The global waste management and recycling industry is undergoing rapid transformation, driven by increasing urbanization, stringent environmental regulations, and growing corporate sustainability targets. Within this landscape, garbage balers have emerged as critical equipment for efficient waste compaction, enabling businesses to reduce disposal costs, streamline logistics, and improve recycling rates. According to a 2023 report by Mordor Intelligence, the global baler market was valued at USD 1.47 billion and is projected to grow at a CAGR of 5.8% from 2024 to 2029. This growth is further validated by Grand View Research, which cites rising demand from commercial, industrial, and municipal sectors—particularly in e-commerce, retail, and manufacturing—as key drivers. With innovation in hydraulic systems, automation, and space-efficient designs, the market for high-performance garbage balers is more competitive than ever. In this evolving environment, identifying leading manufacturers that combine reliability, efficiency, and technological advancement is essential for organizations aiming to optimize their waste handling operations. The following list highlights the top 10 garbage baler manufacturers shaping the future of waste compaction worldwide.

Top 10 Garbage Baler Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Commercial Trash Compactors, Balers & Recycling Equipment For …

Domain Est. 1998

Website: marathonequipment.com

Key Highlights: Marathon Equipment Company is known throughout the world as a leading manufacturer of onsite commercial/industrial trash compactors, balers, and recycling ……

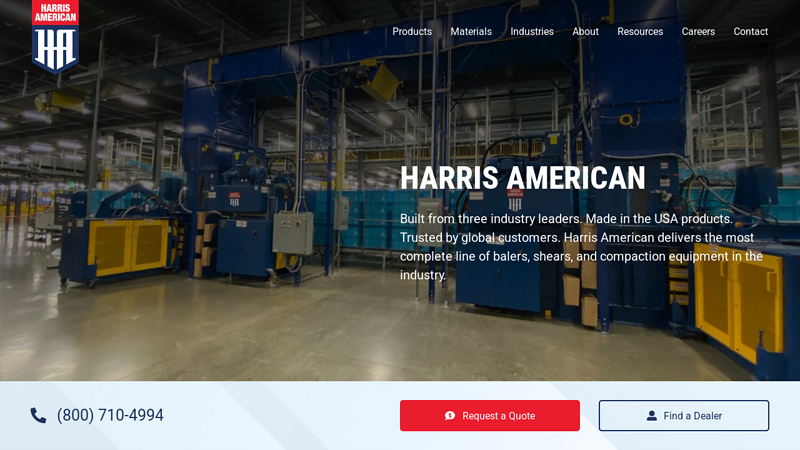

#2 Harris American Co. Balers, Shears & Compaction Equipment

Website: harrisamericanco.com

Key Highlights: Upgrade to industrial balers, shears, and compaction equipment from Harris American Co baler manufacturers. Made in America. Trusted around the globe….

#3 Bramidan

Domain Est. 1996

Website: bramidan.com

Key Highlights: Bramidan offers quality balers and compactors for reliable waste management. Compress waste such as cardboard, plastic, and other recyclable materials….

#4 PTR Baler & Compactor

Domain Est. 2004

Website: ptrco.com

Key Highlights: PTR Baler & Compactor is a leading industry manufacturer of waste and recycling equipment. Serving a variety of industries….

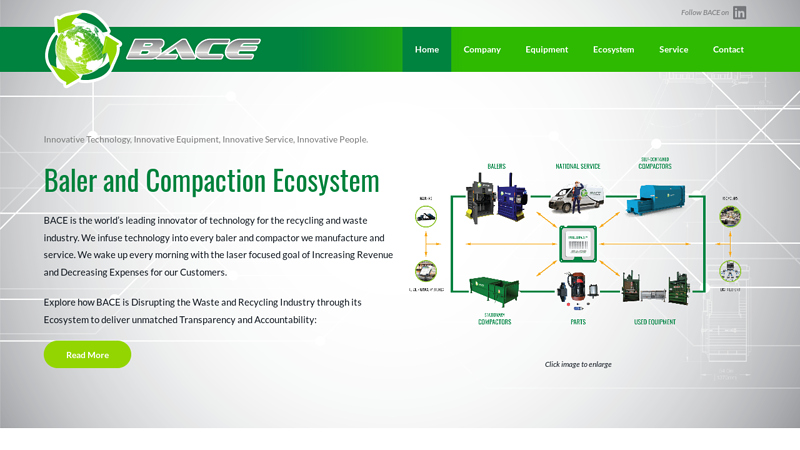

#5 BACE

Domain Est. 2006

Website: bacecorp.com

Key Highlights: The world’s leading innovator of recycling and waste industry technology. We infuse intelligence into every baler and compactor we manufacture and service….

