The global demand for specialized architectural glass, including frosted glass in decorative finishes such as green tint, has seen steady growth driven by rising construction activities and the increasing preference for aesthetic interior design in commercial and residential spaces. According to Grand View Research, the global architectural glass market was valued at USD 124.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is bolstered by advancements in energy-efficient and design-forward glass solutions, with frosted and tinted variants gaining traction for their privacy-enhancing and light-diffusing properties. As sustainability and visual elegance become key priorities in building design, manufacturers specializing in frosted green glass are positioning themselves at the intersection of functionality and style. Below are nine leading manufacturers at the forefront of innovation, quality, and market reach in this niche segment.

Top 9 Frosted Glass Green Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Architectural Glass | Products

Domain Est. 1995

Website: agc.com

Key Highlights: AGC glass make its scope of applications practically unlimited: from external glazing to interior decoration and industrial uses….

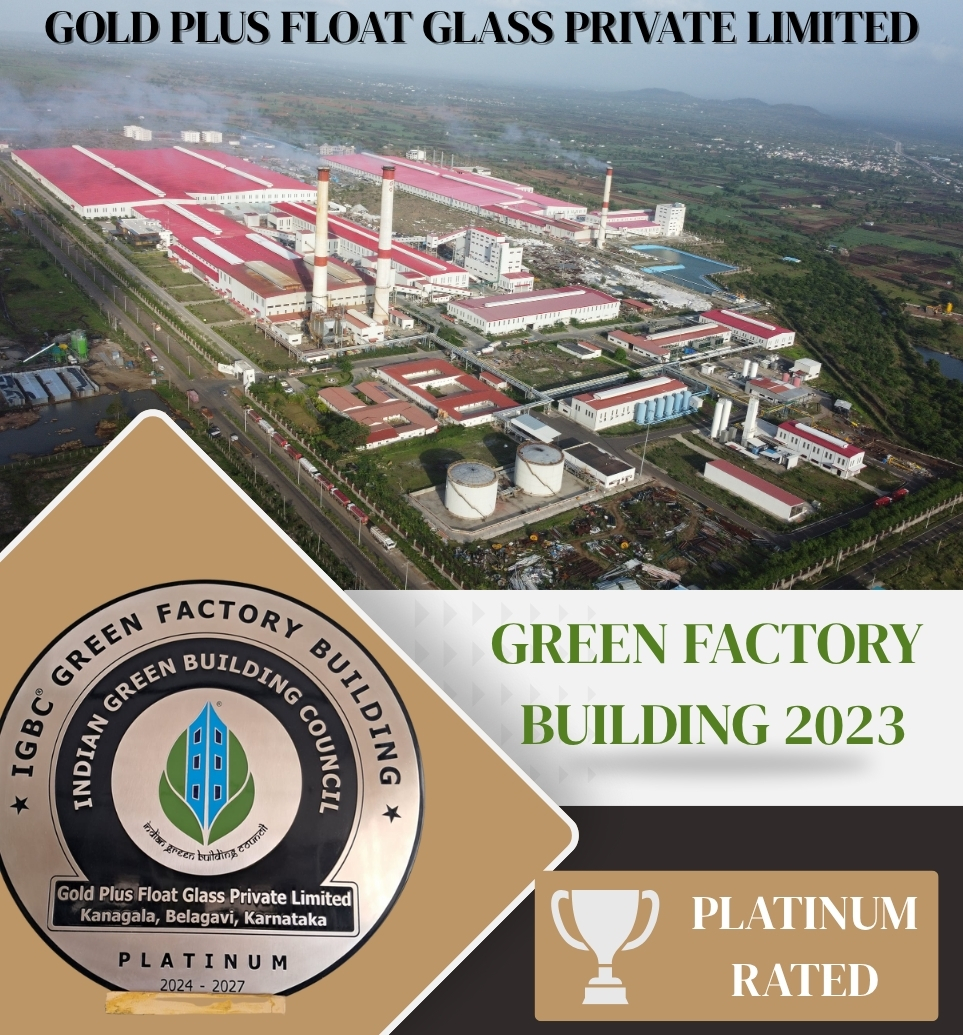

#2 Gold Plus Glass Industry

Domain Est. 2004

Website: goldplusgroup.com

Key Highlights: Gold Plus Glass has made history by becoming the first Indian glass manufacturing company to receive the Platinum rating under the IGBC Green Factory Building ……

