The global electrical accessories market, which includes critical components like gang box extenders, is experiencing steady growth driven by rising construction activities and increased demand for electrical remodeling in residential and commercial sectors. According to Mordor Intelligence, the global electrical enclosures market was valued at USD 8.47 billion in 2023 and is projected to grow at a CAGR of 5.8% from 2024 to 2029. Gang box extenders—used to align electrical boxes with finished wall surfaces during drywall installations—are becoming increasingly essential in modern construction due to tighter building tolerances and a focus on clean, professional finishes. As demand for reliable, code-compliant electrical installations grows, so does the need for high-quality gang box extenders. This report highlights the top four manufacturers leading innovation, scalability, and product consistency in this niche but vital segment of the electrical supply chain.

Top 4 Gang Box Extender Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

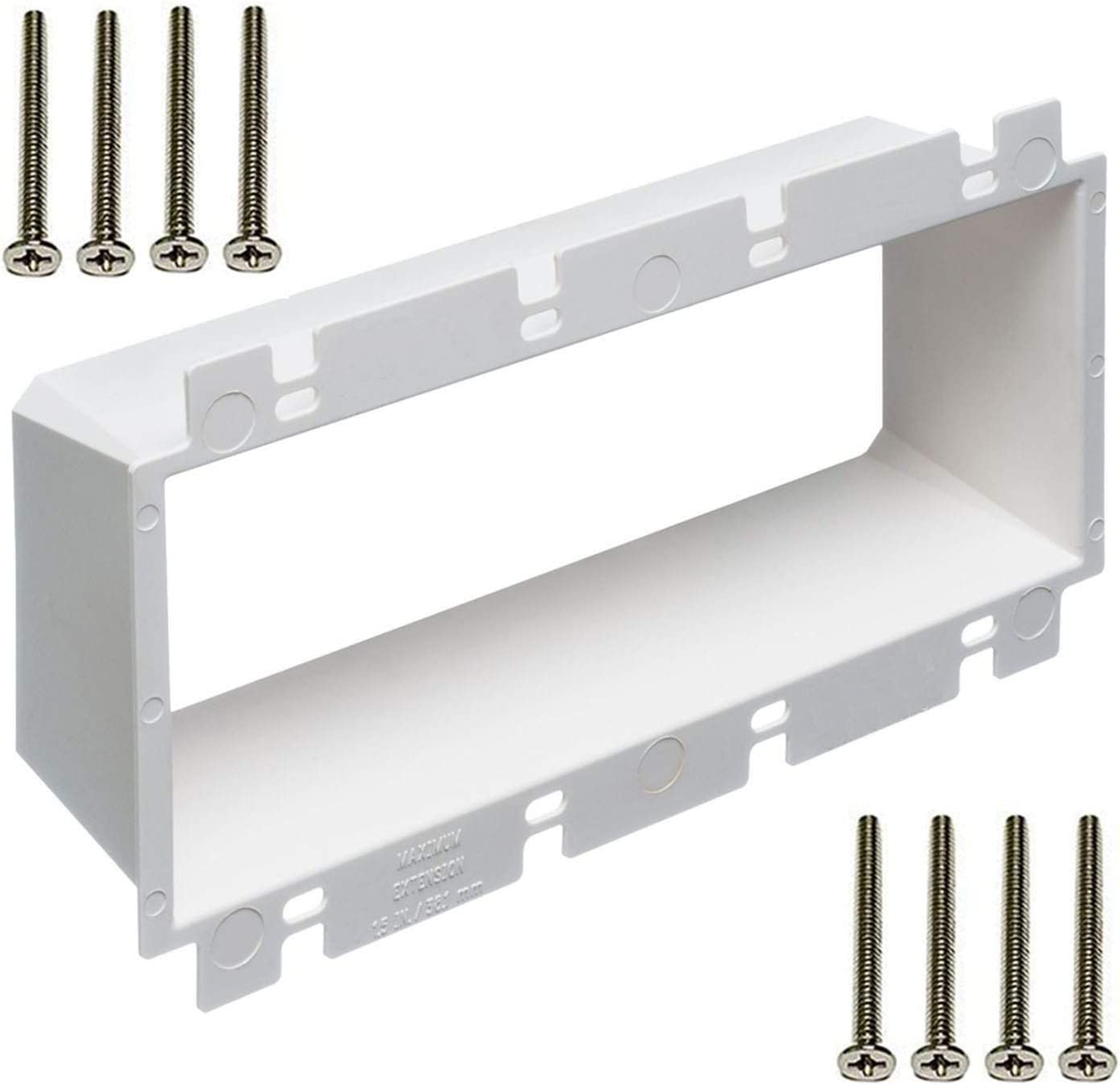

#1 Box Extenders

Domain Est. 1996

Website: hein.com

Key Highlights: ARL BE4 FOUR GANG BOX EXTENDER. Arlington Industries. Manufacturer Ref BE4. ARL BE4 FOUR GANG BOX EXTENDER. Item Code: 15280. 10 Locations: 57 In ……

