The global steel market continues to experience robust growth, driven by rising infrastructure development, urbanization, and industrial expansion—particularly in emerging economies. According to Mordor Intelligence, the global steel market was valued at USD 1.45 trillion in 2022 and is projected to grow at a CAGR of over 5.8% from 2023 to 2028. With increasing demand for corrosion-resistant materials in construction, automotive, and energy sectors, galvanized square steel has emerged as a critical product due to its durability, strength, and longevity. The galvanized steel segment is further bolstered by stringent regulatory standards promoting sustainable and long-life building materials. As demand surges, a select group of manufacturers have risen to prominence by combining advanced production technologies, international distribution networks, and stringent quality controls. Based on market presence, production capacity, and innovation, we’ve identified the top 10 galvanized square steel manufacturers shaping the industry’s future.

Top 10 Galvanized Square Steel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Square Galvanized Steel Tubing Manufacturer

Domain Est. 2000

Website: tottentubes.com

Key Highlights: Get square galvanized steel tubing in custom sizes, lengths, and quantities for commercial and industrial applications….

#2 Structural Steel Tubes & Steel Pipes Manufacturer in India

Domain Est. 2010

Website: aplapollo.com

Key Highlights: APL Apollo Tubes Limited is the largest producer of Structural Steel Tubes in India. We have an extended distribution network of warehouses and branch offices ……

#3 Metals Supplier & Service Center

Domain Est. 1997

Website: sss-steel.com

Key Highlights: Triple-S Steel is one of the largest metals distributor and service center in North and South America. Whether your project is large or small, local or global,…

#4 Pennsylvania Steel Company, Inc.

Domain Est. 1998

Website: pasteel.com

Key Highlights: Pennsylvania Steel has steel distributor warehouses across the northeast offering a wide variety of steel options for various industries….

