The global fuel system components market is witnessing steady expansion, driven by increasing vehicle production and growing demand for high-performance engine parts. According to Grand View Research, the global automotive fuel system market was valued at USD 45.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. This growth is fueled by advancements in fuel delivery efficiency, rising demand for durable aftermarket components, and the enduring popularity of performance engines like the Chevrolet 350 small block. As enthusiasts and mechanics continue to restore, upgrade, and optimize classic V8 platforms, reliable fuel pumps are critical for delivering consistent performance. In this competitive landscape, several manufacturers have emerged as leaders in producing top-tier fuel pumps tailored for the 350 small block engine, combining flow efficiency, durability, and compatibility with both carbureted and fuel-injected systems. Based on performance data, customer feedback, and market presence, we’ve identified the top 7 fuel pump manufacturers meeting the demands of today’s performance-driven automotive sector.

Top 7 Fuel Pump For 350 Small Block Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 OEM mechanical fuel pump for 1970 Small Block

Domain Est. 2017

Website: vccachat.org

Key Highlights: I installed a new OEM fuel pump in this SB/350 1970 motor, it did not work, I took it back to store, and exchanged for same lifetime warranty brand, it too does ……

#2 Engines and Parts

Domain Est. 1994

Website: chevrolet.com

Key Highlights: Chevrolet Performance Parts fuels the passion of automotive enthusiasts by offering crate engines, transmissions, blocks, and parts for project cars….

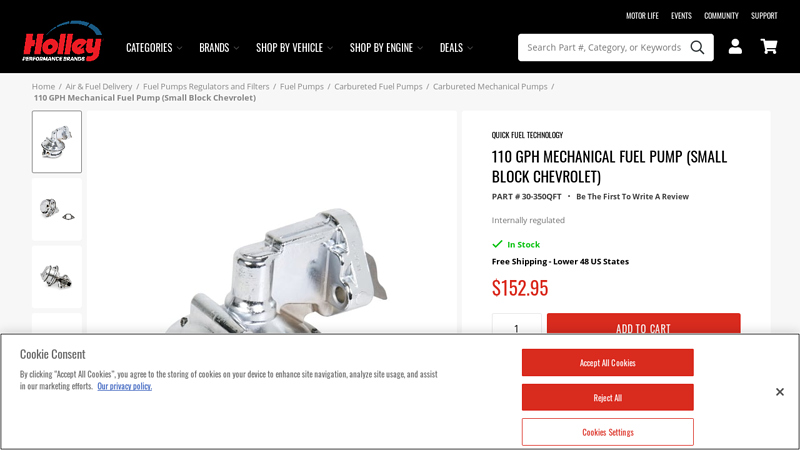

#3 110 GPH Mechanical Fuel Pump (Small Block Chevrolet)

Domain Est. 1995

Website: holley.com

Key Highlights: In stock Rating 4.8 10 Designed for carbureted small block Chevy V8 engines. Flows 110 GPH (Free flow). All Aluminum housing for weight savings. Shutoff pressure pre-set from 6.5…

#4 Powertrain: 350 Small Block Engine

Domain Est. 1996

Website: gmparts.com

Key Highlights: All blocks are four-bolt main; All blocks are roller camshaft-ready; All blocks are mechanical fuel pump-capable (Gen1e has no camshaft eccentric); Machined ……

