The global waste oil heater market is experiencing steady growth, driven by increasing demand for energy-efficient and sustainable heating solutions in automotive, industrial, and commercial facilities. According to Grand View Research, the global waste oil re-refining market was valued at USD 4.3 billion in 2022 and is projected to expand at a CAGR of 6.8% from 2023 to 2030—highlighting a rising emphasis on recycling used oils and reducing dependency on fossil fuels. Parallel trends in circular economy practices and tightening environmental regulations are further fueling adoption of garage waste oil heaters, particularly in North America and Europe. As businesses seek cost-effective heating alternatives that also support environmental compliance, manufacturers specializing in durable, high-efficiency waste oil heaters are gaining strategic market footing. This growing demand has led to increased innovation and competition, positioning the top nine garage waste oil heater manufacturers as key players in a niche yet expanding segment of the sustainable energy equipment market.

Top 9 Garage Waste Oil Heater Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rock Energy Systems

Domain Est. 2016

Website: rockenergysystems.com

Key Highlights: Lanair is the world’s largest manufacturer of factory-direct waste oil heaters. As energy costs rise, our user-friendly systems help businesses save money ……

#2 Commercial Waste Oil Heaters & Burners

Domain Est. 2013

Website: northstock.com

Key Highlights: Free delivery · 30-day returnsRepurpose used oil & warm your facility using industrial waste oil heaters. Browse 350000+ products & get free ground shipping to the lower 48 states…

#3 MorrHeat

Domain Est. 2018

Website: morrheat.com

Key Highlights: MorrHeat offers high-efficiency waste oil heaters and boilers, providing cost-effective and eco-friendly heating solutions for businesses and workshops.Missing: garage manufacture…

#4 Environmentally Friendly

Domain Est. 1996

Website: cleanburn.com

Key Highlights: Clean Burn multi-oil heating systems, storage tanks and recycling centers meet all EPA requirements for waste oil recycling….

#5 Lanair Waste Oil Heaters

Domain Est. 1998

Website: lanair.com

Key Highlights: Lanair waste oil heaters are the most dependable and durable waste oil furnaces. Burns 100% used synthetic oil, #1 and #2 diesel fuel oil and more….

#6 Waste Oil Heaters

Domain Est. 2000

Website: energylogic.com

Key Highlights: EnergyLogic waste oil heaters from 75000-350000 BTU. Heat garages and auto shops for free using used motor oil. EL75H to EL350H models….

#7 Dornback Manufacturing

Domain Est. 2004

Website: dornbackfurnace.com

Key Highlights: Dornback UNI-PAK Waste Oil Heaters available from 75,000 BTU/HR to 500,000 BTU/HR and 150,000 BTU/HR Portable Units . Burns crankcase and gear oil, ……

#8 Waste Oil Furnace Product Line

Domain Est. 2011

Website: cleanenergyheatingsystems.com

Key Highlights: CE-180 Waste Oil Furnace A waste oil furnace that creates clean, safe heat for a garage with 3 to 6 bays. This waste oil furnace heats up to 5,000 sq. ft….

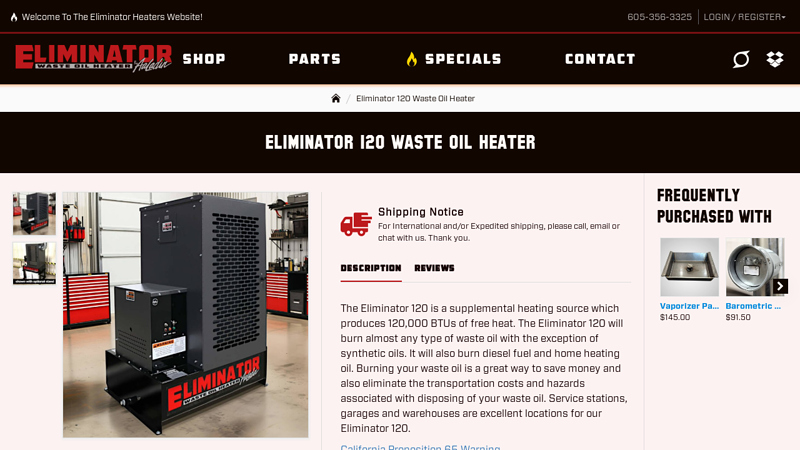

#9 Eliminator 120 Waste Oil Heater

Domain Est. 2024

Website: eliminatorheaters.com

Key Highlights: In stock Free deliveryThe Eliminator 120 is a supplemental heating source which produces 120,000 BTUs of free heat. The Eliminator 120 will burn almost any type of waste oil with ….

