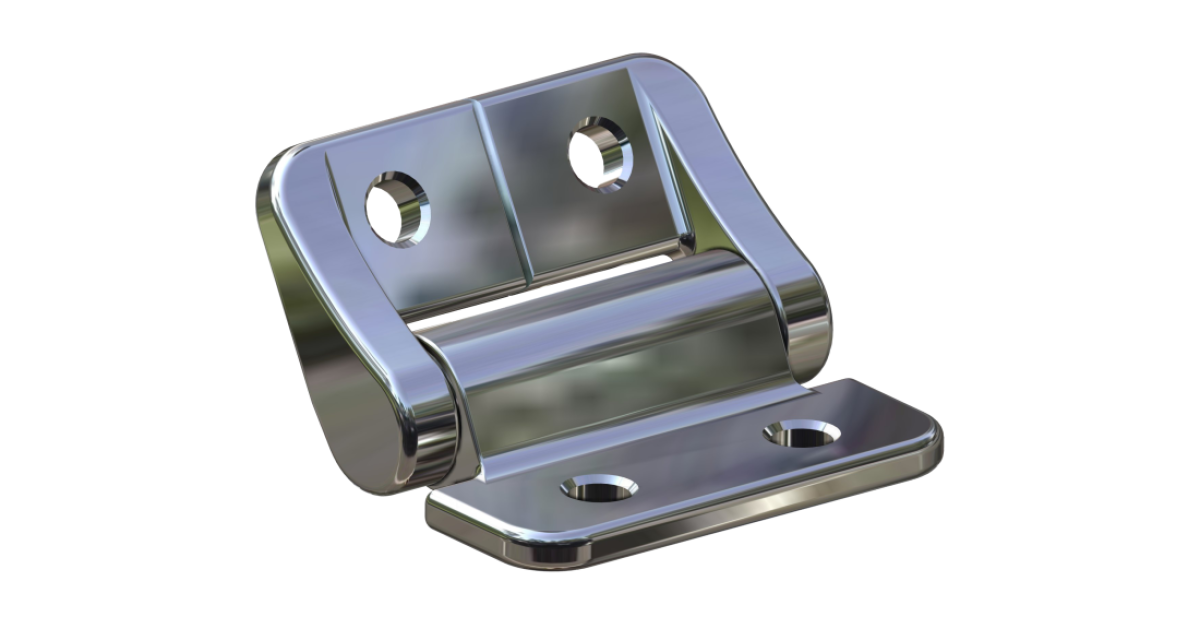

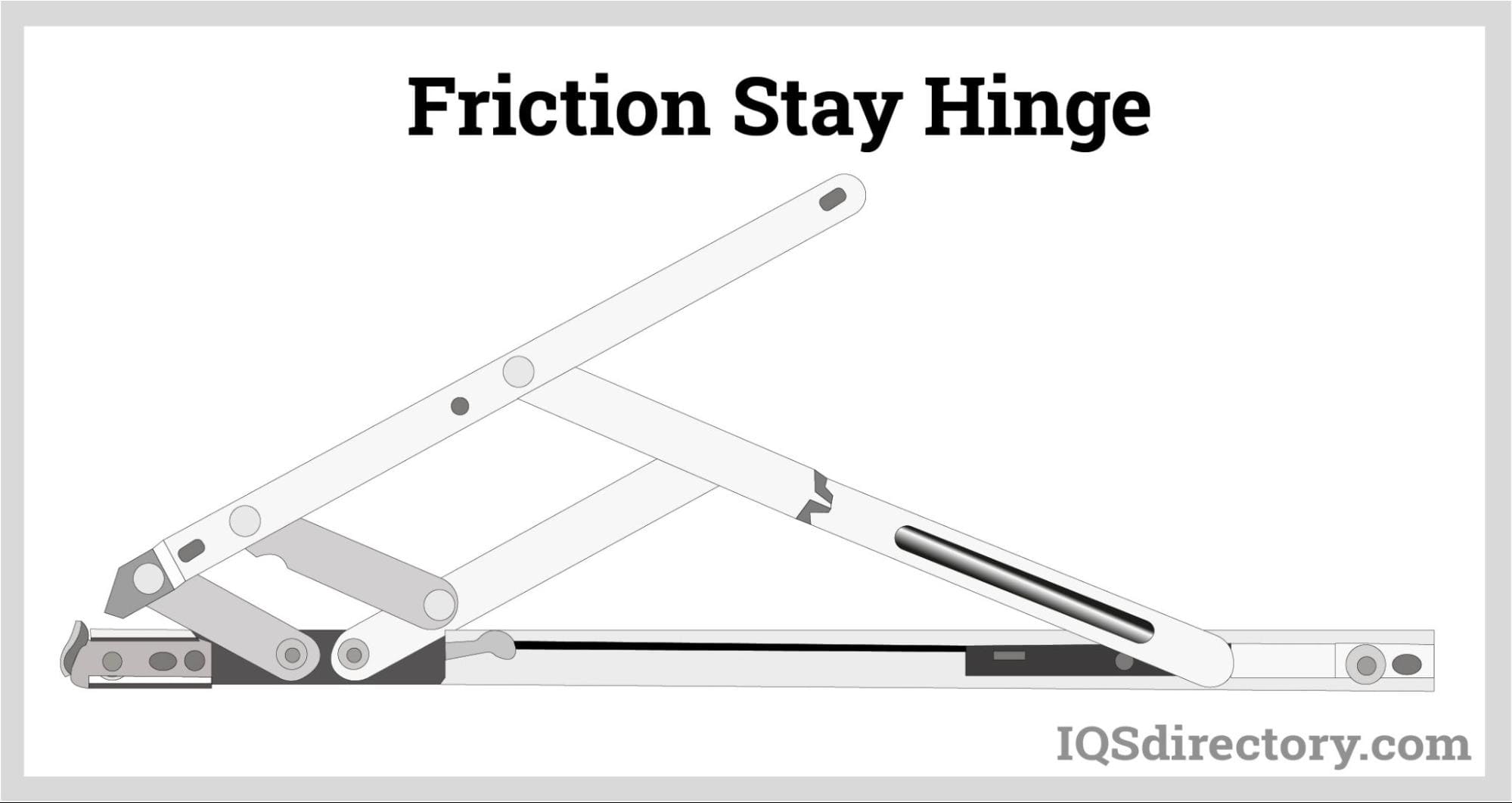

The global friction hinges market is experiencing steady expansion, driven by rising demand across consumer electronics, automotive, medical equipment, and industrial applications. According to a report by Mordor Intelligence, the global hinges market was valued at USD 8.92 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029, with friction hinges representing a significant segment due to their durability, precise motion control, and ability to hold position without additional locking mechanisms. This growth is further fueled by the proliferation of sleek, lightweight devices such as laptops, tablets, and foldable displays, where smooth, reliable hinge performance is critical. As design complexity increases and product lifecycles shorten, manufacturers are under pressure to source high-precision, customizable friction hinges that meet stringent quality and performance standards. In this competitive landscape, a select group of manufacturers has emerged as leaders, combining engineering expertise, scalable production, and innovation to serve diverse global markets. The following analysis highlights the top nine friction hinge manufacturers shaping the industry’s future through advanced technology, strategic partnerships, and robust R&D investments.

Top 9 Friction Hinges Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hanaya, Inc.

Domain Est. 2005

Website: hanayainc.com

Key Highlights: Hanaya, Inc. is a manufacturer of friction hinges for commercial and industrial applications. We offer hinges for electronics, home products, and more….

#2 Reell

Domain Est. 1995

Website: reell.com