#3 Architectural Glass Manufacturers, Glass Products and Glass …

Domain Est. 2005 | Founded: 1988

Website: ccgglass.com

Key Highlights: Central Canadian Glass Ltd. has been a family owned business since 1988. We are an original manufacturer and processor of custom glass products….

#4 China Frosted Glass Supplier and Manufacturer

Domain Est. 2017

Website: tsingglass.com

Key Highlights: TSING GLASS is a professional frosted glass manufacturer and supplier in China, providing bulk glass products for sale. Welcome to buy the best quality ……

#5 General Glass GGI is a leader in the fabrication and distribution of …

Domain Est. 1997

Website: generalglass.com

Key Highlights: We fabricate and distribute architectural glass. Over the last 120 years, our “Can Do” attitude has made us the “Go To” glass supplier for leading architects….

#6 Cardinal Glass Industries

Domain Est. 1997

Website: cardinalcorp.com

Key Highlights: A world-leading glass provider for nearly any application. Advanced LoĒ™ coatings, durable insulating glass, tempering, lamination and more….

#7 Acid Etched Glass

Domain Est. 2002

Website: architecturalglass.com

Key Highlights: Acid-etched glass, also known as satin etched glass, is a popular decorative glass that provides a smooth and classic look in a variety of finishes….

#8 Frosted Tempered Glass Panels

Domain Est. 2009

Website: chinanorthglass.com

Key Highlights: Frosted tempered glass panels are a type of glass that has been treated to make it translucent and frosted in appearance….

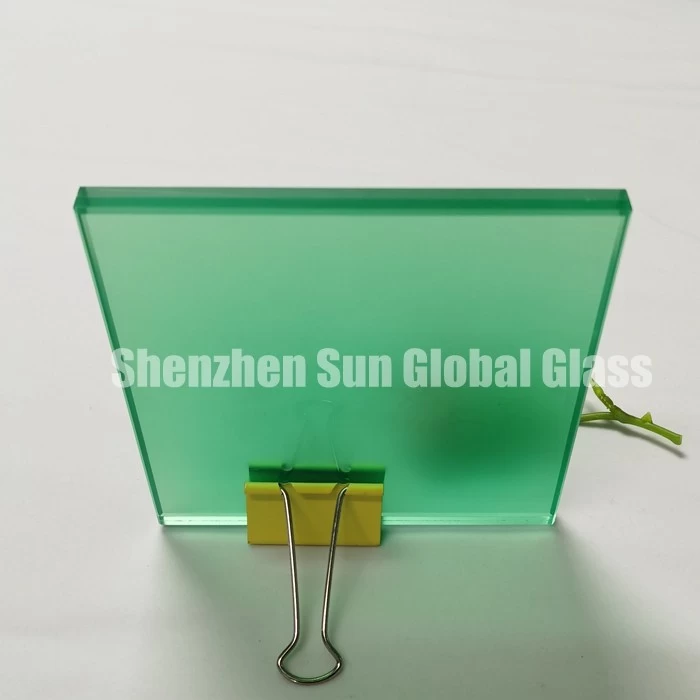

#9 13.52mm Color Frosted PVB Laminated Glass SGCC

Domain Est. 2016

Website: sggglassmanufacturer.com

Key Highlights: 13.52mm colored frosted tempered laminated glass is combined by one piece of 6mm clear or low iron tempered glass and another piece of 6mm clear or low iron ……

Expert Sourcing Insights for Frosted Glass Green

H2: 2026 Market Trends for Frosted Glass in Green Tones

The global architectural and interior design markets are poised for significant evolution by 2026, with frosted glass in green tones emerging as a distinctive trend driven by sustainability, biophilic design, and advanced manufacturing technologies. As consumers and architects increasingly prioritize wellness, energy efficiency, and aesthetic sophistication, green-tinted frosted glass is gaining traction across residential, commercial, and hospitality sectors.