#6 Leading Waste Baler Manufacturers

Website: balermanufacturers.com

Key Highlights: Conveniently connect with the USA’s top waste baler manufacturers. These companies offer a large assortment of waste balers that can handle cardboard and ……

#7 Cardboard balers, trash compactors and other recycling equipment …

Domain Est. 1996

Website: cram-a-lot.com

Key Highlights: Cram-A-Lot Manufactures commercial vertical balers, cardboard balers, trash compactors and horizontal balers quality engineered and designed with today’s ……

#8 Orwak

Domain Est. 1998

Website: orwak.com

Key Highlights: Orwak is a world leader in compaction and baling solutions for solid waste materials. We make waste management more efficient and more profitable….

#9 MAX

Domain Est. 1999 | Founded: 1976

Website: maxpakbalers.com

Key Highlights: MAX-PAK Balers have been making quality balers & compactors for the waste industry since 1976. Our balers are built to perform and built to last….

#10 Excel Baler

Domain Est. 2021

Website: excelbalermfg.com

Key Highlights: Discover top-quality balers and equipment at Excel Baler Manufacturing. Browse our range for efficient baler solutions….

Expert Sourcing Insights for Garbage Baler

2026 Market Trends for Garbage Balers

The garbage baler market is poised for significant transformation by 2026, driven by escalating global waste volumes, tightening environmental regulations, and advancements in automation and sustainability. Key trends shaping the landscape include heightened demand for high-efficiency and automated systems, a growing emphasis on circular economy integration, regional regulatory pushes, and technological innovation enhancing operational performance.

Increasing Demand Driven by Waste Volume and Recycling Mandates

Global municipal solid waste generation is projected to exceed 3.4 billion tons annually by 2050, according to the World Bank, creating urgent demand for efficient waste compaction solutions. By 2026, governments and municipalities are expected to enforce stricter recycling quotas and landfill diversion policies, particularly in North America, Europe, and parts of Asia-Pacific. These regulations will drive adoption of industrial and vertical garbage balers in waste management facilities, recycling centers, and large commercial operations (e.g., supermarkets, manufacturing plants) seeking to reduce disposal costs and comply with environmental standards.

Growth in Automation and Smart Baler Technologies

Automation will be a defining trend in 2026, with a surge in demand for smart garbage balers equipped with IoT sensors, real-time monitoring, and predictive maintenance capabilities. These intelligent systems enable remote diagnostics, optimize bale density, and reduce downtime, improving overall operational efficiency. Fully automated balers integrated with conveyor systems and AI-driven waste sorting lines will become more common in advanced recycling facilities, particularly in developed markets aiming to improve material recovery rates and reduce labor costs.

Expansion in Emerging Markets and E-Commerce Waste

Rapid urbanization and rising consumerism in emerging economies—especially India, Southeast Asia, and Latin America—will fuel demand for cost-effective and scalable baler solutions. Concurrently, the booming e-commerce sector continues to generate vast amounts of packaging waste (cardboard, plastics), prompting logistics hubs and distribution centers to invest in compacting equipment. By 2026, vertical and two-ram balers tailored for high-volume cardboard recycling will see increased deployment in fulfillment centers to manage waste efficiently and reclaim valuable floor space.

Sustainability and Circular Economy Integration

As circular economy principles gain traction, garbage balers will play a pivotal role in closing material loops by enabling efficient recovery and resale of recyclables. Equipment manufacturers are responding with energy-efficient models, modular designs for easier repair, and balers optimized for specific waste streams (e.g., plastics, textiles, agricultural waste). Additionally, lifecycle assessments and eco-design standards will influence procurement decisions, favoring balers with lower carbon footprints and recyclable components.