#2 Steel City Metallic Boxes

Domain Est. 1990

Website: electrification.us.abb.com

Key Highlights: ABB’s Steel City® delivers dependable electrical boxes and covers made in Athens, Tennessee and designed for fast, consistent installation and long-term ……

#3 Multi

Domain Est. 1994

Website: southwire.com

Key Highlights: Make your electrical project a success with Southwire’s high-quality multi-gang boxes and covers….

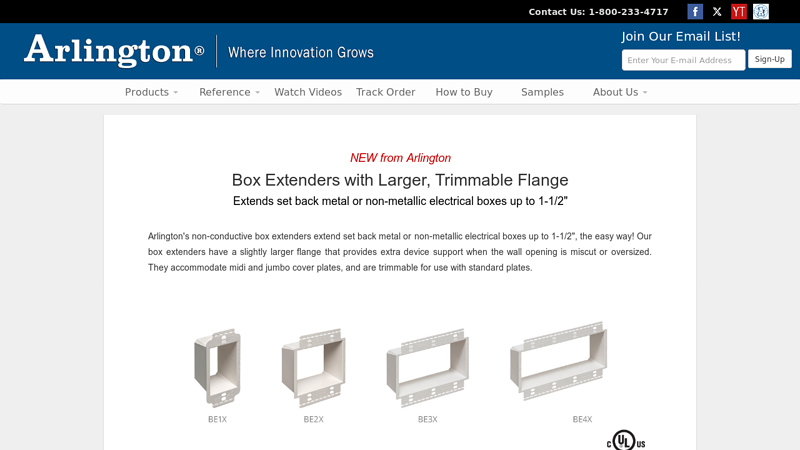

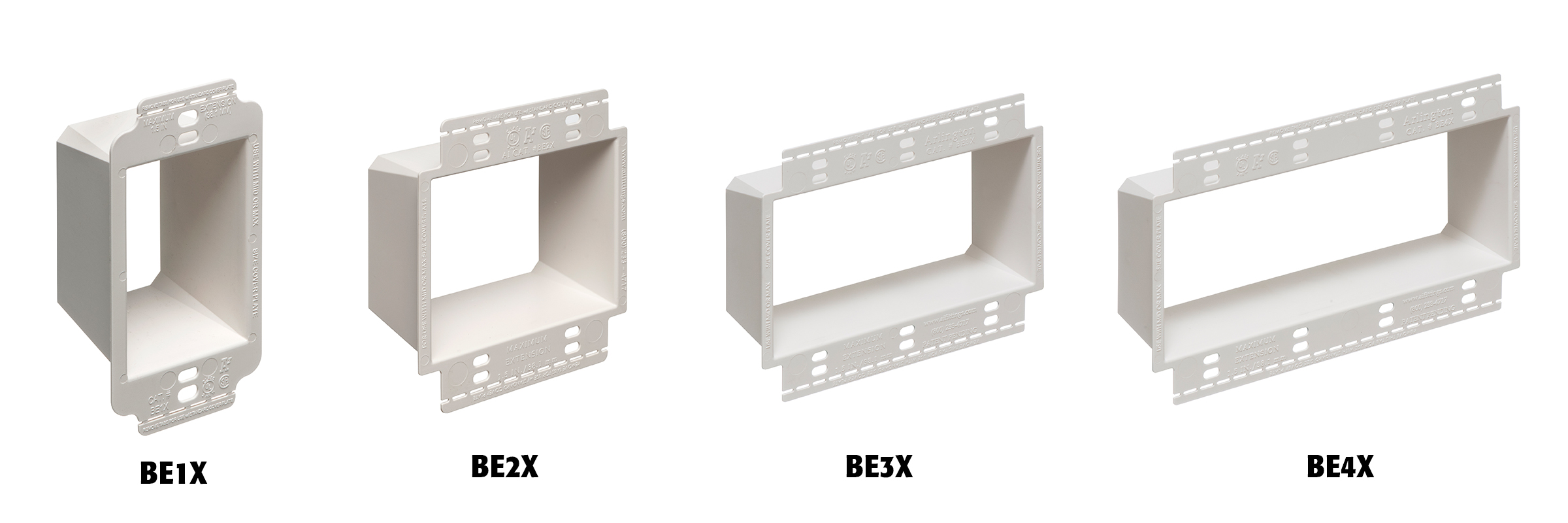

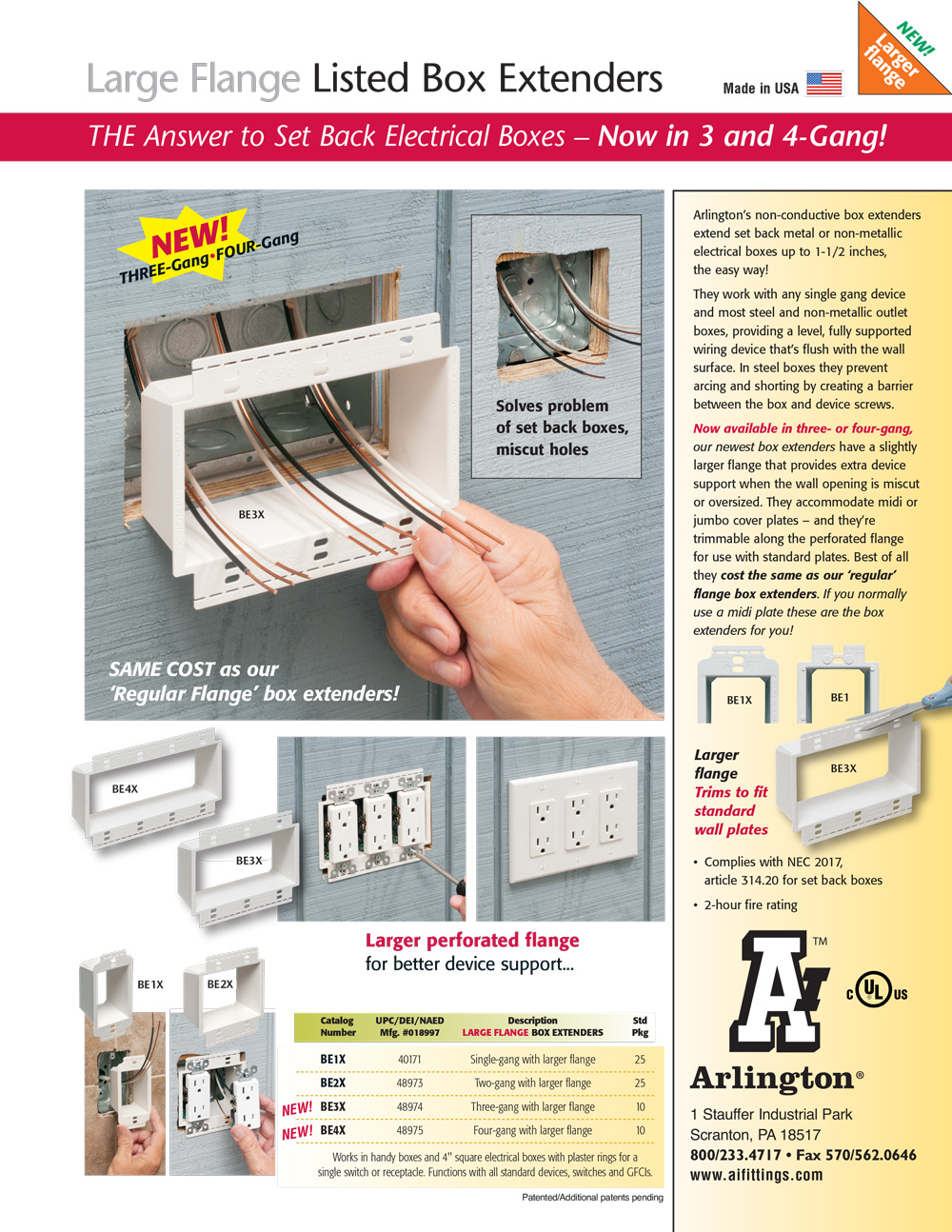

#4 Box Extenders with Larger, Trimmable Flange

Domain Est. 1998

Website: aifittings.com

Key Highlights: NEW from Arlington. Box Extenders with Larger, Trimmable Flange. Extends set back metal or non-metallic electrical boxes up to 1-1/2″….

Expert Sourcing Insights for Gang Box Extender

H2: Market Trends for Gang Box Extenders in 2026

The market for gang box extenders is poised for notable evolution in 2026, driven by advancements in construction practices, evolving electrical standards, and increasing demand for energy efficiency and smart building integration. Here’s a detailed analysis of the key trends shaping the sector:

1. Surge in Demand from Residential Renovation and Retrofit Projects

The aging housing stock in North America and parts of Europe will continue to drive demand for gang box extenders in 2026. As homeowners undertake renovation projects—especially kitchen and bathroom remodels—updating electrical systems to meet current codes (e.g., NEC requirements) becomes critical. Gang box extenders offer a cost-effective and code-compliant solution for aligning outlets and switches with new wall surfaces (e.g., drywall, tile, or insulation), minimizing the need for major wall demolition.

