The global portable fuel transfer pump market is experiencing robust growth, driven by rising demand for efficient and safe fuel handling solutions across automotive, industrial, and recreational sectors. According to Grand View Research, the global fuel pump market size was valued at USD 9.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. This growth is fueled by increasing vehicle production, stringent fuel efficiency regulations, and growing consumer preference for electric-powered, user-friendly gas can pumps over traditional gravity-fed methods. With safety, ease of use, and environmental concerns shaping purchasing decisions, manufacturers are investing heavily in innovation and compliance with EPA and CARB standards. As the market becomes more competitive, a select group of eight leading electric gas can pump manufacturers have emerged, combining engineering excellence, regulatory adherence, and strong distribution networks to capture significant market share. These companies are not only meeting current demand but are also shaping the future of portable fuel transfer through smart design and advanced technology.

Top 8 Gas Can Electric Pump Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 2002

Website: weldonpumps.com

Key Highlights: Weldon Pump is a leading designer and manufacturer of fuel, hydraulic, metering, and thermal management pumps. Our products are customized to meet specific ……

#2 TRFA01-XL

Domain Est. 2022

Website: indysbk.com

Key Highlights: In stock Free delivery over $500This battery operated fuel transfer pump works with VP fuel jugs (and some others – LC2 do not work well with this pump) to fuel your motorcycle, ge…

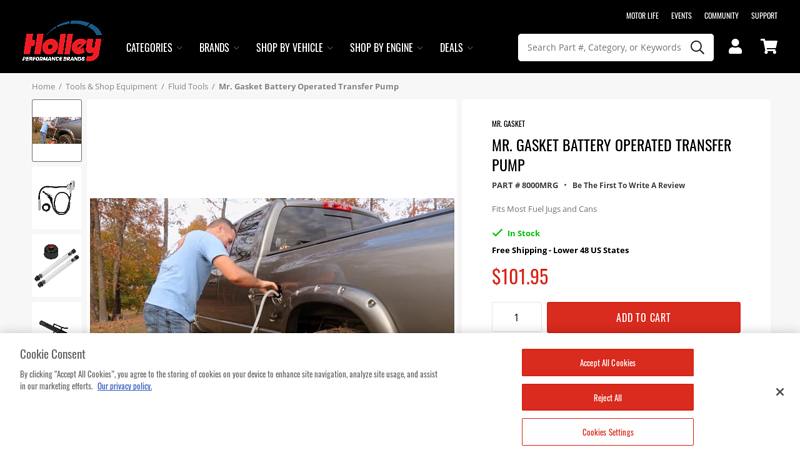

#3 Mr. Gasket Battery Operated Transfer Pump

Domain Est. 1995

Website: holley.com

Key Highlights: In stock Free delivery over $149Gasket Battery Operated Transfer Pump. Fits Most Fuel Jugs and Cans. In Stock … Gasket’s range of performance auto parts for engines, exhaust syst…

#4 Motor Components, LLC

Domain Est. 1996 | Founded: 1950

Website: facet-purolator.com

Key Highlights: Since 1950, Motor Components, LLC has designed and manufactured Facet® and Purolator® electronic fuel pumps in our ISO 9001-2015 facility located in Elmira, NY….

#5 ZE1030D – AA Battery Powered Fuel Can Transfer Pump

Domain Est. 1999

Website: zeeline.com

Key Highlights: Portable fuel transfer pump with 2.4 GPM flow, auto shut-off, and universal can fit. Ideal for gas, diesel, oils, and more….

#6 Fuel Transfer Pumps, Fuel Dispensers & Refuelling Pumps

Domain Est. 1999

Website: centretank.com

Key Highlights: CTS supply a wide range of fluid and fuel transfer pumps, ranging from simple hand fuel pumps to sophisticated, electric fuel dispensers….

#7 ZE1030XL

Domain Est. 2004

Website: miltonindustries.com

Key Highlights: This fuel can transfer pump was designed for use with fuel cans up to 6-gallons and can be used to fill a variety of applications….

#8 Best Pump for 5 Gallon Gas Can

Domain Est. 2024

Website: clixfueling.com

Key Highlights: Looking for a reliable pump for 5 gallon gas can? Our guide helps you find safe, spill-free solutions for lawnmowers, boats, and generators. Click now!…

Expert Sourcing Insights for Gas Can Electric Pump

H2: 2026 Market Trends for Gas Can Electric Pumps

The market for gas can electric pumps is poised for significant transformation by 2026, driven by technological advancements, shifting consumer preferences, regulatory changes, and increased demand for convenience and safety in fuel transfer. As portable fuel storage and transfer solutions grow in popularity across automotive, recreational, agricultural, and emergency preparedness sectors, electric pumps integrated into gas cans are emerging as a preferred alternative to traditional siphoning methods.

