The global plexiglass (polymethyl methacrylate, or PMMA) sheet market is experiencing steady growth, driven by rising demand across industries such as construction, automotive, signage, and consumer electronics. According to a report by Mordor Intelligence, the PMMA market was valued at USD 5.87 billion in 2023 and is projected to grow at a CAGR of approximately 5.4% from 2024 to 2029, reaching over USD 8 billion by the end of the forecast period. Growth is fueled by the material’s lightweight properties, high optical clarity, and superior weather resistance compared to traditional glass. Frost-resistant and impact-modified plexiglass sheets, in particular, are gaining traction in cold-climate construction and outdoor applications, where durability and thermal performance are critical. As demand for specialty acrylic sheets rises, manufacturers are investing in R&D and scaling production to meet increasingly stringent performance standards—setting the stage for a competitive landscape defined by innovation, quality, and technical expertise. The following list highlights the top 10 manufacturers excelling in the production of frost-grade and high-performance plexiglass sheets.

Top 10 Frost Plexiglass Sheet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

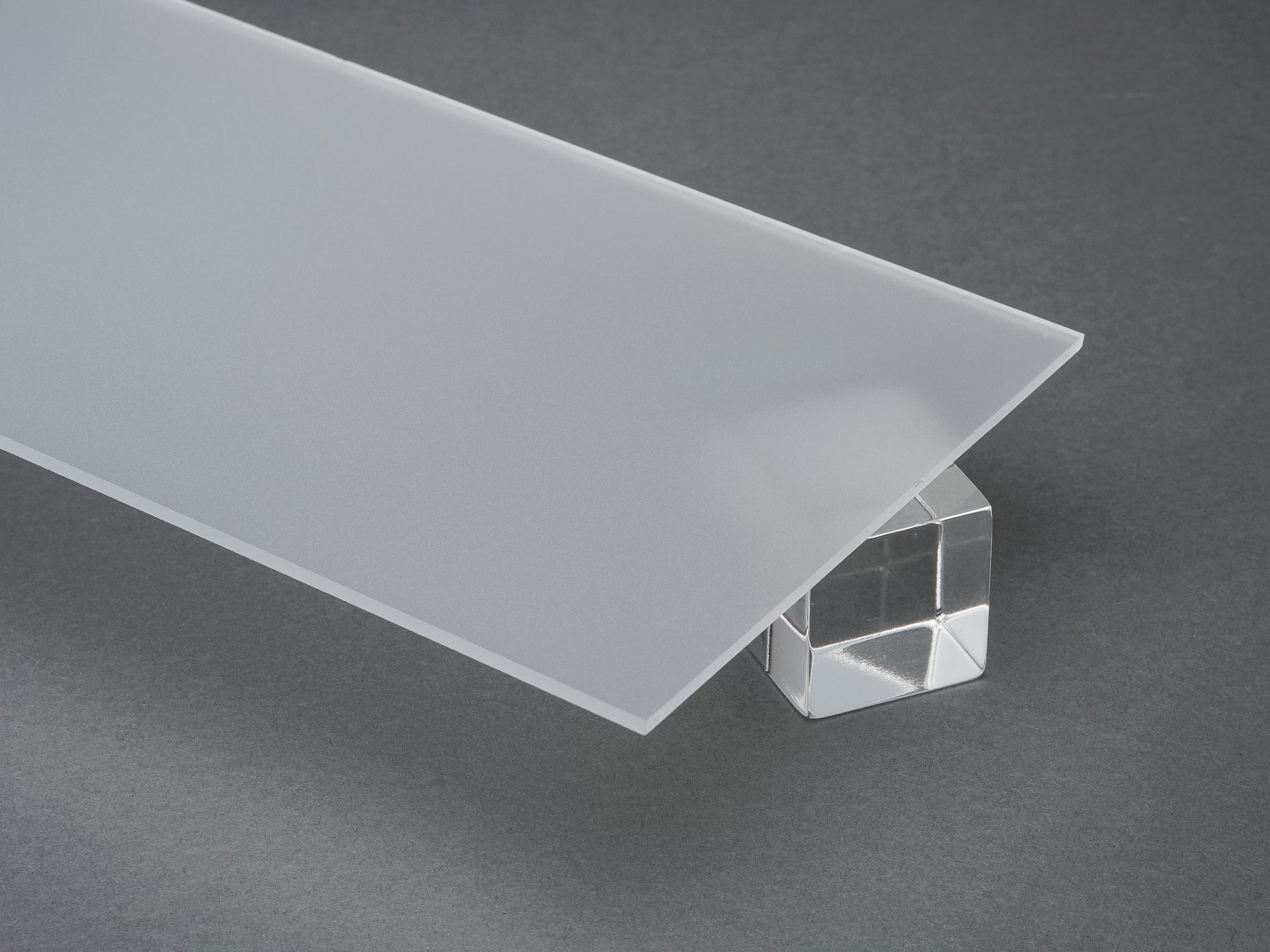

#1 Frosted Acrylic Sheet

Domain Est. 2020

Website: acrylicitemsmaker.com

Key Highlights: Jiayuan is a trustable acrylic material manufacturer offering frosted acrylic sheets with cut to size options. The frosted acrylic sheets feature light ……

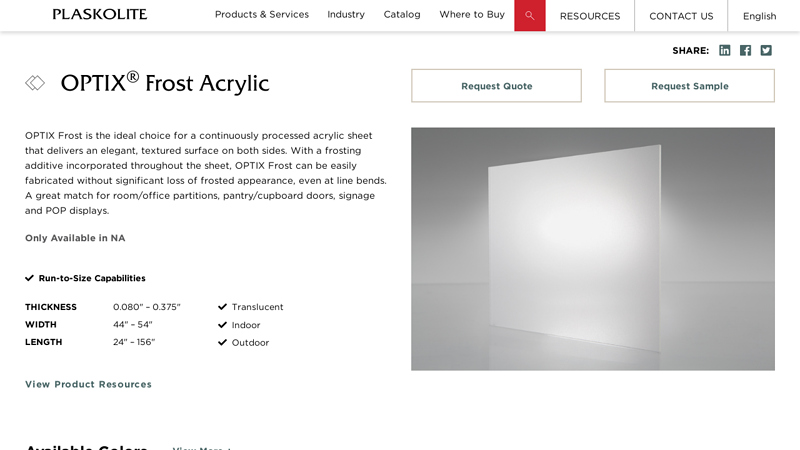

#2 OPTIX Frost Acrylic

Domain Est. 1996

Website: plaskolite.com

Key Highlights: OPTIX Frost is the ideal choice for a continuously processed acrylic sheet that delivers an elegant, textured surface on both sides….

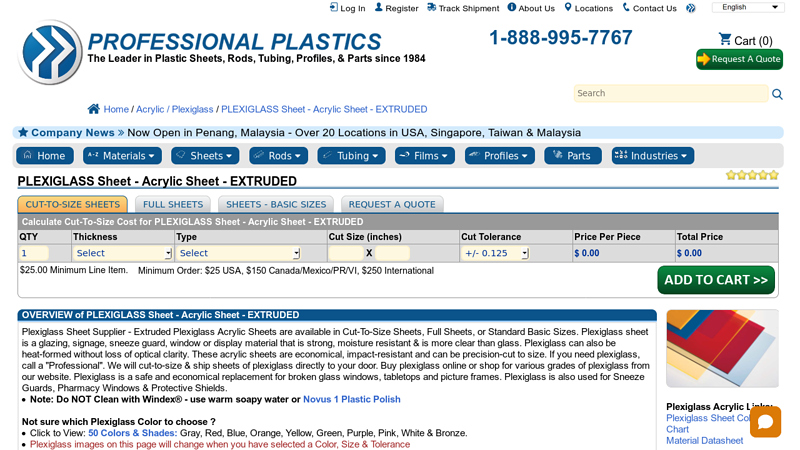

#3 Plexiglass Sheet

Domain Est. 1997

Website: professionalplastics.com

Key Highlights: 3-day returnsWe will cut-to-size & ship sheets of plexiglass directly to your door. Buy plexiglass online or shop for various grades of plexiglass from our website….

