The global laser processing equipment market, driven by rising demand for precision manufacturing across industries such as automotive, electronics, and medical devices, is projected to expand at a CAGR of 7.8% from 2023 to 2030 (Grand View Research, 2023). As laser engraving and cutting applications grow, so does the need for effective fume extraction systems to ensure workplace safety and regulatory compliance. According to Mordor Intelligence (2024), the industrial air filtration market—which includes fume extractors—is expected to grow at a CAGR of over 6.2% during the same period, fueled by stricter occupational health standards and increased automation in manufacturing environments. With over 40% of laser engraving operators reporting exposure to hazardous particulate matter without adequate ventilation (NIOSH, 2022), selecting a reliable fume extractor has become a critical operational imperative. This data-driven analysis identifies the top 10 manufacturers leading innovation, performance, and reliability in fume extraction solutions tailored for laser engraving applications.

Top 10 Fume Extractor For Laser Engraver Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

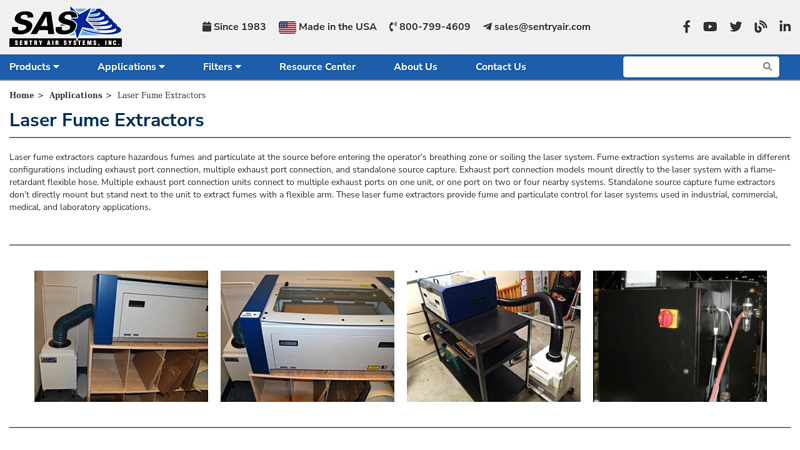

#1 Laser Fume Extractor

Domain Est. 1997

Website: sentryair.com

Key Highlights: These laser fume extractors provide fume and particulate control for laser systems used in industrial, commercial, medical, and laboratory applications….

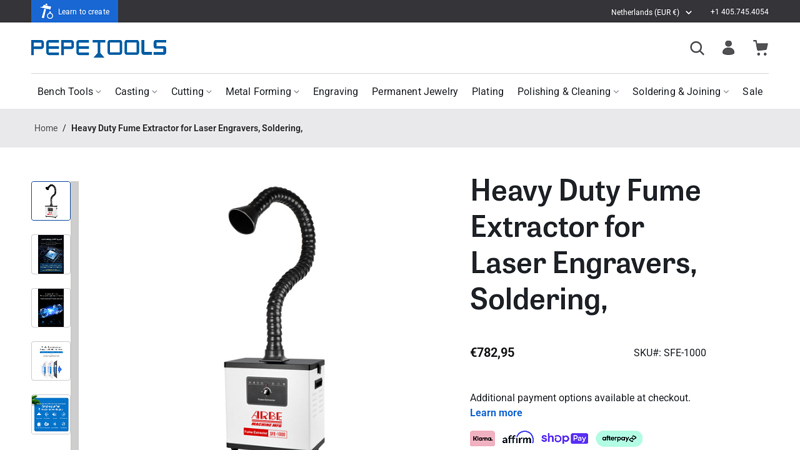

#2 Heavy Duty Fume Extractor for Laser Engravers, Soldering,

Domain Est. 1999

Website: pepetools.com

Key Highlights: In stock $83.69 deliveryThe ARBE Heavy Duty Fume Extractor is a professional-grade air purification system designed for industrial and workshop applications where effective fume …..