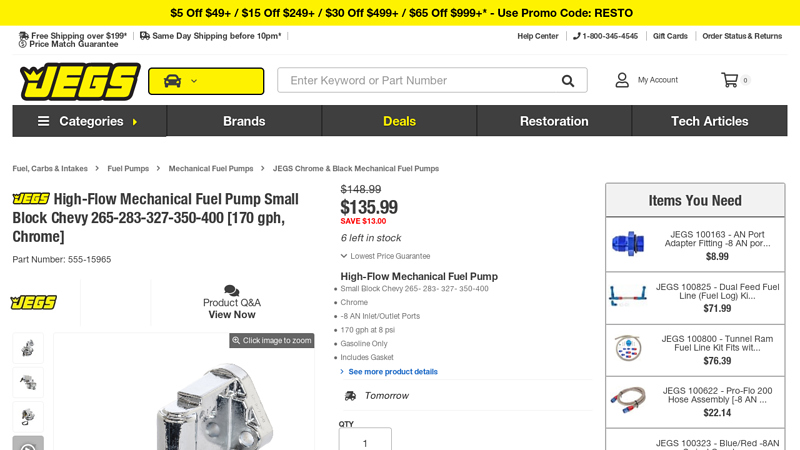

#5 JEGS 15965: High

Domain Est. 1996

Website: jegs.com

Key Highlights: In stock $15.99 deliveryGet the Best Performance with JEGS High-Flow Mechanical Fuel Pump Small Block Chevy 265-283-327-350-400 [170 gph, Chrome] 15965 parts at JEGS….

#6 Small Block Chevrolet Fuel Pumps

Domain Est. 1999

#7 Chevy Small Block V8 Mechanical Fuel Pump

Domain Est. 2008

Expert Sourcing Insights for Fuel Pump For 350 Small Block

H2: 2026 Market Trends for Fuel Pumps for 350 Small Block Engines

The market for fuel pumps designed specifically for the Chevrolet 350 Small Block engine is expected to experience notable shifts by 2026, driven by evolving consumer preferences, technological advancements, and the enduring popularity of classic and performance vehicles. As a cornerstone of the American V8 engine legacy, the 350 Small Block continues to power a wide range of applications—from restored muscle cars to custom hot rods and off-road builds—sustaining demand for compatible fuel delivery components.

-

Continued Demand from Restoration and Enthusiast Markets

Despite the automotive industry’s shift toward electrification, the classic car restoration sector remains robust. By 2026, an aging fleet of vintage GM vehicles equipped with the 350 Small Block is expected to increase the need for reliable replacement parts. Fuel pumps—particularly mechanical and high-flow electric variants tailored to carbureted and fuel-injected conversions—will remain in strong demand among DIY mechanics and restoration shops. -

Growth in Performance and Aftermarket Upgrades

Enthusiasts seeking enhanced horsepower and improved fuel delivery are driving innovation in aftermarket fuel pumps. By 2026, the trend toward crate engine builds and LS swaps will influence demand for compatible fuel systems, including in-tank electric pumps and high-pressure return-style setups that support modern performance expectations. Brands like Holley, Edelbrock, and ACDelco are expected to expand product lines offering 350-compatible fuel pumps with EFI readiness and improved durability. -

Shift Toward EFI Conversions

A growing number of 350 Small Block owners are converting from carburetors to electronic fuel injection (EFI) for better fuel economy, emissions compliance, and drivability. This trend is expected to accelerate through 2026, increasing demand for high-flow electric fuel pumps capable of supporting consistent fuel pressure (typically 40–60 psi). These systems often require complete fuel pump assemblies, sending units, and retrofit kits, creating new revenue streams for manufacturers. -

Consolidation and Brand Differentiation

The fuel pump market is seeing consolidation among suppliers, with increased emphasis on reliability, warranty support, and compatibility assurance. By 2026, leading brands are expected to differentiate themselves through modular designs, OE-replacement quality, and integration with modern fuel types, including ethanol-blended fuels (E15/E85), which require corrosion-resistant materials. -

Sustainability and Regulatory Influences

Environmental regulations, particularly emissions standards in states like California, are pushing older vehicle owners to upgrade fuel systems to reduce evaporative emissions and improve combustion efficiency. This may lead to stricter requirements for fuel pump vapor recovery and sealed fuel systems, indirectly affecting design choices for 350 Small Block retrofits. -

E-Commerce and Distribution Shifts

Online marketplaces such as Amazon, Summit Racing, and JEGS are expected to dominate distribution by 2026, offering consumers quick access to specialized fuel pump kits with detailed compatibility filters. Enhanced product data, video tutorials, and customer reviews will further influence purchasing decisions, favoring brands with strong digital presence and technical support.

