The global galvanized steel tube market is experiencing robust growth, driven by rising demand in construction, infrastructure, and industrial applications. According to Mordor Intelligence, the galvanized steel pipes and tubes market was valued at USD 30.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. This expansion is fueled by increasing urbanization, government investments in infrastructure, and the superior corrosion resistance offered by galvanized square tubes. As industries prioritize durability and cost-efficiency, manufacturers are scaling production and enhancing coating technologies to meet stringent quality standards. In this competitive landscape, identifying key players with consistent output, innovation, and global reach becomes critical for procurement professionals and project planners. Based on market presence, production capacity, and industry reputation, the following are the top 10 galvanized square tube manufacturers leading the sector.

Top 10 Galvanized Square Tube Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Square Galvanized Steel Tubing Manufacturer

Domain Est. 2000

Website: tottentubes.com

Key Highlights: Get square galvanized steel tubing in custom sizes, lengths, and quantities for commercial and industrial applications….

#2 Structural Steel Tubes & Steel Pipes Manufacturer in India

Domain Est. 2010

Website: aplapollo.com

Key Highlights: APL Apollo Tubes Limited is the largest producer of Structural Steel Tubes in India. We have an extended distribution network of warehouses and branch offices ……

#3 Atlas Tube

Domain Est. 1995

Website: atlastube.com

Key Highlights: As the leading manufacturer of structural steel tube, we’re here to help you. From conceptual design through project completion, our engineering team, design ……

#4 Galvanized Square Steel Tube

Domain Est. 1999

Website: industrialmetalsupply.com

Key Highlights: 30-day returnsIndustrial Metal Supply offers a vast inventory of galvanized square tubes, cutting-edge production capabilities, and outstanding customer service….

#5 Rectangular and Square Tubing

Domain Est. 1997

Website: metalsusa.com

Key Highlights: Metals USA is a leading steel distributor offering a wide variety of structural steel tubing in rectangular and square shapes and numerous sizes….

#6 Galvanized Steel Tube & Tubing

Domain Est. 1998

Website: ljtube.com

Key Highlights: Lock Joint Tube is proud to offer a galvanized steel tubing that can meet the specifications of each of our customers. Contact us today!…

#7 Square Pipe and Tubing

Domain Est. 2001

Website: spsfence.com

Key Highlights: Hot-Dip Galvanized pipe is formed before being galvanized and coated with a clear outside finish. This protects the materials from white rust and corrosion….

#8 Ohio Galvanized Tube

Domain Est. 2001

Website: ohgalvanizedtube.com

Key Highlights: Ohio Galvanized Tube is your dependable, high-quality mechanical tubing supplier serving Ohio, Michigan, Indiana, Western Pennsylvania, Kentucky, and West ……

#9 Galvanized Square Tube. Immediate Availability

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: Our Galvanized Square Tubes are available in 4″ square sizes and lengths of 10′, 12′, 14′, 16′, 18′, 20′, and 24’….

#10 Galvanized Steel Square Tube

Domain Est. 2018

Website: coremarkmetals.com

Key Highlights: 7–12 day delivery 30-day returnsGalvanized square tubes are hot rolled steel, or mild steel, tubes that have dipped into a molten zinc coating process….

Expert Sourcing Insights for Galvanized Square Tube

H2: Projected 2026 Market Trends for Galvanized Square Tube

The global galvanized square tube market is anticipated to experience steady growth by 2026, driven by increasing demand across construction, automotive, and industrial sectors. The following key trends are expected to shape the market landscape:

-

Rising Construction Activities

Urbanization and infrastructure development, particularly in emerging economies in Asia-Pacific, Africa, and Latin America, will continue to fuel demand for galvanized square tubes. These products are favored for their strength, corrosion resistance, and durability in structural applications such as scaffolding, fencing, and building frameworks. -

Growth in Renewable Energy Infrastructure

The expansion of solar panel mounting systems and wind energy support structures—both of which commonly use galvanized square tubes due to their weather resistance—will contribute significantly to market growth. As governments push for clean energy adoption, this application segment is poised for strong expansion through 2026. -