#3 Laser Fume Extractor

Domain Est. 2005

Website: ipsystemsusa.com

Key Highlights: IP Systems offers several laser fume extraction systems used by industry leaders across the country. Manufacturers of these laser fume extractors want enough ……

#4 Laser Fume Extraction Systems

Domain Est. 1997

Website: videojet.com

Key Highlights: Explore laser fume extraction systems from Videojet, featuring laser fume extractors and filters designed to remove smoke and debris from marking processes….

#5 Fume Extractors for Laser Engravers

Domain Est. 1998

Website: fumexinc.com

Key Highlights: Fumex laser engraving fume extractors are designed for the laser marking & engraving industry. Removing 99.97% of fumes they are portable & cost efficient….

#6 WeCreat Fume Extractor for Vision & Vista

Domain Est. 2006

#7 Laser exhaust system

Domain Est. 2007

Website: gravotech.us

Key Highlights: Laser fume extractors guarantee clean and safe work and working environment. Their role is to suck up dust and gases and filter out odours produced during ……

#8 Fumeclear® FC

Domain Est. 2017

Website: fumeclear.com

Key Highlights: Rating 4.6 (20) The FC2002 fume extractor is very suitable for laser engravers with 10-20W laser power. Its 260m³/h air intake ensures complete absorption of the fumes ……

#9 Laser Fume Extraction

Domain Est. 2019

Website: donaldsonbofa.com

Key Highlights: Our ADVANTAGE range removes particulates & fumes from engraving, coding, cutting, etching & PVC. Find out more about our laser fume extractors today….

#10 Filtrabox Micro Laser Fume Extractor

Domain Est. 2024

Expert Sourcing Insights for Fume Extractor For Laser Engraver

H2: 2026 Market Trends for Fume Extractors for Laser Engravers

The global market for fume extractors tailored for laser engravers is poised for significant transformation by 2026, driven by advancements in manufacturing technologies, growing environmental and occupational health regulations, and the rising adoption of laser engraving across diverse industries. Key trends shaping this market include:

1. Increased Demand from Industrial Automation and Micro-Manufacturing

The proliferation of laser engraving systems in industries such as electronics, medical devices, automotive, and personalized consumer goods is fueling demand for efficient fume extraction solutions. As laser engraving becomes more prevalent in high-precision and small-batch production environments, the need for compact, high-performance fume extractors will grow. By 2026, integration-ready extractors designed specifically for desktop and benchtop laser systems are expected to capture a larger market share.

2. Stricter Health, Safety, and Environmental Regulations

Governments and regulatory bodies worldwide are tightening air quality and workplace safety standards, particularly concerning volatile organic compounds (VOCs), particulate matter, and hazardous fumes generated during laser processing. Fume extractors that meet or exceed standards such as OSHA, ISO 14001, and REACH will be increasingly mandated in industrial and commercial settings. This regulatory push is accelerating innovation in filtration technologies, including multi-stage HEPA and activated carbon systems.

3. Technological Advancements in Filtration and Smart Features

By 2026, smart fume extractors equipped with IoT connectivity, real-time air quality monitoring, automatic filter replacement alerts, and variable suction control will become standard. These intelligent systems will offer improved energy efficiency and predictive maintenance, appealing to tech-forward manufacturers. Additionally, advancements in electrostatic precipitation (ESP) and UV photocatalytic oxidation are expected to enhance the removal of ultrafine particles and odors.

