The global galvano laser market is experiencing robust growth, driven by increasing demand for high-precision laser systems in industrial manufacturing, automotive, electronics, and medical device sectors. According to Mordor Intelligence, the global laser system market is projected to grow at a CAGR of over 7.2% from 2023 to 2028, with galvano-based scanning technologies representing a critical segment due to their speed, accuracy, and reliability in laser marking, engraving, and micro-machining applications. Advancements in automation and photonics, coupled with rising adoption of Industry 4.0 practices, are further accelerating the deployment of galvano lasers across diverse production environments. As demand intensifies, a select group of manufacturers has emerged at the forefront of innovation, offering high-performance galvo scanners and integrated laser solutions. Based on technological leadership, market presence, and product scalability, the following six companies stand out as the leading galvano laser manufacturers shaping the future of precision laser processing.

Top 6 Galvano Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Sino

Website: galvo-scanner.com

Key Highlights: Welcome to buy customized galvo scanner and laser marking accessories at low price from professional manufacturers and suppliers in China….

#2 Scanner Optics

Website: scanneroptics.com

Key Highlights: Scanner Optics is professional in galvanometer scanners, controllers, software, optics, encoders and customized galvanometer systems. Our galvo scanner ……

#3 Quality sheets save time and money

Website: galvano-metaal.nl

Key Highlights: With SSAB Laser Plus, you can laser-cut faster than the laser manufacturer specifies. SSAB guarantees 3 mm precision per linear meter both before and after ……

#4 Sino Galvo

Website: sinogalvo.com

Key Highlights: SINO-GALVO has been developing and manufacturing optical galvanometer scanners and its control systems since its founding in 2001….

#5 ScannerMAX

Website: scannermax.com

Key Highlights: ScannerMAX offers exceptional galvanometers and rotary actuators, at competitive prices with short lead times, backed up by professional service and ……

#6 Full Spectrum Laser

Expert Sourcing Insights for Galvano Laser

H2: Market Trends Shaping Galvano Laser Technology in 2026

As we approach 2026, the galvano laser market is undergoing significant transformation driven by advancements in precision manufacturing, automation, and digitalization across key industries. Galvano lasers—known for their high-speed, high-accuracy beam steering using galvanometric mirrors—are experiencing increased adoption due to their critical role in laser marking, engraving, micro-machining, and additive manufacturing. Below is an analysis of the major market trends influencing the galvano laser sector in 2026.

1. Surge in Demand from Electric Vehicles (EVs) and Battery Manufacturing

The global push toward electrification is significantly boosting the need for precise laser processing in battery production. Galvano laser systems are essential for tasks such as electrode cutting, weld seam tracking, and barcode marking on battery cells. With EV production expected to double by 2026 compared to 2022 levels, demand for high-throughput, reliable galvano-based laser systems is rising. Manufacturers are investing in integrated galvano solutions that ensure traceability, precision, and minimal thermal damage—critical for battery safety and performance.

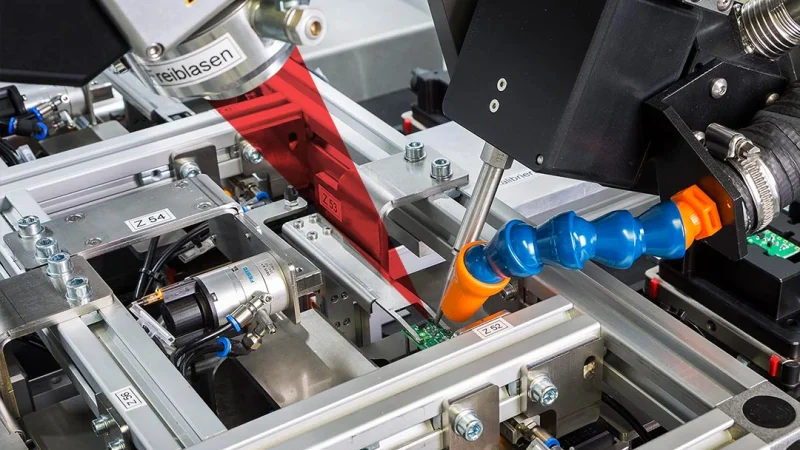

2. Integration with Smart Manufacturing and Industry 4.0

Galvano laser systems are being increasingly embedded into smart factories, where real-time data, IoT connectivity, and AI-driven process optimization are standard. In 2026, galvano laser platforms are evolving into intelligent nodes within production lines, capable of self-calibration, predictive maintenance, and adaptive control based on feedback from vision systems and sensors. This integration enhances uptime, reduces scrap rates, and enables mass customization—key priorities in modern manufacturing.