#4 Plastic, Acrylic & Polycarbonate Sheet Supplier

Domain Est. 1997

Website: acplasticsinc.com

Key Highlights: Our offering includes acrylic sheeting, plexiglass sheeting, polycarbonate sheeting, multiwall sheeting, abs plastic sheeting, HDPE and much more….

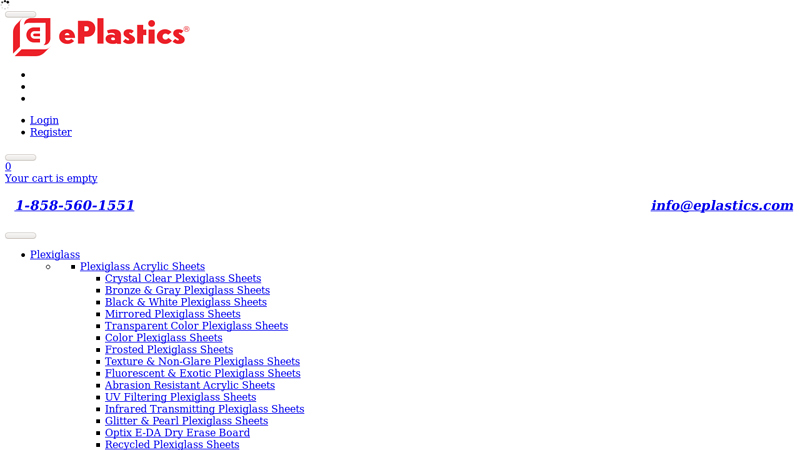

#5 Frosted Plexiglass Sheets Cut

Domain Est. 1998

Website: eplastics.com

Key Highlights: 2–5 day delivery 30-day returnsFrosted Plexiglass Sheets. We cut to size all acrylic sheets we sell, which saves on shipping costs since it offers a more economical means of packag…

#6 Frosted Plexiglass

Domain Est. 2000

Website: polymershapes.com

Key Highlights: Better known as acrylic sheets, Polymershapes sells Acrylic frosted Plexiglass that can be used in a variety of ways….

#7 Clear Frost Cast Acrylic Sheet

Domain Est. 2002

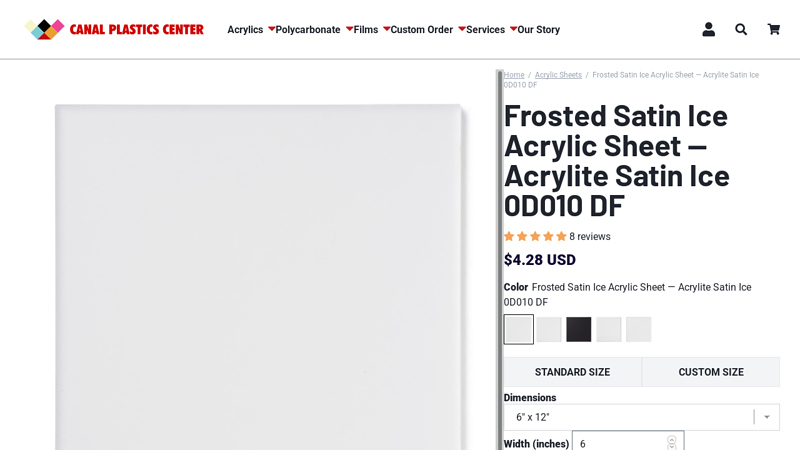

#8 Frosted Satin Ice Acrylic Sheet

Domain Est. 2004

Website: canalplastic.com

Key Highlights: Elegant Frosted Finish with Superior Light Diffusion. Bring a modern, luminous look to your projects with the ACRYLITE® Satin Ice Frosted Acrylic Sheet….