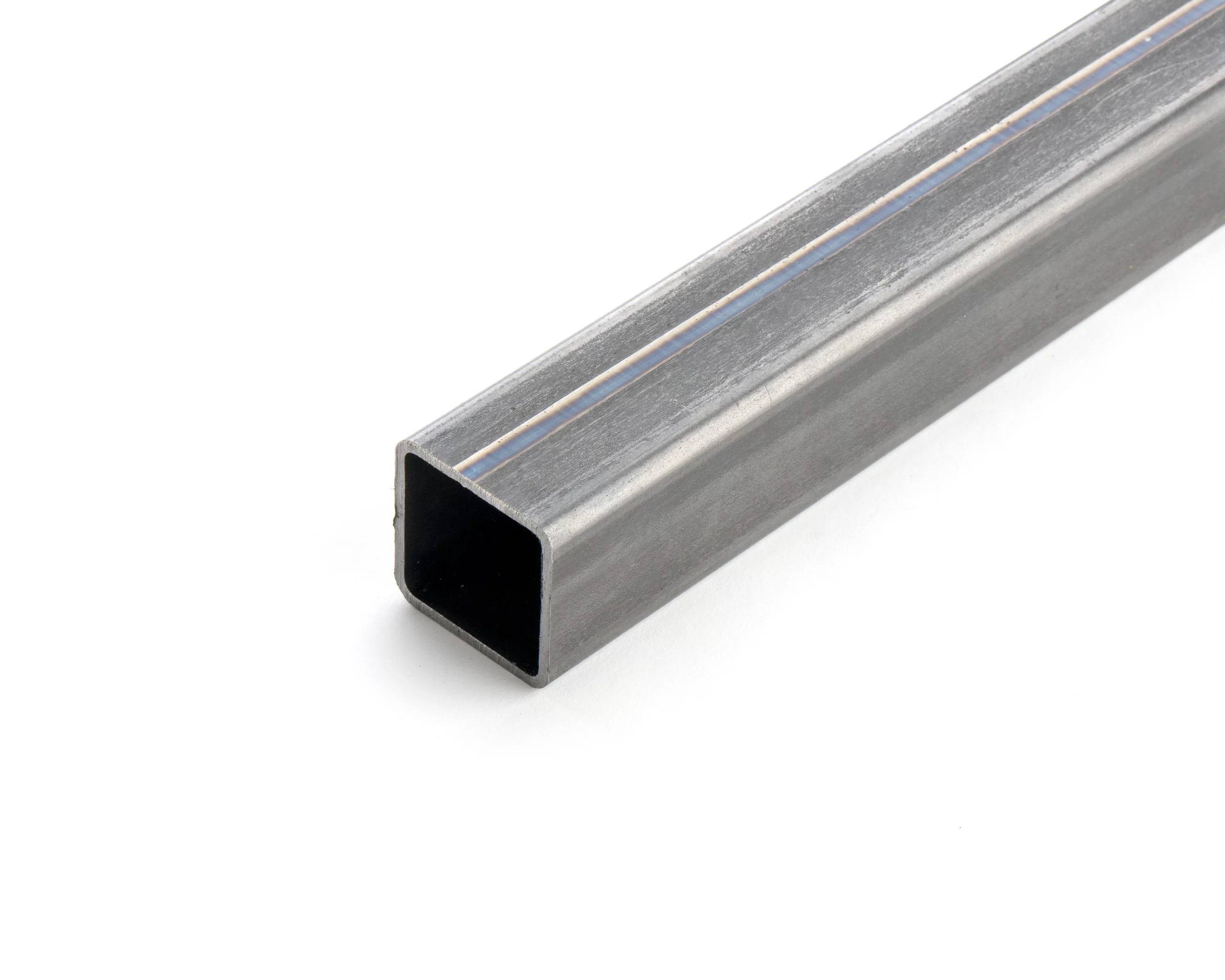

#5 Galvanized Square Steel Tube

Domain Est. 1999

Website: industrialmetalsupply.com

Key Highlights: 30-day returnsIndustrial Metal Supply offers a vast inventory of galvanized square tubes, cutting-edge production capabilities, and outstanding customer service….

#6 Heidtman Steel

Domain Est. 1999

Website: heidtman.com

Key Highlights: At Heidtman, we combine cutting-edge technology with precision craftsmanship to shape steel to your exact needs. From Blanking and Pickling to Galvanizing and ……

#7 Zekelman Industries

Domain Est. 2002 | Founded: 1946

Website: zekelman.com

Key Highlights: The leading full-line manufacturer of galvanized steel and aluminum elbows, couplings and nipples since 1946. Western Tube Icon. Western Tube. Manufactures ……

#8 Galvanized Highway Guardrail, Strut, & Fence Products

Domain Est. 1999

Website: gregorycorp.com

Key Highlights: Gregory Industries leads with quality steel products, innovative processes, and expert people. See how our roll-formed solutions can support you….

#9 LP Tube

Domain Est. 2006

Website: lptube.com

Key Highlights: Welcome to LP Tube. We are a leader in the manufacturing and marketing of high-quality steel pipe and Galvanized Tubing products in the western United States….

#10 Wheeling

Domain Est. 2020

Website: wheeling-nipponsteel.com

Key Highlights: WHEELING-NIPPON STEEL is the only steel coating mill in the United States that produces all major hot-dip coated products under one roof….

Expert Sourcing Insights for Galvanized Square Steel

H2: 2026 Market Trends for Galvanized Square Steel

The global market for galvanized square steel is expected to experience steady growth by 2026, driven by increasing demand across construction, infrastructure, automotive, and renewable energy sectors. This analysis outlines key market trends shaping the industry landscape through the mid-decade.

-

Rising Infrastructure Development

Governments worldwide, particularly in Asia-Pacific, Africa, and Latin America, are investing heavily in urbanization and transportation infrastructure. Galvanized square steel, known for its strength and corrosion resistance, is becoming a preferred material for structural framing, utility poles, and modular construction. China, India, and Indonesia continue to lead in public works projects, fueling regional demand. -

Growth in Prefabricated and Modular Construction

The construction industry is shifting toward faster, cost-effective building methods. Prefabricated and modular structures rely extensively on standardized steel components, including galvanized square tubes. Their durability and ease of assembly make them ideal for residential, commercial, and emergency housing projects, further boosting market adoption. -

Expansion of Renewable Energy Projects

Solar panel mounting structures and wind turbine support systems increasingly utilize galvanized square steel due to its longevity in outdoor environments. With global renewable energy targets intensifying by 2026, solar farm installations—especially in the U.S., Middle East, and India—are expected to drive significant demand. -

Environmental Regulations and Sustainability Focus

Stringent environmental policies are encouraging the use of recyclable and long-lasting materials. Galvanized steel is 100% recyclable and requires minimal maintenance, aligning with green building certifications like LEED and BREEAM. Manufacturers are investing in cleaner galvanizing processes to meet emission standards, especially in Europe and North America. -

Technological Advancements in Production

Automation and digitalization in steel manufacturing are improving precision, yield, and coating consistency. Advanced continuous galvanizing lines (CGL) now offer tighter control over zinc coating thickness, enhancing product performance. These innovations reduce costs and improve competitiveness, especially among large-scale producers. -

