The global fuse switch box market is experiencing steady expansion, driven by rising demand for electrical safety solutions across residential, commercial, and industrial sectors. According to Grand View Research, the global electrical enclosures market—of which fuse switch boxes are a critical component—was valued at USD 20.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2030. This growth is fueled by increasing infrastructure development, stringent safety regulations, and the proliferation of renewable energy installations requiring reliable power distribution systems. Additionally, urbanization and smart city initiatives in emerging economies are accelerating the adoption of advanced fuse protection devices. As demand surges, manufacturers are focusing on innovation, durability, and compliance with international standards to capture market share. In this competitive landscape, nine key players have emerged as leaders, combining technological expertise, global distribution networks, and strong R&D investment to meet the evolving needs of modern electrical systems.

Top 9 Fuse Switch Box Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

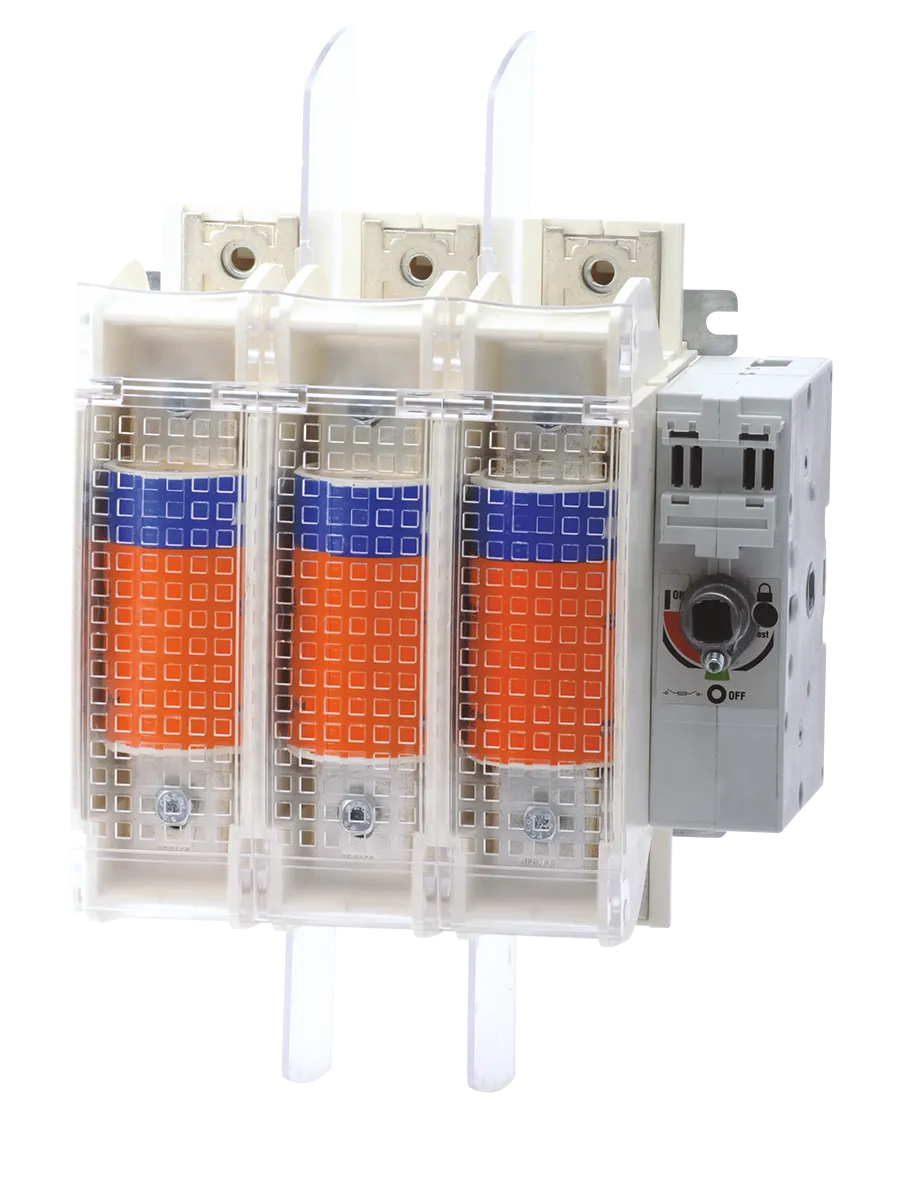

#1 IEC Fuse Switch Disconnectors

Domain Est. 2006

Website: us.mersen.com

Key Highlights: IEC Fuse Switch Disconnectors … Providing the widest range of circuit protection products in the industry means that we offer solutions for everyone from OEMs …Missing: box ma…

#2 Fuses and fuse holders

Domain Est. 1996

Website: eaton.com

Key Highlights: Bussmann series fuses play a major role in industrial or commercial facilities by providing reliable, maximum protection to power systems….