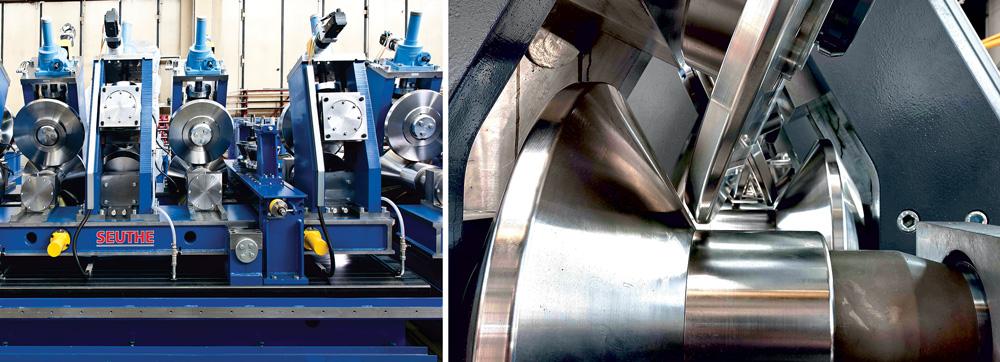

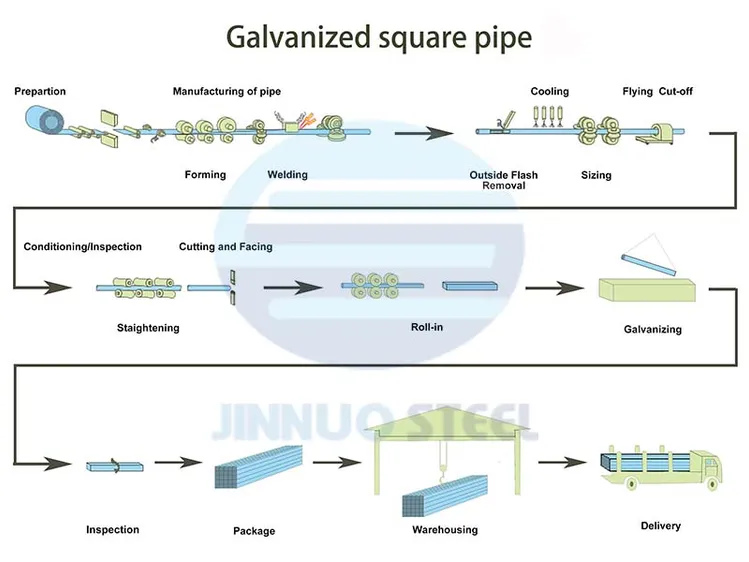

Technological Advancements in Production

Manufacturers are investing in advanced galvanization techniques and automation to enhance production efficiency and product consistency. Continuous improvements in hot-dip galvanizing processes are expected to reduce environmental impact and lower costs, making galvanized square tubes more competitive versus alternative materials. -

Environmental and Regulatory Pressures

Environmental regulations are increasingly influencing material choices. Galvanized steel’s recyclability and long service life align with sustainability goals, supporting its preference over carbon steel or non-metallic alternatives. However, emissions from galvanization processes may prompt stricter regulations, pushing producers toward greener technologies. -

Supply Chain Resilience and Raw Material Volatility

Fluctuations in zinc and steel prices, along with logistical challenges, will remain critical concerns. Companies are expected to adopt localized production and long-term supply agreements to mitigate risks. The shift toward regional manufacturing hubs will also reduce dependency on imports, especially in North America and Europe. -

Competitive Landscape and Market Consolidation

The market is seeing increased consolidation as large players acquire smaller mills to expand capacity and geographic reach. This trend is likely to continue through 2026, leading to enhanced R&D capabilities and broader product portfolios.

In summary, the galvanized square tube market in 2026 will be shaped by infrastructure growth, sustainability demands, technological innovation, and evolving supply chain dynamics. Stakeholders who adapt to these trends through strategic investment and operational agility will be best positioned for long-term success.

Common Pitfalls When Sourcing Galvanized Square Tube (Quality and IP)

Sourcing galvanized square tube can be cost-effective and efficient, but it comes with several common pitfalls—especially concerning quality and intellectual property (IP) risks. Being aware of these issues helps ensure you receive reliable products and avoid legal or reputational damage.

Poor Galvanization Quality

One of the most frequent quality issues with galvanized square tube is inconsistent or inadequate galvanization. Substandard zinc coating can lead to premature rusting, reduced structural integrity, and shorter product lifespan. Common signs include uneven coating thickness, exposed steel spots, or flaking zinc. This often results from suppliers cutting corners on dip time, zinc purity, or pre-treatment processes.

Inaccurate Dimensional Tolerances

Galvanized square tubes with poor dimensional accuracy can cause fitment problems during fabrication or construction. Some suppliers, particularly those using low-grade roll-forming equipment, fail to maintain tight tolerances for wall thickness, side length, or straightness. These inconsistencies can compromise structural performance and increase labor costs due to rework or rejection on-site.

Misrepresentation of Material Grade

Suppliers may falsely claim compliance with standards such as ASTM A500 or EN 10219, providing tubes made from inferior steel grades. This misrepresentation can result in tubes that fail under load or in corrosive environments. Always request mill test certificates (MTCs) and conduct independent material verification when sourcing from unfamiliar vendors.

Inadequate Coating Thickness and Adhesion

IP-rated products—particularly those used in outdoor or industrial environments—require a minimum zinc coating thickness (e.g., 55–85 microns per ASTM A123). Some suppliers falsify coating reports or use post-weld galvanizing methods that result in thin or non-uniform coatings. Poor adhesion can lead to peeling during bending or welding, exposing the base metal to corrosion.

