The global demand for frame nail size products has seen steady growth, driven by expansion in residential and commercial construction, particularly in North America and Asia-Pacific. According to Grand View Research, the global nails market was valued at USD 17.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This growth is fueled by rising infrastructure investments and increasing adoption of prefabricated and modular construction techniques, which rely heavily on precision-manufactured fasteners like frame nails. As demand for high-strength, corrosion-resistant, and dimensionally accurate nails grows, manufacturers are enhancing production capabilities and investing in sustainable materials. In this competitive landscape, nine key players have emerged as leaders in frame nail size manufacturing, combining innovation, scale, and global distribution to meet evolving industry standards and construction needs.

Top 9 Frame Nail Size Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Professional Steel Nails Manufacturer

Domain Est. 2001

Website: litnaglis.com

Key Highlights: Manufacturer of premium-quality steel nails. We ensure that our products meet the highest quality standards at a reasonable price….

#2 Nails

Domain Est. 1993

Website: senco.com

Key Highlights: 30-day returns30° Smooth Shank Paper Tape Collated Nails, 21° Angled Strip Full Round Head Ring Shank Plastic Collated Nails….

#3 Fastener Overview — Nails

Domain Est. 1995

Website: strongtie.com

Key Highlights: A common method used to represent nail sizes is the penny size, which is a length designation. The size is written with a number and the abbreviation “d” for “ ……

#4 Maze Nails Company

Domain Est. 1995

Website: mazenails.com

Key Highlights: Maze Nails have been trusted by professionals for more than a century. Our top quality hot dip galvanizing process delivers superior corrosion resistance….

#5 Framing Nails

Domain Est. 1996

Website: paslode.com

Key Highlights: Framing Nails. We’ve specially designed our framing nails to reduce reloading and jams to help pros like you keep moving….

#6 PRO

Domain Est. 1997

Website: nationalnail.com

Key Highlights: Packaged and Bulk. From framing to finish and beyond, PRO-FIT offers nail, screw, and specialty fastening solutions packaged in convenient job-sized 1lb and 5lb ……

#7 Framing Nails

Domain Est. 2000

Website: tremontnail.com

Key Highlights: Common Nails are popular for framing, roughing in, and face-nailing floors. Also used for cabinet work, interior and exterior siding, furniture repair, batten ……

#8 Framing Nails

Domain Est. 2002

Website: grip-rite.com

Key Highlights: Grip-Rite® offers a vast catalog of framing nails. From common nails to wire weld coil nails, find the best nails for your construction project. Contact us!…

#9 Framing Nails

Domain Est. 2017

Website: metabo-hpt.com

Key Highlights: Our sizes include 1-1/2″ up to 3-1/2” in length. We also offer nails that are compatible with a variety of framing nailer degrees….

Expert Sourcing Insights for Frame Nail Size

H2: Projected 2026 Market Trends for Frame Nail Size

The global frame nail size market in 2026 is expected to reflect a confluence of construction activity, material preferences, technological advancements, and regional regulatory landscapes. While specific size demand varies by region and application, several key trends are anticipated to shape the market:

-

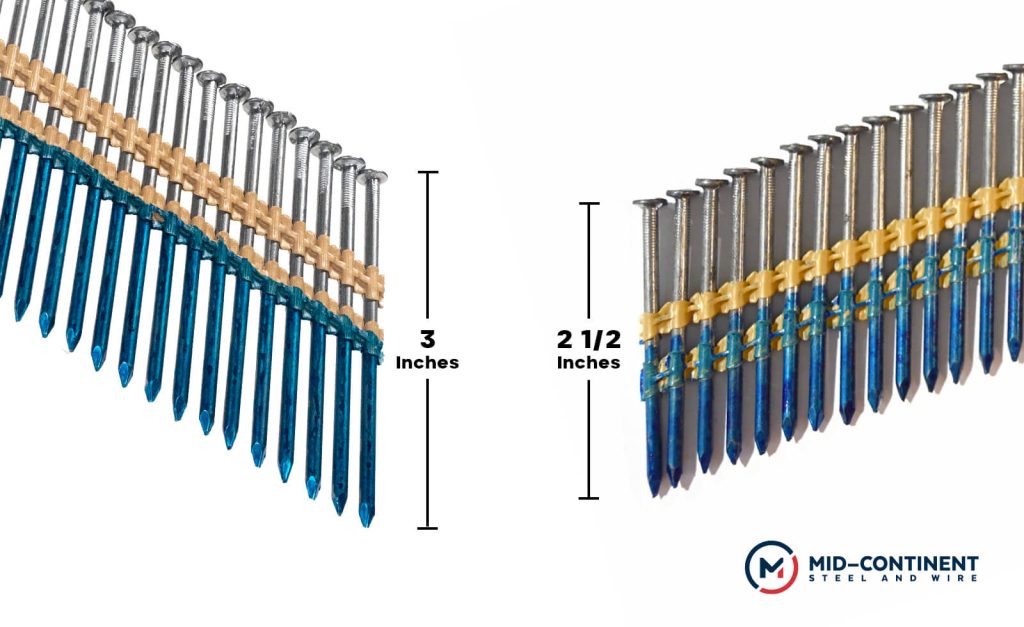

Continued Dominance of Standard Sizes: The 16d (3 1/2 inch) common nail will likely remain the workhorse for structural framing in residential and light commercial construction, particularly in North America, driven by building code specifications and compatibility with pneumatic framing nailers. The 10d (3 inch) and 8d (2 1/2 inch) nails are also expected to maintain strong demand for specific framing applications like sheathing, decking, and lighter framing members.