#3 Circuit Protection, Fuses, Power Control & Sensing Solutions

Domain Est. 1996

Website: littelfuse.com

Key Highlights: Littelfuse is a global manufacturer of leading technologies in circuit protection, power control & sensing. Our products are found in automotive ……

#4 OptiFuse

Domain Est. 2000

Website: optifuse.com

Key Highlights: Trusted stocking manufacturer of fuses and circuit breakers. In stock and ready to ship. Various styles of circuit protection fuses for automotive, electronic, ……

#5 Carling Technologies

Domain Est. 2000

Website: carlingtech.com

Key Highlights: Carling Technologies is a switch manufacturer and circuit breaker manufacturer with registered manufacturing facilities and technical sales offices worldwide ……

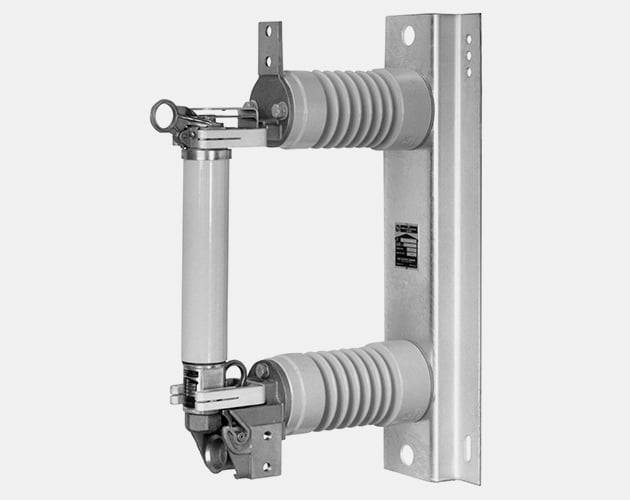

#6 S&C Electric Company

Domain Est. 1995 | Founded: 1911

Website: sandc.com

Key Highlights: S&C Electric Company is a global provider of equipment and services for electric power systems. Founded in 1911, the Chicago-based company designs and ……

#7 Safety Switches and Disconnect Switches

Domain Est. 1997

Website: se.com

Key Highlights: Heavy Duty Safety Switches and VisiPacT isolate power in daily activities and emergencies, with key application as a lockout line of sight disconnect….

#8 Automotive Fuses

Domain Est. 1997

Website: mta.it

Key Highlights: MTA produces certified automotive fuses for electrical protection. Developed according to ISO Standards, MTA’s wide range includes blade fuses and strip ……

#9 FuseBox

Domain Est. 1999

Website: fusebox.co.uk

Key Highlights: Making Electricians Smile. FuseBox design and manufacture a wide range of low voltage electrical products for domestic and commercial applications. FuseBox aim ……

Expert Sourcing Insights for Fuse Switch Box

H2: 2026 Market Trends for Fuse Switch Boxes

The global fuse switch box market is poised for significant transformation by 2026, driven by technological advancements, regulatory shifts, and evolving energy demands. As industries and infrastructure continue to modernize, fuse switch boxes—critical components for electrical circuit protection and distribution—are adapting to meet growing requirements for safety, efficiency, and integration with smart systems.

One of the dominant trends shaping the 2026 landscape is the rising adoption of modular and compact fuse switch designs. With urbanization and space constraints in industrial and commercial installations, manufacturers are prioritizing space-saving solutions without compromising performance. These modular units offer easier maintenance, scalability, and faster installation, appealing to both new construction and retrofit projects.

Another key trend is the integration of fuse switch boxes with digital monitoring and predictive maintenance technologies. By 2026, smart fuse switch boxes equipped with IoT sensors and remote diagnostics are expected to gain substantial market share. These intelligent systems enable real-time monitoring of current, temperature, and fault conditions, enhancing operational reliability and reducing downtime—particularly in critical applications such as data centers, renewable energy installations, and smart grids.

The global push toward renewable energy is also influencing fuse switch box demand. Solar photovoltaic (PV) and wind energy systems require robust overcurrent protection, and fuse switch boxes tailored for DC applications in solar farms are seeing increased deployment. As countries accelerate their clean energy transitions under national climate goals, the need for specialized, high-voltage DC fuse switch solutions is expected to grow steadily through 2026.