Technological Advancements and Market Consolidation

By 2026, ongoing R&D efforts will yield balers with higher compression ratios, faster cycle times, and reduced energy consumption. Hydraulic system improvements and hybrid power options may further enhance sustainability. The market is also likely to experience consolidation, as larger industrial machinery companies acquire niche baler manufacturers to expand their environmental technology portfolios, increasing competition and driving innovation.

In summary, the 2026 garbage baler market will be shaped by regulatory pressure, technological advancement, and the global shift toward sustainable waste management. Stakeholders who prioritize automation, energy efficiency, and adaptability to diverse waste streams will be best positioned to capitalize on emerging opportunities.

Common Pitfalls When Sourcing a Garbage Baler (Quality and Intellectual Property)

Sourcing a garbage baler involves more than selecting a machine based on price or appearance. Overlooking critical quality and intellectual property (IP) aspects can lead to operational inefficiencies, legal risks, and long-term financial losses. Below are key pitfalls to avoid:

Poor Build Quality and Material Selection

Many low-cost balers use substandard steel, inadequate hydraulic components, or poorly engineered frames. This results in frequent breakdowns, reduced bale density, and shorter service life. Always verify material thickness, weld quality, and component brands. Request documentation such as mill test certificates and third-party inspection reports.

Inadequate Safety Features

Some manufacturers, especially in less-regulated markets, omit essential safety mechanisms like emergency stops, light curtains, or proper guarding. Non-compliance with international safety standards (e.g., CE, OSHA) increases liability and risk of workplace injury.

Misrepresentation of Technical Specifications

Suppliers may exaggerate bale pressure, cycle time, or throughput. Always request performance data from existing installations or third-party testing. Be wary of vague or inconsistent technical documentation.

Lack of Genuine Spare Parts and After-Sales Support

Cheap balers often come from manufacturers who do not maintain spare parts inventories or technical support networks. This leads to prolonged downtime when repairs are needed. Confirm the availability of spare parts and the responsiveness of after-sales service before purchase.

Intellectual Property Infringement

A major risk when sourcing from certain regions is purchasing balers that copy patented designs or technologies. Using such equipment can expose your business to legal action, especially in markets with strong IP enforcement. Ensure the manufacturer has original designs or proper licensing for the technology used.

No Proof of Original Design or Patents

Ask for documentation such as patent filings, design registrations, or engineering drawings. Reputable manufacturers will be transparent about their IP ownership. Avoid suppliers who cannot provide proof of originality or who offer “OEM” versions that closely mimic leading brands.

Hidden Costs from Poor Quality Control

Low initial pricing often masks future expenses due to rework, maintenance, and lost productivity. Poor quality control during manufacturing—such as misaligned cylinders or faulty electrical systems—can compromise reliability. Consider a pre-shipment inspection by a third party.

Ignoring Compliance with Local and International Standards

Not all balers meet environmental, electrical, or noise regulations in your country. Verify that the equipment complies with relevant standards (e.g., CE, UL, ISO) to avoid customs delays or operational shutdowns.

By carefully evaluating both the quality and IP integrity of garbage balers during sourcing, businesses can avoid costly mistakes and ensure long-term reliability and legal compliance.

Logistics & Compliance Guide for Garbage Baler

Product Overview

A garbage baler is a waste management machine designed to compress recyclable materials—such as cardboard, plastic, paper, and film—into compact, dense bales. This improves storage efficiency, reduces transportation costs, and supports recycling compliance. Proper logistics planning and regulatory adherence are essential for safe and legal operation and transport.

Transportation & Shipping Requirements

Garbage balers are typically heavy, industrial-grade machines that require careful handling during transport.

– Packaging: Units should be secured on wooden pallets or in crates with protective corner boards and stretch wrap to prevent damage.

– Weight & Dimensions: Confirm the baler’s gross weight and dimensions (L x W x H) prior to booking freight; most industrial balers exceed standard parcel limits.