-

Growth in Ring Shank and Screw Shank Nails: Driven by the need for superior holding power, especially in high-wind zones, seismic areas, and for engineered wood products (like I-joists and LVL), demand for ring shank and screw shank versions of common frame nail sizes (particularly 16d) is projected to grow steadily. This trend supports structural integrity and meets increasingly stringent building codes.

-

Regional Variations in Size Preference:

- North America: 16d (0.148″ shank diameter, 3.5″ length) will dominate, with strong demand for 10d and 8d. The shift towards slightly longer or thicker gauges for specific engineered lumber applications may continue.

- Europe & Asia-Pacific: Metric sizing (e.g., 60mm, 80mm, 100mm lengths with corresponding diameters like 3.0mm, 3.4mm, 3.75mm) prevails. Demand will be tied to local construction methods (e.g., timber framing, platform framing adaptations) and the adoption of prefabricated wooden elements. 70-80mm nails are common for standard stud framing, while 90-100mm are used for heavier beams and connections.

-

Impact of Prefabrication and Modular Construction: The rising trend of off-site construction (prefab panels, modular units) may influence nail size usage. While standard sizes are still used, the controlled factory environment might see optimized nailing patterns and potentially specific nail types (like full-round head for better holding in certain panel assemblies), indirectly affecting demand profiles for specific lengths and diameters.

-

Material and Coating Influences: The choice of nail size is increasingly linked to corrosion resistance requirements. In coastal areas or for treated lumber, the need for galvanized (hot-dip or electro) or stainless steel nails in standard frame sizes (16d, 10d) will drive demand within those size categories. The thickness of the coating can slightly affect the effective shank diameter.

-

Sustainability and Efficiency Pressures: Contractors will continue seeking nails that maximize holding power per nail, minimizing the total number needed. This favors high-performance designs (like ring shank) within standard size ranges, improving efficiency and reducing material waste. Optimization of nail length to match exact joist/rim board depths in platform framing (e.g., precise 3.25″ nails for certain applications) might see niche growth.

-

Price Volatility and Supply Chain: Fluctuations in steel prices and logistics costs will impact the overall nail market, potentially influencing contractor choices between standard common nails and slightly more expensive high-hold alternatives within the same size bracket, depending on project budget and code requirements.

In summary, the 2026 frame nail size market will be characterized by the enduring dominance of established sizes like the 16d common nail, particularly in North America, coupled with a significant and growing preference for enhanced shank designs (ring, screw) within these standard sizes to meet performance and code demands. Regional metric standards will prevail elsewhere, and trends in construction methods and materials will shape nuanced demand shifts within the core size categories.

Common Pitfalls When Sourcing Frame Nail Size (Quality, IP)

Sourcing the right frame nails involves more than just selecting length and diameter—overlooking quality and intellectual property (IP) considerations can lead to structural failures, legal risks, and reputational damage. Below are common pitfalls to avoid:

Overlooking Material Quality and Certification

Many suppliers offer nails made from substandard steel or inconsistent coatings, resulting in poor corrosion resistance, reduced holding power, or breakage under load. Always verify that nails meet recognized standards such as ASTM F1667 (for driven fasteners) or ISO 12772 (for cast iron nails), and request mill test certificates or third-party inspection reports.

Ignoring Coating Specifications

Frame nails often require specific protective coatings like galvanization (electro or hot-dip), aluminized, or proprietary corrosion-resistant finishes. Sourcing nails with inadequate or misrepresented coatings compromises durability, especially in humid or coastal environments. Confirm coating type, thickness, and compliance with ASTM A153 or ASTM B695.

Assuming Dimensional Accuracy Without Verification

Inconsistent nail dimensions—such as shank diameter, head size, or thread pitch—can lead to improper tool feeding, splitting of lumber, or weak joints. Poor quality control in manufacturing may result in non-uniform products. Conduct incoming inspections or request samples before bulk procurement.

Failing to Validate Intellectual Property Rights

Some nail designs, especially helix-coil, ring-shank, or specialty structural nails, are protected by patents or trademarks. Sourcing counterfeit or IP-infringing products exposes your company to legal action, supply chain disruptions, and product recalls. Always verify that the supplier owns or is licensed to produce the nail design, and request documentation of IP compliance.