2. Growth in Commercial and Multi-Family Construction

The commercial and multi-family housing sectors will remain strong markets. With the proliferation of smart buildings and IoT devices, new installations often require deeper or repositioned electrical boxes. Gang box extenders facilitate seamless integration of modern devices such as smart switches, occupancy sensors, and USB outlets, ensuring flush finishes and professional aesthetics in high-end developments.

3. Emphasis on Code Compliance and Safety

Regulatory standards, particularly the National Electrical Code (NEC), will continue to influence product design and usage. In 2026, compliance with NEC 314.20 (Box Flush with Finished Surface) will be a key driver. Manufacturers are responding with UL-listed, fire-rated, and tamper-resistant extenders that ensure safe, long-term installations. Increased inspections and liability concerns will push contractors to adopt certified products, boosting demand for compliant extenders.

4. Innovation in Material and Design

Expect to see wider adoption of advanced thermoplastic and composite materials that offer superior durability, flame resistance, and ease of installation. Modular and adjustable gang box extenders—allowing variable depth adjustment—are gaining traction, reducing inventory needs and increasing adaptability on job sites. Designs that integrate with foam insulation or accommodate thicker wall assemblies (e.g., in net-zero energy homes) will be in higher demand.

5. Sustainability and Green Building Influence

As green building certifications (e.g., LEED, ENERGY STAR) gain prominence, contractors are prioritizing solutions that support energy efficiency and sustainable practices. Gang box extenders that minimize air leakage around electrical boxes contribute to improved building envelope integrity. Products made from recycled or recyclable materials may see increased market share as sustainability becomes a procurement criterion.

6. Digitalization and E-Commerce Growth

The distribution landscape is shifting, with online platforms gaining ground over traditional supply houses. By 2026, contractors and DIYers will increasingly source gang box extenders through e-commerce channels, supported by detailed product specifications, installation videos, and customer reviews. Brands with strong digital presence and B2B integration (e.g., API access for construction management software) will have a competitive edge.

7. Consolidation and Brand Differentiation

The market may see consolidation among manufacturers, with larger electrical equipment companies acquiring niche extender brands. At the same time, differentiation through innovation—such as extenders with built-in cable management, grounding continuity, or compatibility with specific smart devices—will become critical for brand positioning.

Conclusion

By 2026, the gang box extender market will be characterized by stronger demand driven by renovations, tighter regulatory standards, and smart building trends. Success will favor manufacturers and distributors who offer innovative, code-compliant, and sustainable solutions tailored to the complexity of modern electrical installations. The product will remain a small but essential component in ensuring safety, aesthetics, and functionality across residential and commercial sectors.

Common Pitfalls When Sourcing Gang Box Extenders (Quality and IP)

Sourcing gang box extenders—especially for international or large-scale projects—can present several challenges related to both product quality and intellectual property (IP). Being aware of these pitfalls helps ensure compliance, safety, and long-term reliability.

Poor Material Quality and Durability

One of the most frequent issues is receiving gang box extenders made from substandard materials. Low-quality plastics may become brittle over time, especially when exposed to temperature fluctuations or UV light. Inferior metal components can corrode or fail to provide secure connections, compromising electrical safety and code compliance.

Inaccurate Dimensions and Fit

Offshore manufacturers may not adhere strictly to NEMA or other regional standards, resulting in extenders that do not align properly with standard electrical boxes. This leads to installation difficulties, gaps that violate electrical codes, and potential hazards like loose wiring or exposed conductors.

Lack of Certification and Compliance

Many imported gang box extenders lack proper certifications such as UL, CSA, or ETL listing. Using non-certified components can void project warranties, fail inspections, and create liability risks. Always verify that products meet local electrical code requirements (e.g., NEC in the U.S.).

Counterfeit or IP-Infringing Products

Some suppliers offer knock-off versions of patented designs, especially popular branded extenders. These may mimic the appearance of original equipment but infringe on intellectual property rights. Sourcing such products exposes buyers to legal risks, including customs seizures, fines, or lawsuits from IP holders.

Inadequate Intellectual Property Due Diligence

Buyers often overlook the importance of verifying that the supplier has the right to manufacture and sell the product. Partnering with manufacturers who replicate patented designs without licensing can lead to supply chain disruptions and reputational damage.

