The global fiberglass market is experiencing robust expansion, driven by rising demand across aerospace, automotive, construction, and renewable energy sectors. According to Mordor Intelligence, the fiberglass market was valued at USD 10.91 billion in 2023 and is projected to reach USD 14.54 billion by 2029, growing at a CAGR of 4.87% during the forecast period. This growth is fueled by the material’s high strength-to-weight ratio, corrosion resistance, and increasing adoption in wind turbine blades and lightweight automotive components. As the industry scales, a select group of manufacturers—particularly those within the G10 fiberglass segment, known for its high mechanical strength and electrical insulation properties—have emerged as key players shaping global supply chains. Below, we spotlight the top 10 G10 fiberglass manufacturers leading innovation, production capacity, and market penetration in this high-performance composites landscape.

Top 10 G10 Fiberglass Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

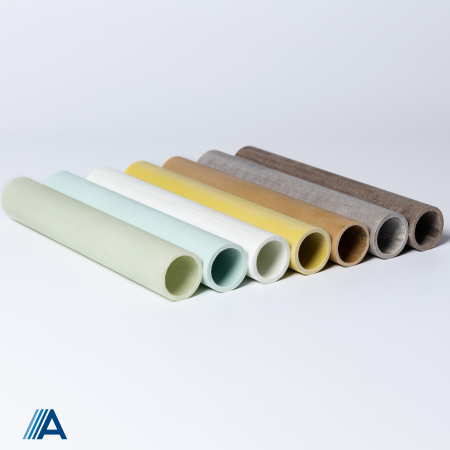

#1 Acculam® Fast Lead Times, Quality Laminates

Domain Est. 1997

Website: acculam.com

Key Highlights: Acculam® is the premier manufacturer of Industrial Thermoset Laminate Plastics like Epoxyglas G10/FR4, Epoxyglas G11/FR5 & GPO-3 in the USA. Acculam was ……

#2 G

Domain Est. 1996

Website: currentcomposites.com

Key Highlights: G-10 is a thermosetting industrial laminated plastic consisting of a woven glass cloth material and an epoxy resin matrix. First introduced in the 1950’s, G-10 ……

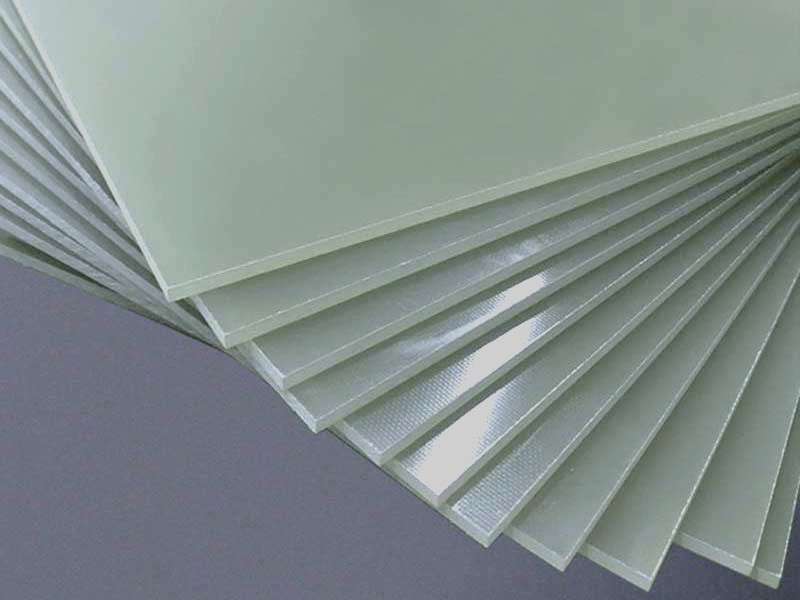

#3 G

Domain Est. 1997

Website: professionalplastics.com

Key Highlights: Rating 5.0 (13) · 3-day returnsG-10/FR-4 is a thermosetting industrial laminate consisting of a continuous filament glass cloth material with an epoxy resin binder. Call Us 1-8…

#4 G10 & G10FR4 Laminates

Domain Est. 1999

Website: itenindustries.com

Key Highlights: G10 and G10FR4 Laminates from Iten Industries deliver superior strength, insulation, and reliability for demanding industrial applications….