Prioritizing Price Over Performance

Choosing the cheapest option can lead to compromised quality, higher long-term costs due to rework, warranty claims, or structural failure. Frame nails are critical structural components—investing in high-quality, certified products from reputable suppliers ensures safety and code compliance.

Not Confirming Compatibility with Installation Tools

Different nail designs require specific nail guns or drivers. Using incompatible nails can damage tools or result in improper installation. Confirm that the nail size, head type (e.g., full round, clipped head), and packaging (stick, coil, strip) are compatible with the intended application equipment.

By addressing these pitfalls proactively, buyers can ensure they source frame nails that meet structural, durability, and legal requirements—protecting both the integrity of construction projects and their organization’s reputation.

Logistics & Compliance Guide for Frame Nail Size

Understanding the logistics and compliance requirements for frame nail sizes is essential for manufacturers, distributors, contractors, and importers. Proper adherence ensures product safety, regulatory compliance, and efficient supply chain operations.

Standardization and Specifications

Frame nails, commonly used in structural framing applications, must conform to industry standards to ensure performance and safety. Key standards include:

- ASTM F1667: Standard Specification for Driven Fasteners: Nails, Spikes, and Staples – This covers dimensional, material, and performance requirements.

- International Building Code (IBC): Specifies approved fastener types and sizes for structural framing based on load and application.

- International Residential Code (IRC): Provides guidelines for nail size, length, and diameter (penny size) in residential construction.

Common frame nail sizes range from 10d (3 inches) to 60d (6 inches), with shank diameters typically from 0.120″ to 0.220″. Compliance with these specifications ensures structural integrity.

Packaging and Labeling Requirements

Proper packaging and labeling are critical for logistics efficiency and regulatory compliance:

- Labeling: Each package must clearly display:

- Nail size (e.g., 16d, 3 1/2″)

- Shank diameter or penny weight

- Material type (e.g., hot-dipped galvanized, vinyl-coated)

- Manufacturer name and lot number

-

Compliance marks (e.g., ASTM, ICC-ES)

-

Packaging: Nails should be packed in moisture-resistant materials to prevent corrosion. Bulk packaging (e.g., 50-lb boxes) must be sturdy and stackable for warehouse and transport safety.

Transportation and Handling

Safe and efficient transport of frame nails requires attention to:

- Weight Management: Frame nails are heavy; standard packaging should not exceed manual handling limits (typically 50 lbs per box).

- Stacking and Palletization: Pallets must be secured with stretch wrap or banding. Load height should comply with OSHA and carrier regulations to prevent tipping.

- Hazard Classification: Nails are generally non-hazardous but must be secured to prevent shifting during transit. Sharp edges require protective packaging to avoid damage to other goods or personnel.

Import/Export Compliance

For international shipping, compliance with customs and trade regulations is essential:

- HTS Codes: Use appropriate Harmonized Tariff Schedule codes (e.g., 7317.00.30 for nails of iron or steel, >6 cm in length).

- Country-Specific Standards: Verify compliance with local building codes (e.g., CE marking in the EU, CSA in Canada).

- Documentation: Include commercial invoice, packing list, bill of lading, and certificate of conformity to ASTM or other applicable standards.

Environmental and Safety Regulations

- RoHS and REACH Compliance: For exports to Europe, ensure coatings or materials do not contain restricted substances.

- OSHA Guidelines: In handling, employers must provide training and protective equipment (e.g., gloves, safety footwear) to prevent injury from sharp fasteners.

- Recycling and Disposal: Steel nails are recyclable; provide guidance for end-of-life disposal in accordance with local regulations.

Quality Assurance and Traceability

Maintain a robust quality management system:

- Implement lot tracking for traceability in case of recalls.

- Conduct periodic testing for dimensions, coating thickness, and withdrawal strength.

- Retain compliance documentation for a minimum of five years.

Adhering to this logistics and compliance guide ensures that frame nail products meet regulatory requirements, perform reliably in the field, and move efficiently through the supply chain.

Conclusion for Sourcing Frame Nail Size:

Selecting the appropriate frame nail size is critical to ensuring structural integrity, durability, and safety in construction and woodworking projects. After evaluating factors such as material type (hardwood vs. softwood), frame thickness, load-bearing requirements, and application method (hand nailing vs. pneumatic tools), it becomes evident that an 8d (2.5-inch) common nail or sinker nail is typically the most suitable choice for standard wood framing applications. This size provides an optimal balance between penetration depth and holding power without splitting the wood when properly driven.

For thicker or engineered lumber, or in high-stress areas such as joints and connections, consideration may be given to 10d or 16d nails, depending on code requirements and structural design. Additionally, using nails that meet ASTM standards ensures consistency in quality and performance. Ultimately, compliance with local building codes and manufacturer recommendations should guide the final sourcing decision. Proper nail selection, combined with correct installation techniques, contributes significantly to the overall strength and longevity of the framed structure.