The global industrial equipment manufacturing market continues to expand, driven by rising demand for reliable sealing solutions in critical industries such as oil & gas, chemical processing, power generation, and pulp & paper. According to Grand View Research, the global mechanical seals market size was valued at USD 4.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by stringent environmental regulations, increased maintenance spending, and the need for energy-efficient and leak-free systems. Garlock, a trusted name in fluid sealing and pipeline integrity, relies on a network of specialized equipment manufacturers to support its product ecosystem. As industrial operators prioritize uptime and safety, the role of high-performing Garlock-compatible equipment becomes increasingly vital. Based on production scale, innovation, and market presence, the following four manufacturers stand out as leading suppliers of equipment designed to integrate seamlessly with Garlock sealing technologies.

Top 4 Garlock Equipment Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Garlock

Domain Est. 1995

Website: garlock.com

Key Highlights: Garlock’s efficient solutions ensure safety, product quality, minimal maintenance, reduced downtime, and adherence to environmental regulations….

#2 Garlock Safety Systems: OSHA

Domain Est. 2012

Website: garlocksafety.com

Key Highlights: More than 35 years in fall protection. Explore our OSHA-compliant solutions, including rail guard, mobile carts, ladder safety, dock gates, and more….

#3 Garlock Equipment

Domain Est. 2021

#4 Garlock Stores

Domain Est. 2021

Website: garlockstores.com

Key Highlights: Garlock Stores – We are a distributor of commercial roofing equipment and supplies with three locations in major metropolitan areas, we service 7 states ……

Expert Sourcing Insights for Garlock Equipment

H2: Market Trends Shaping Garlock Equipment’s Outlook for 2026

As the industrial and manufacturing sectors evolve heading into 2026, Garlock Equipment is positioned at the intersection of several key market dynamics. Driven by advancements in materials science, digital transformation, sustainability mandates, and shifting global supply chains, the following trends are expected to significantly influence Garlock Equipment’s market position and strategic direction.

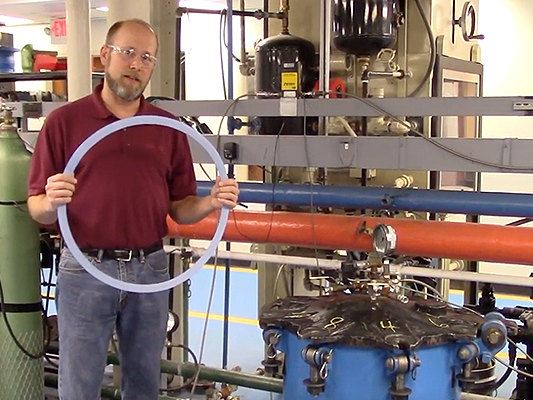

1. Rising Demand for High-Performance Sealing Solutions

Industries such as oil & gas, chemical processing, power generation, and pharmaceuticals are increasingly demanding sealing solutions that can withstand extreme temperatures, pressures, and corrosive environments. Garlock’s expertise in durable, engineered sealing products—such as gaskets, expansion joints, and hydraulic seals—places it in a strong position to benefit from this trend. The growing emphasis on operational uptime and safety compliance will further drive adoption of premium sealing technologies.

2. Digitalization and Predictive Maintenance

The integration of smart sensors and Industrial Internet of Things (IIoT) into industrial equipment is gaining momentum. By 2026, predictive maintenance solutions will be standard in process industries. Garlock can leverage this trend by developing smart sealing systems that provide real-time performance data, enabling early detection of leaks or wear. Partnering with digital platform providers or embedding IoT capabilities into products could differentiate Garlock’s offerings and enhance customer value.

3. Sustainability and Emissions Reduction

With global pressure to reduce fugitive emissions and achieve net-zero goals, regulatory standards such as the U.S. EPA’s methane rules and EU Industrial Emissions Directive are tightening. Garlock’s low-emission (Low-E) sealing technologies, like its AEGIS® radially reinforced gaskets, align well with this trend. As companies seek to minimize environmental impact and avoid regulatory penalties, demand for environmentally compliant sealing solutions is expected to rise, supporting Garlock’s innovation in sustainable materials and leak-free performance.

4. Supply Chain Resilience and Nearshoring

Ongoing geopolitical tensions and supply chain disruptions have prompted industrial firms to reevaluate sourcing strategies. The shift toward nearshoring and regional manufacturing in North America and Europe benefits companies with strong domestic production capabilities. Garlock’s U.S.-based manufacturing and commitment to local supply chain resilience enhance its appeal to customers seeking reliable, timely delivery and reduced logistics risk.

