The global paint booth market is experiencing robust growth, driven by increasing demand from automotive repair, manufacturing, and industrial finishing sectors. According to a 2023 report by Mordor Intelligence, the paint booth market was valued at USD 3.8 billion in 2022 and is projected to grow at a CAGR of over 5.2% through 2028, fueled by rising vehicle production and stringent environmental regulations promoting energy-efficient and low-emission painting systems. Similarly, Grand View Research highlights the expansion of the automotive aftermarket and advancements in spray booth technology—such as improved airflow systems and integration with IoT for performance monitoring—as key drivers of market evolution. As demand for precision, safety, and sustainability intensifies, manufacturers are innovating to deliver high-performance solutions tailored to both commercial and industrial applications. In this competitive landscape, nine garage paint booth manufacturers have emerged as leaders, combining engineering excellence, regulatory compliance, and customer-centric design to set new industry benchmarks.

Top 9 Garage Paint Booth Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Graco Inc.

Domain Est. 1994

Website: graco.com

Key Highlights: Graco is one of the world’s leading suppliers of fluid management products and packages. We manufacture equipment to move, measure, mix, control, ……

#2 Paint Booths

Domain Est. 1997

Website: toolsusa.com

Key Highlights: 30-day returnsPaint booths available from a leading manufacturer and distributor of auto body shop equipment, collision repair tools and supplies….