#5 GLASS EPOXY FIBRE G10 Sheet&Rod

Domain Est. 2016

Website: abvglobal.com.my

Key Highlights: GLASS EPOXY FIBRE G10 Sheet&Rod Penang, Malaysia Supplier, Provider, Manufacturer, ABV Global Holdings Sdn Bhd is an engineering plastic and rubber product ……

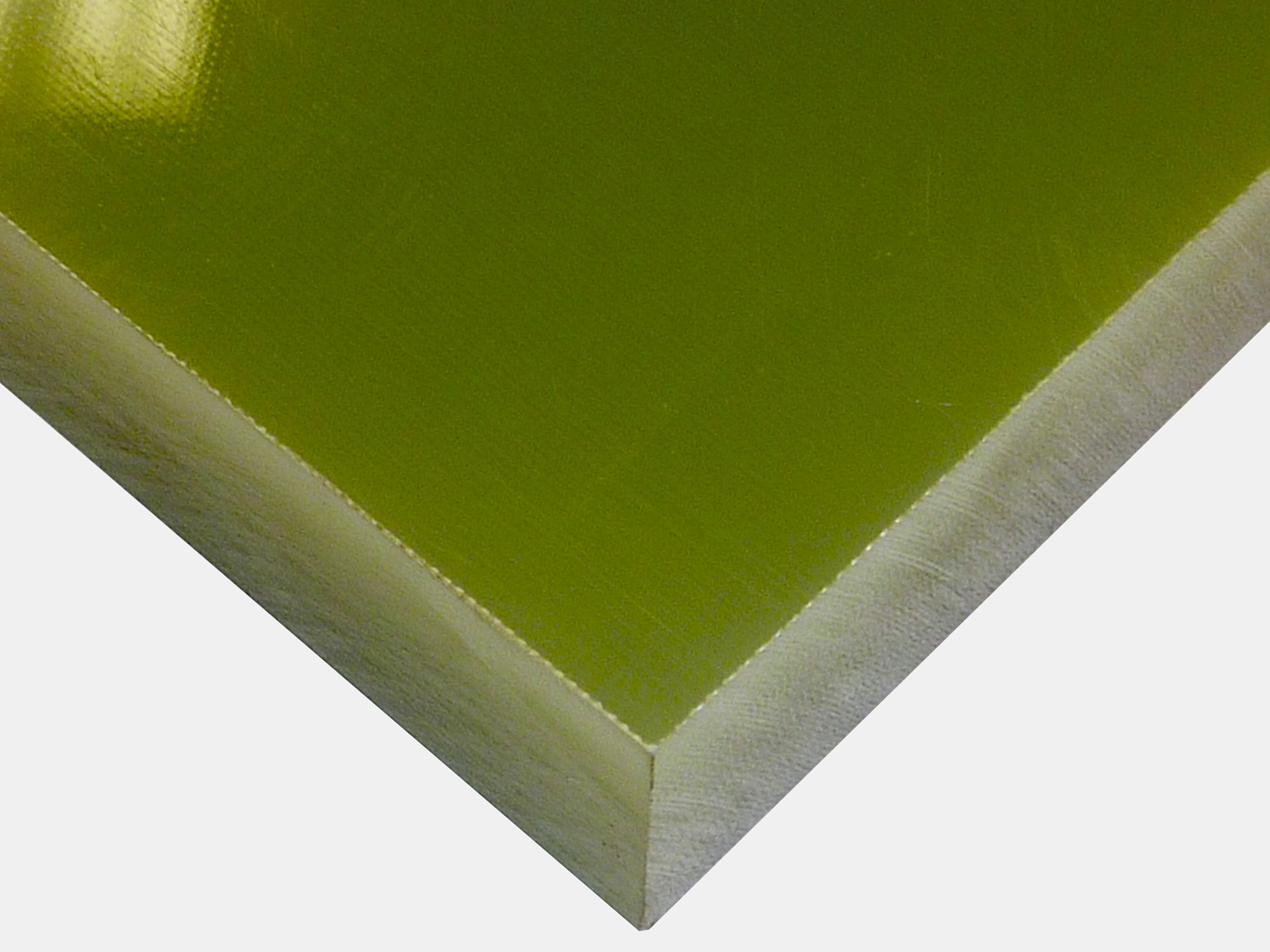

#6 G10/FR-4 Glass Epoxy

Domain Est. 1996

Website: piedmontplastics.com

Key Highlights: G10/FR-4 glass epoxy are high-pressure fiberglass laminates made by stacking multiple layers of glass cloth saturated with epoxy resin and compressing them ……