5. Growth in Renewable Energy and Emerging Industries

The expansion of renewable energy—including hydrogen production, carbon capture, and geothermal systems—introduces new applications for advanced sealing technology. These sectors often operate under extreme conditions, creating opportunities for Garlock to extend its product portfolio into high-growth markets. Additionally, increased investment in infrastructure and clean technology under global green initiatives could open new distribution channels and partnerships.

6. Consolidation and Competitive Dynamics

The industrial sealing market continues to consolidate, with larger players acquiring niche innovators to broaden capabilities. Garlock, as part of EnPro Industries, benefits from corporate backing and R&D resources, enabling it to compete effectively against rivals like EagleBurgmann and Trelleborg. Maintaining a focus on innovation, customer service, and application engineering will be critical to preserving market share.

Conclusion

By 2026, Garlock Equipment is well-positioned to capitalize on converging trends in performance, sustainability, and digital integration. Success will depend on its ability to innovate proactively, expand into emerging markets, and deliver integrated sealing solutions that meet the evolving needs of industrial customers worldwide. Strategic investments in smart technologies and sustainable product development will be key differentiators in a competitive and rapidly transforming marketplace.

Common Pitfalls Sourcing Garlock Equipment (Quality, IP)

Sourcing Garlock equipment—particularly seals, gaskets, expansion joints, and related industrial components—requires careful due diligence to avoid significant risks related to quality and intellectual property (IP). Garlock, a well-known brand under Enpro Industries, is recognized for high-performance engineered products used in demanding environments. However, common pitfalls can compromise safety, performance, and legal compliance.

Counterfeit or Substandard Products

One of the most prevalent risks when sourcing Garlock equipment is encountering counterfeit or imitation products. These items are often manufactured by third parties attempting to replicate Garlock’s design and branding but fail to meet the original specifications, materials, or performance standards.

- Material Misrepresentation: Counterfeit products may use inferior elastomers, metals, or fillers, leading to premature failure under pressure, temperature, or chemical exposure.

- Performance Risks: Substandard seals or gaskets can result in leaks, equipment downtime, or hazardous failures—especially in critical applications like chemical processing or power generation.

- Lack of Certification: Genuine Garlock products typically come with certifications (e.g., FDA, ISO, ASME). Counterfeits often lack proper documentation or provide falsified test reports.

To mitigate this, always purchase from authorized distributors or directly from Garlock/Enpro. Verify distributor credentials on the official Garlock website.

Unauthorized Resale and Gray Market Goods

Gray market equipment refers to genuine Garlock products sourced through unofficial or unauthorized channels—often imported from international markets without the manufacturer’s endorsement.

- Warranty Voidance: Garlock typically does not honor warranties on gray market products, leaving buyers without recourse in case of failure.

- Unknown Storage Conditions: Improper storage (e.g., exposure to extreme temperatures or humidity) during transit or warehousing can degrade product integrity, even if originally genuine.

- Traceability Issues: Gray market goods often lack full traceability, making it difficult to confirm manufacturing date, batch number, or compliance with current industry standards.

Ensure your supplier is an authorized Garlock distributor and request full documentation to verify the product’s chain of custody.

Intellectual Property Infringement

Sourcing non-Garlock products that mimic patented designs or use Garlock’s trademarks without authorization exposes buyers and suppliers to IP infringement risks.

- Patent Violations: Garlock holds numerous patents on seal geometries, materials, and installation methods. Using or supplying copies may lead to legal action.

- Trademark Misuse: Products labeled with Garlock names, logos, or model numbers without authorization constitute trademark infringement, even if marketed as “compatible” or “replacement.”

- Liability Exposure: Companies using infringing equipment may face cease-and-desist orders, fines, or liability for contributory infringement.

Always verify that replacement or “equivalent” products do not copy proprietary designs. When in doubt, consult legal counsel or contact Garlock directly for clarification.

Inadequate Technical Support and Documentation

Genuine Garlock equipment is backed by extensive engineering support, installation guidance, and material data sheets. Sourcing through unofficial channels often results in missing or inaccurate technical documentation.

- Improper Installation: Without correct installation instructions, even genuine parts can fail prematurely.

- Material Compatibility Uncertainty: Lack of accurate chemical resistance data increases the risk of seal degradation in aggressive environments.