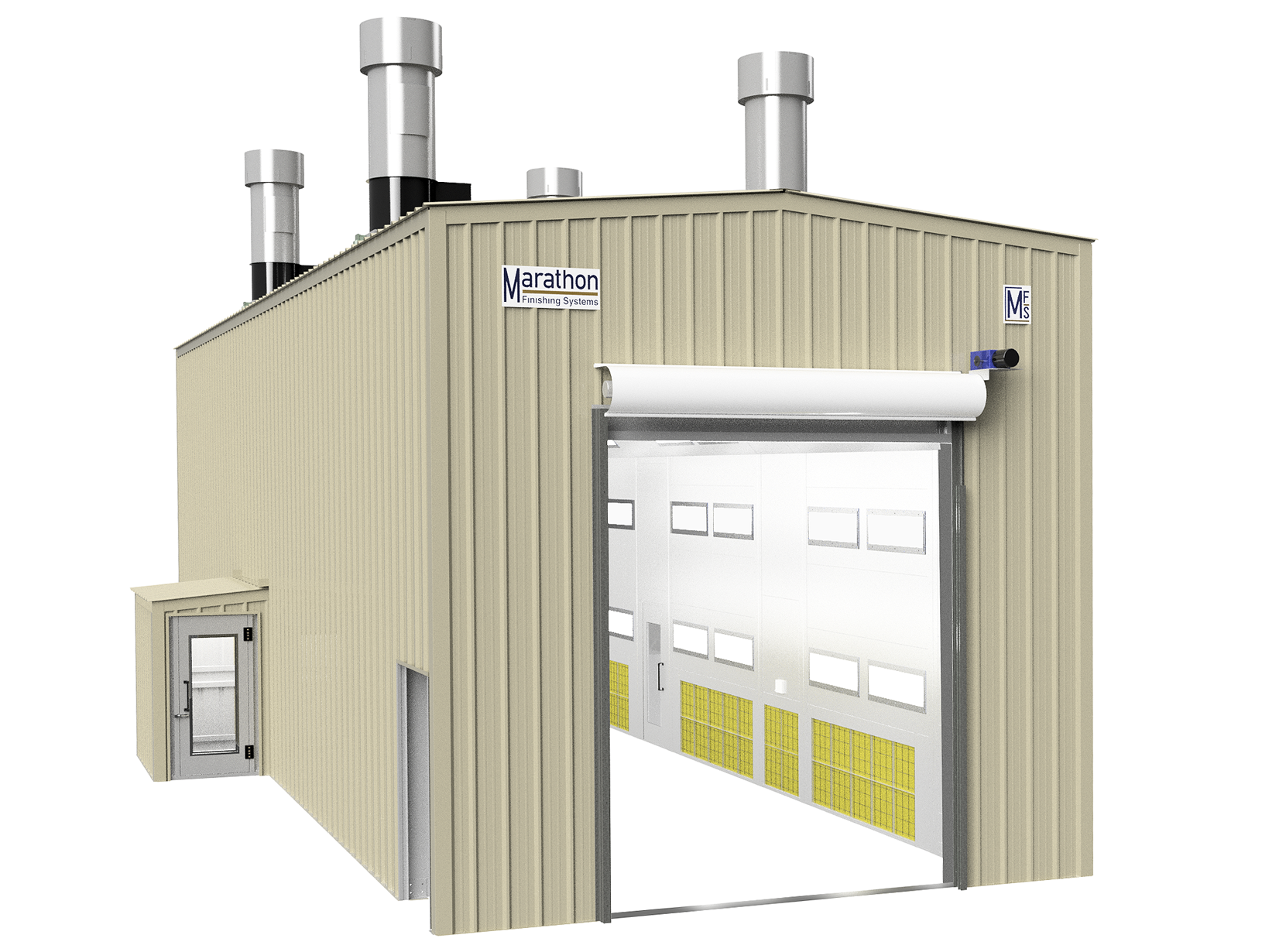

#3 Paint Booth, Industrial Spray Booths Installation

Domain Est. 2000

Website: paintbooth.com

Key Highlights: High-quality paint booth for auto, booths for truck & industrial finishing or powder coating – System Design sales service & installation….

#4 Paint Booths & Industrial Spray Application Systems

Domain Est. 2002

#5 Automotive Paint Booths

Domain Est. 2003

Website: globalfinishing.com

Key Highlights: GFS manufactures an extensive line of high-performance paint booths, prep environments, mix rooms and curing technology for automotive body shops and collision ……

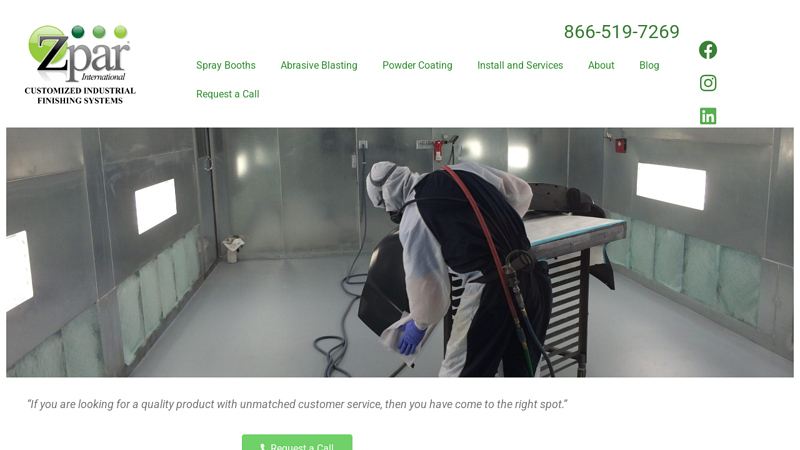

#6 Paintbooth

Domain Est. 2011

Website: zparint.com

Key Highlights: Zpar International specializes in paint booths, spray booths, abrasive blast booths, powder booths, dust collection, batch powder ovens, and more….

#7 Industries

Domain Est. 2014

Website: garmatspraybooths.com

Key Highlights: Custom-engineered spray booths for automotive, truck, marine, aviation, and industrial applications — built in the USA to meet your industry’s unique needs….

#8 Mobile Environmental Solutions

Domain Est. 2013

Website: mobileenvironmentalsolutions.com

Key Highlights: Mobile Environmental Solutions is the leading provider of Mobile Paint booths manufactured in the US. Our design is now patented across the World….

#9 Automotive Paint Booths, Spray Booths, Prep Stations

Domain Est. 2015

Website: novavertapaintbooths.com

Key Highlights: Great Paint Booths Begin with Nova Verta! With over thirty years of experience, we’ve pioneered solutions to create the highest quality paint booths available….

Expert Sourcing Insights for Garage Paint Booth

2026 Market Trends for Garage Paint Booths

As we approach 2026, the garage paint booth industry is undergoing significant transformation driven by technological innovation, environmental regulations, and shifting consumer behavior. This analysis explores key market trends shaping the future of garage paint booths—compact, efficient spray systems designed for small-scale automotive refinishing in residential or commercial garages.

Rising Demand for DIY and At-Home Auto Refinishing

A growing number of automotive enthusiasts and small business owners are investing in garage paint booths to perform high-quality paint jobs independently. The do-it-yourself (DIY) culture, supported by online tutorials and social media platforms, has increased demand for affordable, user-friendly paint booth systems. In 2026, this trend is expected to accelerate, especially among hobbyists, custom car builders, and independent detailers seeking professional results without the overhead of commercial facilities.

Advancements in Portable and Modular Paint Booths

Portable and modular paint booth designs are gaining popularity due to their flexibility, ease of setup, and space-saving features. Innovations in lightweight materials and collapsible frameworks allow users to install temporary booths in standard garages and dismantle them when not in use. In 2026, expect to see smarter modular systems with integrated lighting, filtration, and ventilation controls, catering to urban garages with limited square footage.

Integration of Smart Technology and Automation

Smart technology is making its way into garage paint booths, with features like remote monitoring via mobile apps, automated airflow adjustment, and real-time air quality sensors. In 2026, AI-assisted systems could recommend optimal spray settings based on paint type and ambient conditions, improving finish quality and reducing waste. These intelligent features are expected to appeal to tech-savvy users and enhance operational efficiency.

