The global fuel tank manufacturing market is experiencing steady growth, driven by rising vehicle production, stringent fuel efficiency standards, and increasing demand for lightweight and high-performance fuel storage solutions. According to a report by Mordor Intelligence, the global fuel tank market was valued at USD 33.5 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.8% from 2024 to 2029. This expansion is propelled by advancements in materials—such as high-density polyethylene (HDPE) for plastic fuel tanks—and rising adoption in automotive, aerospace, and industrial sectors. As emissions regulations tighten and electric vehicle (EV) transitional technologies emerge, manufacturers are innovating to meet demands for durability, safety, and environmental compliance. In this evolving landscape, identifying the leading fuel tank manufacturers becomes critical for industry stakeholders. Here are the top 10 fuel tank manufacturers shaping the market in 2024.

Top 10 Fuel Tank Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 IFH Group: Trust in Every Tank

Domain Est. 1998

Website: ifhgroup.com

Key Highlights: We’re proud to be one of the country’s largest manufacturers of fuel tanks, hydraulic oil tanks, and built to print custom OEM tanks for off-road and specialty ……

#2 Metal Products USA

Domain Est. 2023

Website: metalproductsusa.com

Key Highlights: Explore USA-made industrial storage tanks from Metal Products USA—trusted manufacturers serving energy, agriculture, fuel, and commercial industries….

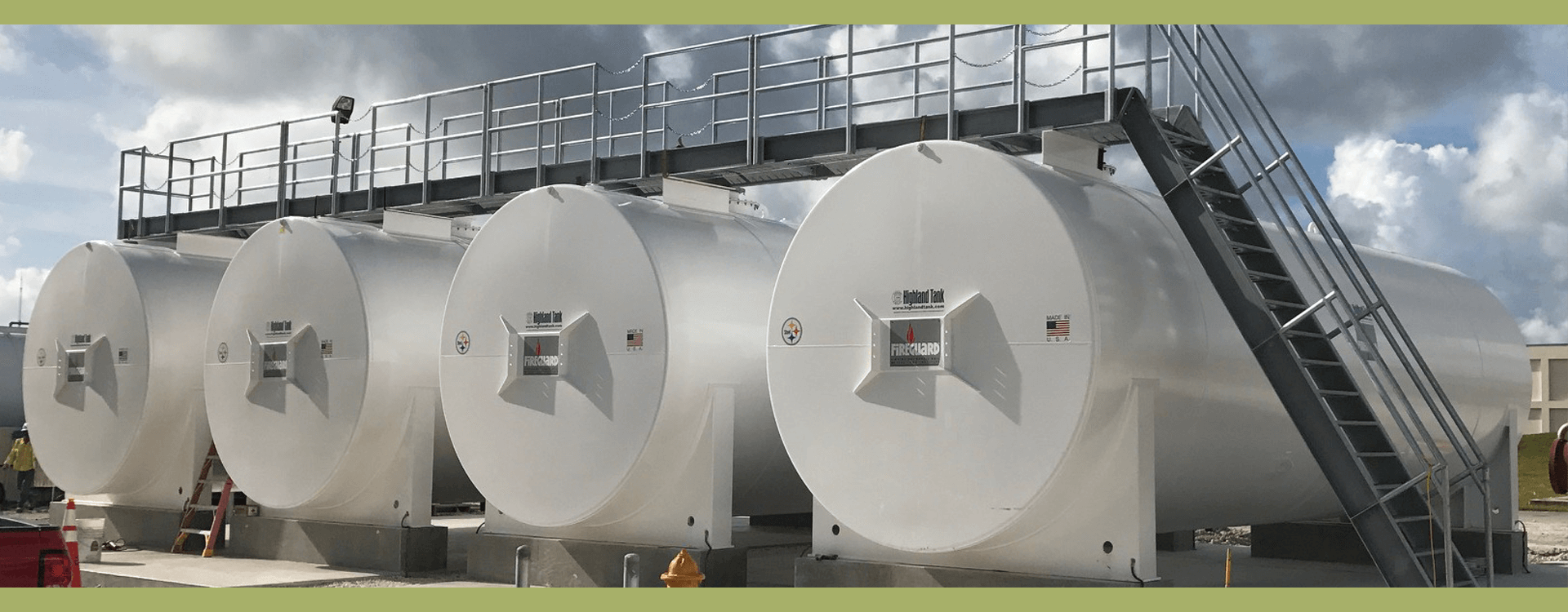

#3 Highland Tank

Domain Est. 1996

Website: highlandtank.com

Key Highlights: Manufacturing high-quality steel storage tank products accommodating commercial and industrial customers. Proven manufacturing and exceptional quality….