-

Surge in Biophilic Design Adoption

By 2026, biophilic design—integrating natural elements into built environments—is expected to dominate architectural planning. Green frosted glass supports this movement by mimicking the hues of foliage and natural light filtered through trees. Its translucent quality allows diffused daylight to enter spaces, promoting occupant well-being and reducing reliance on artificial lighting. Office spaces, healthcare facilities, and urban residences are increasingly incorporating green frosted glass partitions, façades, and skylights to foster calming, nature-inspired atmospheres. -

Growth in Sustainable Building Practices

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing demand for eco-conscious materials. Frosted glass, particularly in green tints achieved through low-iron glass with eco-friendly pigmentation or thin-film coatings, offers high solar control and thermal insulation. By 2026, manufacturers are expected to expand production of recyclable, low-emissivity (Low-E) green frosted glass, aligning with net-zero construction goals and reducing urban heat island effects. -

Technological Advancements in Glass Fabrication

Innovations in digital acid etching, laser frosting, and smart glass integration are enabling more precise and customizable green frosted glass finishes. By 2026, smart green frosted glass with electrochromic properties—allowing users to switch between transparency levels—will gain market share in premium residential and corporate interiors. Additionally, 3D-printed texture patterns in green-frosted variants will allow for bespoke design solutions, enhancing both privacy and visual appeal. -

Regional Market Expansion

The Asia-Pacific region, particularly China and India, is anticipated to lead in demand due to rapid urbanization and luxury real estate development. In Europe, green frosted glass will be favored in retrofitting older buildings for energy efficiency while maintaining aesthetic continuity. North America will see growth in high-end residential remodels and wellness-centric commercial projects embracing green glass for its serene visual properties. -

Shift in Consumer Preferences

Homeowners and designers are increasingly favoring muted, earthy tones—such as sage, moss, and seafoam green—in interior finishes. Frosted glass in these shades offers a modern alternative to solid partitions, enhancing spatial openness while adding subtle color. By 2026, online design platforms and augmented reality (AR) tools will enable consumers to visualize green frosted glass in their spaces, accelerating adoption.

In conclusion, the 2026 market for green frosted glass will be shaped by the convergence of wellness-driven design, environmental responsibility, and technological innovation. As a functional and aesthetic material, it is projected to occupy a growing niche in sustainable architecture and premium interior applications worldwide.

Common Pitfalls Sourcing Frosted Glass Green (Quality, IP)

Sourcing Frosted Glass Green for architectural, design, or manufacturing applications requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to project delays, legal risks, or substandard end results. Below are common pitfalls to avoid:

Quality-Related Pitfalls

Inconsistent Frosted Finish

One of the most frequent quality issues is inconsistency in the frosting process. Variations in texture, opacity, or surface smoothness can occur due to differences in etching techniques (acid, sandblasting, or coated films). This leads to visual mismatch in installations, especially in large-scale projects.

Poor Color Uniformity

“Frosted Glass Green” may vary significantly in hue and saturation between batches. Suppliers may use different base glass tints or apply inconsistent coatings, resulting in mismatched colors across panels. Always request physical samples and batch certifications.

Substandard Thickness and Tolerance

Low-quality suppliers may deliver glass that doesn’t meet specified thickness or flatness tolerances. This can cause installation issues, poor sealing, or structural weakness, especially in load-bearing or safety-critical applications.

Lack of Durability Testing

Some frosted glass products degrade over time when exposed to UV light, moisture, or cleaning agents. Ensure the product has undergone durability tests (e.g., abrasion resistance, weathering) and meets relevant standards (e.g., ANSI, EN, or ASTM).