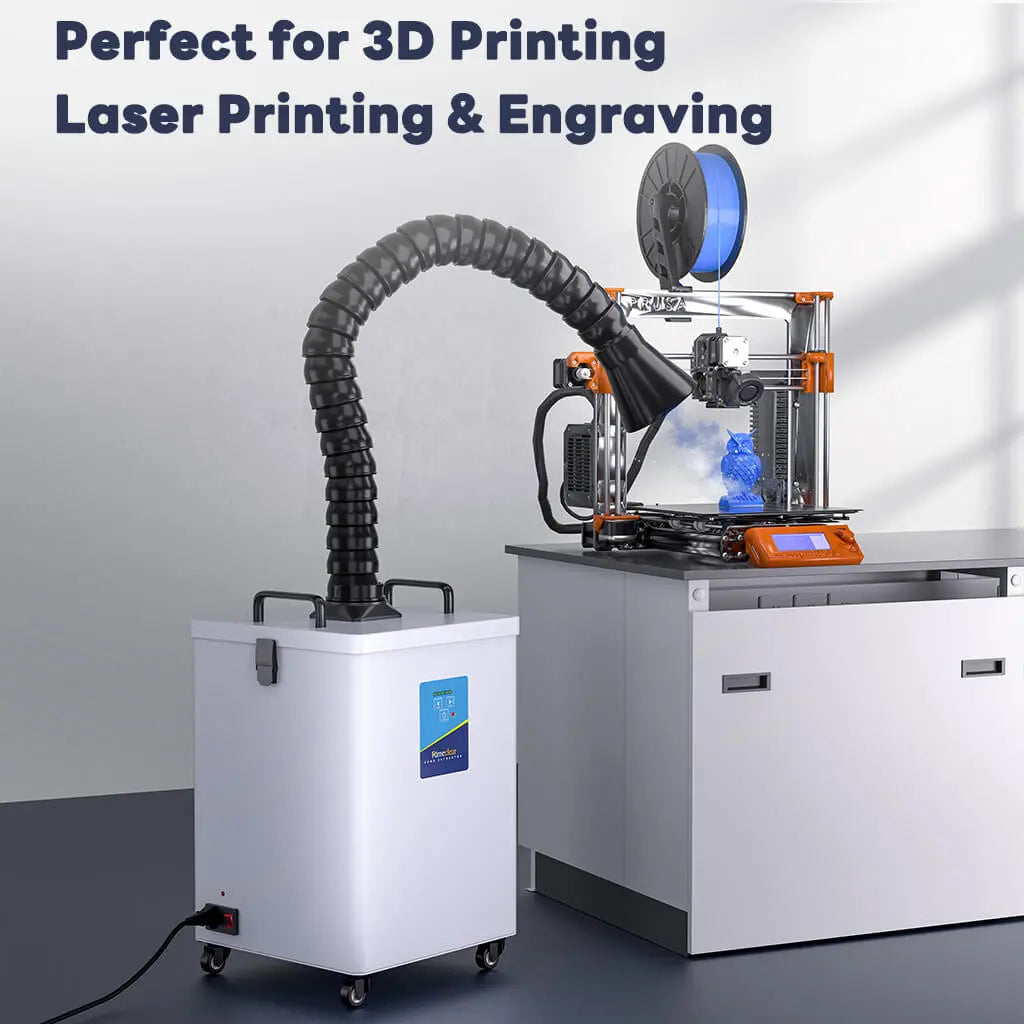

4. Growth in Small Business and Maker Space Adoption

The democratization of laser engraving technology—through affordable CO2 and fiber lasers—has led to widespread adoption in small businesses, educational institutions, and maker spaces. These users prioritize compact, quiet, and user-friendly fume extractors. As a result, manufacturers are focusing on cost-effective, modular designs that are easy to install and maintain, further expanding the market.

5. Regional Market Expansion

While North America and Western Europe remain dominant due to strict safety norms and high manufacturing activity, Asia-Pacific (particularly China, India, and Southeast Asia) is expected to witness the fastest growth. Rising industrialization, supportive government policies for advanced manufacturing, and increasing awareness of occupational health are key drivers in this region.

6. Sustainability and Circular Design

By 2026, sustainability will play a major role in product development. Manufacturers are expected to emphasize recyclable materials, energy-efficient motors, and reusable filter systems to align with global ESG (Environmental, Social, and Governance) goals. Products with lower carbon footprints and extended lifecycles will gain competitive advantage.