– Freight Mode: Use flatbed trucks, step-deck trailers, or containerized shipping for international orders. Lift-gate service may be required for deliveries without loading docks.

– Handling Equipment: Ensure access to forklifts or cranes at both pickup and delivery points to offload safely.

Import/Export Compliance

When shipping across borders, compliance with international trade regulations is mandatory.

– Harmonized System (HS) Code: Typically classified under HS 8474.20 (machines for sorting, grinding, or compacting waste). Confirm with local customs authorities.

– Documentation: Prepare commercial invoice, packing list, bill of lading, and certificate of origin.

– Import Duties & Taxes: Research applicable tariffs in the destination country; some regions offer reduced rates for recycling equipment.

– Export Controls: Verify if the baler contains components subject to export restrictions (e.g., specific motors or control systems).

Installation & Site Logistics

Proper site preparation ensures efficient and safe operation.

– Space Requirements: Allow sufficient clearance around the baler for maintenance, bale removal, and material feeding (typically 3–5 feet on all sides).

– Floor Load Capacity: Confirm the floor can support the baler’s operating weight (including bale weight), often exceeding 10,000 lbs.

– Utility Connections: Ensure access to appropriate power supply (e.g., 208V/240V/480V, 3-phase), and, if applicable, hydraulic or pneumatic lines.

– Ventilation & Drainage: Provide adequate airflow for hydraulic systems and consider drainage for wash-down areas if used in food or wet waste environments.

Safety & Regulatory Compliance

Adherence to safety standards protects personnel and ensures legal operation.

– OSHA Standards (U.S.): Comply with machinery guarding (29 CFR 1910.212), lockout/tagout (29 CFR 1910.147), and workplace safety protocols.

– Electrical Codes: Install in accordance with the National Electrical Code (NEC) or local equivalents.

– CE Marking (EU): Machines sold in the European Union must meet Machinery Directive 2006/42/EC, including risk assessments and technical documentation.

– Operator Training: Provide certified training on safe operation, emergency stops, and maintenance procedures.

Environmental & Waste Handling Regulations

Garbage balers play a role in sustainable waste management but must comply with local environmental laws.

– Waste Storage: Baled materials must be stored in designated, labeled areas to prevent fire hazards and environmental contamination.

– Recycling Reporting: In some jurisdictions, facilities must report volumes of recyclable materials processed; retain bale count records.

– Hazardous Materials: Do not bale hazardous waste (e.g., chemicals, medical waste) unless the baler is specifically designed and permitted for such use.

Maintenance & Documentation

Regular maintenance ensures compliance and operational longevity.

– Scheduled Inspections: Follow the manufacturer’s maintenance schedule for hydraulic systems, belts, and safety controls.

– Recordkeeping: Maintain logs of repairs, safety checks, and operator training to demonstrate compliance during audits.

– Spare Parts Logistics: Keep critical spare parts (e.g., shear blades, seals) on-site or ensure rapid delivery to minimize downtime.

End-of-Life & Decommissioning

Proper disposal or recycling of old balers is governed by environmental regulations.

– Equipment Dismantling: Use certified e-waste or industrial recyclers to dispose of motors, hydraulic fluids, and electronic components.

– Documentation: Retain disposal certificates for compliance audits and environmental reporting.

By following this logistics and compliance guide, organizations can ensure the safe, legal, and efficient deployment of garbage balers within their waste management operations.

Conclusion:

Sourcing a garbage baler is a strategic investment that can significantly enhance waste management efficiency, reduce operational costs, and support sustainability goals. After evaluating various options, considering factors such as capacity, automation level, durability, maintenance requirements, and supplier reputation, the selected garbage baler aligns well with our operational needs and long-term environmental objectives. It offers optimal compaction performance, reliable construction, and integration capabilities within our existing waste handling system. By choosing a reputable supplier with strong after-sales support, we ensure minimal downtime and long-term cost savings. Ultimately, the acquisition of this garbage baler not only improves site cleanliness and safety but also contributes to our commitment to waste reduction and resource recovery, reinforcing our corporate responsibility and operational excellence.