Misrepresentation of Tempering or Safety Ratings

Frosted glass used in doors, railings, or high-traffic areas must often be tempered or laminated for safety. Some suppliers may falsely claim compliance. Verify certifications (e.g., CE, CPSC 16 CFR 1201) and request test reports.

Intellectual Property (IP) Risks

Copying Proprietary Designs or Textures

Some frosted glass patterns or finishes are patented or trademarked. Sourcing a visually similar product from a third party without verifying IP rights can expose you to infringement claims, especially if the design is branded (e.g., “Starphire Ultra-Clear with Aqua Etch™”).

Unauthorized Use of Trademarked Glass Types

“Green” glass may refer to specific proprietary products (e.g., Pilkington Optiwhite Green, Saint-Gobain SGG Vert). Using these names or mimicking their appearance without authorization can lead to legal disputes, even if the physical product differs slightly.

Supplier IP Violations

The supplier you source from might be using illegally copied molds, digital patterns, or patented manufacturing processes. Even if your company is unaware, you could be held liable as a downstream user under some jurisdictions.

Lack of IP Warranty in Contracts

Many purchase agreements fail to include IP indemnification clauses. Without such protection, your business could bear the legal and financial burden if the product is later found to infringe on third-party rights.

Best Practices to Mitigate Risks

- Request physical samples and batch test reports before bulk ordering.

- Audit suppliers for compliance with ISO, CE, or other relevant standards.

- Conduct due diligence on design origins and obtain written IP warranties.

- Work with reputable manufacturers who document their IP rights and processes.

- Consult legal counsel when sourcing custom or designer glass finishes.

By proactively addressing these quality and IP pitfalls, businesses can ensure they receive reliable, compliant, and legally sound Frosted Glass Green products.

Logistics & Compliance Guide for Frosted Glass Green

This guide provides essential information for the safe, efficient, and compliant handling, transportation, storage, and documentation of Frosted Glass Green, a specialty glass product used in architectural and decorative applications. Adherence to these guidelines ensures product integrity, regulatory compliance, and operational safety.

Product Overview

Frosted Glass Green is a type of tempered or annealed glass featuring a textured, matte surface (frosted) achieved through acid etching, sandblasting, or film application, with a distinct green tint due to iron content in the raw materials. Common thicknesses range from 3mm to 12mm, and standard sheet sizes include 2440x1830mm and 3210x2250mm. It is primarily used in interior partitions, doors, shower enclosures, and facades where privacy, diffused light, and aesthetic appeal are desired.

Packaging Requirements

Proper packaging is critical to prevent breakage and surface damage during transit. Frosted Glass Green must be packaged as follows:

- Edge Protection: Use rigid edge protectors (cardboard, plastic, or wood) on all four sides to absorb impact and prevent chipping.

- Interlayer Protection: Place kraft paper or low-adhesion plastic film between each glass sheet to avoid scratching the frosted surface.

- Palletization: Stack sheets vertically or horizontally (as per manufacturer specification) on sturdy wooden pallets. Maximum stack height should not exceed manufacturer recommendations to avoid bottom sheet stress.

- Securing Load: Wrap the entire load with stretch film or strapping to prevent shifting. Use corner boards for added stability.

- Labeling: Clearly label each package with “FRAGILE,” “GLASS – HANDLE WITH CARE,” “THIS SIDE UP,” and product details (e.g., thickness, size, green tint, frosted side).

Transportation Guidelines

Transport Frosted Glass Green using the following protocols:

- Vehicle Type: Use enclosed, dry vans or flatbed trucks with side curtains to protect against weather and debris. Open trailers require waterproof tarping.

- Loading/Unloading: Use mechanical aids (forklifts with glass clamps, suction lifters) only. Never drag or drop glass packages.

- Orientation: Maintain vertical orientation whenever possible to minimize stress. If horizontal stacking is necessary, ensure even support across the entire pallet.

- Bracing & Securing: Secure pallets to the vehicle floor with straps or load locks to prevent movement during transit. Avoid overloading.

- Environmental Conditions: Avoid exposure to extreme temperatures or humidity, which may compromise packaging adhesives or cause condensation.

