The global galvanized metal ceiling market is experiencing steady growth, driven by rising demand for durable, corrosion-resistant, and low-maintenance building materials in commercial and industrial construction. According to Grand View Research, the global metal ceiling market was valued at USD 5.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030, with galvanized steel emerging as a preferred material due to its longevity and cost-efficiency. Similarly, Mordor Intelligence forecasts a CAGR of approximately 6.8% for the metal ceilings market through 2029, citing increased infrastructure development and the adoption of sustainable building practices as key growth catalysts. As demand surges, a select group of manufacturers has risen to prominence by combining advanced coating technologies, scalable production, and compliance with international quality standards. Below, we highlight the top 8 galvanized metal ceiling manufacturers shaping the future of modern architectural spaces.

Top 8 Galvanized Metal Ceiling Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Berridge Manufacturing Co.

Domain Est. 1996

Website: berridge.com

Key Highlights: For over 50 years Berridge has worked to set the standard by designing, developing and manufacturing superior architectural metal products and technology….

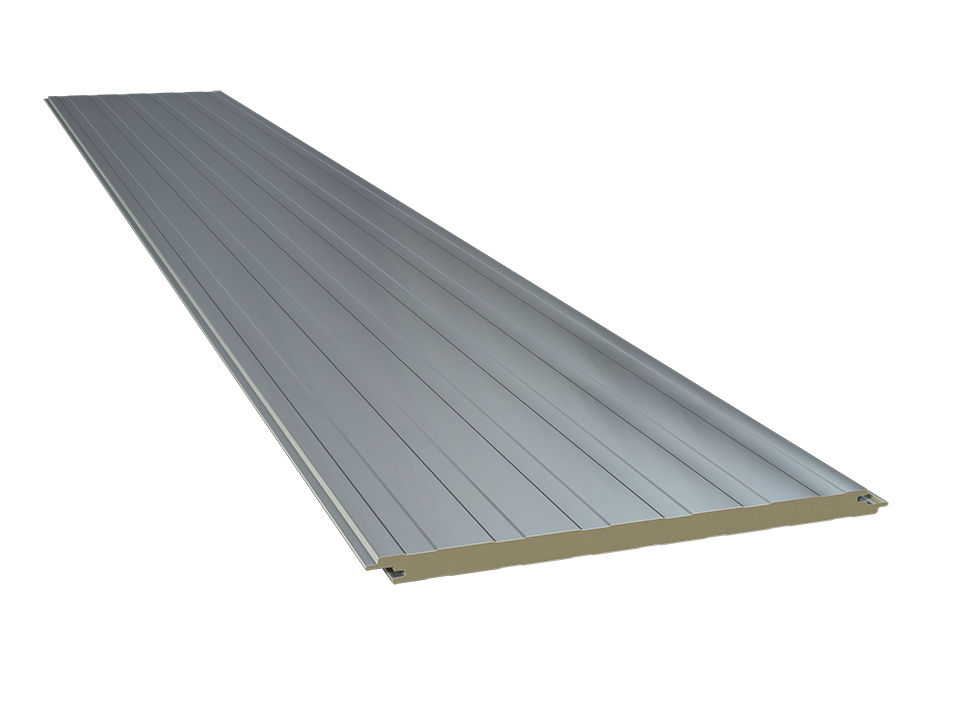

#2 CENTRIA: Insulated Metal Panel Systems

Domain Est. 1996

Website: centria.com

Key Highlights: CENTRIA provides comprehensive architectural services for insulated metal panel systems that include design assist, engineering, spec writing & installation ……

#3 McElroy Metal

Domain Est. 1996

Website: mcelroymetal.com

Key Highlights: McElroy Metal is the leading manufacturer of metal roofing, metal siding, and substructural components with locations across the United States. Learn more….

#4 Metal Roofing Manufacturer

Domain Est. 1997

Website: mbci.com

Key Highlights: MBCI manufactures the highest quality metal roofing & wall panels to meet your project’s aesthetic & structural standards. Request a quote today!…

#5 Armstrong World Industries

Domain Est. 1995

Website: armstrong.com

Key Highlights: Armstrong World Industries is a leader in the design, innovation and manufacture of ceiling and wall system solutions, transforming how people design, ……

#6 Ceiling, Grid & Wall …

Domain Est. 1999

Website: armstrongceilings.com

Key Highlights: Armstrong World Industries is a global leader in the design and manufacture of innovative commercial ceiling, suspension system and wall solutions….