#4 Transfer Flow, Inc.

Domain Est. 1997

Website: transferflow.com

Key Highlights: Transfer Flow offers a range of fuel tanks manufactured in the USA, using durable American-made steel. Whether you need an in-bed auxiliary tank, a larger ……

#5 TANKS Inc. gas tanks for street rods, muscle cars, custom cars and …

Domain Est. 1999

Website: tanksinc.com

Key Highlights: Tanks, Inc. manufactures fuel system components and polyethylene, steel and stainless steel gas tanks for street rods and special interest vehicles….

#6 Fuel Storage Tanks for Diesel & Gasoline

Domain Est. 2000

Website: southerntank.net

Key Highlights: Southern Tank is a leading manufacturer of fuel storage tanks. We fabricate carbon steel and stainless steel fuel storage tanks that are compatible with all ……

#7 Fuel Storage Solutions & Tanks

Domain Est. 2013

Website: western-global.com

Key Highlights: Fuel storage solutions from the experts at Western Global – world-leading manufacturers of safe & secure fuel tanks including renewable diesel tanks….

#8 Underground Storage for Fuel, Water and Stormwater

Domain Est. 1998

Website: xerxes.com

Key Highlights: Our underground fuel and water tanks, and stormwater management products are designed and manufactured to meet – and exceed – industry standards….

#9 Fuel Total Systems

Domain Est. 2002

Website: fueltotalsystems.com

Key Highlights: Fuel Total Systems Kentucky Corporation (formerly known as FTS California Corporation) was established in Lathrop, CA in 2001 and began producing fuel tanks ……

#10 TITAN Fuel Tanks

Domain Est. 2004 | Founded: 2003

Website: titanfueltanks.com

Key Highlights: Founded in 2003, Titan Fuel Tanks is world renowned for our cutting-edge designs made from cross-linked high-density polyethylene (XLHDPE)….

Expert Sourcing Insights for Fuel Tank

H2: 2026 Market Trends for Fuel Tanks

The global fuel tank market is poised for significant transformation by 2026, driven by evolving regulatory standards, technological advancements, and shifting energy dynamics. Key trends shaping the industry include the transition toward alternative fuels, material innovation, increasing demand from the automotive and aerospace sectors, and sustainability mandates.

-

Shift Toward Alternative Fuel Tanks

By 2026, demand for fuel tanks designed for alternative fuels—such as compressed natural gas (CNG), liquefied petroleum gas (LPG), and hydrogen—is expected to grow substantially. Governments worldwide are implementing stricter emissions regulations, pushing automakers to develop cleaner fuel systems. Hydrogen fuel tanks, in particular, are gaining traction in heavy-duty vehicles and public transportation, supported by investments in hydrogen infrastructure. -

Adoption of Lightweight and Composite Materials

A major trend is the increased use of high-density polyethylene (HDPE) and advanced composites to replace traditional metal tanks. These materials offer improved weight reduction, corrosion resistance, and design flexibility. By 2026, composite fuel tanks are projected to capture a larger market share, especially in electric and hybrid vehicles where weight savings directly impact efficiency and range. -

Integration with Electric and Hybrid Vehicles

While battery electric vehicles (BEVs) do not require traditional fuel tanks, hybrid electric vehicles (HEVs) and range-extender models continue to rely on compact, high-efficiency fuel storage systems. The fuel tank market is adapting by offering smaller, modular tanks optimized for hybrid configurations, contributing to sustained demand even in an electrified future. -

Stringent Safety and Environmental Regulations

Regulatory bodies such as the EPA (U.S.) and Euro 7 standards (EU) are enforcing tighter controls on fuel permeability and evaporative emissions. By 2026, fuel tank manufacturers will need to comply with advanced vapor recovery and leak detection systems, accelerating the adoption of multi-layer barrier technologies and smart monitoring solutions. -

Growth in Emerging Markets

Developing regions such as Southeast Asia, India, and Africa are expected to drive volume growth due to rising vehicle ownership and infrastructure development. These markets favor cost-effective, durable fuel tanks, creating opportunities for manufacturers offering scalable and robust solutions. -

Focus on Sustainability and Recycling

Environmental concerns are pushing the industry toward recyclable and bio-based materials. By 2026, leading manufacturers are expected to implement closed-loop recycling systems for plastic fuel tanks and explore bio-HDPE alternatives to reduce the carbon footprint of production.

