The global demand for galvanized pipe railings has surged in recent years, driven by their durability, corrosion resistance, and cost-effectiveness in both residential and commercial construction. According to a report by Mordor Intelligence, the global steel pipes and tubes market—of which galvanized pipe products are a key segment—is projected to grow at a CAGR of over 5.2% from 2023 to 2028. This expansion is fueled by increasing infrastructure development, especially in emerging economies, and growing emphasis on long-lasting, low-maintenance building materials. Similarly, Grand View Research estimates that the global construction steel market was valued at USD 1.17 trillion in 2022 and is expected to grow steadily, further supporting demand for galvanized steel components like pipe railings. With these trends in mind, identifying leading manufacturers who combine innovation, scale, and quality becomes critical for specifiers and buyers. The following list highlights the top 10 galvanized pipe railing manufacturers, evaluated based on production capacity, geographic reach, product certification, and market reputation.

Top 10 Galvanized Pipe Railing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Structural Steel Tubes & Steel Pipes Manufacturer in India

Domain Est. 2010

Website: aplapollo.com

Key Highlights: APL Apollo Tubes Limited is the largest producer of Structural Steel Tubes in India. We have an extended distribution network of warehouses and branch offices ……

#2 Hollaender Manufacturing Co.

Domain Est. 1996

Website: hollaender.com

Key Highlights: Hollaender is the leading manufacturer of high-strength, corrosion-resistant aluminum fittings for use with any pipe including aluminum, galvanized steel, ……

#3 Over 45 Years of Quality Manufacturing

Domain Est. 2000

Website: imperialgroup.ca

Key Highlights: We design, manufacturer, assemble, and distribute over 7000 metal and plastic heating, air conditioning, ventilation, and building products….

#4 Galvanized Railings

Domain Est. 2018

Website: modularrailing.com

Key Highlights: Our galvanized railings are all hot dipped galvanized using Gatorshield technology prior to being delivered to the customer….

#5 Steel Safety Railings (VDKR)

Domain Est. 1998

Website: vestil.com

Key Highlights: Protect people from uneven walkways and mezzanine drop-off’s. The safety railing is constructed of schedule 10 steel. All models have an outside pipe ……

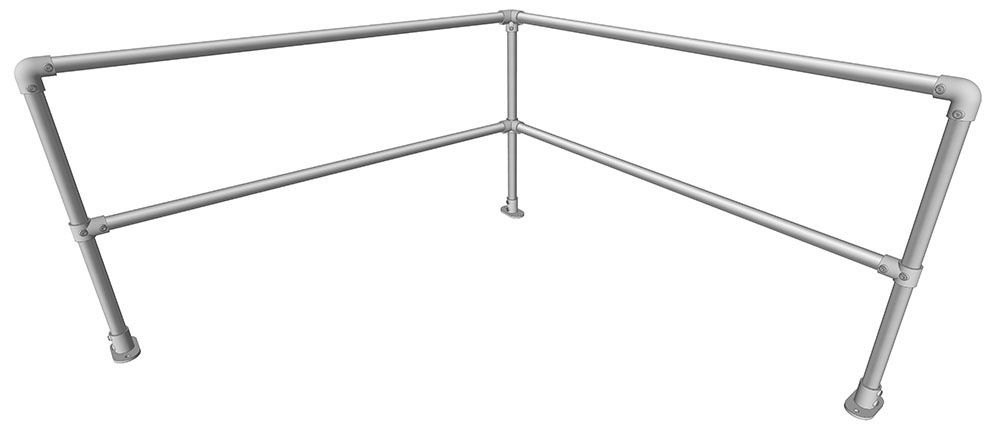

#6 Simplified Building

Domain Est. 2005

Website: simplifiedbuilding.com

Key Highlights: Simplify your DIY projects & engage your imagination with pipe and fittings. Need a long-lasting pipe handrail? Need it ADA compliant? We have that too….

#7 Kee Klamp® Pipe Fittings

Domain Est. 2007

Website: keesafety.com

Key Highlights: Kee Klamp is modular so it can be easily configured and installed precisely to your needs. Railings come in a variety of galvanized steel or aluminum finishes….

