Website: gatedepot.com

Key Highlights: 5-day delivery 30-day returnsA selection of gate hardware for swing gates, slide gates, cantilever gates, barn doors, overhead doors, driveway gates, pedestrian gates, and garden g…

#9 Gatemaster Locks

Domain Est. 2016

Website: gatemasterlocks.com

Key Highlights: Gatemaster manufactures a comprehensive range of robust and easy-to-install key and code gate locks and hardware for metal and wooden gates….

#10 GH Gate Products Gate Latch Pull

Domain Est. 2017

Expert Sourcing Insights for Gate Latch Parts

H2: Market Trends for Gate Latch Parts in 2026

The global market for gate latch parts is poised for steady growth and transformation in 2026, driven by advancements in smart technology, increasing demand for home security, and a surge in residential and commercial construction. As urbanization continues and homeowners prioritize safety and automation, gate latch components are evolving beyond basic mechanical functions to become integral parts of integrated access control systems.

One of the most significant trends shaping the 2026 market is the rising adoption of smart gate latch systems. These systems, often equipped with Bluetooth, Wi-Fi, or app-based controls, allow users to remotely operate gates via smartphones or voice assistants. Integration with home automation platforms such as Google Home, Apple HomeKit, and Amazon Alexa is becoming standard, boosting consumer demand for compatible latch components.

Additionally, there is a growing emphasis on durability and weather resistance, particularly in regions with extreme climates. Manufacturers are increasingly using corrosion-resistant materials such as marine-grade stainless steel, powder-coated aluminum, and reinforced polymers to enhance product longevity. This shift is supported by stricter building codes and sustainability standards, which are influencing both residential and industrial procurement decisions.

The do-it-yourself (DIY) home improvement movement is also fueling demand for user-friendly, modular gate latch parts. Consumers are seeking products that offer easy installation without professional assistance, prompting companies to design intuitive packaging, clear instructions, and compatibility with standard gate frameworks.

On the supply side, supply chain optimization and localized manufacturing are helping reduce lead times and mitigate global logistics challenges. Companies are investing in regional production hubs to meet regional demand swiftly and comply with local regulations.

Finally, sustainability is emerging as a key differentiator. Eco-conscious buyers are favoring brands that utilize recyclable materials and energy-efficient production methods. Some leading manufacturers are introducing take-back programs and carbon-neutral certifications to align with environmental, social, and governance (ESG) goals.

In summary, the 2026 gate latch parts market reflects a convergence of smart technology, enhanced security, and sustainable innovation. Companies that prioritize connectivity, durability, and environmental responsibility are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Gate Latch Parts: Quality and Intellectual Property Concerns

Sourcing gate latch parts involves several potential challenges, particularly related to quality inconsistencies and intellectual property (IP) risks. Being aware of these pitfalls can help procurement teams and manufacturers avoid costly errors, legal issues, and product failures.

1. Inconsistent Material Quality

One of the most frequent issues is receiving components made from substandard materials. Suppliers may use lower-grade metals or plastics that compromise the durability, corrosion resistance, and load-bearing capacity of the latch. This often results in premature wear, mechanical failure, or safety hazards, especially in outdoor or high-traffic environments.

2. Lack of Quality Control Standards

Many overseas or low-cost suppliers lack rigorous quality assurance processes. Without certifications such as ISO 9001 or adherence to industry-specific standards (e.g., ASTM, DIN), there’s a higher risk of dimensional inaccuracies, poor surface finishes, or inconsistent batch quality. This can lead to assembly issues or increased rejection rates during inspection.

3. Counterfeit or Reverse-Engineered Components

Some suppliers offer parts that mimic branded or patented designs without authorization. These knockoffs may infringe on intellectual property rights, exposing buyers to legal liability. Even if the parts appear functional, they may not meet the original performance standards and could damage a company’s reputation or lead to product recalls.

4. Inadequate Documentation and Traceability

Reliable sourcing requires clear documentation, including material certifications, test reports, and compliance statements. Suppliers that fail to provide traceability data make it difficult to verify authenticity or troubleshoot failures. This lack of transparency also complicates compliance with regulatory or safety standards.

5. Unverified Supplier Credentials

Engaging with suppliers without proper due diligence increases exposure to fraud and IP theft. Suppliers may claim to be authorized distributors or original equipment manufacturers (OEMs) when they are not. Always verify business licenses, factory audits, and references before committing to large orders.

6. Hidden IP Infringement in Custom Designs

When developing custom latch components, there’s a risk that the design unintentionally violates existing patents or trademarks. Without thorough IP clearance searches, companies may face litigation or be forced to redesign products mid-production, leading to delays and added costs.

7. Poor Packaging and Handling Leading to Damage

Even high-quality parts can be compromised during transit if packaging is insufficient. Poor handling can cause deformation, scratching, or corrosion, especially with metal components. Ensure suppliers follow proper packaging protocols to maintain part integrity.