#9 1/8″ Clear Frosted Transparent Glossy Acrylic Sheet Plexiglass (3pcs)

Domain Est. 2013

Website: xtool.com

Key Highlights: Out of stock Rating 5.0 (4) 1/8″ Clear Frosted Transparent Glossy Acrylic Sheet Plexiglass (3pcs) … Explore year-end tax deductions & apply for up to 7% tax savings….

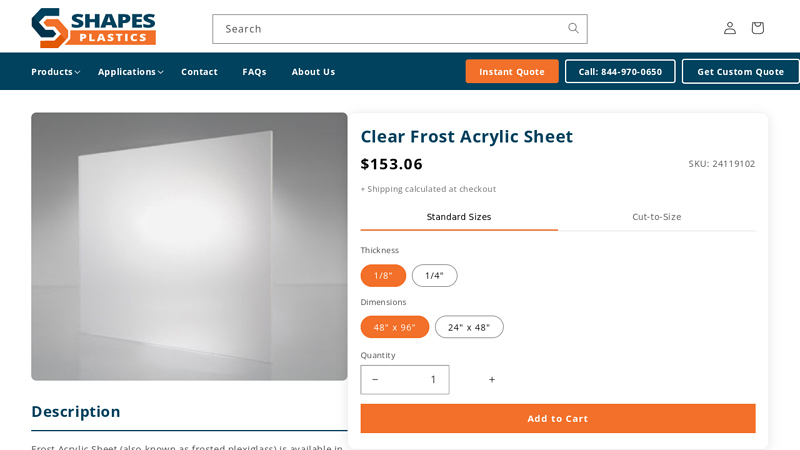

#10 Frosted Acrylic Sheet

Domain Est. 2019

Website: shapesplastics.com

Key Highlights: Frost Acrylic Sheet (also known as frosted plexiglass) is available in 1/8″ and 1/4″ thicknesses. Standard sheet sizes include 48″ × 96″ and 24″ × 48″….

Expert Sourcing Insights for Frost Plexiglass Sheet

H2: Market Trends for Frost Plexiglass Sheet in 2026

The global market for Frost Plexiglass Sheet is poised for significant evolution by 2026, driven by advancements in material science, rising demand across industries, and shifting consumer preferences toward sustainable and aesthetically pleasing materials. As a versatile variant of polymethyl methacrylate (PMMA), frosted plexiglass—known for its translucent, matte finish and light-diffusing properties—is gaining traction in architecture, interior design, signage, and retail applications.

One of the dominant trends shaping the 2026 market is the growing emphasis on energy-efficient and eco-conscious building materials. Frost plexiglass sheets offer superior light transmission compared to traditional glass while being significantly lighter and more impact-resistant. These attributes align with green building standards such as LEED and BREEAM, increasing adoption in commercial and residential construction, particularly in skylights, partitions, and façades.

Another key driver is the expansion of the interior design and retail sectors, especially in emerging economies. Designers are increasingly favoring frosted plexiglass for creating modern, minimalist spaces that balance privacy with illumination. Its use in display cases, room dividers, and decorative lighting is expected to grow, supported by innovations in surface texturing and UV-resistant coatings that enhance durability and design flexibility.

Technological advancements are also influencing the market. Manufacturers are investing in advanced extrusion and laser-etching techniques to produce consistent, high-quality frosted finishes with customized opacity levels. By 2026, smart integration—such as coupling frosted plexiglass with embedded LED systems or switchable privacy films—could open new applications in smart homes and offices.

Regionally, Asia-Pacific is anticipated to lead market growth due to rapid urbanization, infrastructure development, and increasing disposable incomes in countries like China, India, and Southeast Asian nations. Meanwhile, North America and Europe will continue to see steady demand, bolstered by renovation activities and stringent safety regulations favoring shatter-resistant materials over glass.

Sustainability concerns are prompting shifts in raw material sourcing and end-of-life management. Leading producers are exploring bio-based PMMA and recycling programs to reduce environmental impact, a trend likely to gain momentum by 2026 as regulatory pressures and consumer awareness intensify.