Stricter Environmental and Safety Regulations

Environmental compliance is a major driver in the design and adoption of modern paint booths. Regulatory bodies in North America and Europe are tightening VOC (volatile organic compound) emission standards, pushing manufacturers to develop booths with advanced filtration and abatement systems. In 2026, garage paint booths with closed-loop air recycling, HEPA filters, and low-VOC compliance certifications will become standard, helping users meet legal requirements and reduce environmental impact.

Growth of E-Commerce and Direct-to-Consumer Sales

Online marketplaces and direct-to-consumer (DTC) models are reshaping how garage paint booths are sold. In 2026, expect an increase in digital-first brands offering customizable kits, augmented reality (AR) product previews, and virtual installation support. This shift enables broader market access, especially for rural or underserved areas, and reduces reliance on traditional distributors.

Increased Focus on Energy Efficiency and Sustainability

Sustainability is influencing product development across industries, including garage equipment. By 2026, energy-efficient LED lighting, solar-compatible ventilation systems, and recyclable booth materials will be prominent features. Consumers are increasingly prioritizing eco-friendly options, prompting manufacturers to adopt greener production practices and promote long-term cost savings through reduced energy consumption.

Expansion of Aftermarket and Retrofit Solutions

As more garages retrofit existing spaces into professional-grade work areas, demand for retrofit paint booth kits is growing. These solutions allow users to upgrade standard garage setups with paint booth functionality without full structural changes. In 2026, the market will likely see a surge in retrofit ventilation systems, fire-resistant enclosures, and plug-and-play filtration units designed for easy integration.

Conclusion

The garage paint booth market in 2026 will be defined by innovation, accessibility, and sustainability. Driven by the DIY movement, regulatory demands, and technological advancements, manufacturers and consumers alike are embracing smarter, cleaner, and more compact solutions. As the line between hobbyist and professional tools continues to blur, garage paint booths will play a pivotal role in democratizing high-quality automotive refinishing.

Common Pitfalls When Sourcing a Garage Paint Booth (Quality and IP)

When sourcing a garage paint booth, overlooking key quality and intellectual property (IP) considerations can lead to costly mistakes, operational inefficiencies, and legal risks. Here are the most common pitfalls to avoid:

Inadequate Build Quality and Materials

Many low-cost paint booths use substandard materials such as thin-gauge steel, poor welds, or non-compliant filters. These compromise durability, safety, and performance. Buyers often discover too late that cheaper models require frequent repairs or fail to meet airflow and curing standards, resulting in poor paint finishes and increased downtime.

Lack of Compliance with Safety and Environmental Regulations

Some suppliers offer booths that do not meet local or international standards (e.g., NFPA, OSHA, CE, or ATEX). This can result in failed inspections, regulatory fines, or even business shutdowns. Always verify certifications and ensure the booth includes proper fire suppression, explosion relief panels, and compliant ventilation systems.

Insufficient Airflow and Filtration Design

A common quality issue is poorly engineered airflow systems. Inadequate air velocity, unbalanced pressure, or inefficient filtration (e.g., missing pre-filters or final filters) lead to dust contamination, uneven paint application, and longer curing times. Ensure the booth is designed for cross-draft, downdraft, or semi-downdraft as required, with validated airflow patterns.

Poor Supplier Transparency on IP and Design Ownership

Some manufacturers resell rebranded or copied designs without owning the original engineering IP. This can limit customization, future upgrades, or spare part availability. It may also expose buyers to legal risks if the design infringes on patented technologies. Always confirm whether the supplier holds full IP rights or licenses the design legitimately.

Hidden Costs from Incomplete IP Licensing

If the paint booth includes proprietary control systems, software, or energy-saving technologies, verify that all necessary licenses are included. Some suppliers may omit these, leading to unexpected fees for software updates, diagnostics, or integration with existing workshop systems.

Inability to Scale or Integrate Due to Proprietary Systems

Booths built on closed or proprietary platforms (especially in control systems or automation) can prevent integration with other workshop tools. Lack of open communication protocols (like Modbus or Ethernet/IP) limits future scalability and maintenance flexibility, especially if the original supplier goes out of business.

Compromised After-Sales Support Due to IP Restrictions

Suppliers without full IP control may not have access to critical design schematics or software code, leading to long wait times for repairs or replacement parts. This dependency can leave you stranded if the original designer discontinues support or changes licensing terms.

Failure to Verify Manufacturer Credentials and Track Record

Many buyers source from third-party suppliers or online marketplaces without vetting the actual manufacturer. This increases the risk of receiving counterfeit or reverse-engineered booths that lack quality control and IP legitimacy. Always request references, factory audits, and proof of design ownership.