#7 G10

Domain Est. 1996

Website: atlasfibre.com

Key Highlights: G-10 consists of woven fiberglass and an epoxy resin binder. Originally used in printed circuits, it was introduced in the 1950s and was the first glass epoxy ……

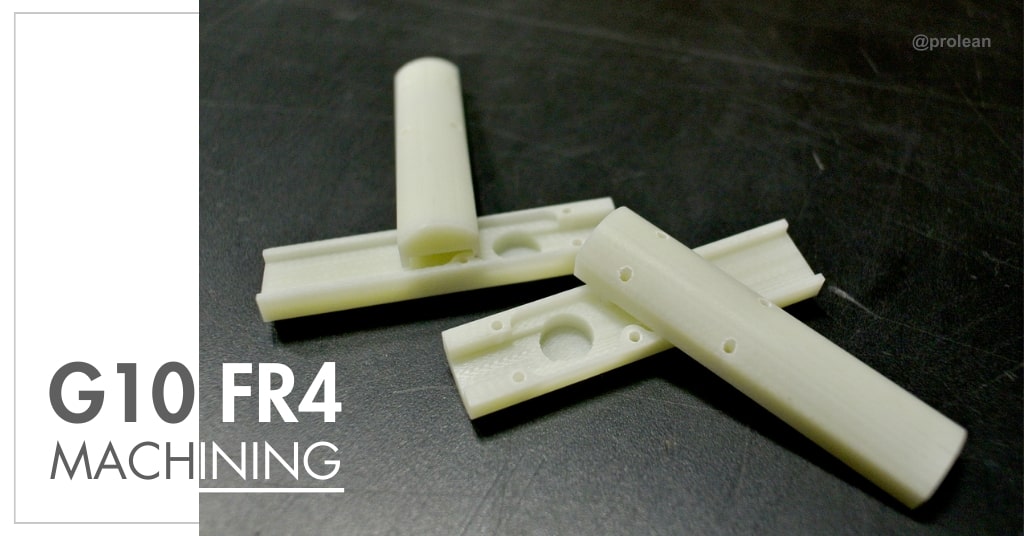

#8 G10/FR4 Machining

Domain Est. 2001

Website: americanmicroinc.com

Key Highlights: Garolite G10/FR4 is a thermoset reinforced glass-epoxy laminate first introduced in the 1950s. It is made from an alkali-free electrical glass cloth….

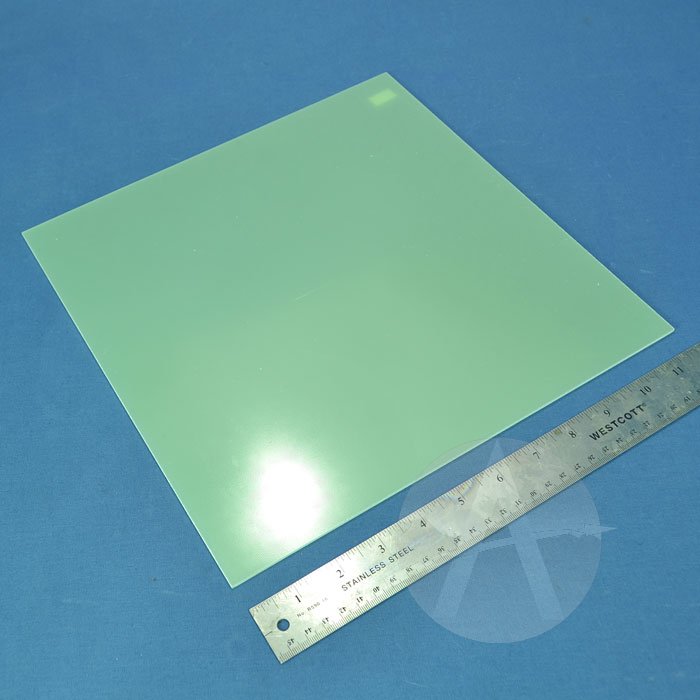

#9 G10 Epoxy Fiberglass Laminated Sheet

Domain Est. 2021

Website: xx-insulation.com

Key Highlights: NEMA Grade G-10 materials are 7628 fiberglass reinforced laminates,bonded with epoxy resin.With high mechanical and dielectric properties,good heat and wave ……