In conclusion, the 2026 fuel tank market will be characterized by innovation in materials and design, alignment with low-carbon transportation goals, and adaptation to diverse fuel types. Companies that invest in R&D, sustainability, and compliance will be best positioned to lead in this evolving landscape.

H2: Common Pitfalls in Sourcing Fuel Tanks (Focus on Quality and Intellectual Property)

Sourcing fuel tanks—especially for automotive, aerospace, or industrial applications—requires careful attention to both quality assurance and intellectual property (IP) considerations. Failure to address these aspects can lead to safety risks, regulatory non-compliance, legal disputes, and reputational damage. Below are common pitfalls in these two critical areas:

1. Quality-Related Pitfalls

a. Inadequate Material Specifications

– Pitfall: Selecting suppliers who use substandard materials (e.g., non-compliant polymers or corrosion-prone metals) that fail under environmental stress (UV exposure, temperature extremes, fuel permeation).

– Risk: Leaks, structural failure, or emissions non-compliance (e.g., evaporative emissions exceeding EPA or Euro standards).

– Mitigation: Enforce strict material certifications (e.g., ISO 17081 for permeation, ASTM D570 for water absorption) and require material test reports (MTRs).

b. Poor Manufacturing Process Control

– Pitfall: Suppliers lacking robust process validation (e.g., inconsistent blow molding or welding techniques) leading to weak seams or dimensional inaccuracies.

– Risk: Field failures, recalls, or incompatibility with vehicle assembly lines.

– Mitigation: Conduct supplier process audits (e.g., APQP, PPAP submissions) and require statistical process control (SPC) data.

c. Insufficient Testing and Validation

– Pitfall: Relying on supplier-provided test data without independent verification or skipping full environmental and safety testing (drop tests, pressure cycling, vibration).

– Risk: Undetected design flaws causing safety hazards or non-compliance with FMVSS 301 (U.S.) or UNECE R34 (EU).

– Mitigation: Mandate third-party testing and require full validation dossiers before production release.

d. Lack of Traceability and Documentation

– Pitfall: Incomplete batch traceability or missing quality documentation (e.g., COC, FAIs).

– Risk: Inability to respond to field issues or conduct recalls efficiently.

– Mitigation: Require serialized tracking and digital quality records compliant with ISO 9001 or IATF 16949.

2. Intellectual Property (IP)-Related Pitfalls

a. Unlicensed Use of Proprietary Designs

– Pitfall: Sourcing fuel tanks that replicate patented designs (e.g., shape, mounting features, internal baffling) without authorization.

– Risk: Infringement lawsuits, customs seizures, or forced redesigns.

– Mitigation: Conduct freedom-to-operate (FTO) analyses and require suppliers to warrant IP ownership or licensing rights.

b. Supplier Ownership of Custom Tooling or Designs

– Pitfall: Allowing suppliers to retain IP rights to molds, CAD models, or custom-engineered tanks developed for your application.

– Risk: Vendor lock-in, increased costs, or inability to switch suppliers.

– Mitigation: Include IP assignment clauses in contracts; ensure all custom designs and tooling are owned by the buyer.

c. Reverse Engineering and Gray Market Replicas

– Pitfall: Sourcing from regions with weak IP enforcement where original designs are copied without consent.

– Risk: Lower-quality counterfeit tanks entering the supply chain, damaging brand reputation.

– Mitigation: Perform supplier due diligence, audit manufacturing sites, and use anti-counterfeit measures (e.g., unique markings, blockchain tracking).

d. Inadequate Confidentiality and NDA Enforcement

– Pitfall: Sharing sensitive design or performance specs without robust NDAs or data protection agreements.

– Risk: Leakage of proprietary information to competitors.

– Mitigation: Use comprehensive NDAs and limit data access to need-to-know personnel.