In summary, the 2026 market for fuel pumps compatible with the 350 Small Block engine will be shaped by the enduring appeal of classic American V8s, rising performance expectations, and technological adaptation. While original mechanical pumps will retain a niche, the growth will center on modern electric systems supporting EFI conversions, ensuring the 350 Small Block remains relevant in a changing automotive landscape.

Common Pitfalls Sourcing a Fuel Pump for a 350 Small Block (Quality & IP Issues)

When replacing or upgrading the fuel pump on a classic 350 Small Block Chevrolet, enthusiasts often encounter significant challenges related to both quality and Intellectual Property (IP). Avoiding these pitfalls is crucial for reliability, performance, and long-term satisfaction.

1. Counterfeit or Misrepresented “OEM-Equivalent” Pumps

One of the most prevalent issues is the proliferation of fuel pumps marketed as “OEM-replacement” or “direct fit” that are poor-quality counterfeits. These pumps often mimic the appearance of reputable brands (like Carter, Holley, or ACDelco) but fail to meet original performance or durability standards.

- Symptoms of Low Quality: Premature diaphragm failure, inconsistent fuel pressure, excessive noise, or complete pump failure within months.

- IP Aspect: Many knockoff manufacturers reverse-engineer genuine parts without licensing, infringing on trademarks and design patents. Logos and packaging may be nearly identical, misleading consumers into believing they are purchasing authentic products.

Tip: Buy from authorized dealers or reputable performance parts suppliers. Check for manufacturer certifications, part numbers, and warranty information.

2. Unlicensed Replicas of Performance Brand Pumps

Performance fuel pumps from brands like Holley, Edelbrock, or Carter are frequently copied by third-party manufacturers, especially in overseas markets. These clones often use inferior materials (e.g., weaker diaphragms, lower-grade alloys) and lack proper IP licensing.

- Performance Risks: Inconsistent fuel flow at high RPM, pressure drop under load, or failure in high-heat environments.

- IP Violations: These replicas infringe on registered trademarks and patented designs. Purchasing them supports illegal manufacturing and denies revenue to innovating companies.

Tip: Verify the manufacturer’s authenticity. Look for holograms, official distributor stickers, or consult the brand’s website to confirm authorized sellers.

3. Inadequate Flow/Pressure Ratings for Modified Engines

A common mistake is selecting a fuel pump based solely on fitment, ignoring engine demands. Stock replacement pumps may not support modifications like higher-lift cams, performance carburetors, or forced induction.

- Quality Concern: Low-cost pumps often exaggerate flow specs (e.g., claiming 70 GPH when actual is 45 GPH).

- IP Angle: Some brands inflate performance claims using misleading benchmarks or stolen data from patented testing methods.

Tip: Match the pump’s flow rate (GPH) and pressure (PSI) to your engine’s horsepower and configuration. Use trusted brands with published, independently verified specs.

4. Poor Material Quality and Manufacturing Tolerances

Even non-counterfeit pumps from budget manufacturers may use substandard materials and loose tolerances, leading to leaks, noise, or early wear.

- Quality Red Flags: Plastic linkages instead of metal, thin casting walls, rubber components prone to ethanol degradation.

- IP Relevance: Reputable brands invest in R&D for durable designs protected by utility patents. Cheap copies avoid these innovations, resulting in unreliable products.

Tip: Choose pumps with brass or high-temperature composite bodies, compatible with modern ethanol-blended fuels (E10/E15).

5. Lack of Warranty and Support

Many low-cost or counterfeit fuel pumps come with no warranty or limited support. If the pump fails, recourse is minimal, and diagnosing the root cause becomes difficult.

- IP Connection: Legitimate manufacturers protect their designs and stand behind them with warranties—this builds brand trust and deters IP theft.

Tip: Opt for pumps backed by at least a 1-2 year warranty and accessible technical support.

Bottom Line: When sourcing a fuel pump for your 350 Small Block, prioritize authenticity, verified performance data, and IP-respecting manufacturers. Investing in a quality, legally produced pump ensures reliability, protects your engine, and supports continued innovation in the performance aftermarket.