#7 ClarkDietrich Building Systems

Domain Est. 2011

Website: clarkdietrich.com

Key Highlights: With ClarkDietrich, walls and ceilings do more than delineate spaces. They define continual technological progress in solving the most complex challenges in ……

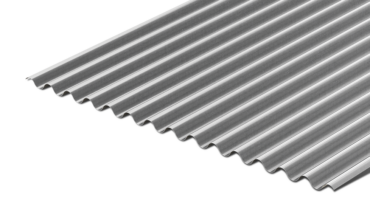

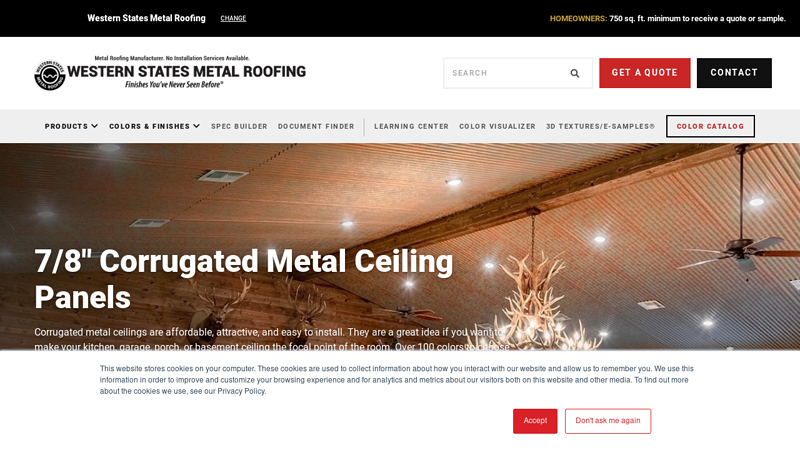

#8 Corrugated Metal Ceiling

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: Corrugated metal ceilings are affordable, attractive, and easy to install. They are a great idea if you want to make your kitchen, garage, porch, or basement ……

Expert Sourcing Insights for Galvanized Metal Ceiling

H2: 2026 Market Trends for Galvanized Metal Ceilings

The global market for galvanized metal ceilings is poised for significant transformation by 2026, driven by evolving construction practices, sustainability mandates, and technological advancements in material science. Key trends shaping this sector include increased demand in commercial and industrial infrastructure, growing emphasis on eco-friendly building materials, and the integration of smart building technologies.

-

Rising Demand in Urban and Industrial Construction

As urbanization accelerates, particularly in Asia-Pacific and emerging markets in Africa and Latin America, there is a surge in construction of commercial complexes, airports, data centers, and industrial warehouses. Galvanized metal ceilings are gaining preference due to their durability, fire resistance, and low maintenance. Their ability to withstand harsh environments makes them ideal for industrial applications, contributing to market expansion. -

Sustainability and Green Building Certifications

Environmental regulations and the push for LEED, BREEAM, and other green building certifications are influencing material selection. Galvanized steel is 100% recyclable and has a long service life with minimal environmental impact, making it a sustainable choice. By 2026, architects and developers are expected to increasingly specify galvanized metal ceilings to meet stringent sustainability goals and reduce carbon footprints. -

Design Innovation and Aesthetic Flexibility

Modern architectural trends favor sleek, minimalist designs with exposed structural elements. Galvanized metal ceilings support these aesthetics through customizable profiles, perforations, and finishes. Manufacturers are investing in R&D to offer improved coating techniques and color options, enabling integration into both industrial and high-end commercial interiors. -

Advancements in Coating Technology

Ongoing innovations in galvanization processes—such as zinc-aluminum-magnesium (ZAM) coatings—are enhancing corrosion resistance and extending product lifespan. These improvements reduce lifecycle costs and are expected to drive adoption in coastal and high-humidity regions where traditional materials degrade faster. -