#8 Galvanized Steel OSHA Railing Kit

Domain Est. 2007

Website: simplifiedsafety.com

Key Highlights: In stock $108.69 deliveryGalvanized steel OSHA railing kits are perfect for indoor and outdoor use. No welding required. Simple and quick to install. Railing kits are easy to order…

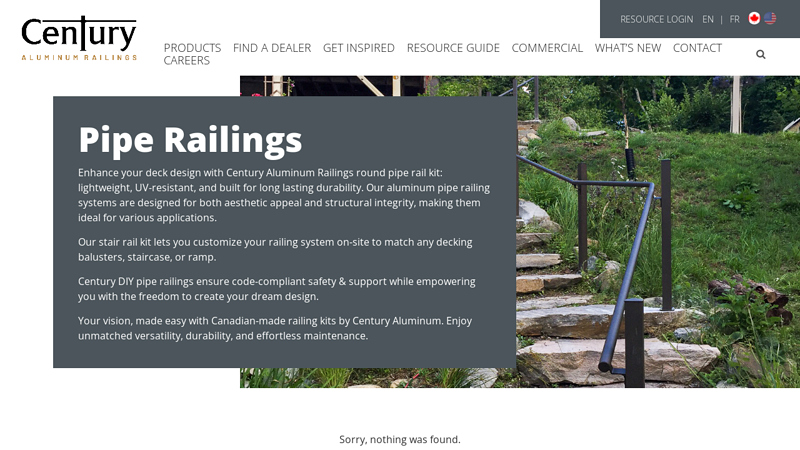

#9 Pipe Railings

Domain Est. 2012

Website: centuryrailings.com

Key Highlights: Compared to traditional railing materials like iron or galvanized steel railings, Century aluminum pipe railings are lightweight, easy to cut to size, UV ……

#10 Galvanized Railings

Domain Est. 2021

Website: gonzatogroup.us

Key Highlights: $37 delivery 18-day returnsUse galvanized railings along side stainless steel handrails and iron railings on any staircase around the home. Shop galvanized railings & parts at www….

Expert Sourcing Insights for Galvanized Pipe Railing

H2: 2026 Market Trends for Galvanized Pipe Railing

The galvanized pipe railing market is poised for notable evolution by 2026, shaped by shifts in construction practices, material preferences, and regulatory standards. Below are key trends expected to influence the market in the coming years:

1. Rising Demand in Residential and Commercial Construction

The expansion of urban infrastructure and growth in residential developments—particularly in emerging economies—are driving demand for durable and cost-effective railing solutions. Galvanized pipe railings, known for their strength and corrosion resistance, are increasingly favored in multi-family housing, commercial buildings, and industrial facilities. This trend is expected to continue through 2026, supported by ongoing investments in smart cities and affordable housing projects.

2. Emphasis on Sustainability and Longevity

With increased focus on sustainable building materials, galvanized steel is gaining traction due to its recyclability and long service life. The hot-dip galvanization process provides a protective zinc coating that significantly reduces maintenance and replacement needs, aligning with green building certifications such as LEED. By 2026, environmental considerations are anticipated to play a central role in material selection, benefiting galvanized pipe railing adoption.

3. Technological Advancements in Coating and Fabrication

Innovations in galvanization techniques—including improved zinc alloy coatings and automated fabrication processes—are enhancing the performance and aesthetic versatility of pipe railings. Prefabricated and modular galvanized railing systems are becoming more popular due to faster installation and consistent quality. These advancements are expected to lower labor costs and expand market reach into DIY and mid-tier renovation sectors.

4. Regulatory and Safety Standards Driving Adoption

Stringent building codes and safety regulations, especially in North America and Europe, are mandating the use of robust railing systems in public and private buildings. Galvanized pipe railings meet or exceed many of these requirements due to their structural integrity and resistance to environmental degradation. As regulations tighten by 2026, especially in coastal and high-moisture areas, demand for corrosion-resistant railings is projected to grow.

5. Competitive Pressure from Alternative Materials

Despite its advantages, galvanized pipe railing faces competition from materials such as stainless steel, aluminum, and composite systems. Aluminum, in particular, is lighter and does not rust, appealing to designers seeking modern aesthetics. However, galvanized steel maintains a cost-performance edge, especially in heavy-duty applications. Market players are responding by offering hybrid designs and powder-coated finishes to improve visual appeal without sacrificing durability.