- Regulatory Non-Compliance: Industries like pharmaceuticals or oil and gas require auditable documentation. Missing or falsified documents can lead to compliance failures during audits.

Ensure all products come with complete, authentic technical documentation and access to manufacturer support.

Conclusion

To avoid quality and IP pitfalls when sourcing Garlock equipment, prioritize authorized distribution channels, verify product authenticity, and maintain thorough documentation. Investing time in due diligence protects operational reliability, legal standing, and long-term cost-efficiency.

Logistics & Compliance Guide for Garlock Equipment

This guide outlines the essential logistics and compliance protocols for handling, transporting, and managing Garlock equipment to ensure safety, regulatory adherence, and operational efficiency.

Equipment Handling and Storage

All Garlock equipment must be handled with care to prevent damage and maintain performance integrity. Store equipment in a clean, dry, and temperature-controlled environment, away from direct sunlight and corrosive substances. Use original packaging or protective covers when available. Follow manufacturer-recommended stacking heights and handling procedures to avoid deformation or mechanical stress.

Transportation Requirements

When shipping Garlock equipment, use secure packaging and appropriate cushioning materials to prevent movement during transit. Choose carriers with experience in handling industrial machinery and confirm they comply with DOT (Department of Transportation) and IATA (if applicable) regulations. Clearly label shipments with handling instructions (e.g., “Fragile,” “This Side Up”) and include all necessary documentation, including packing lists and bills of lading.

Regulatory Compliance

Ensure all equipment meets relevant industry standards and certifications, including but not limited to ANSI, ASME, and ISO specifications. Verify compliance with local, state, and federal regulations, such as OSHA standards for workplace safety and EPA guidelines for environmental impact. International shipments must adhere to customs requirements, including proper HS codes, export licenses (if required), and adherence to ITAR or EAR regulations where applicable.

Documentation and Recordkeeping

Maintain accurate records for all logistics and compliance activities. This includes equipment serial numbers, shipping manifests, inspection reports, compliance certificates, and maintenance logs. Retain documentation for a minimum of seven years or as required by regulatory authorities. Digital records should be securely backed up and accessible to authorized personnel.

Import/Export Controls

For cross-border shipments, ensure compliance with U.S. Customs and Border Protection (CBP) and foreign regulatory bodies. Complete all required forms (e.g., Commercial Invoice, Certificate of Origin, Shipper’s Export Declaration). Classify equipment accurately under the Export Administration Regulations (EAR) and confirm no restrictions apply based on destination country, end-user, or end-use.

Quality Assurance and Inspections

Conduct pre-shipment inspections to verify equipment condition, functionality, and conformity to specifications. Perform regular audits of logistics partners and internal processes to ensure ongoing compliance. Document all inspections and corrective actions taken. Report any non-conformances immediately to the Quality Assurance department.

Environmental and Safety Considerations

Dispose of packaging materials and non-functional equipment in accordance with environmental regulations. Recycle where possible and follow proper e-waste procedures for electronic components. Train personnel on safe handling practices and emergency response procedures for hazardous materials, if applicable.

Training and Accountability

All personnel involved in logistics and equipment management must complete training on handling procedures, regulatory requirements, and company policies. Assign clear roles and responsibilities for compliance oversight. Conduct periodic refresher training and maintain training records.

Adherence to this guide ensures the safe, legal, and efficient movement and management of Garlock equipment across all operational phases.

Conclusion for Sourcing Garlock Equipment:

Sourcing Garlock equipment offers a reliable solution for organizations requiring high-performance sealing, fluid handling, and pipeline integrity products across demanding industrial environments. Garlock’s reputation for engineering excellence, stringent quality standards, and commitment to innovation makes it a trusted partner in mission-critical applications within sectors such as oil and gas, chemical processing, power generation, and pulp and paper.

By choosing Garlock equipment, companies benefit from durable, long-lasting products designed to enhance safety, reduce maintenance costs, and improve operational efficiency. Additionally, Garlock’s global supply network, technical support, and compliance with international standards ensure seamless integration and regulatory compliance.

In conclusion, sourcing equipment from Garlock represents a strategic investment in quality, reliability, and performance. It supports long-term operational success while minimizing downtime and mitigating risks associated with equipment failure. Proper supplier vetting, adherence to procurement best practices, and engagement with authorized distributors are recommended to ensure authenticity and optimal service throughout the equipment lifecycle.