In conclusion, the fume extractor market for laser engravers in 2026 will be characterized by smarter, safer, and more sustainable solutions, shaped by regulatory demands, technological innovation, and the expanding footprint of laser-based manufacturing across global industries.

Common Pitfalls When Sourcing a Fume Extractor for a Laser Engraver (Quality and IP)

Poor Build Quality and Materials

Many low-cost fume extractors are constructed with substandard materials such as thin plastic housings, weak fans, and low-grade filtration components. This results in reduced durability, increased noise, and ineffective fume removal. Over time, poor build quality can lead to mechanical failure or even pose safety hazards when handling hazardous laser byproducts like volatile organic compounds (VOCs) or particulate matter.

Inadequate Filtration Efficiency

A common issue is sourcing extractors with undersized or ineffective filters—especially lacking a proper combination of pre-filters, HEPA filters, and activated carbon filters. Without multi-stage filtration, harmful particles and odors are not fully captured, compromising air quality and operator health. Some suppliers exaggerate filter efficiency ratings without third-party testing or certifications.

Misrepresented Airflow and CFM Ratings

Suppliers may inflate airflow (measured in CFM—cubic feet per minute) specifications to make units appear more powerful. In reality, actual performance under real-world conditions (with filters installed and ducting resistance) can be significantly lower. This leads to insufficient fume capture, especially during prolonged or high-intensity laser engraving operations.

Lack of IP (Ingress Protection) Rating Compliance

Many fume extractors marketed for industrial use lack a certified IP rating or falsely claim protection against dust and moisture. Without a proper IP rating (e.g., IP54 or higher), the unit may not be safe for environments with dust, debris, or occasional spills—common in workshop settings. This increases the risk of electrical failure or fire, especially near laser systems that generate fine particulates.

Intellectual Property (IP) Infringement Risks

OEMs or resellers may unknowingly source fume extractors that copy patented designs, control systems, or filter configurations from reputable brands. This exposes buyers to legal risks, especially in regions with strict IP enforcement (e.g., EU or USA). Using counterfeit or cloned products can result in liability, product seizures, or damage to brand reputation.

Absence of Safety and Compliance Certifications

Many low-cost extractors lack essential certifications such as CE, RoHS, or UL. This not only raises safety concerns but may also violate workplace regulations. Units without proper electrical or fire safety certifications can become liabilities in commercial or industrial environments.

Poor After-Sales Support and Spare Parts Availability

Sourcing from unknown suppliers often means limited access to technical support, replacement filters, or repair services. When a critical component fails, downtime can disrupt production. Additionally, proprietary filter designs may become obsolete or unavailable, forcing costly replacements.

Conclusion

To avoid these pitfalls, always verify product specifications with independent testing data, demand clear documentation of IP ratings and certifications, and source from reputable suppliers with transparent manufacturing and IP practices. Investing in a high-quality, compliant fume extractor ensures safety, regulatory compliance, and long-term operational reliability.

Logistics & Compliance Guide for Fume Extractor for Laser Engraver

Product Classification and HS Code

The Fume Extractor for Laser Engraver is categorized under air purification or industrial ventilation equipment. The most appropriate Harmonized System (HS) Code for customs and import/export purposes is typically:

8421.39 – Air filtering or purifying machinery and apparatus.

This code covers mechanical filters and air purifiers used in industrial settings, including those designed for fume extraction from laser engraving processes.

Note: Confirm the specific HS code with your local customs authority, as sub-classifications may vary by country.

Import/Export Regulations

When shipping fume extractors internationally, compliance with the following regulations is essential:

- Customs Documentation: Ensure accurate commercial invoices, packing lists, and a bill of lading or air waybill are provided.

- Country-Specific Restrictions: Some countries may require additional certifications for electrical equipment or air quality devices. Verify import requirements in the destination country.