6. Regional Market Dynamics

Asia-Pacific is expected to emerge as the fastest-growing market by 2026, fueled by rapid urbanization in countries like India, Indonesia, and Vietnam. North America and Europe will maintain steady demand, driven by infrastructure renewal and retrofitting projects. Meanwhile, government initiatives promoting industrialization in Africa and the Middle East may open new opportunities for galvanized railing suppliers.

In conclusion, the 2026 outlook for galvanized pipe railing is positive, supported by structural demand, technological progress, and sustainability trends. Manufacturers who innovate in design, improve supply chain efficiency, and align with green building standards will be best positioned to capitalize on expanding market opportunities.

Common Pitfalls When Sourcing Galvanized Pipe Railing (Quality & IP)

Sourcing galvanized pipe railing involves several potential pitfalls that can compromise safety, longevity, and compliance. Being aware of these issues—particularly regarding material quality and intellectual property (IP)—is essential for making informed procurement decisions.

Poor Galvanization Quality

One of the most frequent issues is inadequate or inconsistent galvanization. Low-quality galvanized coatings may be too thin, unevenly applied, or improperly cured, leading to premature rust and corrosion—especially in outdoor or high-moisture environments. This not only affects aesthetics but also structural integrity over time.

Use of Substandard Base Materials

Some suppliers may use low-grade steel pipes that do not meet ASTM or other industry standards (e.g., ASTM A53 or A135). These pipes may have inconsistent wall thickness, poor weld integrity, or lower tensile strength, increasing the risk of failure under load or impact.

Inadequate Coating Thickness

The zinc coating on galvanized pipe should meet minimum thickness requirements (typically conforming to ASTM A123). Suppliers cutting corners may provide pipes with insufficient zinc layers, reducing corrosion resistance and shortening the lifespan of the railing system.

Misrepresentation of “Galvanized” Finish

Not all galvanized finishes are equal. Some suppliers may pass off painted or electro-galvanized (thin-layer) pipes as hot-dip galvanized. Hot-dip galvanizing provides a thicker, more durable coating, and mistaking alternatives for true hot-dip galvanizing can lead to premature degradation.

Lack of Certifications and Traceability

Reputable suppliers provide material test reports (MTRs) and certification that the pipe meets required standards. Sourcing without these documents increases the risk of receiving non-compliant materials, which can lead to project delays, rework, or safety hazards.

Intellectual Property (IP) Infringement

Some railing designs—especially custom or architecturally significant profiles—may be protected by design patents or registered trademarks. Sourcing from manufacturers or suppliers who replicate these designs without authorization exposes buyers to legal liability, including claims of IP infringement, fines, or project stoppages.

Use of Counterfeit or Knockoff Components

In global supply chains, especially when sourcing from low-cost regions, there is a risk of receiving counterfeit fittings or pre-fabricated sections that mimic branded products. These knockoffs often fail to meet mechanical or safety standards and may lack proper IP licensing.

Inconsistent Welding and Fabrication Standards

Even with high-quality pipe, poor welding or fabrication practices can undermine the system. Look for inconsistent welds, misaligned joints, or lack of quality control during fabrication—issues that compromise both safety and appearance.

Failure to Meet Local Building Codes

Galvanized pipe railings must comply with local building codes (e.g., IBC, OSHA, or ADA requirements for height, spacing, and load capacity). Sourcing without verifying code compliance can result in failed inspections and costly modifications.

Limited Warranty or Support

Suppliers offering little or no warranty on materials or workmanship may indicate low confidence in their product quality. A reputable supplier should stand behind their galvanized railing systems with clear warranty terms covering corrosion and structural performance.

Avoiding these pitfalls requires due diligence: vetting suppliers, demanding certifications, verifying IP rights for designs, and insisting on compliance with applicable standards and regulations.

Logistics & Compliance Guide for Galvanized Pipe Railing

Product Overview and Classification

Galvanized pipe railings are structural components commonly used in construction, industrial, and architectural applications for safety and support. They consist of steel pipes coated with a protective layer of zinc (galvanization) to resist corrosion. These products are typically classified under HTS Code 7306.61 or 7306.69 depending on dimensions and composition, which is essential for accurate international shipping and tariff determination.