1. Rising Consumer Demand for Convenience and Safety

By 2026, safety and ease of use will remain primary drivers of adoption. Electric pumps eliminate the risks associated with manual siphoning—such as fuel ingestion, spills, and vapor inhalation—making them especially appealing to homeowners, outdoor enthusiasts, and DIY users. The integration of child-resistant features, automatic shut-off mechanisms, and leak-proof designs will further enhance user confidence and regulatory compliance.

2. Technological Integration and Smart Features

Electric pumps are expected to become smarter and more efficient. By 2026, leading models may include USB-C charging, Bluetooth connectivity for usage tracking via mobile apps, and variable flow rate controls. Some premium gas cans will likely feature built-in batteries with solar charging capabilities, targeting off-grid and emergency use cases. These innovations will cater to tech-savvy consumers and expand product utility beyond basic fuel transfer.

3. Growth in Recreational and Off-Road Applications

The booming outdoor recreation market—including off-roading, camping, and boating—will fuel demand for reliable, portable fuel solutions. Electric pump-equipped gas cans offer precision and control when refueling ATVs, generators, marine engines, and RVs. As more consumers invest in adventure-ready gear, manufacturers will respond with durable, ruggedized models designed for extreme environments.

4. Regulatory and Environmental Pressures

Environmental regulations, particularly in North America and Europe, are increasingly focused on reducing fuel vapor emissions and spillage. By 2026, compliance with EPA and CARB standards will be a competitive necessity. Electric pumps that minimize vapor release and incorporate closed-loop fueling systems will gain favor among both consumers and regulators, potentially leading to mandates or incentives for their use.

5. Expansion of E-Commerce and Direct-to-Consumer Sales

Online retail will continue to dominate distribution channels. Brands offering subscription-based replacement parts (e.g., batteries, nozzles) or bundled kits (pump + can + storage bag) will gain market share. Enhanced product videos, customer reviews, and influencer marketing in outdoor and automotive niches will further drive online sales.

6. Competitive Landscape and Market Consolidation

The market will likely see a consolidation of smaller brands and increased R&D investment by major players such as Gasboy, Scepter, and Stream Products. New entrants may focus on niche markets, such as eco-friendly bioplastics or ultra-lightweight composite materials. Price competition will intensify, but premiumization—especially around durability, safety, and smart features—will allow for higher margins.

7. Sustainability and Material Innovation

Environmental concerns will push manufacturers toward recyclable materials and longer product lifespans. By 2026, we can anticipate electric pumps powered by rechargeable lithium-ion batteries with improved energy density and recyclability. Some brands may introduce take-back programs or modular designs to support circular economy principles.

In conclusion, the 2026 market for gas can electric pumps will be shaped by a convergence of safety demands, technological innovation, and regulatory forces. As consumers prioritize efficiency and environmental responsibility, electric pump systems will transition from a convenience feature to a standard component in premium fuel storage solutions.

Common Pitfalls When Sourcing Gas Can Electric Pumps (Quality & IP)

Sourcing gas can electric pumps involves navigating significant risks related to product quality and intellectual property (IP) infringement. Failing to address these pitfalls can lead to safety hazards, legal liabilities, reputational damage, and financial losses. Here are the key challenges to watch for:

Quality Concerns Leading to Safety and Reliability Issues

-

Substandard Materials & Construction:

- Pitfall: Suppliers may use cheap, non-chemical-resistant plastics, inferior seals (O-rings), or low-grade motors to cut costs. This leads to rapid degradation when exposed to gasoline, ethanol blends, or diesel.

- Consequence: Leaks, pump failure, potential fire hazards, and contamination of fuel. Reduced lifespan means frequent replacements and customer dissatisfaction.

-

Inadequate Sealing and Leak Prevention:

- Pitfall: Poor design or manufacturing of the pump head, hose connections, or tank interface can result in fuel leaks during operation or storage.

- Consequence: Safety hazard (fire, fumes), environmental contamination, product damage, and non-compliance with safety standards.

-

Motor and Electrical Component Failures:

- Pitfall: Using undersized, low-quality, or non-spark-proof motors and wiring. Lack of proper waterproofing (IP rating) for the electrical connections and motor housing.

- Consequence: Motor burnout, electrical shorts, sparks near flammable fuel vapors (extreme fire risk), and complete pump failure, especially in damp conditions.

-

Lack of Safety Features:

- Pitfall: Omitting essential safety features like automatic shut-off when the receiving tank is full (preventing overflow), or thermal overload protection for the motor.