Inconsistent Batch-to-Batch Quality

When sourcing from low-cost suppliers, quality can vary significantly between production runs. One batch may meet expectations, while the next contains warped parts, weak threads, or inconsistent finishes. This inconsistency complicates large installations and increases rejection rates.

Limited Technical Support and Traceability

Offshore suppliers may offer minimal documentation, lack responsive customer service, or be unable to provide lot traceability. This becomes critical during recalls, warranty claims, or when troubleshooting installation issues in the field.

Failure to Meet Environmental and Safety Standards

Some extenders may contain restricted substances (e.g., high levels of lead or halogens) that violate environmental regulations like RoHS or REACH. Non-compliant materials can pose health risks and lead to project delays or penalties.

By carefully vetting suppliers, demanding certification documentation, and conducting quality audits, these pitfalls can be avoided—ensuring safe, compliant, and legally sound sourcing of gang box extenders.

Logistics & Compliance Guide for Gang Box Extender

Product Overview

A Gang Box Extender is a device used in electrical installations to align flush-mounted electrical boxes (such as those for outlets or switches) with the finished wall surface when additional wall layers (e.g., drywall, paneling) are added. It ensures proper alignment and compliance with electrical codes.

Regulatory Compliance

Gang Box Extenders must comply with national and international electrical safety standards. Key compliance requirements include:

– NEC (National Electrical Code): Must meet NEC Article 314, which governs the installation of outlet, junction, and device boxes.

– UL Listing: Devices should carry UL (Underwriters Laboratories) certification or equivalent (e.g., ETL) to verify safety and performance.

– RoHS Compliance: In regions like the EU, extender materials must comply with Restriction of Hazardous Substances (RoHS) directives.

– Material Safety: Non-conductive, flame-retardant materials (e.g., thermoplastics) are typically required to reduce fire and shock risks.

Packaging and Labeling Requirements

- Each extender should be clearly labeled with:

- Manufacturer name and part number

- UL/ETL certification mark

- Material type (e.g., PVC, polycarbonate)

- Applicable standards (e.g., NEC 314.20)

- Packaging must be durable to prevent damage during transit and include:

- Quantity per pack

- Installation instructions

- Compliance statements

Shipping and Handling

- Storage Conditions: Store in a dry, temperature-controlled environment (10°C to 30°C) away from direct sunlight and flammable materials.

- Transportation: Use standard parcel or freight shipping; avoid exposure to moisture or extreme temperatures.

- Stacking Limits: Do not stack more than 1.5 meters (5 feet) high to prevent crushing.

- Hazard Classification: Non-hazardous; no special handling required under IATA, IMDG, or DOT regulations.

Import/Export Considerations

- HS Code: Typical classification: 8538.90 (Parts suitable for use solely or primarily with apparatus of heading 8535, 8536, or 8537).

- Documentation: Include commercial invoice, packing list, and certificate of compliance (e.g., RoHS, UL).

- Customs Clearance: Ensure product markings meet destination country requirements (e.g., CE marking for EU).

Installation & Usage Compliance

- Must be installed by a licensed electrician in accordance with:

- Local building codes

- NEC 314.20 – Flush-Device Requirements

- Manufacturer’s instructions

- Improper installation may void compliance and create safety hazards.

Environmental and Disposal Guidelines

- At end-of-life, dispose of according to local electronic waste (e-waste) regulations.

- Recycle plastic components where facilities exist; do not incinerate due to potential toxic fumes.

Warranty and Support

- Standard warranty: Typically 1–5 years, depending on manufacturer.

- Defective units should be returned through authorized distributors with proof of purchase.

For full compliance, always verify product specifications and local regulations before installation or shipment.

Conclusion on Sourcing Gang Box Extenders:

After evaluating various suppliers, product specifications, pricing, and quality standards, it is clear that sourcing gang box extenders requires a balanced approach focusing on compatibility, material durability, and cost-efficiency. Key considerations include ensuring compliance with electrical codes (such as NEC standards), selecting appropriate materials (typically PVC or metal) based on installation environment, and verifying dimensional accuracy to match existing or planned electrical boxes.

Sourcing from reputable manufacturers or suppliers with proven track records ensures product reliability and reduces the risk of installation issues or safety hazards. While domestic suppliers may offer faster lead times and better customer support, international options can provide cost advantages if quality control and shipping logistics are carefully managed.

In conclusion, the optimal sourcing strategy involves partnering with pre-qualified suppliers who offer high-quality, code-compliant gang box extenders at competitive prices, backed by consistent availability and reliable delivery. This approach supports efficient project execution, ensures electrical safety, and minimizes rework or compliance risks in both residential and commercial electrical installations.