3. Growth in Medical Device and Microelectronics Fabrication

The medical and microelectronics sectors are leveraging galvano lasers for micron-level precision applications such as stent cutting, semiconductor scribing, and microvia drilling. As wearable medical devices and advanced semiconductor packaging (e.g., fan-out wafer-level packaging) gain momentum, the need for compact, high-frequency galvano scanners with sub-micron accuracy is expanding. In 2026, we see more hybrid systems combining galvano mirrors with ultrafast lasers (e.g., femtosecond) to achieve cold ablation with minimal heat-affected zones.

4. Advancements in Software and User Interfaces

Software plays a pivotal role in maximizing galvano laser performance. By 2026, user-friendly, cloud-connected software platforms are enabling non-expert operators to program complex marking and machining patterns via intuitive graphical interfaces or even AI-assisted design tools. Real-time simulation, digital twin integration, and remote monitoring are becoming standard, improving operational efficiency and reducing setup times.

5. Sustainability and Energy Efficiency Focus

Environmental regulations and corporate sustainability goals are pushing manufacturers to reduce energy consumption and waste. Galvano laser systems, particularly those paired with fiber lasers, offer energy-efficient, contactless processing with minimal material waste. In 2026, OEMs are introducing “green galvano” systems with optimized scanning algorithms and low-power standby modes, aligning with the broader industrial shift toward carbon-neutral operations.

6. Regional Market Shifts and Supply Chain Localization

Asia-Pacific remains the dominant market for galvano lasers, driven by electronics manufacturing in China, South Korea, and India. However, reshoring trends in North America and Europe—especially in defense, aerospace, and high-value medical devices—are creating new opportunities. In 2026, we observe a rise in localized production of galvano components to mitigate supply chain risks and reduce lead times, supported by government incentives for domestic advanced manufacturing.

Conclusion

By 2026, the galvano laser market is characterized by higher integration, smarter operation, and broader application scope. Key growth drivers include electrification, digital transformation, and the need for micron-level precision across industries. Companies investing in R&D for faster scanning speeds, improved thermal management, and seamless system integration are best positioned to capitalize on these trends. As galvano laser technology becomes increasingly embedded in next-generation manufacturing ecosystems, its role as an enabling technology for precision and automation will only grow stronger.

Common Pitfalls When Sourcing Galvano Laser Systems

Sourcing Galvano laser systems—commonly used in precision applications such as laser marking, engraving, and micromachining—can present several challenges, particularly concerning quality consistency and intellectual property (IP) risks. Being aware of these pitfalls helps ensure reliable performance and legal compliance.

Quality Inconsistencies and Performance Issues

One of the primary risks when sourcing Galvano laser systems, especially from lesser-known or cost-driven suppliers, is inconsistent quality. This can manifest in various ways: uneven beam scanning accuracy, reduced lifespan of galvanometer motors, or poor integration between the laser source and control software. Many suppliers may use substandard components to cut costs, leading to frequent maintenance needs and downtime. Additionally, inadequate thermal management or lack of proper calibration can result in reduced precision and repeatability—critical factors in high-tolerance manufacturing. Without rigorous testing and certification, end users may face performance shortfalls that impact production quality.

Intellectual Property (IP) and Legal Risks

Another significant pitfall involves intellectual property concerns. Some manufacturers, particularly in regions with lax IP enforcement, may produce systems that replicate patented technologies or incorporate unauthorized firmware and software. Sourcing such systems can expose buyers to legal liability, including infringement claims from original equipment manufacturers (OEMs). Additionally, counterfeit or cloned control boards and laser drivers may lack necessary safety certifications (e.g., CE, FDA), increasing regulatory and operational risks. Buyers should verify the authenticity of components, ensure suppliers provide proper licensing documentation, and conduct due diligence on the supply chain to mitigate IP exposure.

Logistics & Compliance Guide for Galvano Laser

This guide outlines the essential logistics and compliance procedures for Galvano Laser to ensure efficient operations, regulatory adherence, and customer satisfaction. All departments must follow these guidelines to maintain safety, legality, and operational excellence.