- Dual-Use Considerations: While fume extractors are not typically classified as dual-use items, verify with export control authorities if components (e.g., high-efficiency filtration systems) could trigger additional scrutiny.

Electrical Safety and Certification

Fume extractors with electric motors and fans must comply with electrical safety standards in the destination market:

- CE Marking (European Union): Required for electrical safety under the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive.

- UL/ETL Listing (United States and Canada): Indicates compliance with North American safety standards (e.g., UL 1278 for portable electrical appliances).

- PSE Mark (Japan): Mandatory for electrical products sold in Japan.

- CCC Certification (China): Required if the product is manufactured in or imported into China.

Ensure the product includes voltage compatibility (e.g., 110V/220V) for the target market and is labeled accordingly.

Packaging and Shipping Requirements

Proper packaging ensures product integrity during transit:

- Use sturdy corrugated cardboard boxes with internal cushioning (foam or molded inserts) to protect fans, filters, and housing.

- Label packages with handling instructions such as “Fragile,” “This Side Up,” and “Do Not Stack.”

- Include all accessories (filters, hoses, power cords) securely packed and listed on the packing slip.

For air or sea freight:

– Comply with IATA (air) or IMDG (sea) regulations if transporting lithium components (rare in fume extractors, but verify).

– Declare the product as non-hazardous machinery.

Environmental and Emissions Compliance

Fume extractors used with laser engravers must meet air quality and environmental standards:

- EPA and OSHA (USA): While the extractor itself isn’t regulated, its use may be required to comply with workplace air quality standards. Ensure the product meets performance claims for particulate and VOC filtration.

- REACH and RoHS (EU): Confirm that materials used (plastics, wiring, filters) comply with RoHS (restriction of hazardous substances) and REACH (chemical safety) regulations.

Warranty and After-Sales Support Logistics

- Provide clear documentation on warranty terms, including duration and coverage (e.g., motor, fan, electronic controls).

- Establish a supply chain for replacement filters and spare parts in key markets.

- Include multilingual user manuals and safety instructions, especially for CE-marked or globally distributed units.

Return and Repair Logistics

- Define a reverse logistics process for defective units.

- Partner with local distributors or service centers for faster turnaround.

- Use trackable shipping methods for return shipments and maintain records for compliance audits.

Summary

Shipping and selling fume extractors for laser engravers requires attention to classification, electrical safety, environmental standards, and packaging. Proactive compliance with regional regulations ensures smooth international logistics and customer satisfaction. Always consult with legal and logistics experts when entering new markets.

Conclusion: Sourcing a Fume Extractor for a Laser Engraver

When sourcing a fume extractor for a laser engraver, it is essential to prioritize safety, efficiency, and compatibility with your specific application. Laser engraving produces hazardous fumes and particulates, including volatile organic compounds (VOCs), fine dust, and potentially toxic byproducts, all of which pose serious health risks and can damage equipment if not properly managed.

After evaluating various options, a high-quality fume extractor with a multi-stage filtration system — including a pre-filter, HEPA filter, and activated carbon filter — proves to be the most effective solution. These systems efficiently capture particulate matter and neutralize harmful gases before releasing clean air back into the workspace, making them ideal for indoor environments.

When selecting a unit, consider key factors such as airflow rate (CFM), noise levels, filter lifespan and replacement costs, portability, and compatibility with your laser machine’s size and output. Units specifically designed for laser applications tend to offer better performance than generic air purifiers.

Additionally, sourcing from reputable suppliers that provide technical support, warranties, and transparent specifications ensures long-term reliability and regulatory compliance. While initial costs may be higher for professional-grade extractors, the investment pays off through improved workplace safety, reduced maintenance for the laser machine, and enhanced operational efficiency.

In conclusion, a properly sourced fume extractor is not merely an accessory but a necessary component of any laser engraving setup. By carefully selecting a system that matches your operational needs and safety requirements, you protect both your health and your investment, ensuring a cleaner, safer, and more productive working environment.