Key Highlights: Reell constant torque friction hinges hold position throughout their full range of motion. Patented ReellTorq® clip technology, provides a smooth quality feel ……

#3 Torque and Friction Hinge Manufacturer

Domain Est. 1996

Website: torqmaster.com

Key Highlights: We offer stock, semi-custom, and full custom torque hinge designs. We are ISO registered; RoHS, Reach, and Conflict Minerals compliant. Standard Friction Hinges….

#4 Friction Hinges

Domain Est. 1997

Website: spep.com

Key Highlights: We offer flush mount, adjustable friction hinges in ranging specs, including sizes, materials, and finishes, to better meet your needs….

#5 LEECO: Position Hinge

Domain Est. 2009

Website: leecotech.com

Key Highlights: LEECO provides position, friction, and torque hinges, including stainless steel and custom hinge solutions for industrial, automotive, and marine use….

#6 Friction Hinge Suppliers

Domain Est. 2015

Website: hingemanufacturers.org

Key Highlights: Locate Friction Hinge suppliers and manufacturing companies offering top of the line industrial high quality friction hinges in the United States….

#7 Hinges

Domain Est. 1996

Website: southco.com

Key Highlights: Southco’s extensive range of Hinges designed with unique friction / torque options, concealed and removeable styles for many industries….

#8 Friction hinges

Domain Est. 1999

Website: industrilas.com

Key Highlights: Friction hinges are used when you need a door or hatch to stay in the open position. They work for both horizontally and vertically opened doors….

#9 Friction hinges

Domain Est. 2002

Website: pinet-industrie.com

Key Highlights: The range of friction hinges consists of small and large adjustable friction, with or without stainless steel friction, torque between 3N.m and 8N.m….