In conclusion, the Frost Plexiglass Sheet market in 2026 will be characterized by innovation, sustainability, and expanding application scopes. Companies that invest in R&D, eco-friendly production, and tailored design solutions are expected to capture significant market share in this dynamic landscape.

Common Pitfalls When Sourcing Frost Plexiglass Sheets (Quality and Intellectual Property)

Sourcing frost plexiglass sheets—often used for diffusers, signage, and architectural applications—can present several challenges, particularly concerning material quality and intellectual property (IP) risks. Being aware of these pitfalls helps ensure you receive a reliable, legally compliant product.

Quality-Related Pitfalls

Inconsistent Optical Clarity and Light Diffusion

Not all frost plexiglass delivers uniform light diffusion. Low-quality sheets may exhibit streaks, cloudiness, or uneven frosting, impacting aesthetic and functional performance. Suppliers may use inconsistent etching or coating processes, leading to batch-to-batch variation.

Poor Surface Durability and Scratch Resistance

Cheaply manufactured frost plexiglass often has a fragile matte finish that scratches or wears easily during handling, installation, or cleaning. This diminishes visual quality over time, especially in high-traffic or commercial environments.

Off-Spec Thickness and Dimensional Accuracy

Tolerances in thickness, flatness, and cut dimensions can vary significantly among suppliers. Poor dimensional accuracy leads to fitting issues during installation, increasing labor costs and project delays.

UV and Weathering Degradation

Standard acrylic may yellow or become brittle when exposed to sunlight unless UV-stabilized. Sourcing non-UV-resistant sheets for outdoor use results in premature failure. Ensure specifications include weatherability data and UV protection.

Material Substitution and Mislabeling

Some suppliers may substitute lower-grade acrylic or polystyrene for genuine polymethyl methacrylate (PMMA), especially when branding “plexiglass” loosely. This compromises clarity, strength, and longevity.

Intellectual Property (IP) and Compliance Risks

Unauthorized Use of Branded Materials

“Plexiglas®” is a registered trademark (by Röhm GmbH). Using or sourcing materials labeled as “Plexiglas” without proper licensing—especially in branding or marketing—can lead to trademark infringement claims. Always verify trademark usage rights.

Counterfeit or Illegally Manufactured Sheets

Some suppliers, particularly in unregulated markets, may produce or distribute counterfeit branded sheets. These not only violate IP laws but also lack performance guarantees and traceability.

Lack of Certification and Documentation

Reputable suppliers provide material safety data sheets (MSDS), compliance certificates (e.g., ISO, REACH, RoHS), and IP documentation. Absence of these raises red flags about legitimacy and regulatory compliance.

Design or Pattern Copyright Infringement

If the frost pattern or surface texture is proprietary (e.g., a unique diffuser design), reproducing it without permission—even if the base material is generic—may infringe on design patents or copyrights.

To mitigate these risks, partner with certified, transparent suppliers, request samples and documentation, and conduct due diligence on both material specifications and IP compliance.

Logistics & Compliance Guide for Frost Plexiglass Sheet

Frost plexiglass (also known as frosted acrylic or matte acrylic sheet) is widely used in signage, displays, partitions, and architectural applications. Proper logistics and compliance handling ensures product integrity, safety, and adherence to regulatory standards. This guide outlines key considerations for the transportation, storage, and regulatory compliance of frost plexiglass sheets.

Product Characteristics and Handling

Frost plexiglass is a lightweight, shatter-resistant thermoplastic with a diffused, translucent surface. Despite its durability, it is susceptible to scratching, warping, and static buildup. Always handle with clean gloves to prevent surface oil transfer. Avoid dragging sheets across surfaces; instead, lift and carry them vertically when possible. Use non-abrasive padding between stacked sheets during transport and storage.