8. Language and Communication Barriers

Miscommunication with international suppliers—especially regarding technical specifications, tolerances, or quality expectations—can lead to incorrect or non-compliant parts. Use detailed drawings, standardized terminology, and third-party inspections to mitigate misunderstandings.

By addressing these common pitfalls proactively—through supplier vetting, quality audits, IP due diligence, and clear contractual agreements—businesses can source gate latch parts reliably and protect both product performance and legal compliance.

Logistics & Compliance Guide for Gate Latch Parts

This guide outlines key logistics and compliance considerations for the import, export, storage, and distribution of gate latch parts. Adhering to these standards ensures smooth operations, regulatory compliance, and product safety.

Product Classification & Tariff Codes

Accurately classify gate latch parts using the Harmonized System (HS) or Harmonized Tariff Schedule (HTS) codes. Common classifications may fall under:

– HS Code 8302 (Fittings for furniture, doors, etc., of base metal)

– HTS 8302.41 or 8302.42 (specific to iron or steel door or window fittings)

Classification impacts duties, taxes, and import regulations—verify with customs authorities or a licensed customs broker.

Import/Export Regulations

Comply with all relevant national and international trade laws:

– Obtain necessary import/export licenses where required (e.g., for shipments to or from restricted countries).

– Ensure compliance with U.S. Customs and Border Protection (CBP), EU Import Controls, or other regional customs authorities.

– Complete accurate commercial invoices, packing lists, and bills of lading.

– Declare country of origin clearly—mislabeling may result in penalties or shipment delays.

Packaging & Labeling Standards

- Use durable packaging to prevent damage during transit (e.g., corrugated boxes, protective wrapping).

- Label each package with:

- Product description and part number

- Quantity and weight

- Country of origin

- Handling instructions (e.g., “Fragile,” “Do Not Stack”)

- Include safety and compliance labels if required (e.g., CE marking for EU, UKCA for UK).

Safety & Product Compliance

Ensure products meet applicable safety and performance standards:

– EU: Comply with CE marking requirements under relevant directives (e.g., Construction Products Regulation (CPR) if applicable).

– USA: Follow ANSI, ASTM, or other relevant product safety standards.

– Canada: Meet CSA standards where applicable.

– Conduct regular quality audits and maintain documentation (test reports, certifications).

Chemical & Material Restrictions

Gate latch parts may be subject to substance restrictions:

– REACH (EU): Register and disclose substances of very high concern (SVHC) in articles.

– RoHS (EU): Restrict hazardous substances in electrical components (if applicable).

– Prop 65 (California): Warn consumers if products contain listed chemicals (e.g., lead in metal parts).

Verify material composition and maintain supplier declarations of conformity (DoC).

Transportation & Shipping

- Choose appropriate transport mode (air, sea, or ground) based on volume, urgency, and cost.

- Use freight forwarders experienced in handling metal components.

- Ensure proper cargo insurance coverage.

- Monitor transit times and comply with Incoterms® (e.g., FOB, CIF) agreed upon with buyers/suppliers.

Storage & Inventory Management

- Store parts in a dry, secure environment to prevent rust or damage.

- Implement FIFO (First In, First Out) inventory practices.

- Maintain accurate inventory records and conduct regular cycle counts.

- Use warehouse management systems (WMS) to streamline logistics and traceability.

Documentation & Recordkeeping

Retain all compliance and logistics documents for a minimum of 5–7 years (as required by customs and regulatory bodies):

– Certificates of Compliance (CoC)

– Test reports

– Import/export declarations

– Supplier agreements and material declarations

– Shipping and customs documentation

Returns & Reverse Logistics

Establish a clear process for handling defective or non-compliant parts:

– Define return authorization (RMA) procedures.

– Inspect returned items and determine cause (manufacturing defect, shipping damage, etc.).

– Recycle or dispose of non-repairable parts in compliance with local environmental regulations.

Audits & Continuous Improvement

- Conduct regular internal audits of logistics and compliance processes.

- Stay updated on regulatory changes (e.g., tariff updates, new environmental laws).

- Train staff on compliance requirements and best practices.

- Partner with certified suppliers and logistics providers to maintain standards.

By following this guide, businesses can ensure reliable supply chain operations and full compliance when handling gate latch parts globally.

In conclusion, sourcing gate latch parts requires careful consideration of quality, compatibility, durability, and supplier reliability. By identifying the specific type and specifications of the latch needed—such as material, size, locking mechanism, and environmental resistance—procurement can be streamlined effectively. Exploring multiple sourcing options, including local hardware suppliers, online marketplaces, and specialized manufacturers, ensures competitive pricing and availability. Additionally, prioritizing suppliers with strong reputations, warranties, and customer service helps mitigate risks related to defective or incorrect parts. Ultimately, a well-researched and strategic sourcing approach ensures the acquisition of reliable gate latch components that enhance security, functionality, and longevity of the gate system.