Expert Sourcing Insights for Friction Hinges

H2: Emerging Market Trends for Friction Hinges in 2026

As the global industrial and consumer product landscape evolves, friction hinge technology is poised for significant shifts driven by demand for precision, durability, and smart integration. By 2026, several key trends are expected to shape the friction hinges market, influencing design, materials, applications, and regional dynamics.

Rising Demand Across Expanding Application Sectors

The proliferation of compact, ergonomic, and multifunctional devices continues to drive demand for high-performance friction hinges. Key growth areas include foldable smartphones and tablets, ultra-thin laptops, wearable technology, and advanced medical devices such as surgical monitors and diagnostic equipment. Additionally, the automotive sector is increasingly adopting friction hinges in center consoles, sun visors, and heads-up displays, particularly in electric and autonomous vehicles where interior modularity and user interface refinement are priorities.

Advancements in Materials and Engineering

To meet durability and weight requirements, manufacturers are investing heavily in advanced materials like magnesium alloys, high-strength polymers, and composite materials. These materials offer enhanced torque consistency, corrosion resistance, and reduced weight—critical for portable electronics and aerospace applications. Concurrently, precision engineering and miniaturization are enabling smaller, quieter, and more reliable hinge mechanisms capable of withstanding thousands of open-close cycles without performance degradation.

Integration with Smart and IoT-Enabled Systems

A defining trend for 2026 is the integration of friction hinges with sensors and IoT technologies. Smart hinges equipped with position sensors, torque feedback systems, and adaptive resistance mechanisms are emerging, particularly in industrial automation, robotics, and high-end consumer electronics. These “intelligent” hinges can adjust resistance dynamically based on user behavior or environmental conditions, enhancing user experience and system efficiency.

Sustainability and Circular Economy Pressures

Environmental regulations and consumer preferences are pushing manufacturers toward sustainable production practices. By 2026, expect increased use of recyclable materials, modular designs that enable easy repair or replacement, and manufacturing processes with lower carbon footprints. OEMs are prioritizing suppliers who offer eco-certified components, driving innovation in biodegradable lubricants and lead-free alloys.

Regional Market Shifts and Supply Chain Resilience

Asia-Pacific, particularly China, Japan, and South Korea, remains the dominant manufacturing hub for friction hinges due to its strong electronics and automotive industries. However, nearshoring and supply chain diversification efforts—spurred by geopolitical tensions and pandemic disruptions—are accelerating production in regions like Eastern Europe, Mexico, and Southeast Asia. This shift emphasizes localized manufacturing to reduce lead times and enhance supply chain resilience.

Competitive Landscape and Innovation

The market is becoming increasingly competitive, with both established players and niche innovators focusing on differentiation through IP development. Patents around self-lubricating mechanisms, zero-backlash designs, and multi-axis articulation are rising. Strategic partnerships between hinge manufacturers and OEMs are also on the rise to co-develop application-specific solutions, ensuring tighter integration and faster time-to-market.

In summary, the 2026 friction hinge market will be defined by technological sophistication, application diversification, and sustainability imperatives. Companies that embrace innovation in materials, smart functionality, and sustainable practices will be best positioned to capture growth in this dynamic and essential component sector.

Common Pitfalls When Sourcing Friction Hinges: Quality and Intellectual Property Risks

Overlooking Material Quality and Tolerance Standards

One of the most frequent issues in sourcing friction hinges is underestimating the importance of material quality and manufacturing precision. Low-cost suppliers may use inferior metals or plastics that degrade quickly under repeated use, leading to reduced torque consistency and premature failure. Poor machining tolerances can result in inconsistent friction performance, wobbling, or binding. Always verify material specifications (e.g., stainless steel grade, zinc alloy composition) and insist on dimensional and torque testing reports.

Assuming All Friction Hinges Perform the Same

Friction hinges vary significantly in torque control, adjustability, and durability based on design and engineering. Sourcing generic versions without clearly defined performance requirements can lead to products that don’t meet functional needs—such as insufficient holding strength or uneven motion. Be sure to specify torque values, cycle life, and environmental resistance (e.g., temperature, humidity) upfront to avoid mismatches.

Ignoring Intellectual Property (IP) Risks

Many high-performance friction hinge designs are protected by patents, especially those used in electronics, medical devices, and aerospace. Sourcing from suppliers offering “compatible” or “equivalent” versions of branded hinges can expose your company to IP infringement claims. Always conduct due diligence on the hinge design’s patent status and ensure your supplier can provide legal assurances or design-around solutions.

Relying on Inadequate Testing and Certification

Some suppliers provide hinges that pass basic visual inspection but fail under real-world stress. Lack of standardized testing—such as cycle testing (e.g., 20,000+ open/close cycles), salt spray resistance, or torque consistency checks—can result in field failures. Require third-party test reports and consider pre-production sampling with independent lab verification.