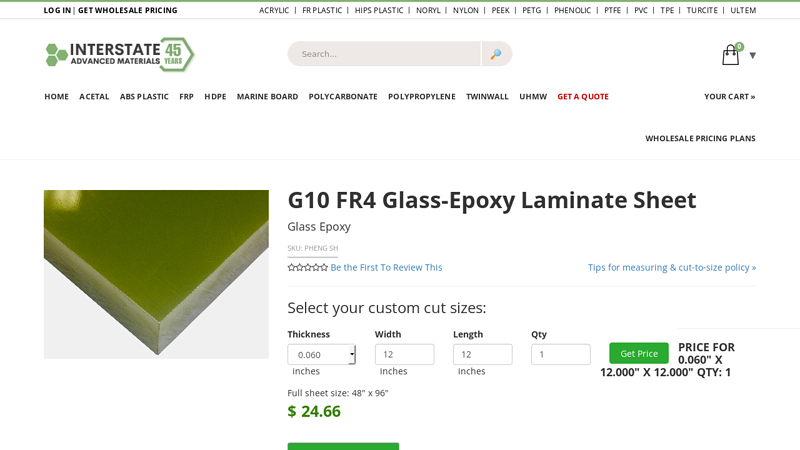

#10 G10 FR4 Glass

Domain Est. 2022

Website: interstateam.com

Key Highlights: In stock 6–7 day deliveryG-10/FR4 phenolic sheet features great electrical properties and high mechanical strength. Its low water absorption and dissipation factors make it a good …

Expert Sourcing Insights for G10 Fiberglass

H2: 2026 Market Trends for G10 Fiberglass

The global G10 fiberglass market is poised for significant transformation by 2026, driven by technological advancements, expanding industrial applications, and increasing demand for high-performance composite materials. G10, a high-pressure fiberglass laminate made from epoxy resin and woven glass fabric, is valued for its excellent mechanical strength, electrical insulation, and resistance to moisture and heat. The following analysis outlines key market trends expected to shape the G10 fiberglass industry in 2026.

1. Rising Demand in Electrical and Electronics Industries

The electrical and electronics sector remains the largest consumer of G10 fiberglass, particularly in printed circuit boards (PCBs), insulating components, and switchgear. As global electrification accelerates and demand for smart infrastructure grows, the need for reliable, high-dielectric-strength materials like G10 is expected to rise. The expansion of 5G networks, electric vehicles (EVs), and renewable energy systems will further bolster market growth.

2. Growth in Aerospace and Defense Applications

The aerospace and defense industries are increasingly adopting lightweight, durable composites to enhance fuel efficiency and performance. G10 fiberglass, with its high strength-to-weight ratio and dimensional stability under extreme conditions, is being integrated into avionics housings, radar systems, and non-structural components. Government investments in defense modernization, especially in North America and Asia-Pacific, are expected to drive demand.

3. Expansion in Renewable Energy Infrastructure

With the global push toward clean energy, G10 is finding growing use in wind turbines, solar panel frames, and energy storage systems. Its resistance to environmental degradation makes it ideal for outdoor and harsh-climate applications. By 2026, increased installations of offshore wind farms and distributed solar energy systems are likely to elevate the need for durable composite insulation materials like G10.

4. Technological Advancements and Material Innovation

Manufacturers are investing in R&D to improve the thermal stability and flame retardancy of G10 laminates. Innovations such as halogen-free epoxy systems and nano-reinforced composites are expected to broaden G10’s applicability in high-temperature and safety-critical environments. These advancements will support compliance with evolving environmental and safety regulations.

5. Regional Market Dynamics

Asia-Pacific is projected to dominate the G10 fiberglass market by 2026, fueled by rapid industrialization, expanding electronics manufacturing in China and India, and government support for infrastructure and clean energy. North America and Europe will maintain strong demand due to advanced manufacturing ecosystems and stringent safety standards in aerospace and electrical sectors.