- Consequence: Fuel spills (hazardous, wasteful, environmental), potential fire/explosion, and motor damage.

-

Inaccurate or Misleading Specifications:

- Pitfall: Suppliers exaggerate flow rates, maximum lift height, or compatible fuel types (e.g., claiming compatibility with high-ethanol blends or diesel when the materials aren’t suitable).

- Consequence: Product underperformance, customer frustration, misuse leading to failure or safety incidents, and potential warranty claims.

Intellectual Property (IP) Infringement Risks

-

Direct Counterfeiting and Copying:

- Pitfall: Sourcing pumps that are blatant copies of well-known, patented designs (e.g., mimicking the shape, nozzle design, or unique features of brands like Gasboy, Scepter, or OEM equipment).

- Consequence: Seizure of goods by customs, injunctions preventing sales, significant financial damages, destruction of inventory, and reputational ruin. Legal action from the IP owner is highly likely.

-

Design Patent Infringement:

- Pitfall: Even if the function is similar, copying the specific ornamental design of a pump (unique housing shape, button layout, nozzle profile) can infringe design patents.

- Consequence: Legal liability for infringement, forced redesign, product recall, and financial penalties.

-

Utility Patent Infringement (Functionality):

- Pitfall: Copying innovative functional aspects covered by utility patents, such as a specific automatic shut-off mechanism, a unique priming system, or a particular pump impeller design.

- Consequence: Serious legal action, potential for treble damages, injunctions, and complete prohibition on selling the product.

-

Trademark Infringement:

- Pitfall: Using logos, brand names, or packaging that is confusingly similar to established brands, even if the pump itself is slightly different.

- Consequence: Trademark infringement lawsuits, customs seizures, and damage to brand reputation.

-

Supplier Misrepresentation of IP Status:

- Pitfall: Suppliers falsely claiming their pumps are “original designs,” “patent-free,” or “safe to export,” when they are actually infringing on existing IP.

- Consequence: The buyer (you) bears the ultimate legal and financial responsibility. Relying solely on the supplier’s statement is insufficient due diligence.

Mitigation Strategies:

- Rigorous Supplier Vetting: Audit manufacturers, demand proof of material certifications (e.g., fuel resistance), and inspect production facilities if possible.

- Independent Product Testing: Test samples for fuel compatibility, flow rate, head height, leak integrity, and electrical safety (including IP rating verification) in a lab.

- Comprehensive IP Due Diligence: Conduct freedom-to-operate (FTO) searches for relevant patents and trademarks before finalizing sourcing. Consult an IP attorney.

- Clear Contractual Protections: Include strong IP indemnification clauses in supplier contracts, requiring them to warrant non-infringement and cover legal costs if infringement occurs.

- Verify IP Ownership: Request evidence from the supplier that they own the IP for the design or have valid licenses.

- Prioritize Safety Certifications: Look for pumps tested and certified to relevant safety standards (e.g., UL, CE – though verify authenticity).

Ignoring quality and IP pitfalls when sourcing gas can electric pumps is a high-risk strategy. Proactive due diligence is essential to ensure product safety, reliability, and legal compliance.

Logistics & Compliance Guide for Gas Can Electric Pumps

Product Overview

Gas can electric pumps are portable devices designed to transfer fuel from gas cans to vehicles, equipment, or machinery. Typically powered by a 12V DC connection (e.g., cigarette lighter socket) or batteries, these pumps simplify fueling tasks. However, due to their use with flammable liquids, strict logistics and compliance protocols are required throughout handling, storage, transportation, and distribution.

Regulatory Classification and Hazards

Gas can electric pumps are often classified as hazardous goods when shipped due to their association with fuel transfer and potential ignition sources. Key concerns include:

– Flammability Risk: Pumps may retain fuel residue or be packaged with accessories that increase fire risk.

– Electrical Components: Internal wiring and motors may pose short-circuit or spark hazards if damaged.

– UN/DOT Regulations: Pumps may fall under hazardous materials (hazmat) regulations if shipped with fuel residue or in proximity to flammable liquids.

Determine whether the pump is shipped empty, clean, and free of fuel residue. If so, it may be reclassified as non-hazardous. Always consult the Safety Data Sheet (SDS) and manufacturer specifications.

Packaging Requirements

Proper packaging is essential to prevent leaks, electrical damage, and transportation hazards:

– Clean and Dry: Ensure pumps are thoroughly cleaned and dried before packaging to remove any fuel residue.

– Protective Enclosure: Use rigid, crush-resistant boxes with adequate cushioning (e.g., foam inserts or bubble wrap) to protect electrical components.

– Moisture Barrier: Include moisture-resistant liners if shipping in high-humidity environments or by sea.