Logistics & Compliance Guide for Fuel Pump For 350 Small Block

Shipping and handling fuel pumps—especially those designed for internal combustion engines like the 350 Small Block—require careful attention to logistics, packaging, transportation regulations, and compliance standards. This guide outlines key considerations to ensure safe, legal, and efficient distribution of the Fuel Pump For 350 Small Block.

1. Product Classification and Identification

- Product Name: Fuel Pump For 350 Small Block (typically mechanical or electric aftermarket part)

- HS Code: 8413.30 (Pumps for liquids, including fuel pumps for internal combustion engines)

- UN Number: Not typically classified as hazardous when new and uncontaminated, but may be subject to residual fuel or oil content

- NAICS Code: 336340 (Automotive Parts Manufacturing)

2. Packaging and Labeling Requirements

- Protective Packaging: Use anti-static and moisture-resistant materials. Secure internal components to prevent movement during transit.

- Labeling:

- Part number, model compatibility (e.g., “For Chevrolet 350 Small Block”)

- Manufacturer name and contact information

- “Fragile” and “This Side Up” indicators if applicable

- Country of origin (mandatory for international shipments)

- Barcodes/UPC: Include standardized UPC or SKU for inventory and customs tracking

3. Domestic and International Shipping Considerations

- Domestic (U.S.):

- Standard ground or air freight via carriers (e.g., FedEx, UPS, USPS)

- No hazardous material classification if free of fuel residue

-

Comply with FMVSS and DOT labeling for automotive components (if applicable)

-

International:

- Declare accurate value, description, and HS code on commercial invoice

- Include Certificate of Origin if claiming preferential duty under trade agreements (e.g., USMCA)

- Check destination country regulations (e.g., EU, Canada, Australia) for automotive part compliance

4. Regulatory Compliance

- EPA Regulations (U.S.):

- Fuel pumps must meet evaporative emissions standards if sold as replacement parts (under Clean Air Act)

- Aftermarket parts may need Executive Order (EO) number from CARB (California Air Resources Board) for legal sale in California

- CARB Compliance:

- Verify if the fuel pump is CARB-exempt or EO-approved

- Label with appropriate CARB certification if required

- RoHS/REACH (Europe):

- Ensure materials used comply with Restriction of Hazardous Substances (RoHS) and REACH regulations

- DOT/Transport Canada:

- No special restrictions for non-fuel-contaminated pumps; otherwise, may fall under TDG (Transportation of Dangerous Goods) if residual flammable liquid present

5. Returns and Reverse Logistics

- Establish clear return authorization (RMA) process

- Inspect returned units for contamination or damage

- Dispose of or recycle non-functional units per local environmental regulations (e.g., EPA or state hazardous waste rules if contaminated)

6. Storage and Handling

- Store in dry, temperature-controlled environments to prevent corrosion

- Keep away from open flames or ignition sources (due to potential residual fuel vapors)

- Rotate inventory using FIFO (First In, First Out) method

7. Documentation Checklist

- Commercial Invoice

- Packing List

- Bill of Lading (BOL)

- Certificate of Origin (for international)

- CARB EO Number (if applicable)

- Safety Data Sheet (SDS) — only required if the pump contains residual fuel or lubricants

By following this guide, distributors, retailers, and manufacturers can ensure compliant, efficient, and safe logistics operations for the Fuel Pump For 350 Small Block across domestic and international markets.

In conclusion, sourcing a fuel pump for a 350 small block engine requires careful consideration of your vehicle’s specific application, fuel delivery needs, and performance goals. Whether you’re restoring a classic GM truck or building a high-performance street machine, selecting the right fuel pump—mechanical or electric—ensures reliable fuel delivery and optimal engine operation. Key factors such as engine horsepower, fuel system type (carburetor vs. fuel injection), and compatibility with mounting location and drive mechanisms must be evaluated. Aftermarket options from reputable brands like Holley, Edelbrock, ACDelco, and Holley offer reliable performance and durability. By matching the fuel pump’s flow rate and pressure to your engine’s demands and verifying fitment with your specific 350 small block configuration, you can ensure efficient, long-lasting performance. Always consult manufacturer specifications and, when in doubt, seek advice from trusted automotive specialists to make the best choice for your build.