Supply Chain Resilience and Regionalization

Post-pandemic disruptions and geopolitical tensions have prompted companies to regionalize supply chains. Nearshoring and onshoring trends in North America and Europe are leading to increased local production of galvanized steel products, reducing dependency on imports and shortening delivery times. -

Price Volatility and Raw Material Challenges

Fluctuations in zinc and iron ore prices, along with energy costs, remain a concern. The war in Ukraine and trade policies continue to impact raw material availability. Producers are adopting hedging strategies and long-term supplier contracts to mitigate financial risks. -

Competitive Landscape and Market Consolidation

The market is witnessing consolidation among mid-tier manufacturers seeking economies of scale. Major players such as Nippon Steel, ArcelorMittal, and Tata Steel are expanding their coated steel portfolios. Meanwhile, Chinese and Indian manufacturers maintain a strong export presence due to cost advantages.

Conclusion

By 2026, the galvanized square steel market is projected to grow at a CAGR of approximately 4.5–5.2%, reaching an estimated market value of USD 38–42 billion. Demand will be sustained by infrastructure modernization, green building practices, and industrial expansion in emerging economies. Companies that invest in sustainable production, supply chain agility, and product innovation will be best positioned to capitalize on these trends.

Common Pitfalls When Sourcing Galvanized Square Steel (Quality, IP)

Sourcing galvanized square steel involves several critical considerations, particularly concerning material quality and intellectual property (IP) compliance. Overlooking these aspects can lead to project delays, increased costs, or legal issues. Below are common pitfalls to avoid:

Poor Material Quality Control

One of the most frequent issues when sourcing galvanized square steel is receiving material that does not meet specified standards. This includes insufficient galvanization coating thickness, inconsistent zinc coverage, warping, or dimensional inaccuracies. Suppliers may cut corners to reduce costs, resulting in premature corrosion or structural failure. Always verify compliance with international standards such as ASTM A500 or ISO 1461 and request mill test certificates (MTCs).

Lack of Certification and Traceability

Many suppliers, especially in less regulated markets, may provide material without proper documentation or traceability. This absence makes it difficult to verify steel grade, manufacturing process, or galvanizing quality. Without certified test reports or heat numbers, you risk receiving substandard or non-compliant materials. Ensure your supplier provides full certification and batch traceability.

Inadequate Intellectual Property Due Diligence

When sourcing galvanized square steel for proprietary designs or patented applications, failing to assess IP implications can lead to infringement. For example, using steel profiles or coatings protected by patents (e.g., specific anti-corrosion technologies) without proper licensing may expose your business to legal action. Conduct IP audits and consult legal experts when integrating sourced materials into innovative products.

Misrepresentation of Galvanizing Process

Some suppliers claim hot-dip galvanizing but deliver pre-galvanized or electro-galvanized steel, which offers inferior corrosion resistance. Hot-dip galvanizing provides a thicker, more durable coating suitable for harsh environments. Confirm the galvanizing method used and inspect sample materials or production facilities if possible.

Inconsistent Dimensional Accuracy

Square steel tubes must meet precise dimensional tolerances for structural and aesthetic applications. Poorly manufactured products may have out-of-spec corner radii, wall thickness variations, or length deviations. These inconsistencies can disrupt fabrication processes and compromise structural integrity. Insist on dimensional inspection reports and conduct random incoming quality checks.

Supply Chain Transparency Issues

Opaque supply chains increase the risk of receiving counterfeit or recycled materials misrepresented as virgin steel. This is particularly common in regions with weak regulatory oversight. Work with reputable suppliers who disclose their manufacturing sources and allow third-party audits to ensure ethical and quality standards.

Overlooking Environmental and Compliance Standards

Galvanizing processes can involve hazardous materials and emissions. Sourcing from suppliers that do not comply with environmental regulations (e.g., REACH, RoHS) may expose your company to compliance risks, especially in regulated industries. Verify environmental certifications and request documentation on sustainable practices.

By addressing these pitfalls proactively—through rigorous supplier vetting, clear contractual specifications, and independent quality verification—buyers can ensure reliable, high-quality, and legally compliant galvanized square steel sourcing.

Logistics & Compliance Guide for Galvanized Square Steel

Overview

Galvanized square steel is widely used in construction, manufacturing, and infrastructure due to its corrosion resistance and structural strength. Transporting and handling this material requires adherence to international logistics standards and regulatory compliance frameworks. This guide outlines key considerations for the safe, efficient, and compliant shipment and handling of galvanized square steel.

Packaging and Handling

Proper packaging prevents damage during transit and ensures product integrity.

– Bundling: Steel sections are typically bundled using steel strapping or banding. Bundles should be tightly secured to prevent shifting.