– Labeling: Clearly mark packages as “Electric Fuel Pump – Clean and Empty” to assist customs and carriers in classification.

Avoid packaging pumps with fuel containers unless specifically designed and approved for combined shipment.

Transportation & Shipping Compliance

Shipping gas can electric pumps requires adherence to international and national regulations:

Ground Transport (e.g., DOT in the U.S.)

- If free of fuel and classified as non-hazardous: Standard freight protocols apply.

- If classified as hazardous (e.g., due to residual fuel): Must comply with 49 CFR hazmat rules, including proper packaging, labeling, shipping papers, and carrier notification.

Air Freight (IATA Regulations)

- Most electric pumps without fuel residue are permitted as non-dangerous goods.

- Must pass IATA Section II lithium battery rules if battery-powered (common for portable models).

- Prohibited if contaminated with flammable liquids or shipped alongside fuel.

Ocean Freight (IMDG Code)

- Declare accurately on the bill of lading.

- If classified as hazardous, use proper UN number, hazard class (typically Class 3 Flammable Liquids or Class 9 Miscellaneous), and marine pollutant markings if applicable.

Always verify classification with a certified dangerous goods safety advisor (DGSA) when in doubt.

Import/Export Regulations

Cross-border shipments require compliance with destination country regulations:

– Customs Documentation: Include commercial invoice, packing list, and bill of lading. Clearly describe the product as “Electric Fuel Transfer Pump – Non-Hazardous, Clean and Empty.”

– Product Standards: Verify compliance with local electrical safety standards (e.g., CE in Europe, UL in the U.S., CCC in China).

– Prohibited Items: Some countries restrict or ban fuel transfer equipment due to theft or safety concerns. Research import policies in target markets.

Storage & Handling Procedures

Safe warehousing is critical to prevent accidents:

– Storage Environment: Keep in dry, well-ventilated areas away from heat sources, open flames, or oxidizers.

– Segregation: Store separately from flammable liquids and reactive chemicals.

– Electrostatic Precautions: Ground storage racks if pumps are stored in bulk to prevent static discharge.

– Inventory Control: Rotate stock (FIFO) and inspect for damaged packaging or corrosion.

Compliance with Safety Standards

Ensure products meet relevant safety certifications:

– Electrical Safety: UL 174, CSA C22.2 No. 68 (North America), IEC 60335 (International).

– Electromagnetic Compatibility (EMC): FCC Part 15 (U.S.), CE-EMC Directive (EU).

– RoHS and REACH: Comply with restrictions on hazardous substances in electronics (EU).

Retailers and distributors should verify certification marks on product labels and packaging.

Labeling and Documentation

Accurate labeling prevents misclassification and ensures safe handling:

– Product Label: Include voltage, model number, manufacturer, certifications (e.g., UL, CE), and warnings (e.g., “For Use with Gasoline Only – Keep Away from Open Flame”).

– Shipping Label: Indicate proper classification, handling instructions, and contact information.

– SDS Availability: Provide Safety Data Sheet upon request, especially if residue is possible.

Training and Personnel Safety

Train warehouse, logistics, and customer service staff on:

– Hazards associated with fuel-handling equipment.

– Proper handling, storage, and emergency response (e.g., fuel spill or electrical fire).

– Recognition of hazardous vs. non-hazardous shipments.

Environmental and Disposal Compliance

At end-of-life, electric pumps must be disposed of responsibly:

– Waste Electrical Equipment: Follow WEEE (EU) or state e-waste regulations (U.S.).

– Battery Disposal: Remove and recycle lithium or alkaline batteries separately per local laws.

– Contaminated Units: Treat fuel-contaminated pumps as hazardous waste.

Conclusion

Gas can electric pumps require careful logistics planning and strict compliance due to their association with flammable materials and electrical components. By ensuring proper classification, packaging, documentation, and adherence to international regulations, businesses can safely and legally distribute these products worldwide. Always consult regulatory authorities or compliance experts when shipping in unfamiliar jurisdictions.

Conclusion:

Sourcing a gas can electric pump offers a convenient, efficient, and safer alternative to traditional manual fuel transfer methods. These pumps are designed for ease of use, enabling quick and spill-free fuel transfer from gas cans to vehicles, machinery, or equipment. With features such as battery-powered operation, built-in safety mechanisms, and portability, electric transfer pumps enhance user experience while reducing the risk of fuel exposure and environmental contamination. When selecting a pump, considerations such as flow rate, power source (rechargeable battery vs. 12V adapter), durability, and compatibility with fuel types are essential to ensure optimal performance. Overall, investing in a quality electric gas can pump is a practical solution for both personal and professional fuel management needs, saving time, minimizing waste, and improving safety.