6. Sustainability and Supply Chain Considerations

Environmental concerns are prompting manufacturers to explore recyclable or bio-based alternatives. However, G10’s long service life and durability contribute to its sustainability profile. Efforts to optimize production processes and reduce volatile organic compound (VOC) emissions will be critical for maintaining market competitiveness.

In conclusion, the G10 fiberglass market in 2026 will be shaped by increasing industrial adoption, technological innovation, and a global shift toward electrification and sustainability. Companies that invest in advanced formulations, expand into emerging markets, and align with environmental standards are likely to gain a strategic advantage in this evolving landscape.

Common Pitfalls When Sourcing G10 Fiberglass (Quality and IP)

Sourcing G10 fiberglass involves navigating several potential challenges related to material quality and intellectual property (IP) concerns. Overlooking these pitfalls can lead to product failures, supply chain disruptions, or legal issues.

Inconsistent Material Quality

One of the most prevalent issues when sourcing G10 fiberglass is variability in material quality. G10 is a high-pressure fiberglass laminate made from epoxy resin and woven glass fabric, and its performance hinges on precise manufacturing processes. Sourcing from suppliers with inconsistent quality control can result in:

- Poor mechanical strength: Variations in resin content or curing processes may reduce tensile and flexural strength, leading to premature part failure.

- Dimensional instability: Inadequate curing or improper lamination can cause warping, delamination, or inconsistent thickness.

- Electrical property inconsistencies: G10 is often used in electrical insulation applications; inconsistent resin distribution or moisture absorption can compromise dielectric strength.

To avoid this, verify supplier certifications (e.g., NEMA LI 1, MIL-I-24768), request material test reports (MTRs), and conduct batch testing.

Lack of Traceability and Certification

Many suppliers, especially those in less-regulated markets, may not provide full traceability or proper documentation. This becomes critical in regulated industries such as aerospace, defense, or medical devices. Without proper certification:

- It’s difficult to ensure compliance with industry standards.

- Recalls or audits may be complicated due to missing batch or production data.

- Risk increases for counterfeit or substandard materials entering the supply chain.

Always require mill certificates, lot traceability, and proof of compliance with relevant standards.

Intellectual Property (IP) Risks

When sourcing G10, especially custom formulations or shapes, IP concerns can arise:

- Reverse engineering: Suppliers may replicate proprietary designs or material blends if proper non-disclosure agreements (NDAs) or IP clauses are not in place.

- Unauthorized use: There’s a risk that tooling or specifications provided for custom orders could be used for competing products.

- Brand infringement: Some suppliers may falsely claim to provide “brand-equivalent” or “G10” materials that infringe on registered trademarks or patented manufacturing processes.

Mitigate these risks by using strong contractual agreements, specifying IP ownership clearly, and conducting due diligence on supplier reputation.

Misrepresentation of Material Specifications

Some suppliers may label materials as “G10” even if they don’t meet standard specifications. For example:

- Using polyester instead of epoxy resin (resulting in FR-4 or other grades, not true G10).

- Substituting lower-grade fiberglass weaves or fillers.

- Claiming flame resistance without proper UL testing (true G10 is not inherently flame-retardant unless modified).

Always validate claims through independent testing or third-party verification.

Supply Chain Vulnerability

Relying on a single or unproven supplier can expose your operation to supply disruptions. Geopolitical issues, logistical delays, or lack of scalable production capacity can all impact availability. Diversifying suppliers and maintaining safety stock can reduce this risk.

Conclusion

To avoid these pitfalls, conduct thorough due diligence on potential suppliers, insist on documentation and testing, protect IP through legal agreements, and prioritize partners with a proven track record in high-performance composite materials.

Logistics & Compliance Guide for G10 Fiberglass

Overview of G10 Fiberglass

G10 Fiberglass is a high-pressure thermoset laminate made from epoxy resin and woven fiberglass cloth. Known for its excellent strength-to-weight ratio, electrical insulation properties, and resistance to moisture and chemicals, G10 is widely used in aerospace, electrical, and industrial applications. Due to its composite nature, proper handling, storage, transportation, and regulatory compliance are essential.

Shipping and Transportation

G10 Fiberglass is generally non-hazardous and can be shipped via standard freight methods including air, sea, and ground transport. However, proper packaging and handling are required to prevent damage.