Regulatory standards and safety compliance are becoming stricter worldwide, particularly in Europe and North America. Harmonization with IEC 60947 and UL 508 standards is driving innovation in arc flash protection, fault current interruption capacity, and environmental resilience. Manufacturers are investing in high-performance materials and design improvements to meet these requirements, further differentiating product offerings.

Additionally, sustainability is emerging as a competitive factor. By 2026, eco-friendly materials, recyclable enclosures, and energy-efficient manufacturing processes are expected to play a larger role in product development. End-users in both public and private sectors are increasingly favoring suppliers with strong environmental, social, and governance (ESG) commitments.

In summary, the 2026 fuse switch box market will be characterized by smart integration, miniaturization, renewable energy adaptation, and heightened safety standards. Companies that innovate in digital connectivity, sustainability, and application-specific design are likely to lead the market, capturing opportunities across industrial automation, infrastructure modernization, and green energy sectors.

Common Pitfalls When Sourcing Fuse Switch Box (Quality, IP)

Sourcing a fuse switch box involves more than just finding the lowest price—overlooking critical quality and Ingress Protection (IP) rating factors can lead to safety hazards, equipment failure, and costly downtime. Below are common pitfalls to avoid:

Inadequate IP Rating for the Environment

One of the most frequent mistakes is selecting a fuse switch box with an IP rating unsuitable for its operating environment. For example, using an IP44-rated enclosure outdoors or in wet industrial areas can allow dust and moisture ingress, leading to short circuits or corrosion. Always match the IP rating to the application—IP65 or higher for outdoor or washdown areas, and at least IP54 for indoor industrial settings.

Poor Quality Enclosure Materials

Low-cost fuse switch boxes may use substandard thermoplastics or thin metal housings that degrade under UV exposure, extreme temperatures, or mechanical stress. This compromises durability and safety. Ensure enclosures are made from UV-resistant polycarbonate, fiberglass, or corrosion-resistant metal (e.g., stainless steel or galvanized steel), depending on environmental demands.

Non-Compliant or Counterfeit Components

Sourcing from unreliable suppliers increases the risk of receiving non-compliant or counterfeit fuses, switches, or internal components. These may not meet IEC, UL, or local standards, posing serious fire and electrical hazards. Always verify certifications (e.g., CE, CCC, UL listing) and source from reputable manufacturers or authorized distributors.

Insufficient Current and Voltage Ratings

Selecting a fuse switch box with inadequate current or voltage ratings for the load can result in overheating, arcing, or catastrophic failure. Ensure the device is rated for the maximum expected load and system voltage, with appropriate safety margins. Don’t overlook ambient temperature derating, especially in hot environments.

Poor Sealing and Gland Quality

Even with a high IP rating, poor-quality cable glands, gaskets, or door seals can compromise protection. Look for robust, UV-stable gaskets and knockouts with proper sealing mechanisms. Inferior glands may loosen over time, allowing moisture and dust to enter.

Lack of Proper Mounting and Installation Features

Some low-quality fuse switch boxes lack secure mounting options or clear wiring compartments, making installation difficult and unsafe. Ensure the design includes adequate space for wiring, clear terminal markings, and robust mounting brackets to prevent vibration-related damage.

Ignoring Temperature and Environmental Ratings

Beyond IP ratings, consider the operating temperature range, resistance to chemicals, and flame retardancy (e.g., UL94 V-0). Using a box outside its specified temperature range can cause material brittleness or deformation, leading to enclosure failure.

Skipping Third-Party Testing and Documentation

Avoid suppliers who cannot provide test reports, material certifications, or compliance documentation. Reputable manufacturers conduct dielectric strength, temperature rise, and IP verification tests. Requesting and reviewing these documents helps verify quality and reliability.

By carefully evaluating IP ratings, material quality, compliance, and environmental suitability, buyers can avoid these common sourcing pitfalls and ensure safe, long-lasting performance of fuse switch boxes.

Logistics & Compliance Guide for Fuse Switch Box

This guide outlines the essential logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence of Fuse Switch Boxes. Adherence ensures safety, legal conformity, and efficient supply chain operations.

Product Overview

A Fuse Switch Box is an electrical distribution device that combines switching functionality with overcurrent protection via fuses. It is commonly used in industrial, commercial, and residential applications to safely isolate circuits and protect electrical systems from short circuits and overloads.