Expert Sourcing Insights for Garage Waste Oil Heater

H2: 2026 Market Trends for Garage Waste Oil Heaters

The market for garage waste oil heaters is poised for notable evolution by 2026, driven by increasing environmental awareness, regulatory changes, and advancements in recycling technology. These heaters, which repurpose used motor oil into a cost-effective heat source, are gaining traction among auto repair shops, fleet maintenance facilities, and industrial garages. Below are key trends expected to shape the garage waste oil heater market in 2026:

-

Rising Demand for Sustainable Heating Solutions

As businesses face growing pressure to reduce carbon footprints, waste oil heaters offer an eco-friendly alternative to fossil fuel-based heating systems. By reusing waste oil that would otherwise require costly disposal or risk environmental contamination, these heaters align with circular economy principles. By 2026, demand is expected to rise significantly among environmentally conscious small and mid-sized enterprises. -

Stricter Environmental Regulations

Governments worldwide are tightening regulations on waste oil disposal. In the U.S., EPA guidelines and state-level compliance requirements incentivize proper handling and reuse of used oil. Waste oil heaters that meet emissions standards (such as those certified by EPA or CARB) will be preferred, driving manufacturers to enhance combustion efficiency and reduce particulate emissions. -

Technological Advancements and Efficiency Improvements

The 2026 market will likely see widespread adoption of smart, high-efficiency waste oil heaters equipped with digital controls, automatic ignition, and remote monitoring via IoT integration. These features improve safety, reduce maintenance needs, and optimize fuel consumption, making the systems more user-friendly and appealing to a broader customer base. -

Cost Savings Driving Adoption

With rising energy costs, businesses are increasingly seeking cost-effective heating solutions. Waste oil heaters offer nearly free heating for facilities that generate used oil, providing rapid ROI—often within 1–3 years. This economic advantage will continue to drive adoption, especially in regions with high heating demands. -

Expansion into New Geographies

While North America currently leads the market due to established automotive infrastructure and regulatory frameworks, regions like Europe and parts of Asia-Pacific are expected to see accelerated growth by 2026. Emerging markets with growing vehicle ownership and industrial activity may adopt waste oil heating as a practical, low-cost solution. -

Increased Competition and Product Differentiation

As the market expands, manufacturers are likely to differentiate through features such as lower emissions, quieter operation, modular designs, and compatibility with mixed oil types (including antifreeze-contaminated oils, within safe limits). This competition will spur innovation and reduce prices over time. -

Integration with Facility Energy Management Systems

By 2026, integration of waste oil heaters with broader energy management platforms will become more common. This allows facility managers to monitor fuel usage, track emissions, and optimize heating schedules—enhancing operational efficiency and compliance reporting.

In conclusion, the garage waste oil heater market in 2026 will be characterized by stronger environmental drivers, technological innovation, and expanded global adoption. Businesses that invest in compliant, efficient waste oil heating systems will benefit from reduced operating costs and improved sustainability profiles.

Common Pitfalls When Sourcing a Garage Waste Oil Heater (Quality & IP)

Sourcing a garage waste oil heater can offer significant cost savings on heating, but it comes with several critical pitfalls related to quality and intellectual property (IP) that buyers must be aware of to avoid safety hazards, poor performance, and legal complications.

Poor Build Quality and Safety Risks

Many budget or unbranded waste oil heaters are constructed using substandard materials and lack essential safety features. Thin-gauge steel, inadequate insulation, and poorly designed combustion chambers can lead to premature failure, excessive emissions, or even fire hazards. Look for units with robust construction, proper certifications (e.g., UL, ETL), and built-in safety shutoffs such as flame sensors and overheat protection.

Lack of Emissions Compliance

Low-quality heaters often fail to meet environmental regulations for particulate matter, carbon monoxide, and NOx emissions. Operating a non-compliant unit can result in fines, especially in residential or commercial zones with strict air quality standards. Always verify that the heater is EPA-certified or meets local emissions requirements before purchase.

Inadequate Combustion Efficiency

Cheaply made heaters frequently suffer from incomplete combustion, leading to soot buildup, reduced heat output, and higher fuel consumption. This not only diminishes efficiency but also increases maintenance frequency and the risk of chimney fires. Seek models with advanced burner technology and proper airflow design to ensure clean, efficient burning.

Misrepresentation of Intellectual Property (IP)

A major concern in this market is the unauthorized replication of patented designs. Some manufacturers reverse-engineer high-performance heaters and sell near-identical copies without licensing the original technology. These knock-offs often lack the engineering precision of the genuine product, compromising performance and safety.

Purchasing a heater that infringes on IP not only supports unethical manufacturing practices but may also expose buyers to legal risks, especially in commercial settings. Always verify the manufacturer’s credentials, check for registered patents, and avoid deals that seem too good to be true—often a sign of counterfeit or pirated designs.