-

Packaging Requirements:

Use protective wrapping (e.g., bubble wrap, plastic film) and rigid outer packaging (e.g., wooden crates or corrugated boxes) to prevent chipping, cracking, or surface abrasion during transit. -

Labeling:

Clearly label packages with “Fragile,” “This Side Up,” and the material type (G10 Fiberglass). Include handling instructions if the material is precision-cut or sensitive to moisture. -

Stacking and Weight Distribution:

Avoid stacking heavy loads on top of G10 panels to prevent warping or cracking. Use pallets and secure loads with straps or shrink wrap.

Storage Conditions

Proper storage ensures material integrity and performance.

-

Environment:

Store G10 in a dry, climate-controlled environment with temperatures between 15°C and 30°C (59°F–86°F) and relative humidity under 60%. Moisture exposure can compromise mechanical properties over time. -

Shelf Life:

G10 has an indefinite shelf life if stored properly. However, inspect for signs of delamination or surface degradation before use after long-term storage. -

Handling:

Use clean gloves and tools to prevent contamination. Avoid dragging materials across surfaces to prevent scratches.

Regulatory Compliance

G10 Fiberglass is not classified as a hazardous material under most international regulations, but compliance with regional standards is required.

-

Globally Harmonized System (GHS):

G10 is typically not subject to GHS labeling, as it is a solid composite material. However, safety data sheets (SDS) should be available for processing stages (e.g., cutting, sanding) where dust may be generated. -

OSHA and WHMIS (North America):

While the solid form of G10 is not regulated, dust from machining operations may contain respirable particles. Use local exhaust ventilation and provide appropriate PPE (respirators, eye protection). -

REACH and RoHS (European Union):

G10 generally complies with RoHS (Restriction of Hazardous Substances) and REACH regulations, but suppliers should provide compliance documentation confirming the absence of restricted substances. -

TSCA (USA):

G10 is compliant with the Toxic Substances Control Act (TSCA) as a manufactured article. No pre-manufacture notification (PMN) is required.

Environmental and Disposal Considerations

-

Recycling:

G10 is not easily recyclable due to its thermoset nature. Incineration or landfill disposal may be necessary. Check local waste regulations. -

Dust Management:

Fiberglass dust generated during cutting or drilling is considered a nuisance dust. Use HEPA-filtered vacuum systems and dispose of waste in accordance with local industrial waste guidelines.

Import/Export Documentation

When shipping internationally, ensure compliance with customs requirements.

-

HS Code:

Common HS Code: 3926.30 (Other articles of plastics, including of reinforced plastics). Confirm with local customs authorities. -

Certificates:

Provide a Certificate of Conformance (CoC) and Material Test Report (MTR) upon request. Some industries (e.g., aerospace) may require additional traceability documentation. -

Export Controls:

Generally, G10 is not subject to ITAR or EAR restrictions unless used in defense-related applications. Verify end-use and destination country requirements.

Summary

G10 Fiberglass is a robust and versatile material with straightforward logistics under normal conditions. Adherence to proper handling, storage, and regulatory practices ensures safety, performance, and compliance. Always consult material safety data sheets and local regulations to address specific operational or regional requirements.

Conclusion for Sourcing G10 Fiberglass

Sourcing G10 fiberglass requires a strategic approach that balances material quality, supplier reliability, cost efficiency, and specific application requirements. G10 is a high-performance composite known for its exceptional strength, electrical insulation, and resistance to moisture and heat, making it ideal for applications in aerospace, electronics, military, and industrial manufacturing.

When sourcing G10 fiberglass, it is essential to partner with reputable suppliers or manufacturers who provide certified materials meeting industry standards (such as NEMA LE or MIL specifications). Factors such as resin content, glass weave style, thickness tolerance, and flatness should be carefully evaluated to ensure compatibility with machining or end-use conditions.

Additionally, lead times, minimum order quantities, and geographic logistics can significantly impact procurement decisions—especially for large-scale or time-sensitive projects. Evaluating multiple suppliers, requesting material test reports, and obtaining samples for performance validation are recommended best practices.

In conclusion, successful sourcing of G10 fiberglass hinges on a thorough understanding of technical specifications, rigorous supplier vetting, and alignment with project demands. By prioritizing quality, consistency, and supply chain reliability, organizations can secure high-performance G10 material that meets both technical and operational goals.