By carefully evaluating both the build quality and intellectual property aspects of a garage paint booth, buyers can avoid performance issues, legal complications, and long-term operational disruptions. Prioritize transparency, compliance, and supplier credibility throughout the sourcing process.

Logistics & Compliance Guide for Garage Paint Booth

Site Preparation and Location Requirements

Ensure the garage paint booth is installed in a well-ventilated area away from ignition sources and high-traffic zones. Confirm adequate ceiling height and floor space to accommodate the booth, vehicle access, and clearance for spray operations. The site must allow for proper exhaust duct routing and comply with local setback regulations from property lines, windows, and air intakes. Verify electrical service capacity—most booths require 208V or 240V dedicated circuits with proper grounding.

Regulatory Compliance and Permits

Obtain necessary permits from local building, fire, and environmental authorities before installation or operation. Key regulations may include:

– EPA NESHAP (National Emission Standards for Hazardous Air Pollutants): Compliance required for facilities using coatings containing HAPs; may mandate filter systems and emission controls.

– State and Local Air Quality Regulations: Rules on VOC (Volatile Organic Compound) emissions; may require air filtration, carbon adsorption, or permit registration.

– OSHA Standards: Ensure worker protection through proper ventilation, respiratory protection, fire safety, and hazard communication (e.g., SDS availability).

– NFPA 33: Standard for Spray Application Using Flammable and Combustible Materials: Mandates fire-resistant construction, explosion relief, electrical classification (Class I, Division 2), and spark-resistant tools.

Ventilation and Filtration System Standards

Install a certified airflow system that maintains a minimum face velocity of 100 feet per minute (fpm) across the booth opening. Use dual-stage filtration:

– Inlet (supply) filters: Pre-filters and mid-efficiency panels to protect internal components.

– Exhaust (outlet) filters: Final filters and optional activated carbon filters to capture overspray and VOCs before discharge.

Regularly inspect and replace filters according to manufacturer guidelines to maintain air quality and comply with emission standards.

Fire Safety and Electrical Compliance

Equip the booth with:

– Explosion-proof lighting and motors rated for Class I, Division 2 locations.

– Automatic fire suppression systems (e.g., wet chemical or dry chemical) approved by NFPA 33.

– Clearly marked emergency shutoff switches for fans and power.

– Proper grounding of all metal components to prevent static discharge.

Ensure electrical wiring follows NEC (National Electrical Code) Article 511 for spray finishing areas.

Hazardous Materials Handling and Storage

Store flammable paints, thinners, and solvents in UL-approved, self-closing metal cabinets outside the booth when not in use. Limit on-site quantities to what is necessary for daily operations. Implement proper labeling, secondary containment, and spill response kits. Follow OSHA’s Hazard Communication Standard (HCS) with accessible Safety Data Sheets (SDS) and employee training.

Waste Management and Environmental Compliance

Dispose of paint-contaminated filters, rags, and overspray residue as hazardous waste per EPA and state regulations. Use only lint-free, non-synthetic rags, and store in closed, labeled metal containers. Partner with a licensed hazardous waste disposal service and maintain manifests and records for at least three years. Recycle solvents where possible using approved on-site or off-site methods.

Operator Training and Documentation

Train all personnel on:

– Safe spray application techniques and PPE use (respirators, suits, gloves).

– Emergency procedures for fires, spills, and medical incidents.

– Booth operation, maintenance schedules, and regulatory obligations.

Maintain training records, inspection logs, filter change history, and permit documentation for audits.

Routine Maintenance and Inspection

Perform weekly checks of filters, airflow, lighting, and exhaust systems. Conduct monthly inspections of fire suppression systems, electrical components, and structural integrity. Annually validate compliance with NFPA 33 and local fire codes through third-party or internal audits. Keep detailed logs to demonstrate due diligence during regulatory inspections.

Conclusion: Sourcing a Garage Paint Booth

Sourcing a garage paint booth requires careful consideration of several key factors, including booth type, size, ventilation, filtration, compliance with local environmental and safety regulations, and budget. Whether for automotive refinishing, custom painting, or hobby use, selecting the right paint booth ensures high-quality finishes, improved efficiency, and a safer working environment.

Through thorough research and evaluation of options—such as cross-draft, downdraft, or side-draft configurations—along with reputable suppliers and brands, you can find a solution that balances performance, durability, and cost-effectiveness. Additionally, integrating energy-efficient features and proper maintenance practices will extend the booth’s lifespan and reduce long-term operational costs.

Ultimately, investing in the right garage paint booth enhances workflow, meets regulatory standards, and supports professional-grade results—making it a critical component for any serious painting operation. Proper sourcing today lays the foundation for safety, productivity, and quality output tomorrow.