Conclusion

To avoid quality and IP pitfalls when sourcing fuel tanks, organizations must implement a structured supplier qualification process that includes technical audits, legal reviews, and contractual safeguards. Proactive management of both physical performance and intellectual rights ensures long-term reliability, compliance, and competitiveness.

Logistics & Compliance Guide for Hydrogen (H₂) Fuel Tanks

Hydrogen (H₂) is a clean, high-energy fuel increasingly used in transportation, power generation, and industrial applications. However, due to its unique physical and chemical properties, the logistics and compliance requirements for hydrogen fuel tanks are highly regulated and require specialized handling. This guide outlines key logistics considerations, transportation regulations, safety protocols, and compliance standards for hydrogen fuel tanks.

1. Overview of Hydrogen Fuel Tanks

Hydrogen fuel tanks store compressed gaseous hydrogen (CGH₂) or, in some cases, cryogenic liquid hydrogen (LH₂). They are typically made from advanced composite materials (e.g., carbon fiber-reinforced polymers) and designed to withstand high pressures (up to 700 bar for vehicular applications).

Types:

– Type I: All-metal (steel or aluminum), low weight efficiency.

– Type II: Hoop-wrapped metal liner.

– Type III: Fully wrapped metal liner with composite overwrap.

– Type IV: Non-metallic (plastic) liner with full composite wrap – most common in modern vehicles.

2. Key Logistics Considerations

A. Storage

- Pressure & Temperature: Compressed hydrogen is stored at high pressure (350–700 bar); liquid hydrogen at cryogenic temperatures (−253°C / −423°F).

- Ventilation: H₂ is lighter than air but highly flammable. Storage areas must be well-ventilated and free of ignition sources.

- Separation: Store away from oxidizers, flammable materials, and high-traffic zones. Minimum 20 ft (6 m) separation from buildings or property lines per NFPA 2.

- Indoor vs. Outdoor: Outdoor storage preferred. Indoor storage requires explosion-proof ventilation and gas detection systems.

B. Handling & Transport

- Filling & Dispensing: Use certified hydrogen refueling stations with pressure regulators, leak detection, and emergency shutoffs.

- Loading/Unloading: Use proper lifting equipment. Avoid dropping or impact. Use grounding straps to prevent static discharge.

- Transport Modes:

- Road: Tube trailers (for CGH₂), cryogenic tankers (for LH₂).

- Rail: Specialized cryogenic or high-pressure railcars.

- Marine: Cryogenic carriers (LH₂) with double-hull containment.

- Pipeline: Limited to dedicated H₂ pipelines (not applicable for tanks).

C. Infrastructure Requirements

- Filling Stations: Must comply with codes like SAE J2601 (fueling protocol), NFPA 2, and local fire codes.

- Monitoring Systems: Real-time pressure, temperature, and leak monitoring.

- Emergency Systems: Flame arrestors, pressure relief devices (PRDs), and rupture disks required on all tanks.

3. Regulatory Compliance

A. United States

- DOT (Department of Transportation)

- 49 CFR Parts 100–185: Governs transportation of hazardous materials.

- Hydrogen is classified as Hazard Class 2.1 (Flammable Gas).

- UN1049: Compressed hydrogen.

- UN1966: Cryogenic liquid hydrogen.

-

Cylinders must meet DOT-SP or DOT-E special permits and be tested every 3–5 years.

-

NFPA (National Fire Protection Association)

- NFPA 2: Hydrogen Technologies Code – Covers production, storage, use, and handling.

- NFPA 55: Compressed and Liquefied Gases Code – Applies to storage and use in facilities.

-

NFPA 70 (NEC) – Electrical classifications in hazardous (Class I, Division 1 or 2) areas.

-

OSHA (Occupational Safety and Health Administration)

- 29 CFR 1910.106: Flammable liquids and gases.

- Hazard Communication Standard (HazCom): Proper labeling, SDS availability.

B. International Regulations

- ADR (Europe): For road transport; Class 2.1, UN1049/1966.

- RID (Rail): Rail transport of dangerous goods in Europe.

- IMDG Code: Maritime shipping; requires special stowage and segregation.

- IATA DGR: Air transport – hydrogen is generally prohibited in fuel tanks on passenger aircraft due to extreme risk.

