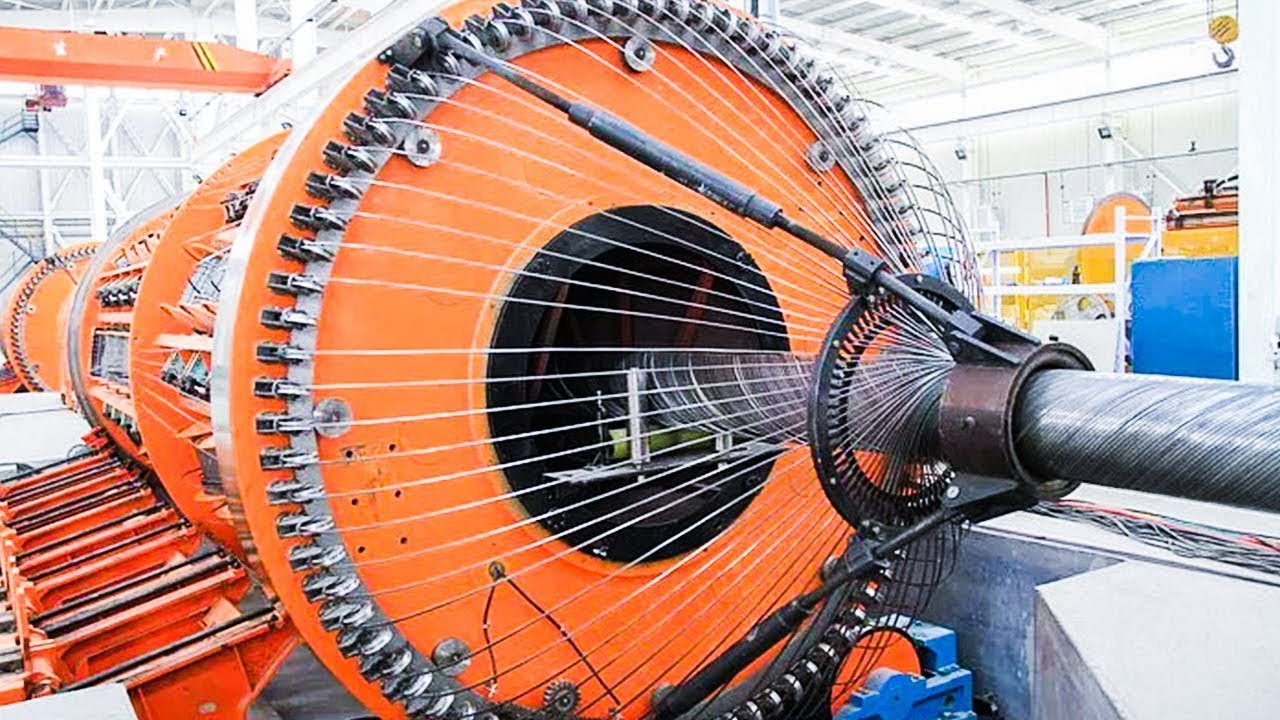

The global wire and cable market is experiencing steady growth, driven by rising infrastructure development, industrialization, and increased demand across construction, energy, and manufacturing sectors. According to Grand View Research, the global wire and cable market size was valued at USD 184.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2030. This expanding demand trickles down to specialized segments such as industrial wire and rope, where durability, tensile strength, and performance under stress are critical. In California’s Central Valley, Fresno has emerged as a regional hub for industrial manufacturing, including a growing concentration of wire and rope producers serving agriculture, construction, and transportation industries. With local manufacturers adapting to national trends—such as increased demand for galvanized steel and high-performance synthetic ropes—the city is positioning itself as a key player in the Western U.S. supply chain. Based on production capacity, industry reputation, and product range, here are the top four wire and rope manufacturers in Fresno shaping this evolving market landscape.

Top 4 Fresno Wire And Rope Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CHAPTER 13

Domain Est. 1995

Website: library.municode.com

Key Highlights: No person shall run, or stretch or maintain, through, along or across any street any wire, cable, rope, cord, flag, banner or similar thing with less clearance ……

#2 Fresno Wire Rope & Rigging in Fresno, Ca

Domain Est. 2002

Website: fresnowirerope.com

Key Highlights: Fresno Wire Rope & Rigging offers Wire rope, Fittings, Custom Slings, Other Rope, Shackles, Cable Clamps, Rigging Accessories, Ground Engaging Tools And ……

#3 Wire Rope, Lifting, Crane Hoisting, Fall Protection & Tow Truck …

Domain Est. 2008

Website: contecwirerope.com

Key Highlights: At Contec Wire Rope, we provide top-quality lifting solutions and equipment to businesses and industries in Fresno, CA, and beyond. It’s our commitment to you!…

#4 Fresno

Domain Est. 2018

Website: tradeimex.in

Key Highlights: Explore complete Fresno Wire And Rope Rigging trade data to analyze import trends, monitor buyer networks, & track international trade activity across major ……

Expert Sourcing Insights for Fresno Wire And Rope

2026 Market Trends for Fresno Wire and Rope

Industry Demand and Economic Drivers

By 2026, Fresno Wire and Rope can expect steady demand growth driven by expansion in key sectors such as construction, agriculture, logistics, and renewable energy. Infrastructure development funded by federal and state initiatives—particularly in California—will boost demand for high-tensile wire rope in cranes, bridges, and commercial buildings. Additionally, the continued growth of solar and wind energy projects will require specialized cabling and support systems, creating niche opportunities for engineered wire products.