Packaging Requirements

Sheets must be securely packaged to prevent surface damage and edge chipping. Standard packaging includes:

– Protective masking film on both sides (typically polyethylene)

– Edge protectors made of corrugated cardboard or plastic

– Bundling with non-abrasive strapping or shrink wrap

– Placement on wooden pallets with corner boards for stability

Ensure packaging is weather-resistant if shipping outdoors or in humid conditions.

Transportation Guidelines

Transport frost plexiglass sheets in enclosed, dry vehicles to avoid moisture exposure and UV degradation. Secure loads with straps to prevent shifting. Avoid extreme temperatures—do not expose sheets to prolonged heat above 80°C (176°F) or cold below -40°C (-40°F), as this may cause warping or embrittlement. Store vertically during transit when possible to reduce stress and minimize risk of bowing.

Storage Conditions

Store in a clean, dry, and temperature-controlled environment (15–25°C or 59–77°F ideal). Keep sheets away from direct sunlight and heat sources to prevent yellowing and deformation. Store vertically on racks with adequate support, or horizontally on flat, clean surfaces with spacers between layers. Maximum stack height should not exceed manufacturer recommendations (typically 1–1.5 meters or 3–5 feet).

Regulatory Compliance

Frost plexiglass sheets (typically made of polymethyl methacrylate, PMMA) are subject to various national and international regulations:

- REACH (EU): Compliant with Registration, Evaluation, Authorisation and Restriction of Chemicals. No SVHCs (Substances of Very High Concern) above threshold limits.

- RoHS (EU): Complies with restrictions on hazardous substances in electrical and electronic equipment (if applicable).

- California Proposition 65: Products do not contain chemicals known to cause cancer or reproductive harm in quantities requiring warning labels.

- Fire Safety (ASTM/UL Standards): Some grades meet flame-retardant specifications (e.g., UL 94 HB). Confirm fire rating based on application.

- REACH & TSCA (USA): Complies with U.S. Toxic Substances Control Act for chemical reporting.

Provide Safety Data Sheets (SDS) upon request, in accordance with GHS standards.

Import and Export Documentation

For international shipments, ensure the following documentation is accurate:

– Commercial invoice with correct HS Code (typically 3920.51 for acrylic sheets)

– Packing list

– Certificate of Origin

– SDS (Safety Data Sheet)

– Any applicable test reports (e.g., fire resistance, REACH compliance)

Verify import regulations in destination countries, particularly for environmental and material safety standards.

Sustainability and Disposal

Frost plexiglass is recyclable (Resin Identification Code #7 “Other Plastics”). Encourage recycling through certified plastic recyclers. If incinerated, do so in controlled facilities with proper emissions treatment, as burning acrylic releases methyl methacrylate fumes. Landfilling should be a last resort.

Summary

Proper logistics and compliance practices are essential for maintaining the quality and regulatory acceptability of frost plexiglass sheets. Adhering to handling, packaging, transportation, storage, and regulatory guidelines ensures product performance, customer satisfaction, and legal compliance across global markets. Always consult the manufacturer’s specifications and local regulations for application-specific requirements.

Conclusion for Sourcing Frost Plexiglass Sheets

After a thorough evaluation of suppliers, material specifications, pricing, lead times, and quality standards, sourcing frost plexiglass (also known as frosted acrylic or matte acrylic) sheets is both feasible and advantageous for the intended application. The material offers excellent light diffusion, aesthetic appeal, durability, and ease of fabrication—making it ideal for architectural, signage, display, and interior design uses.

Key sourcing considerations include selecting suppliers who provide consistent quality with uniform frosting, UV resistance (if needed), and compliance with relevant industry standards. Bulk purchasing from reputable manufacturers or distributors can yield cost savings without compromising on clarity or finish. Additionally, evaluating lead times, shipping logistics, and customization options (such as cut-to-size or special thicknesses) ensures timely project execution.

In conclusion, sourcing frost plexiglass sheets from vetted suppliers offers a reliable, cost-effective solution that meets both functional and aesthetic requirements. Establishing long-term partnerships with trusted vendors will further enhance supply chain efficiency and product consistency for future projects.