Shipping & Receiving Protocols

All incoming and outgoing shipments must be documented and inspected. Receiving staff must verify purchase orders against delivered goods, checking for damage and quantity discrepancies. Shipments must be labeled with correct product codes, batch numbers, and destination details. Use certified carriers with track-and-trace capabilities for all outbound shipments. Maintain a digital log of all shipments for audit readiness.

Export Controls & International Trade Compliance

Galvano Laser products may be subject to export control regulations, including EAR (Export Administration Regulations). All international shipments require proper classification under the Commerce Control List (CCL). Obtain necessary export licenses prior to shipment when required. Screen all international customers and partners against government restricted party lists (e.g., BIS Denied Persons List, OFAC SDN List) before transaction initiation. Maintain records of export documentation for a minimum of five years.

Product Safety & Regulatory Standards

Ensure all laser products comply with relevant safety standards, including IEC 60825-1 (laser safety), CE marking requirements (for EU), FDA 21 CFR Part 1040.10 (for U.S. market), and other regional regulations. Conduct periodic internal audits to verify compliance. Label products with appropriate warning labels, laser class designation, and compliance marks. Maintain technical files and EU Declaration of Conformity for all products.

Hazardous Materials Handling

Laser systems may contain components classified as hazardous (e.g., certain batteries, optical coatings). When handling or shipping such materials, comply with UN/DOT regulations (e.g., 49 CFR in the U.S.). Use certified packaging, proper labeling (e.g., Class 9 for miscellaneous hazardous materials), and complete shipping documentation (e.g., Safety Data Sheets, Dangerous Goods Declarations). Train relevant staff in hazardous materials handling and emergency response.

Documentation & Recordkeeping

Maintain accurate, up-to-date records for all compliance and logistics activities. Required documentation includes:

– Bill of Lading and Air Waybills

– Commercial Invoices and Packing Lists

– Certificates of Origin

– Export Licenses and Authorizations

– Product Conformity Certifications

– Internal Audit Reports

– Training Records

All records must be stored securely, either physically or digitally, with access restricted to authorized personnel. Retention period: minimum of five years unless otherwise specified by regulation.

Quality Assurance & Traceability

Implement a product traceability system using unique batch or serial numbers. This enables rapid recall response and helps track product lifecycle. Conduct regular quality inspections at key stages: incoming materials, in-process production, and final product. Non-conforming products must be quarantined and documented. Ensure calibration of all measurement and testing equipment according to ISO 9001 standards.

Supplier & Vendor Compliance

Require all suppliers to adhere to Galvano Laser’s Supplier Code of Conduct. Assess key vendors for compliance with environmental, labor, and safety standards. Obtain material declarations (e.g., RoHS, REACH) to ensure restricted substance compliance. Audit high-risk suppliers periodically and maintain compliance certifications on file.

Incident Reporting & Corrective Actions

All logistics or compliance incidents (e.g., shipment delays, regulatory violations, safety concerns) must be reported immediately to the Compliance Officer. Conduct root cause analysis and implement corrective and preventive actions (CAPA). Document all incidents and responses in the non-conformance management system. Report mandatory incidents to relevant authorities within required timeframes.

Training & Responsibilities

All employees involved in logistics, shipping, manufacturing, or compliance must complete annual training on relevant procedures and regulations. Assign clear compliance responsibilities:

– Logistics Manager: Oversees shipping, receiving, and carrier coordination

– Compliance Officer: Ensures regulatory adherence and manages audits

– Quality Manager: Maintains QA systems and traceability

– Export Coordinator: Manages export documentation and license applications

Regularly review and update this guide to reflect changes in regulations or business operations.

Conclusion for Sourcing Galvano Laser Systems

In conclusion, sourcing a galvano laser system requires a strategic evaluation of technical specifications, application needs, supplier reliability, and long-term cost of ownership. Galvano lasers are critical in high-precision industries such as automotive, electronics, medical devices, and aerospace, where accuracy, speed, and repeatability are paramount. When selecting a supplier, it is essential to prioritize partners with proven expertise, robust after-sales support, and compliance with international quality and safety standards.

Key considerations include laser power, marking speed, beam quality, software compatibility, and integration capabilities with existing production lines. Additionally, assessing the total cost—beyond initial investment to include maintenance, training, and potential downtime—is vital for maximizing ROI.

Ultimately, investing in a high-quality galvano laser from a reputable supplier ensures enhanced productivity, superior marking/engraving results, and long-term operational efficiency. A well-informed sourcing decision will position organizations to meet current demands and adapt to future technological advancements in laser processing.