Shift Toward Durable and Corrosion-Resistant Solutions

A major trend shaping the market is the increasing preference for longer-lasting, corrosion-resistant wire ropes, especially in outdoor and high-moisture environments. Galvanized and stainless-steel wire ropes are expected to see higher adoption across agriculture and marine applications. Fresno Wire and Rope can capitalize on this by emphasizing product durability, offering enhanced coatings, and providing technical support for proper selection and maintenance.

Supply Chain Resilience and Local Sourcing

Ongoing global supply chain volatility will continue to drive demand for domestic manufacturing and regional distribution. By 2026, customers will increasingly favor suppliers with reliable inventory and fast turnaround times. Fresno’s central California location positions it well to serve the Western U.S. market efficiently. Strengthening local partnerships and maintaining strategic inventory levels will be critical to meeting customer expectations for speed and reliability.

Sustainability and Regulatory Pressures

Environmental regulations and corporate sustainability goals are influencing procurement decisions. Buyers are beginning to prioritize vendors with eco-conscious practices, including recyclable materials and reduced packaging waste. Fresno Wire and Rope can differentiate itself by highlighting recycling programs for used wire rope, minimizing waste in operations, and sourcing from mills with strong environmental credentials.

Digital Integration and Customer Experience

The B2B industrial sector is rapidly adopting digital tools for ordering, inventory tracking, and technical support. By 2026, customers will expect seamless online ordering, real-time inventory visibility, and access to product specifications and safety data via mobile-friendly platforms. Investing in an enhanced digital presence—such as an e-commerce portal with configurators and AR-assisted installation guides—can significantly improve customer retention and competitive positioning.

Workforce and Skills Gap Challenges

The industrial sector faces an ongoing shortage of skilled technicians and riggers, which may affect end-user demand and installation services. Fresno Wire and Rope can address this by expanding training programs, partnering with trade schools, and offering value-added services such as on-site consultations and certification support, turning product sales into comprehensive solutions.

Common Pitfalls When Sourcing Fresno Wire and Rope (Quality, IP)

Sourcing industrial wire and rope from Fresno—whether referring to the city in California or a brand name—can present several challenges, particularly concerning product quality and intellectual property (IP) considerations. Being aware of these pitfalls helps ensure reliable supply and legal compliance.

Inconsistent Material Quality

One of the most frequent issues is variability in material quality. Suppliers may offer wire rope made from substandard alloys or with inconsistent tensile strength. This can lead to premature failure under load, posing serious safety risks in lifting, rigging, or structural applications. Always verify certifications such as ASTM, ISO, or ASME compliance and request mill test reports.

Lack of Traceability and Certification

Many suppliers, especially smaller or non-reputable ones, fail to provide full traceability from raw material to finished product. Without proper documentation like heat numbers, lot tracking, or third-party inspection reports, it’s difficult to verify quality claims or meet regulatory requirements in industries such as construction or oil and gas.

Misrepresentation of Specifications

Some vendors may misrepresent wire rope specifications—such as diameter, construction (e.g., 6×19 vs. 6×36), core type (fiber vs. steel), or breaking strength. This can result in mismatched components and compromised performance. Always independently verify specifications through physical inspection or third-party testing.

Counterfeit or Gray Market Products

When sourcing branded wire and rope, counterfeit or gray market goods may enter the supply chain. These products may lack proper quality control and could infringe on intellectual property rights. Purchasing from unauthorized dealers increases the risk of receiving rebranded, used, or falsely labeled products.

Intellectual Property Infringement

Manufacturers in certain regions may produce wire ropes that mimic patented designs or registered trademarks of established brands (e.g., specific lay patterns, coating technologies, or branding). Sourcing such products—even unknowingly—can expose your company to legal liability for IP infringement, especially in international trade.

Inadequate Coating and Corrosion Protection

Poorly applied or substandard galvanization, zinc-aluminum coatings, or polymer sheathing reduce the lifespan of wire rope, particularly in corrosive environments. Some suppliers cut costs by using inadequate coating thickness or skipping post-coating treatments, leading to early rust and degradation.

Non-Compliance with Industry Standards

Not all wire rope meets required industry standards (e.g., OSHA, ANSI, or API). Using non-compliant products can result in failed inspections, regulatory fines, or workplace accidents. Ensure suppliers adhere to relevant standards and provide documentation to prove compliance.

Poor Supply Chain Transparency

Lack of visibility into the manufacturing origin and supply chain increases risks related to both quality and IP. Without knowing where and how the product is made, it’s difficult to assess labor practices, environmental compliance, or the authenticity of branded components.

Overlooking Post-Purchase Support

Some suppliers fail to provide technical support, warranty coverage, or replacement policies. If a batch of wire rope fails prematurely, the absence of responsive customer service or liability assumption can lead to costly downtime and project delays.