C. ISO & SAE Standards

- ISO 11439: Gaseous hydrogen systems in vehicles.

- ISO 16111: Transportable gas storage devices – high-pressure hydrogen.

- SAE J2579: Performance requirements for fuel cell vehicles.

- SAE J2580: Hydrogen safety for fuel cell vehicles.

4. Safety & Risk Mitigation

A. Hazards

- Flammability: H₂ has a wide flammability range (4–75% in air) and low ignition energy.

- Embrittlement: H₂ can cause metal embrittlement; materials must be H₂-compatible.

- Leakage: Small molecule; prone to leakage through micro-cracks. Use H₂-specific leak detectors (e.g., electrochemical sensors).

- Pressure Risks: Catastrophic failure if over-pressurized or damaged.

B. Safety Protocols

- Leak Testing: Perform before transport or use (helium leak testing recommended).

- Ventilation: Ensure natural or mechanical ventilation in enclosed spaces.

- Fire Protection: Use Class B fire extinguishers. Water spray to cool tanks during fire.

- Training: Personnel must be trained in H₂ hazards, emergency response, and PPE use.

C. Emergency Response

- Leak: Evacuate area, eliminate ignition sources, ventilate, isolate tank.

- Fire: Fight from maximum distance. Cool exposed tanks with water. Do not extinguish flame unless leak can be stopped.

- Spill (Cryogenic LH₂): Evacuate, avoid frostbite, ensure vapor disperses upward.

5. Documentation & Labeling

Required Labels (per DOT & GHS)

- Placards: “FLAMMABLE GAS” (Class 2.1), UN1049 or UN1966.

- GHS Pictograms: Flame (flammable gas), gas cylinder.

- Tanks: Must be marked with:

- Manufacturer

- Working pressure

- Test pressure

- Last test date

- Service medium (H₂)

- Serial number

Shipping Papers

- Bill of lading with proper shipping name, UN number, hazard class, packing group (II), and emergency contact.

- Safety Data Sheet (SDS) per OSHA HazCom.

6. Inspection & Maintenance

- Visual Inspection: Monthly checks for dents, corrosion, valve damage.

- Pressure Testing: Hydrostatic requalification every 3–5 years (DOT requirement).

- Valve & Fitting Checks: Ensure seals are H₂-compatible (e.g., PTFE, Viton).

- Record Keeping: Maintain logs of inspections, repairs, and compliance certifications.

7. Best Practices Summary

| Area | Best Practice |

|——|—————|

| Storage | Store upright, secured, outdoors, away from ignition sources |

| Transport | Use certified H₂ tube trailers; secure tanks; avoid extreme temps |

| Handling | Use non-sparking tools; ground all equipment |

| Compliance | Follow DOT, NFPA, ISO, and local codes |

| Training | Certify personnel in H₂ safety and emergency response |

| Monitoring | Install H₂ detectors and fire suppression systems |

8. Resources

- U.S. DOT PHMSA: https://www.phmsa.dot.gov

- NFPA: https://www.nfpa.org

- Hydrogen Tools (DOE): https://www.hydrogentools.org

- ISO Standards: https://www.iso.org

Conclusion

Handling hydrogen fuel tanks requires strict adherence to safety, logistics, and compliance standards due to hydrogen’s flammability and high-pressure storage. By following this guide—integrating engineering controls, regulatory compliance, and staff training—organizations can ensure safe and efficient hydrogen fuel tank operations across the supply chain.

Always consult local authorities and a qualified hydrogen safety engineer before deploying or transporting hydrogen systems.

In conclusion, sourcing fuel tank manufacturers requires a strategic approach that balances quality, compliance, cost, and reliability. It is essential to evaluate potential suppliers based on their manufacturing capabilities, adherence to international safety and environmental standards (such as ISO, CE, or DOT certifications), material expertise, and capacity for customization and scalability. Conducting thorough due diligence—including site visits, audits, and sample testing—helps ensure that the chosen manufacturer can consistently deliver durable, safe, and reliable fuel storage solutions. Additionally, building strong partnerships with manufacturers who offer technical support and responsive service contributes to long-term operational efficiency and risk mitigation. Ultimately, a well-vetted supplier not only meets current requirements but also supports future growth and regulatory changes in the fuel storage industry.