Integration with Smart Building Systems

By 2026, galvanized metal ceilings are likely to serve as platforms for integrating smart technologies such as IoT sensors, LED lighting systems, HVAC components, and acoustic panels. Their robust structure supports the mounting of digital infrastructure, positioning them as functional elements within smart buildings. -

Regional Market Growth

North America and Europe are expected to maintain steady growth due to retrofitting projects and stringent building codes. Meanwhile, the Asia-Pacific region—led by China, India, and Southeast Asian nations—will likely record the highest CAGR, fueled by large-scale infrastructure development and industrialization. -

Supply Chain and Cost Dynamics

Fluctuations in raw material prices, especially zinc and steel, may impact production costs. However, economies of scale, localized manufacturing, and recycling initiatives are anticipated to mitigate these challenges. The trend toward vertical integration among key players will enhance supply chain resilience.

In conclusion, the 2026 outlook for galvanized metal ceilings is optimistic, underpinned by structural, environmental, and technological drivers. Stakeholders who prioritize innovation, sustainability, and adaptability to regional demands are likely to capture significant market share in this evolving landscape.

Common Pitfalls When Sourcing Galvanized Metal Ceilings (Quality and IP Rating)

Sourcing galvanized metal ceilings requires careful attention to both material quality and Ingress Protection (IP) ratings to ensure long-term performance and suitability for the intended environment. Overlooking key factors can lead to premature corrosion, structural failure, or inadequate protection against dust and moisture. Below are common pitfalls to avoid:

Inadequate Galvanization Quality

One of the most frequent issues is sourcing galvanized metal with insufficient zinc coating thickness or poor adherence. Low-quality galvanization—such as thin electro-galvanized layers instead of hot-dip galvanizing—can result in rapid rust formation, especially in humid or corrosive environments. Always verify coating weight (e.g., Z275 or higher for hot-dip galvanized steel) and request test certifications to confirm compliance with standards like ASTM A653 or ISO 1461.

Misunderstanding IP Ratings for Ceiling Applications

Many buyers assume that all metal ceilings are inherently dust- or water-resistant, but IP ratings vary significantly. Selecting a product without verifying its actual IP classification (e.g., IP20 vs. IP54) can lead to failures in environments requiring protection from moisture or particulates—such as restrooms, kitchens, or industrial facilities. Ensure the specified IP rating matches the environmental demands, and confirm whether the rating applies to the panel alone or the entire installed system, including joints and fixtures.

Ignoring Substrate and Coating Compatibility

Galvanized metal ceilings often feature additional coatings (e.g., powder coating or PVDF) for aesthetics and enhanced corrosion resistance. A common oversight is poor adhesion between the zinc layer and the topcoat due to improper surface preparation. This can lead to flaking, chalking, or delamination over time. Specify pre-treated substrates and request compatibility data or accelerated weathering test results for coated products.

Overlooking System Integrity Beyond the Panel

The IP rating and durability of a ceiling depend not only on the panel but also on the suspension system, joint design, and sealing methods. Using non-galvanized or incompatible hangers and runners can create galvanic corrosion points and compromise the entire ceiling’s longevity. Ensure all system components are galvanized or corrosion-resistant and designed to maintain the stated IP rating when fully assembled.

Relying Solely on Supplier Claims Without Verification

Suppliers may advertise “high-quality galvanized” or “IP55-rated” ceilings without providing third-party test reports or material certifications. Failing to independently verify these claims through documentation or on-site material testing increases the risk of receiving substandard products. Always request mill test certificates, IP test reports (per IEC 60529), and, if possible, conduct sample inspections before bulk ordering.

Neglecting Environmental and Installation Conditions

Even high-quality galvanized ceilings can fail if installed in unsuitable conditions without proper ventilation or if exposed to aggressive chemicals (e.g., chlorine in swimming pools). Failing to assess the specific environmental stressors during sourcing can result in unexpected degradation. Engage with engineers or consultants to match the ceiling specification to real-world exposure conditions.

Avoiding these pitfalls requires due diligence, clear technical specifications, and collaboration with reputable suppliers who provide full transparency on materials and performance data.