Packaging and Handling Requirements

Proper packaging is critical to maintain the integrity of galvanized pipe railings during transit. Pipes should be bundled securely using steel or nylon strapping, with wooden or plastic end caps to prevent damage to threads or cut edges. Each bundle must be clearly labeled with product specifications, batch number, and handling instructions (e.g., “Do Not Stack,” “Protect from Moisture”). For export, materials must be free of soil and organic contaminants to comply with phytosanitary regulations.

Domestic and International Shipping Regulations

When transporting galvanized pipe railings domestically (e.g., within the U.S.), standard freight regulations apply, with attention to load securement per FMCSA guidelines. For international shipments, compliance with IMDG (sea), IATA (air), or ADR (road, in Europe) may be required if accompanying hazardous materials (e.g., cleaning solvents) are present. While galvanized steel itself is non-hazardous, proper documentation including a commercial invoice, packing list, and bill of lading must be maintained.

Import/Export Documentation and Customs Clearance

Ensure complete documentation for customs clearance, including:

– Commercial Invoice (indicating value, quantity, and country of origin)

– Packing List (detailing dimensions, weight, and packaging type)

– Certificate of Origin (required for preferential tariff treatment under trade agreements)

– Bill of Lading or Air Waybill

Some destinations may require a test report or conformity certificate confirming compliance with local building or material standards (e.g., ASTM A123 for zinc coating thickness).

Regulatory Compliance and Standards

Galvanized pipe railings must meet relevant industry standards to ensure safety and durability:

– ASTM A53/A53M: Standard specification for pipe, steel, black and hot-dipped, zinc-coated, welded and seamless

– ASTM A123/A123M: Standard for zinc (hot-dip galvanized) coatings on iron and steel products

– OSHA 1910.29 and 1926.502: Requirements for fall protection systems, including railing strength and height

– International Building Code (IBC): Specifies load and dimensional requirements for guardrails

Compliance with these standards is often mandatory for project approval and regulatory inspections.

Environmental and Safety Considerations

Galvanizing involves zinc, which is regulated under environmental laws such as REACH (EU) and TSCA (U.S.). Ensure zinc coating processes comply with local emissions and waste disposal regulations. During transportation and handling, workers should wear appropriate PPE to prevent cuts or exposure to metal dust, especially during cutting or welding operations on site.

Destination-Specific Compliance

Different countries may have additional requirements:

– Canada: Must meet CSA G164 standards for hot-dip galvanizing; use B335 for customs documentation

– European Union: Requires CE marking if part of a construction product under CPR (Construction Products Regulation)

– Australia: Complies with AS/NZS 4680 for zinc coatings; import permits may be needed based on volume

Verify local building codes and conformity assessment procedures before shipment.

Storage and On-Site Management

Upon delivery, galvanized pipe railings should be stored on flat, elevated surfaces under cover to avoid moisture accumulation and potential white rust formation. Avoid contact with acidic or alkaline materials. Rotate stock using FIFO (First In, First Out) to ensure coating quality over time, especially in humid environments.

Non-Compliance Risks and Mitigation

Failure to comply with logistics or regulatory standards can result in customs delays, fines, rejected shipments, or safety liabilities. Mitigate risks by:

– Conducting pre-shipment compliance audits

– Partnering with certified freight forwarders experienced in steel products

– Maintaining up-to-date technical documentation and test reports

– Training staff on handling and regulatory requirements

Adhering to this guide ensures efficient, safe, and lawful transportation and use of galvanized pipe railing systems globally.

In conclusion, sourcing galvanized pipe railing offers a durable, cost-effective, and low-maintenance solution for a wide range of residential, commercial, and industrial applications. The corrosion resistance provided by the galvanization process ensures longevity, even in harsh weather conditions, making it ideal for outdoor use. When sourcing, it is essential to consider factors such as material quality, compliance with industry standards, supplier reliability, and total cost—including shipping and installation. By carefully evaluating suppliers and specifications, buyers can secure a high-performance railing system that combines strength, safety, and aesthetic appeal. Ultimately, galvanized pipe railing proves to be a smart investment for projects requiring resilience and value over time.