Failing to Secure Long-Term Supply Agreements

Friction hinge designs can become obsolete quickly, especially if sourced from small or non-specialized manufacturers. Without a long-term supply agreement or second-source options, you risk production delays. Ensure your supplier has stable manufacturing capacity and consider tooling ownership and documentation access to mitigate supply chain risks.

Neglecting Customization and Documentation Control

When sourcing custom friction hinges, unclear specifications or lack of design control can lead to inconsistencies across batches. Poor documentation (e.g., missing CAD files, torque specs, material certs) hampers quality control and future sourcing. Maintain ownership of design files and require comprehensive product documentation as part of the procurement contract.

Logistics & Compliance Guide for Friction Hinges

Overview

Friction hinges are mechanical components used to control the motion and positioning of lids, doors, and panels in various applications, including electronics, industrial equipment, and furniture. Due to their mechanical function and material composition, specific logistics and compliance considerations must be addressed during international shipment and regulatory compliance.

Packaging & Handling Requirements

Proper packaging ensures friction hinges arrive undamaged and ready for use. Follow these guidelines:

– Use anti-static or protective packaging for hinges used in sensitive electronic devices.

– Secure parts in partitioned containers or blister packs to prevent scratching or deformation.

– Label packages with handling instructions such as “Fragile” or “Do Not Stack” when applicable.

– Ensure packaging materials are recyclable and compliant with environmental regulations (e.g., EU Packaging Directive 94/62/EC).

Transportation & Shipping

Friction hinges are generally non-hazardous but require careful logistics planning:

– Classify under HS Code 8302.41 or 8302.42 (Other hinges and pivots, iron/steel or other metals), depending on material composition.

– Declare correct weight, quantity, and value for customs clearance.

– Use insured freight services for high-value shipments.

– Comply with Incoterms (e.g., FOB, DAP) agreed upon with the buyer to clarify responsibilities.

Material Compliance

Friction hinges may be subject to material restrictions based on their metal content:

– Ensure compliance with RoHS (EU Directive 2011/65/EU) for electrical/electronic applications—restricts lead, cadmium, mercury, and other hazardous substances.

– Adhere to REACH (EC 1907/2006) regulations—register and disclose SVHCs (Substances of Very High Concern) if present above thresholds.

– For products sold in the U.S., confirm compliance with CPSIA if used in consumer goods, particularly regarding lead and phthalates.

Country-Specific Regulations

Different markets have unique import and safety requirements:

– USA: No specific safety certification for hinges alone, but final products may require UL, FCC, or CPSC compliance.

– EU: May require CE marking if part of a safety-critical assembly; ensure traceability and technical documentation per Machinery Directive or Low Voltage Directive as applicable.

– China: Follow CCC certification rules if integrated into regulated end-products.

– Canada: Comply with the Canada Consumer Product Safety Act (CCPSA) for consumer applications.

Documentation Requirements

Maintain accurate records to support compliance and customs clearance:

– Commercial Invoice and Packing List with detailed part descriptions.

– Certificate of Conformity (CoC) for RoHS, REACH, or other relevant standards.

– Material Declaration (e.g., IMDS submission for automotive clients).

– Origin Certificate if claiming preferential tariff treatment under trade agreements.

Environmental & Sustainability Considerations

- Use recyclable metals (e.g., zinc, stainless steel, aluminum) and minimize hazardous coatings.

- Support customers’ ESG goals by providing lifecycle data and recyclability information.

- Follow WEEE guidelines if hinges are part of electronic equipment subject to take-back obligations.

Conclusion

Successfully shipping and distributing friction hinges globally requires attention to packaging, material compliance, and regional regulations. Proactive documentation and adherence to environmental standards ensure smooth logistics operations and long-term market access. Always consult with legal and compliance experts when entering new markets.

Conclusion on Sourcing Friction Hinges

Sourcing friction hinges requires a balanced approach that considers application requirements, quality, cost, and supplier reliability. These specialized hinges, designed to hold position under load while allowing smooth, controlled movement, are critical in industries such as electronics, medical devices, aerospace, and industrial equipment. When sourcing, it is essential to clearly define torque specifications, durability needs, materials (e.g., stainless steel, aluminum, or engineered plastics), size constraints, and environmental resistance (e.g., corrosion, temperature, UV exposure).

Working with reputable manufacturers or suppliers who offer customization, rigorous quality control, and compliance with industry standards ensures long-term performance and reliability. While cost is a factor, prioritizing value over the lowest price helps avoid issues related to premature wear or mechanical failure. Additionally, evaluating lead times, minimum order quantities, and technical support capabilities contributes to a successful sourcing strategy.

In summary, effective sourcing of friction hinges involves thorough technical assessment, supplier evaluation, and lifecycle cost analysis to ensure optimal functionality, durability, and integration into the final product.