Regulatory Compliance

All Fuse Switch Boxes must comply with relevant international, national, and regional electrical safety standards. Key certifications include:

- IEC 60947-3: Low-voltage switchgear and controlgear – Part 3: Switches, disconnectors, switch-disconnectors, and fuse-combination units.

- UL 508: Standard for Industrial Control Equipment (for North American markets).

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- RoHS Compliance: Restriction of Hazardous Substances Directive (2011/65/EU) – ensures the product does not contain restricted materials such as lead, mercury, or cadmium.

- REACH: Registration, Evaluation, Authorisation and Restriction of Chemicals – ensures safe use of chemical substances.

- Local Approvals: Country-specific certifications (e.g., CCC for China, KC for South Korea, PSE for Japan) may be required depending on destination.

Ensure all units are labeled with appropriate certification marks and technical data (voltage, current rating, short-circuit capacity, etc.).

Packaging Requirements

To prevent damage during transit and ensure product integrity:

- Use robust, corrugated cardboard boxes with internal foam or molded inserts to secure the unit.

- Include moisture-resistant lining if shipping to humid or variable climates.

- Clearly label packages with:

- Product name and model number

- Quantity per box

- Gross and net weight

- “Fragile” and “This Side Up” handling indicators

- Compliance marks (CE, UL, etc.)

- Barcodes and batch/lot numbers for traceability

Storage Conditions

Store Fuse Switch Boxes in a clean, dry, and temperature-controlled environment:

- Temperature Range: 5°C to 40°C (41°F to 104°F)

- Relative Humidity: Max 70%, non-condensing

- Avoid direct sunlight, corrosive atmospheres, and proximity to strong electromagnetic sources.

- Keep packaging sealed until ready for installation to prevent dust or moisture ingress.

Transportation Guidelines

- Use enclosed, climate-controlled vehicles where possible, especially for international or long-distance transport.

- Secure loads to prevent shifting during transit.

- Avoid stacking beyond manufacturer-recommended limits to prevent crushing.

- For air freight, ensure compliance with IATA regulations—no hazardous materials are present.

- For sea freight, use moisture barriers and desiccants to prevent saltwater and humidity damage.

Import/Export Documentation

Ensure all shipments are accompanied by the following documentation:

- Commercial Invoice

- Packing List

- Certificate of Conformity (CoC)

- Test Reports (e.g., from notified bodies)

- Bill of Lading or Air Waybill

- Import licenses or permits (if required by destination country)

- RoHS and REACH Declarations of Conformity

Verify export control regulations—no Fuse Switch Box models contain ITAR-controlled or dual-use components unless specifically designated.

Handling & Installation Safety

- Only qualified electricians should install Fuse Switch Boxes.

- Follow local electrical codes (e.g., NEC in the U.S., IEC or BS 7671 in Europe).

- De-energize circuits before installation or maintenance.

- Use appropriate personal protective equipment (PPE).

- Dispose of faulty units according to local electronic waste (WEEE) regulations.

Warranty & Traceability

- Maintain batch records for traceability in case of recalls or field failures.

- Warranty typically covers defects in materials and workmanship for a period of 1–2 years, subject to proper installation and use.

- Register products upon sale where applicable for service and compliance tracking.

Environmental & Disposal Compliance

- End-of-life Fuse Switch Boxes must be recycled in accordance with WEEE (Waste Electrical and Electronic Equipment) directives.

- Do not dispose of in regular landfill; use certified e-waste recycling facilities.

- Fuses may contain small amounts of hazardous materials—handle and dispose per local regulations.

Adhering to this guide ensures safe, compliant, and efficient logistics for Fuse Switch Boxes across global markets.

Conclusion for Sourcing a Fuse Switch Box:

In conclusion, sourcing a suitable fuse switch box requires careful consideration of electrical specifications, environmental conditions, safety standards, and compliance with local regulations. It is essential to evaluate factors such as current rating, breaking capacity, pole configuration, enclosure type (e.g., IP rating), and mounting method to ensure compatibility with the intended application. Sourcing from reputable suppliers or manufacturers that provide certified, durable, and high-quality products helps ensure long-term reliability, operational safety, and compliance with industry standards such as IEC or NEC. Additionally, considering lifecycle costs, availability of spare parts, and technical support can further enhance efficiency and reduce downtime. A well-informed sourcing decision ultimately contributes to the safety, performance, and longevity of the electrical installation.