Logistics & Compliance Guide for Galvanized Metal Ceiling

Product Overview

Galvanized metal ceilings are durable, corrosion-resistant ceiling systems commonly used in commercial, industrial, and high-moisture environments. These panels are made from steel coated with a layer of zinc (galvanization) to enhance longevity and resistance to rust. Proper logistics planning and compliance with relevant standards are essential for safe handling, transportation, and installation.

Packaging and Handling

Galvanized metal ceiling panels are typically shipped in sealed, protective packaging to prevent scratches, moisture exposure, and mechanical damage. Panels should be stored horizontally on flat, dry surfaces, elevated off the ground, and covered to avoid condensation. During handling, use padded forklifts or lifting equipment to avoid denting or edge damage. Workers should wear gloves to prevent oil transfer from skin, which could compromise coatings.

Transportation Requirements

Shipments must be secured tightly on pallets using straps or shrink wrap to prevent shifting during transit. Transport vehicles should be weatherproof and equipped with adequate ventilation to minimize condensation. Avoid stacking heavy materials on top of ceiling panel loads. For international shipments, ensure compliance with Incoterms (e.g., FOB, CIF) and coordinate with carriers experienced in handling sheet metal products.

Storage Conditions

Store galvanized metal ceiling panels in a dry, well-ventilated indoor area with stable temperatures. Relative humidity should be kept below 60% to prevent white rust (zinc oxide formation). Avoid prolonged outdoor storage—even under cover—due to risk of moisture accumulation. Rotate stock using a first-in, first-out (FIFO) system to minimize aging-related degradation.

Regulatory Compliance

Galvanized metal ceilings must comply with regional building and safety standards. Key regulations include:

– International Building Code (IBC): Ensures structural and fire safety compliance.

– ASTM A653/A653M: Standard specification for steel sheet, zinc-coated (galvanized) by the hot-dip process.

– UL 263 / ASTM E119: Fire resistance testing for building construction materials.

– REACH & RoHS (EU): Restriction of hazardous substances in construction products.

– LEED & BREEAM: Environmental standards promoting sustainable materials; galvanized steel may contribute to credits due to recyclability.

Environmental and Safety Considerations

Galvanized steel is 100% recyclable and often contains recycled content, supporting sustainability goals. During cutting or installation, zinc fumes may be released when heated (e.g., welding), requiring proper ventilation and worker protection (respiratory gear). Dispose of off-cuts and packaging in accordance with local waste regulations.

Installation Compliance

Installation must follow manufacturer guidelines and local building codes. Ensure proper fastening techniques to avoid compromising the galvanized coating. Use compatible fasteners (e.g., stainless steel or zinc-plated) to prevent galvanic corrosion. Inspect panels prior to installation for coating damage; repair minor scratches with approved zinc-rich paint.

Documentation and Certification

Maintain documentation including:

– Material Test Reports (MTRs) verifying galvanized coating weight and steel grade

– Fire classification certificates

– Environmental Product Declarations (EPDs)

– CE Marking (for EU markets) or ICC-ES evaluation reports (for North America)

These documents are essential for project audits, building inspections, and LEED certification submissions.

Import/Export Considerations

For cross-border shipments, ensure Harmonized System (HS) code 7308.90 is correctly applied for prefabricated structural components. Check country-specific import duties, anti-dumping regulations (especially on Chinese steel products), and customs documentation requirements. Use certified freight forwarders familiar with metal product logistics.

Conclusion

Successful logistics and compliance for galvanized metal ceilings require attention to handling, environmental conditions, regulatory standards, and documentation. Partnering with certified suppliers and experienced logistics providers ensures product integrity and adherence to all legal and safety requirements throughout the supply chain.

In conclusion, sourcing galvanized metal ceiling panels offers a durable, cost-effective, and low-maintenance solution for both commercial and residential applications. The galvanization process provides excellent corrosion resistance, extending the lifespan of the ceiling system, especially in humid or harsh environments. Additionally, galvanized metal ceilings offer design flexibility with various profiles, finishes, and configurations to meet aesthetic and functional requirements. When sourcing, it’s essential to partner with reputable suppliers who provide high-quality, compliant materials—meeting relevant standards such as ASTM A653—to ensure performance and longevity. Careful consideration of lead times, logistics, and lifecycle costs will further support a successful project outcome. Overall, galvanized metal ceilings represent a smart investment in sustainable and resilient building design.