Counterfeit or Stolen Intellectual Property

When sourcing from manufacturers in regions with weak IP enforcement, there’s a risk of purchasing tubes that infringe on patented designs, branding, or manufacturing processes. Some suppliers replicate branded products (e.g., mimicking trademarked surface finishes or profiles) without authorization. This exposes buyers to legal liability, especially if the product is resold under a brand name.

Lack of Traceability and Certification

Reputable suppliers provide full traceability through heat numbers, batch certifications, and compliance documentation. Without these, it becomes difficult to verify quality, respond to failures, or prove due diligence in case of IP disputes. Sourcing from uncertified mills increases the risk of receiving non-compliant or counterfeit materials.

Supply Chain Transparency Issues

Complex supply chains—especially those involving third-party traders—can obscure the origin of the product. This lack of transparency raises concerns about sourcing from blacklisted manufacturers or regions subject to anti-dumping duties. It also makes it harder to enforce quality standards or pursue legal remedies in IP disputes.

To avoid these pitfalls, conduct thorough due diligence, audit suppliers, insist on verifiable certifications, and engage legal counsel when using branded or patented tube designs.

Logistics & Compliance Guide for Galvanized Square Tube

Product Overview

Galvanized square tubes are steel hollow sections coated with a protective layer of zinc to enhance corrosion resistance. Commonly used in construction, automotive, and manufacturing industries, these tubes require careful handling and compliance with international standards during transport and import/export.

Packaging and Handling

Galvanized square tubes are typically bundled using steel strapping or plastic banding to maintain structural integrity. End caps or protective sleeves are often used to prevent damage to the galvanized coating. For logistics, tubes should be stored off the ground on wooden pallets and covered to protect against moisture and scratches. Avoid direct contact with wet surfaces to prevent white rust formation.

Transportation Methods

Transport options include containerized shipping (20ft or 40ft dry containers), flatbed trucks for domestic haulage, or open-top containers for oversized loads. Secure loads properly to prevent shifting; use dunnage and edge protectors to avoid coating damage. For sea freight, ensure moisture-resistant wrapping to mitigate condensation during transit.

Regulatory Compliance

Galvanized steel products must comply with regional and international standards. Key regulations include:

– ASTM A500 (US standard for cold-formed welded and seamless carbon steel structural tubing)

– EN 10219 (European standard for cold-formed welded structural hollow sections)

– ISO 14666 (international standard for steel square and rectangular hollow sections)

Verify product certification (e.g., mill test certificates) to confirm compliance with applicable standards.

Import/Export Documentation

Required documents typically include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Mill Test Certificate (MTC)

– Phytosanitary Certificate (if wooden dunnage or pallets are used)

Ensure Harmonized System (HS) code accuracy; galvanized square tubes often fall under 7306.61 (hollow sections of iron or steel, galvanized).

Customs Clearance and Duties

Customs authorities may inspect for material composition, zinc coating thickness, and adherence to safety standards. Be prepared to provide product specifications and test reports. Duty rates vary by country—consult local tariff schedules. Anti-dumping or countervailing duties may apply in regions like the US or EU, depending on the country of origin.

Environmental and Safety Regulations

Galvanized steel may release zinc oxide fumes when cut or welded; ensure handling complies with OSHA (US) or equivalent occupational health standards. Dispose of packaging materials according to local waste regulations. Some jurisdictions regulate zinc runoff; store materials to prevent environmental contamination.

Quality Assurance and Inspection

Pre-shipment inspections are recommended to verify dimensions, coating thickness (typically 50–150 microns), and absence of surface defects. Use third-party inspection services if required by the buyer or customs authority. Retain quality documentation throughout the supply chain.

Risk Mitigation

- Insure shipments against damage, delay, and rust.

- Partner with logistics providers experienced in steel products.

- Monitor geopolitical and trade regulation changes affecting steel tariffs or quotas.

- Maintain traceability from manufacturer to end-user for compliance audits.

Conclusion for Sourcing Galvanized Square Tube:

Sourcing galvanized square tubes requires a strategic approach that balances quality, cost, and reliability. After evaluating various suppliers, material specifications, and market conditions, it is evident that selecting the right source involves considering factors such as coating thickness, dimensional accuracy, compliance with international standards (e.g., ASTM A123 or ISO 1461), and the reputation of the manufacturer. Local suppliers may offer faster lead times and lower transportation costs, while international suppliers could provide competitive pricing but may involve longer delivery times and import considerations.

Establishing long-term partnerships with certified and audited suppliers ensures consistent product quality and supply chain resilience. Additionally, conducting periodic quality checks and requesting material test certificates help maintain performance standards, especially for applications requiring corrosion resistance and structural integrity.

In conclusion, an effective sourcing strategy for galvanized square tubes integrates thorough supplier vetting, clear technical specifications, and ongoing supply chain management to achieve optimal cost-efficiency, reliability, and product performance in end-use applications such as construction, automotive, and manufacturing.