– End Protection: Use protective caps or covers on tube ends to prevent deformation and injury.

– Palletization: Load bundles onto wooden or metal pallets suitable for forklift handling. Overhang should not exceed 15 cm.

– Labeling: Clearly label bundles with product specifications (grade, dimensions, length), batch number, and handling instructions (e.g., “Do Not Stack,” “Forklift Only”).

Storage Requirements

Improper storage can lead to corrosion or mechanical damage.

– Indoor Storage: Store in a dry, well-ventilated warehouse when possible. Avoid direct contact with soil or standing water.

– Outdoor Storage: Elevate bundles on timber dunnage (minimum 15 cm above ground). Cover with waterproof tarpaulins, ensuring airflow to prevent condensation.

– Stacking Limits: Do not exceed recommended stack heights (usually 3–4 layers) to prevent bottom deformation or collapse.

Transportation Guidelines

Transportation must comply with regional and international freight regulations.

– Road Transport:

– Use flatbed trucks with sufficient load capacity.

– Secure loads with ratchet straps or chains; cover with tarpaulin to prevent weather exposure.

– Adhere to local weight and dimension limits (e.g., length, overhang).

– Rail & Sea Freight:

– For container shipping, use open-top or flat-rack containers for oversized lengths.

– Ensure cargo is lashed and blocked to prevent movement during transit.

– Comply with IMDG Code (for sea) and AAR regulations (for rail) where applicable.

International Trade Compliance

Export and import of galvanized steel are subject to various trade regulations.

– HS Code Classification:

– Typical HS Code: 7306.61 (Hollow sections of galvanized steel).

– Confirm exact code based on country-specific tariff schedules.

– Export Controls:

– Check for export licensing requirements, especially for dual-use or strategic materials.

– Comply with U.S. EAR, EU Dual-Use Regulation, or other national export control regimes if applicable.

– Anti-Dumping & Countervailing Duties (AD/CVD):

– Be aware of AD/CVD measures in destination countries (e.g., U.S., EU, Canada).

– Maintain documentation proving origin and manufacturing process.

Documentation Requirements

Accurate documentation ensures smooth customs clearance.

– Commercial Invoice: Must include full product description, quantity, weight, value, Incoterms® (e.g., FOB, CIF), and seller/buyer details.

– Packing List: Detail bundle count, dimensions, weights, and packaging type.

– Certificate of Origin: Required for tariff preference or trade remedy compliance.

– Mill Test Certificate (EN 10204 3.1 or 3.2): Certifies chemical and mechanical properties, galvanizing thickness (typically 50–100 µm), and compliance with standards (e.g., ASTM A500, EN 10219).

– Dangerous Goods Declaration (if applicable): Not usually required, unless coated with hazardous substances.

Environmental & Safety Compliance

Galvanized steel involves zinc coating, which has environmental and handling implications.

– REACH & RoHS Compliance (EU): Confirm zinc coating complies with substance restrictions.

– OSHA & WHMIS (North America): Provide Safety Data Sheet (SDS) for galvanized steel, especially if cutting or welding (zinc fumes are hazardous).

– Waste Disposal: Scrap galvanized steel is recyclable; follow local hazardous waste regulations if coating removal is involved.

Quality Assurance & Inspection

Pre-shipment inspection ensures compliance with buyer and regulatory standards.

– Dimensional Checks: Verify side length, wall thickness, and straightness per order specifications.

– Galvanizing Inspection: Check for coating uniformity, adhesion (quench test), and absence of bare spots or excess zinc buildup.

– Third-Party Inspections: Consider SGS, BV, or Intertek for independent verification, especially for large export orders.

Conclusion

Efficient logistics and full compliance for galvanized square steel require proactive planning, proper documentation, and adherence to international standards. By following this guide, suppliers and logistics providers can minimize delays, avoid penalties, and ensure product quality upon delivery. Always consult local regulations and update procedures based on destination country requirements.

In conclusion, sourcing galvanized square steel requires careful consideration of several key factors to ensure quality, cost-efficiency, and project suitability. It is essential to identify reliable suppliers who adhere to industry standards and provide certified materials with consistent galvanization (typically in accordance with ASTM A123 or equivalent). Evaluating the steel’s dimensional accuracy, zinc coating thickness, and corrosion resistance is crucial for long-term durability, especially in harsh environments. Additionally, balancing cost, lead times, and logistical considerations helps optimize the procurement process. By conducting thorough market research, verifying supplier credentials, and aligning specifications with project requirements, stakeholders can secure high-quality galvanized square steel that offers structural integrity and extended service life, ultimately contributing to a successful and sustainable construction or manufacturing outcome.