Storage Procedures

Store Frosted Glass Green in controlled conditions to preserve quality:

- Location: Indoors, in a dry, well-ventilated area protected from direct sunlight, rain, and temperature fluctuations.

- Positioning: Store vertically in racks at a 5–10° incline to prevent slumping and facilitate drainage of any moisture. If stored horizontally, limit stack height and ensure flat, level support.

- Flooring: Use even, solid flooring free of debris. Avoid damp or uneven surfaces.

- Handling During Storage: Always use appropriate lifting equipment. Do not stack other materials on glass packages.

- Shelf Life: While glass itself does not degrade, prolonged storage may risk packaging failure or edge damage. Rotate stock using FIFO (First In, First Out) principles.

Regulatory Compliance

Ensure all operations comply with applicable local, national, and international regulations:

- Hazard Classification: Frosted Glass Green is not classified as hazardous under GHS or DOT regulations but is considered fragile cargo.

- Packaging Standards: Comply with ISTA 3A or equivalent for transport testing where applicable.

- Workplace Safety (OSHA/Equivalent): Adhere to safety standards for manual handling, use of PPE (gloves, safety glasses, steel-toe boots), and machine operation.

- Environmental Regulations: Recycle packaging materials (wood, cardboard, plastic) in accordance with local waste management laws. Avoid disposal of glass fragments in regular waste; recycle or dispose via licensed waste handlers.

- Import/Export Documentation: For international shipments, provide accurate HS Code (e.g., 7007.11 or 7007.21 for toughened glass), commercial invoice, packing list, and certificate of origin. Verify CITES requirements if applicable (not typically required for standard glass).

Handling & Installation Safety

Train personnel on safe handling practices:

- Personal Protective Equipment (PPE): Mandatory use of cut-resistant gloves, safety goggles, and protective footwear.

- Lifting Techniques: Use team lifting for large sheets; employ vacuum lifters or mechanical aids for sheets over 50 lbs (23 kg).

- Installation Precautions: Follow manufacturer guidelines for framing, sealing, and structural support. Ensure edges are properly supported and sealed to prevent water ingress and stress cracks.

- Breakage Protocol: In case of breakage, clear shards immediately using approved methods (brooms, dustpans—no bare hands). Dispose of broken glass in puncture-resistant containers labeled “Broken Glass.”

Documentation & Traceability

Maintain accurate records throughout the supply chain:

- Batch Tracking: Each shipment should include batch/lot numbers for traceability.

- Certificates: Provide or request Certificates of Compliance (CoC), Test Reports (e.g., for tempering or optical quality), and Safety Data Sheets (SDS – though generally not required for glass, may be provided for coatings or films).

- Shipping Documents: Include detailed packing lists, bills of lading, and delivery notes specifying product type, dimensions, quantity, and handling instructions.

Emergency Procedures

Prepare for potential incidents:

- Breakage Response: Isolate area, post warning signs, and clean up using proper tools and PPE. Report significant breakage for root cause analysis.

- Spill Management: No chemical spill risk, but manage packaging debris responsibly.

- Accident Reporting: Document all handling accidents or injuries per company policy and regulatory requirements.

Adhering to this Logistics & Compliance Guide ensures the safe and compliant movement of Frosted Glass Green from manufacturer to end-user, minimizing damage, ensuring regulatory alignment, and protecting personnel. Always consult product-specific data and local regulations for full compliance.

In conclusion, sourcing frosted green glass requires careful consideration of quality, supplier reliability, application requirements, and cost-effectiveness. By identifying reputable suppliers—whether local fabricators, specialty glass manufacturers, or international exporters—you can ensure the material meets aesthetic, functional, and safety standards for your project. Evaluating factors such as tint consistency, frosting technique (acid-etched, sandblasted, or film-applied), thickness, and customization options will further support a successful procurement process. With proper due diligence and clear communication with suppliers, frosted green glass can be effectively sourced to enhance privacy, light diffusion, and visual appeal in architectural or design applications.