Conclusion

To avoid these pitfalls, conduct thorough due diligence on suppliers, request verifiable certifications, inspect samples before bulk orders, and consult legal experts when sourcing branded or patented products. Partnering with reputable, transparent suppliers is key to ensuring both quality and IP compliance in wire and rope procurement.

Logistics & Compliance Guide for Fresno Wire and Rope

Effective logistics and strict compliance are essential for maintaining operational efficiency, customer satisfaction, and regulatory adherence at Fresno Wire and Rope. This guide outlines key procedures, best practices, and compliance requirements relevant to our supply chain, transportation, warehousing, and regulatory standards.

Supply Chain Management

Fresno Wire and Rope relies on a robust supply chain to deliver high-quality wire, cable, and rope products to customers across various industries. Key supply chain practices include:

- Vendor Qualification: All suppliers must meet quality, sustainability, and delivery performance standards. Regular audits ensure compliance.

- Inventory Management: Utilize just-in-time (JIT) and safety stock models to balance inventory levels, reduce carrying costs, and prevent stockouts.

- Demand Forecasting: Leverage historical sales data and market trends to anticipate customer needs and adjust procurement accordingly.

Warehousing & Inventory Control

Proper warehouse operations ensure product integrity and timely order fulfillment.

- Storage Standards: Store wire and rope products on racks or spools off the floor in dry, climate-controlled areas to prevent corrosion and damage.

- Labeling & Tracking: Use barcode or RFID systems for real-time inventory tracking. Clearly label all products with item number, size, material type, and lot number.

- Cycle Counts: Conduct regular cycle counts to maintain 99% inventory accuracy and reconcile discrepancies promptly.

- Safety Protocols: Enforce PPE requirements, load-bearing limits, and equipment training for all warehouse personnel.

Transportation & Shipping

Efficient and safe transportation is critical for on-time delivery and customer satisfaction.

- Carrier Selection: Partner with certified carriers experienced in handling heavy, industrial-grade materials. Verify insurance and safety records.

- Load Securement: Follow FMCSA guidelines to properly secure wire coils and reels using straps, blocking, and bracing to prevent shifting.

- Shipping Documentation: Ensure bills of lading, packing slips, and delivery confirmations are accurate and retained for audit purposes.

- Delivery Scheduling: Coordinate with customers for delivery windows and site accessibility, especially for large or heavy shipments.

Regulatory Compliance

Fresno Wire and Rope must comply with federal, state, and industry-specific regulations.

- OSHA Standards: Adhere to OSHA 29 CFR 1910 for workplace safety, including material handling, forklift operation, and hazard communication.

- DOT Regulations: Comply with Department of Transportation rules for shipping hazardous materials (if applicable) and commercial vehicle operations.

- EPA & Environmental Compliance: Follow EPA guidelines for waste disposal, spill prevention, and use of protective coatings or lubricants.

- ITAR/EAR (if applicable): Monitor export controls for products that may be subject to International Traffic in Arms Regulations or Export Administration Regulations.

Quality Assurance & Product Compliance

Ensure all products meet industry and customer specifications.

- Certification Documentation: Provide mill test reports, certificates of conformance, and material safety data sheets (MSDS/SDS) upon request.

- Inspection Protocols: Conduct incoming and outgoing quality inspections for diameter, tensile strength, corrosion resistance, and spool integrity.

- Traceability: Maintain full lot traceability from raw material to final shipment to support recalls or audits.

Customer & Industry Standards

Align operations with key industry benchmarks.

- ASME, ASTM, and ISO Standards: Manufacture and test products in accordance with relevant standards (e.g., ASTM A1023 for wire rope).

- Customer-Specific Requirements: Document and implement special handling, labeling, or reporting needs for key accounts.

- Continuous Improvement: Participate in third-party audits and use feedback to refine logistics and compliance processes.

Training & Documentation

Ongoing education ensures team competency and regulatory adherence.

- Compliance Training: Provide annual training on safety, hazardous materials, and transportation regulations for relevant staff.

- Record Retention: Maintain logs for training, inspections, shipments, and compliance audits for a minimum of seven years.

- Internal Audits: Conduct quarterly audits of logistics and compliance procedures to identify gaps and implement corrective actions.

By adhering to this guide, Fresno Wire and Rope ensures reliable service, regulatory compliance, and continued trust from customers and partners.

Conclusion for Sourcing Fresno Wire & Rope:

After a thorough evaluation of supply options, Fresno Wire & Rope emerges as a reliable and strategic sourcing partner for high-quality wire, cable, and rigging solutions. Their extensive product inventory, industry expertise, and strong regional presence in California position them as a valuable supplier for construction, industrial, and agricultural applications. With a demonstrated commitment to customer service, competitive pricing, and logistical efficiency, sourcing from Fresno Wire & Rope supports supply chain reliability and project continuity. Ultimately, establishing a partnership with Fresno Wire & Rope offers operational benefits, product consistency, and long-term cost-effectiveness, making them a recommended choice for organizations requiring dependable wire and rope solutions.