Incomplete or Missing Documentation

Reputable heaters come with detailed user manuals, installation guides, and warranty information. Counterfeit or low-quality units may lack proper documentation, making installation, maintenance, and troubleshooting difficult. Absence of clear IP markings or certification labels is another red flag.

Conclusion

To avoid these pitfalls, prioritize heaters from established manufacturers with verifiable safety certifications, transparent IP status, and strong customer support. Investing in a quality, legally compliant unit ensures long-term reliability, safety, and peace of mind.

Logistics & Compliance Guide for Garage Waste Oil Heaters

Overview

A waste oil heater is an energy-efficient solution for heating garages and workshops by repurposing used motor oil and other compatible waste oils. However, its safe and legal operation requires strict adherence to environmental regulations, proper handling procedures, and routine maintenance. This guide outlines the key logistics and compliance considerations for operating a waste oil heater in a garage setting.

Regulatory Compliance

Federal and State Environmental Regulations

- EPA Standards: Waste oil heaters must comply with U.S. Environmental Protection Agency (EPA) regulations under the Resource Conservation and Recovery Act (RCRA).

- Clean Air Act: Emission standards apply to combustion devices. Ensure your waste oil heater is EPA-certified for air emissions (e.g., particulate matter, carbon monoxide).

- State and Local Laws: Many states have additional requirements. Check with your state environmental agency (e.g., DEP, DTSC) for permits, burner certification, and usage limitations.

Permits and Certifications

- Obtain required permits before installation and operation.

- Use only EPA-certified waste oil heaters listed under 40 CFR Part 279.

- Maintain documentation of heater certification, fuel source, and emissions testing (if applicable).

Waste Oil Collection & Storage

Acceptable Fuels

- Used motor oil (engine, transmission, hydraulic) from vehicles and machinery.

- Certain synthetic oils (verify compatibility with heater specifications).

- Prohibited fuels: Antifreeze, gasoline, solvents, halogenated oils, or any hazardous waste.

Storage Requirements

- Store waste oil in leak-proof, labeled containers (e.g., 55-gallon drums or tanks) with tight-fitting lids.

- Use secondary containment (e.g., spill pallets) capable of holding 110% of the largest container’s volume.

- Keep storage area indoors or under cover to prevent rainwater contamination.

- Label containers: “Used Oil – For Reuse in Waste Oil Heater.”

Handling and Transportation

On-Site Transfer

- Use dedicated pumps and hoses designed for waste oil.

- Avoid spills; clean up immediately with absorbents and dispose of contaminated materials properly.

- Never mix waste oil with other fluids.

Off-Site Disposal of Residuals

- Ash and filter waste from the heater may be regulated. Test ash for hazardous constituents if large volumes are generated.

- Dispose of non-recyclable residues through a licensed hazardous or non-hazardous waste handler.

Operational Best Practices

Heater Maintenance

- Clean heat exchangers, burn chambers, and exhaust systems regularly (per manufacturer’s schedule).

- Replace filters and inspect fuel lines monthly.

- Keep an operational log including fuel source, maintenance dates, and any malfunctions.

Safety Measures

- Install carbon monoxide and smoke detectors near the heater and in occupied areas.

- Ensure proper ventilation and exhaust venting to the outside.

- Maintain a fire extinguisher (Class B) nearby.

- Prohibit smoking and open flames in the heater area.

Recordkeeping and Inspections

Documentation

- Keep records for at least 3 years:

- Waste oil source (e.g., vehicles serviced, dates)

- Volume collected and burned

- Maintenance logs

- Proof of heater certification

- Disposal manifests (for ash or waste)

Inspections

- Conduct monthly visual inspections for leaks, corrosion, or blockages.

- Schedule annual professional inspection of burner performance and emissions.

Conclusion

Operating a garage waste oil heater offers cost and environmental benefits but demands rigorous compliance with environmental and safety regulations. By following this guide—ensuring proper fuel handling, regulatory adherence, and maintenance—you can operate your heater safely, legally, and efficiently. Always consult local authorities for jurisdiction-specific rules before installation or use.

Conclusion:

Sourcing a garage waste oil heater presents a cost-effective, environmentally responsible, and energy-efficient solution for heating workshops, garages, and similar spaces. By repurposing used motor oil—often considered a hazardous waste—these heaters not only reduce disposal costs and environmental contamination but also turn a waste product into a valuable energy source.

When sourcing such a heater, it’s crucial to consider factors like heater capacity, build quality, safety features, compliance with environmental regulations (such as EPA certification), and ease of maintenance. Additionally, ensuring a reliable supply of waste oil and access to proper filtration systems can maximize performance and longevity.

Overall, a waste oil heater is a smart investment for businesses and individuals seeking sustainable heating solutions while reducing operational costs and environmental impact. With proper sourcing and maintenance, it offers long-term benefits both economically and ecologically.